Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Codex Standard 171 - 1989 Pulses

Caricato da

Hamid RazaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Codex Standard 171 - 1989 Pulses

Caricato da

Hamid RazaCopyright:

Formati disponibili

1 Codex Standard 171-1989

CODEX STANDARD FOR CERTAIN PULSES

CODEX STAN 171-1989

1. SCOPE

This Standard applies to the whole, shelled or split pulses defined below which are intended for direct human

consumption. The Standard does not apply to pulses intended for factory grading and packaging, industrial

processing, or to those pulses intended for use in the feeding of animals. It does not apply to fragmented

pulses when sold as such, or to other legumes for which separate standards may be elaborated.

2. DESCRIPTION

2.1 Product definition

Pulses are dry seeds of leguminous plants which are distinguished from leguminous oil seeds by their low fat

content. The pulses covered by this Standard are the following:

– Beans of Phaseolus spp. (except Phaseolus mungo L. syn. Vigna mungo (L.) Hepper and Phaseolus

aureus Roxb. syn. Phaseolus radiatur L., Vigna radiata (L.) Wilczek);

– Lentils of Lens culinaris Medic. Syn. Lens esculenta Moench.;

– Peas of Pisum sativum L.;

– Chick peas of Cicer arientinum L.;

– Field beans of Vicia faba L.;

– Cow peas of Vigna unguiculata (L.) Walp., syn. Vigna sesquipedalis Fruhw., Vigna sinensis (L.) Savi exd

Hassk.

3. ESSENTIAL COMPOSITION AND QUALITY FACTORS

3.1 Quality factors – general

3.1.1 Pulses shall be safe and suitable for human consumption.

3.1.2 Pulses shall be free from abnormal flavour, odours, and living insects.

3.1.3 Pulses shall be free from filth (impurities of animal origin, including dead insects) in amounts which may

represent a hazard to human health.

3.2 Quality factors – specific

3.2.1 Moisture content

3.2.1.1 Two maximum moisture levels are provided to meet different climatic conditions and marketing practices.

Lower values in the first column are suggested for countries with tropical climates or when long-term (more

than one crop year) storage is a normal commercial practice. The values in the second column are suggested

for more moderate climates or when other short-term storage is the normal commercial practice.

Pulse Moisture content

(percent)

beans 15 19

lentils 15 16

peas 15 18

chick peas 14 16

cow peas 15 18

field beans 15 19

Lower moisture limits should be required for certain destinations in relation to the climate, duration of transport

and storage. Governments accepting the Standard are requested to indicate and justify the requirements in

force in their country.

3.2.1.2 In the case of pulses sold without their seed coat, the maximum moisture content shall be 2 per cent

(absolute) lower in each case.

Adopted 1989. Revision 1995.

2 Codex Standard 171-1989

3.2.2 Extraneous matter is mineral or organic matter (dust, twigs, seedcoats, seeds of other species, dead insects,

fragments, or remains of insects, other impurities of animal origin). Pulses shall have not more than 1%

extraneous matter of which not more than 0.25% shall be mineral matter and not more than 0.10% shall be

dead insects, fragments or remains of insects, and/or other impurities of animal origin.

3.2.2.1 Toxic or noxious seeds

The products covered by the provisions of this standard shall be free from the following toxic or noxious seeds

in amounts which may represent a hazard to human health.

– Crotolaria (Crotalaria spp.), Corn cockle (Agrostemma githago L.), Castor bean (Ricinus communis L.),

Jimson weed (Datura spp.), and other seeds that are commonly recognized as harmful to health.

4. CONTAMINANTS

4.1 Heavy metals

Pulses shall be free from heavy metals in amounts which may represent a hazard to health.

4.2 Pesticide residues

Pulses shall comply with those maximum residue limits established by the Codex Alimentarius Commission for

this commodity.

4.3 Mycotoxins

Pulses shall comply with those maximum mycotoxin limits established by the Codex Alimentarius Commission

for this commodity.

5. HYGIENE

5.1 It is recommended that the products covered by the provisions of this standard be prepared and handled in

accordance with the appropriate sections of the Recommended International Code of Practice – General

Principles of Food Hygiene (CAC/RCP 1-1969), and other Codes of Practice recommended by the Codex

Alimentarius Commission which are relevant to these products.

5.2 To the extent possible in good manufacturing practice, the products shall be free from objectionable matter.

5.3 When tested by appropriate methods of sampling and examination, the products:

– shall be free from micro-organisms in amounts which may represent a hazard to health;

– shall be free from parasites which may represent a hazard to health; and

– shall not contain any substance originating from micro-organisms in amounts which may represent a

hazard to health.

6. PACKAGING

6.1 Pulses shall be packaged in containers which will safeguard the hygienic, nutritional, technological, and

organoleptic qualities of the product.

6.2 The containers, including packaging material, shall be made of substances which are safe and suitable for

their intended use. They should not impart any toxic substance or undesirable odour or flavour to the product.

6.3 When the product is packaged in sacks, these must be clean, sturdy and strongly sewn or sealed.

7. LABELLING

In addition to the requirements of the Codex General Standard for the Labelling of Prepackaged Foods

(CODEX STAN 1-1985), the following specific provisions apply:

7.1 Name of the product

The name of the product to be shown on the label shall be the commercial type of the pulse.

7.2 Labelling of non-retail containers

Information for non-retail containers shall either be given on the container or in accompanying documents,

except that the name of the product, lot identification and the name and address of the manufacturer or packer

shall appear on the container. However, lot identification and the name and address of the manufacturer or

3 Codex Standard 171-1989

packer may be replaced by an identification mark, provided that such a mark is clearly identifiable with the

accompanying documents.

8. METHODS OF ANALYSIS AND SAMPLING

See relevant Codex texts on methods of analysis and sampling.

ANNEX

ANNEX

In those instances where more than one factor limit and/or method of analysis is given we strongly recommend

that users specify the appropriate limit and method of analysis.

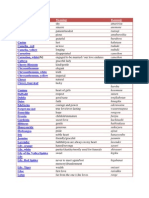

Factor/Description Limit Method of analysis

DEFECTS Visual Examination

seeds with serious defects. Seeds in which the cotyledons have been MAX: 1.0%

affected or attached by pests; seeds with very slight traces of mould or

decay; or slight cotyledon staining

seeds with slight defects. Seeds which have not reached normal MAX: 7.0% of which broken

development; seeds with extensive seedcoat staining, without the cotyledon pulses must not exceed 3.0%

being affected; seeds in which the seedcoat is wrinkled, with pronounced

folding, or broken pulses

broken pulses. Broken in whole pulses are pulses in which the cotyledons

are separated or one cotyledon has been broken. Broken in split pulses are

pulses in which the cotyledon has been broken

SEED DISCOLORATION Visual Examination

seeds of a similar colour but a different commercial type (except in beans MAX: 3.0%

with white seeds)

seeds of different colour MAX: 6.0%

(other than discoloured seeds)

discoloured seeds MAX: 3.0%

discoloured seeds of the same commercial type MAX: 10.0%

beans with green seed and peas with green seeds with slight discolouration MAX: 20.0%

of the seed

PRESENTATION Buyer Preference Visual Examination

Shelled pulses. Pulses without their seedcoat, with the cotyledons not

separated

split pulses. Pulses without their seedcoat, with the two cotyledons

separated one from the other

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Maize Cultivation in Pakistan1Documento8 pagineMaize Cultivation in Pakistan1Chudhary KhuShnoodNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Corn Testing MethodologyDocumento8 pagineCorn Testing MethodologyHamid RazaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Commodity Grading CriteriaDocumento12 pagineCommodity Grading CriteriaHamid RazaNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Instructions For WHM - WH Online RegistrationDocumento51 pagineInstructions For WHM - WH Online RegistrationHamid RazaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Cotton Production Marketing and ExportDocumento26 pagineCotton Production Marketing and ExportMaham KhanNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Guidelines Inspection Final-2018 PDFDocumento73 pagineGuidelines Inspection Final-2018 PDFHamid RazaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Mapping The Cotton Value Chain in PakistanDocumento61 pagineMapping The Cotton Value Chain in PakistanHamid RazaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Cotton Cultivation in PakistanDocumento18 pagineCotton Cultivation in PakistanHamid RazaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Codex Standard for Whole Maize MealDocumento3 pagineCodex Standard for Whole Maize Mealbidrohi75Nessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Guidelines Inspection Final-2018 PDFDocumento73 pagineGuidelines Inspection Final-2018 PDFHamid RazaNessuna valutazione finora

- Pakistan's Agriculture Emergency Program and 2018-19 PerformanceDocumento23 paginePakistan's Agriculture Emergency Program and 2018-19 PerformanceHamid RazaNessuna valutazione finora

- Rose Mwaniki CVDocumento10 pagineRose Mwaniki CVHamid RazaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- SECURITIES AND EXCHANGE COMMISSION OF PAKISTAN ISSUES COLLATERAL MANAGEMENT COMPANIES REGULATIONSDocumento25 pagineSECURITIES AND EXCHANGE COMMISSION OF PAKISTAN ISSUES COLLATERAL MANAGEMENT COMPANIES REGULATIONSHamid RazaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Pakistan Wheat Standards PS 3747-1996Documento19 paginePakistan Wheat Standards PS 3747-1996Hamid RazaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- 6632Documento208 pagine6632ماهر زارعيNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Calculating Warehouse SpaceDocumento2 pagineCalculating Warehouse SpaceJohnXReeveNessuna valutazione finora

- WAREHOUSE INSPECTION GUIDE AND REPORTDocumento7 pagineWAREHOUSE INSPECTION GUIDE AND REPORTAnonymous qT66pyKNessuna valutazione finora

- CXS - 212e - U Zahar PDFDocumento5 pagineCXS - 212e - U Zahar PDFdorinutza280Nessuna valutazione finora

- Traditional Vegetables of SicilyDocumento7 pagineTraditional Vegetables of Sicilya.santamNessuna valutazione finora

- HanakotobaDocumento20 pagineHanakotobaMaheela Nair50% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ၂၀၁၄ တကၠသိုလ္ဝင္စာေမးပြဲ မေကြး ဇီဝေဗဒေမးခြန္းDocumento4 pagine၂၀၁၄ တကၠသိုလ္ဝင္စာေမးပြဲ မေကြး ဇီဝေဗဒေမးခြန္းKyi Htin PawNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- 19092016095638PM - File - Info (Done Excel, Done CC)Documento12 pagine19092016095638PM - File - Info (Done Excel, Done CC)CK AngNessuna valutazione finora

- CPG Horti Final-2019 PDFDocumento447 pagineCPG Horti Final-2019 PDFselvi vijiNessuna valutazione finora

- Stabilization of Black Cotton Soil Using Fly Ash and GeopolymerDocumento4 pagineStabilization of Black Cotton Soil Using Fly Ash and Geopolymerbhaskar pallaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Villamanca - Plant JournalDocumento14 pagineVillamanca - Plant JournalJOHN JERALD VILLAMANCANessuna valutazione finora

- Building Materials & Construction - BooksDocumento12 pagineBuilding Materials & Construction - Bookssbpathi0% (1)

- 601 Layne BLVD - LandscapeDocumento7 pagine601 Layne BLVD - LandscapeSergio GonzálezNessuna valutazione finora

- Chapter 8 Revisions III - QuizletDocumento24 pagineChapter 8 Revisions III - QuizletChristianAvelinoNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- AR 308 Building Construction &materials - VDocumento23 pagineAR 308 Building Construction &materials - Vswarna raviNessuna valutazione finora

- Calculation SheetDocumento21 pagineCalculation SheetEngAmr ElmohndesNessuna valutazione finora

- Annual FlowerDocumento6 pagineAnnual FlowerGaurav TiwariNessuna valutazione finora

- Strength Development of Ternary Blended Cement With Limestone Filler and Blast-Furnace SlagDocumento7 pagineStrength Development of Ternary Blended Cement With Limestone Filler and Blast-Furnace Slagdevildriver_990Nessuna valutazione finora

- Magway University, Men Chummery (158'-0" X 30'-0") 2-Storyde R.C.C Building, SUB-Structure Bill of Quantity Particulars Quantity Unit Rate Per AmountDocumento1 paginaMagway University, Men Chummery (158'-0" X 30'-0") 2-Storyde R.C.C Building, SUB-Structure Bill of Quantity Particulars Quantity Unit Rate Per Amountnang homNessuna valutazione finora

- Urban PermacultureDocumento43 pagineUrban Permacultureapi-252298332Nessuna valutazione finora

- Lilyturf: Liriope Muscari Evergreen Giant' Evergreen GiantDocumento2 pagineLilyturf: Liriope Muscari Evergreen Giant' Evergreen GiantVernika AgrawalNessuna valutazione finora

- Four-Laning NH-69 Nagpur-Saoner-Betul Section Concrete StructuresDocumento3 pagineFour-Laning NH-69 Nagpur-Saoner-Betul Section Concrete StructurespreetcivilNessuna valutazione finora

- Astm C 76-19Documento12 pagineAstm C 76-19Carlos Manuel Ampié BerriosNessuna valutazione finora

- Herbal Books To ReadDocumento4 pagineHerbal Books To Reademily fisherNessuna valutazione finora

- Concrete Construction Article PDF - Ice Rink Floor Placed in One PourDocumento2 pagineConcrete Construction Article PDF - Ice Rink Floor Placed in One PourHasim AbdulNessuna valutazione finora

- 05.a. ITB-NAOH-2013-017 - Section V Annex IIa - Tech Drgs Arch and STRCTRL PDFDocumento51 pagine05.a. ITB-NAOH-2013-017 - Section V Annex IIa - Tech Drgs Arch and STRCTRL PDFjavier rangel argoteNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Monitoring Report of Agriculture Extension NowsheraDocumento8 pagineMonitoring Report of Agriculture Extension Nowsherauetprince9647Nessuna valutazione finora

- Plants Around UsDocumento67 paginePlants Around UsmanasmanojNessuna valutazione finora

- Cost Estimation in RevitDocumento4 pagineCost Estimation in RevitSubash MNessuna valutazione finora

- Evidencia 5 Writing A Product CatalogueDocumento12 pagineEvidencia 5 Writing A Product CataloguedesacuerdoNessuna valutazione finora

- Bentley and Trimen-Medicinal Plants Vol 2 1875Documento412 pagineBentley and Trimen-Medicinal Plants Vol 2 1875RonLayton100% (1)

- Popular Spring Flowers: An Introduction to TulipsDocumento38 paginePopular Spring Flowers: An Introduction to TulipsNad 2MNessuna valutazione finora

- How To Create A Mini GardenDocumento32 pagineHow To Create A Mini GardenLászló ÉvaNessuna valutazione finora

- Item 600Documento4 pagineItem 600Alexander DelimaNessuna valutazione finora

- A-level Biology Revision: Cheeky Revision ShortcutsDa EverandA-level Biology Revision: Cheeky Revision ShortcutsValutazione: 5 su 5 stelle5/5 (5)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (241)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)