Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SRB-02-2011 - (Welding of Pipes)

Caricato da

kkalviTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SRB-02-2011 - (Welding of Pipes)

Caricato da

kkalviCopyright:

Formati disponibili

Page 1 of 4

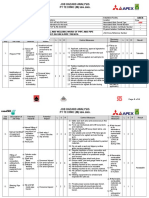

JOB SAFETY ANALYSIS WORK SHEET

New

Date D / M / Y Contractor: Suedrohrbau S.A Ltd.

JSA # 002 Contract No/ BI. No. 10-00451&00454

Revised Prepared 26 / 03 / 2010

JSA Function Name Badge# Job Title Mobile Phone #

SRB Site Foreman - Civil. Mohammed Safdar Site Foreman 0505503803

SRB Construction Engineer Mr. Martin Project Engineer 0500605943

SRB Site Safety Supervisor Mr.Zahid Hussain Safety Officer 0543169774

SAPMT Safety Advisor Mr. Luisito P Torres Safety Advisor 0540669774

DESCRIPTION OF TASK: WELDING OF PIPES

Work Location:

Prepared By : (Contractor) Reviewed By : Approved By :

Khurram Khalid Alvi Luisito. P. Torres Manifa Safety Dept:

SRB Safety. Manager: SAPMT Safety Advisor

Signature: ----------------------------- Signature: ---------------------------- Signature: -----------------------------

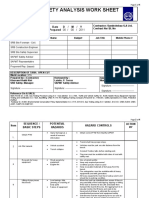

Page 2 of 4

SR # SEQUENCE OF BASIC POTENTIAL HAZARDS HAZARDS CONTROLS ACTION BY

STEPS

1 Obtain PTW Injury / damage as a result of • Obtain correct PTW

incorrect information

2 Pipe fittings Crush injuries • Remove all unnecessary personnel from the

area.

Dropping the pipe ,slips &

trips • Ensure personnel are clear of moving pipe

• Ensure spotter has good communication with the

side boom operator

• Ensure all lifting equipment is in good condition

3 Cutting pipe and grinding Eye injury • Check gas cutting equipment for damage (hoses,

hand piece and flash back arresters) for leakage

Burns

• Wear appropriate PPE for gas cutting (gloves,

Electric shock cutting goggles or appropriate shield)

Fire & explosion • Sun glasses must not be worn

Gases & fumes • Ensure all cables and hoses are in good

condition

Heat

• Fire Extinguishers (A, B & C chemical

Noise powder) in the area

• Ensure no flammable and combustible

material store near welding area.

• Welding machine must be properly

grounded

• Welders must wear flame resistance work

clothing and supplied leather PPE where

applicable. Wear gloves to protect hands and

arms.

• Hearing protection must be worn if require

Page 3 of 4

Rigging / lifting operation Material handling of heavy • Side boom operators shall have valid SAG

loads. license & Saudi Aramco side boom operator

4 certification.

Crushing injury or pinch

points. • All Side boom shall be inspected with valid SGS

inspection sticker.

Heavy equipments collisions

• Side boom operator shall complete the pre lift

operation checklist and ensure to maintain a safe

distance from any existing facilities

5 Welding of pipe Electrocution • Ensure job is set up as per safe welding

procedure. Only trained personnel to carry out

welding. Fit earth clamp securely to job.

Burns • Welders must wear flame resistance work

clothing and supplied leather PPE where

applicable. Wear gloves to protect hands and

arms.

Eye injury (weld wash)

• Wear welders shield with filter shade No. 7 to 15

inclusive. Wear AS1337 safety spectacles under

welding shields.

Radiation and sparks

• Use welding screens or blankets to shield arc

from other personnel. Welders assistants must

Fumes wear anti weld flash eye protection to AS1337. If

assistant required to look at the arc then the

same protection as welder is required.

fire • A suitable fire extinguisher must be available all

times when welding is in progress. Check

condition of extinguisher prior to starting job.

SR # RECOMMENDATIONS / NOTES ASSIGNED TO PHONE #

Page 4 of 4

1 TOOLBOX MUST BE CONDUCTED PRIOR TO COMMENCEMENT OF CONTRACTOR MECHANICAL

WORK SUPERVISOR / FORMAN

2 EXPLAIN TO THE KEY WORKERS THEMPURPOSE OF THIS “JSA” AND SAFETY OFFICER

ENFORCE IMPLIMENATION OF CONTENT

3 IF AN INJURY OR NEAR MISS OCCURS, THE JSA SHALL BE SAFETY / PROJECT MANAGERS

REVIEWED IMMEDIATEL TO DETERMINE WHETHER CHANGES ARE

NEEDED IN THE JOB PROCEDURES (CONTRACTOR)

4 USE THE JSA TO IDENTIFY THE HAZARDS AND LIST THE ISSUER & RECEIVER / FOREMAN

PRECAUTIONS ON THE WORK PERMIT

Potrebbero piacerti anche

- Hot Works Safety AnalysisDocumento8 pagineHot Works Safety AnalysisUğur BilenNessuna valutazione finora

- JSA - For Trays ErectionDocumento1 paginaJSA - For Trays ErectionAvinash RaiNessuna valutazione finora

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocumento5 pagineJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNessuna valutazione finora

- Risk Assessment On Demolition Work - CompressDocumento8 pagineRisk Assessment On Demolition Work - CompressAbegail Manuel GatusNessuna valutazione finora

- Jsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonDocumento7 pagineJsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonMon Trang NguyễnNessuna valutazione finora

- May-2022 Safety Campaign - Working at Height HazardsDocumento6 pagineMay-2022 Safety Campaign - Working at Height HazardsHSE99 BHDC100% (1)

- Jsa D. G. INSTALLATIONDocumento5 pagineJsa D. G. INSTALLATIONRavi thokalNessuna valutazione finora

- Risk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesDocumento8 pagineRisk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesGopinath SekarNessuna valutazione finora

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Documento2 pagineJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNessuna valutazione finora

- JSA For Dewatering PumpDocumento1 paginaJSA For Dewatering Pumpwahyu nugrohoNessuna valutazione finora

- JSA Fitting and Welding Work For Pipe Trench InstalationDocumento6 pagineJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNessuna valutazione finora

- OCP Confined Space ShahiDocumento4 pagineOCP Confined Space ShahiVishal SrivastavaNessuna valutazione finora

- Fire Fighting Line MethodDocumento4 pagineFire Fighting Line MethodAbdul Rehman Sheikh100% (1)

- J S A Electrical Distributaton Board MaintenenceDocumento4 pagineJ S A Electrical Distributaton Board MaintenenceASLAM MULANINessuna valutazione finora

- Safety and Security Committe Meeting Presentation 12Documento32 pagineSafety and Security Committe Meeting Presentation 12R Sahadeo Reddy100% (1)

- Hazard Risk Assessment for Earthing WorkDocumento10 pagineHazard Risk Assessment for Earthing WorkProjects INTSNessuna valutazione finora

- Ast Jsa - Piping FabricationDocumento3 pagineAst Jsa - Piping Fabricationmd_rehan_2Nessuna valutazione finora

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Documento3 pagine50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNessuna valutazione finora

- Commercial Electrical Inspection ChecklistsDocumento1 paginaCommercial Electrical Inspection ChecklistsRao UmarNessuna valutazione finora

- Jha - de Spading Activities For N2 PurgingDocumento4 pagineJha - de Spading Activities For N2 PurgingNasrullah100% (1)

- RA Excavation For Site Establish LEW-ALLDocumento7 pagineRA Excavation For Site Establish LEW-ALLChoubi ChoubacaNessuna valutazione finora

- Job Safety Analysis for Excavation by Hand Around Live ElectricalDocumento2 pagineJob Safety Analysis for Excavation by Hand Around Live Electricalfrancis100% (1)

- JHA Blasting and Painting in Open AreaDocumento4 pagineJHA Blasting and Painting in Open Areashaiful annuarNessuna valutazione finora

- Al-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Documento7 pagineAl-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Numan SaleemNessuna valutazione finora

- JSA For PVC FlooringDocumento4 pagineJSA For PVC FlooringJavedNessuna valutazione finora

- JSA Format Erection of Column 903-C-02,03Documento5 pagineJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Documento5 pagineCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNessuna valutazione finora

- Job Hazard Analysis - Granite Surface PlateDocumento2 pagineJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNessuna valutazione finora

- Safe Work Method StatementDocumento8 pagineSafe Work Method StatementParasNessuna valutazione finora

- Emergency Drill Fall From HeightDocumento5 pagineEmergency Drill Fall From HeightBinay100% (1)

- Jsa Tank CleaningDocumento5 pagineJsa Tank CleaningASLAM MULANINessuna valutazione finora

- Hand DrillDocumento1 paginaHand DrillDth InfraNessuna valutazione finora

- JSA Hand ToolsDocumento1 paginaJSA Hand ToolsInoy dy hesusNessuna valutazione finora

- JSA Concereting and PaintingDocumento4 pagineJSA Concereting and PaintingHow Chin Engineering Sdn BhdNessuna valutazione finora

- Breaker Machine Safety ChecklistDocumento1 paginaBreaker Machine Safety ChecklistNair R RakeshNessuna valutazione finora

- Safety Engineer JobDocumento3 pagineSafety Engineer Jobخلف الله التوم0% (1)

- Risk Assessment For Pools MaintenanceDocumento11 pagineRisk Assessment For Pools Maintenanceطارق رضوانNessuna valutazione finora

- Safe Work Practice: Title General Application Protective MechanismsDocumento1 paginaSafe Work Practice: Title General Application Protective Mechanismssriset100% (1)

- Welding Procedure - Arc Welding Machine - Method Statement HQDocumento8 pagineWelding Procedure - Arc Welding Machine - Method Statement HQSaaed EllalaNessuna valutazione finora

- Hot Work Activities (Cutting)Documento9 pagineHot Work Activities (Cutting)Al Mughsar CompanyNessuna valutazione finora

- Al-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassDocumento11 pagineAl-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassMuhammad Muneeb Naeem NaeemNessuna valutazione finora

- Jha Earth WorkDocumento10 pagineJha Earth WorkStephen LowNessuna valutazione finora

- JSP 42 Use of Power ToolsDocumento6 pagineJSP 42 Use of Power ToolsMuhammad AtifNessuna valutazione finora

- JSA-012 Low-Flow Groundwater SamplingDocumento3 pagineJSA-012 Low-Flow Groundwater SamplingfrancisseeNessuna valutazione finora

- Job Safety Analysis: Work at HeightDocumento3 pagineJob Safety Analysis: Work at Heightmarlon armamentoNessuna valutazione finora

- IOCL Bench Cutting Machine ChecklistDocumento2 pagineIOCL Bench Cutting Machine ChecklistmurthyNessuna valutazione finora

- Caretaker Risk Assessment - Working at HeightDocumento8 pagineCaretaker Risk Assessment - Working at HeightLina MarcelaNessuna valutazione finora

- PTW JHA Prayer Garment Hanging Rack InstallationDocumento2 paginePTW JHA Prayer Garment Hanging Rack InstallationPHH9834Nessuna valutazione finora

- JSA CT Cement (Example)Documento2 pagineJSA CT Cement (Example)aneshseNessuna valutazione finora

- Cable Laying Safety MeasuresDocumento5 pagineCable Laying Safety MeasuresDwitikrushna RoutNessuna valutazione finora

- Akk Jha Installation of Diesel TankDocumento3 pagineAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Field Test LV Underground Cable InstallationsDocumento9 pagineField Test LV Underground Cable InstallationskarlNessuna valutazione finora

- 07 Manual Excavations & Exposing of Underground FacilitiesDocumento6 pagine07 Manual Excavations & Exposing of Underground FacilitiesPangky Abasolo100% (1)

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Documento3 pagineRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNessuna valutazione finora

- Unsafe MEWP Operation ReviewDocumento2 pagineUnsafe MEWP Operation ReviewAbdulKatherNessuna valutazione finora

- Job Safety Analysis WorksheetDocumento4 pagineJob Safety Analysis WorksheetSAHIL SHARMANessuna valutazione finora

- Risk Assessment For Welding JobsDocumento16 pagineRisk Assessment For Welding Jobsمحمد عمر حسينNessuna valutazione finora

- JSA for Drain Line ReplacementDocumento5 pagineJSA for Drain Line ReplacementMadhan KannanNessuna valutazione finora

- Jsa Steel ErectionDocumento9 pagineJsa Steel Erection01095902062ahmedNessuna valutazione finora

- Job Safety Analysis For: Hcu & Lobs Revamp ProjectDocumento6 pagineJob Safety Analysis For: Hcu & Lobs Revamp ProjectShilpiengg SafetyNessuna valutazione finora

- Nebosh IGC Element 8 Accident Investigation Recording and Reporting (Notes)Documento3 pagineNebosh IGC Element 8 Accident Investigation Recording and Reporting (Notes)kkalvi83% (30)

- Nebosh IGC Element 2. Policy (Notes)Documento3 pagineNebosh IGC Element 2. Policy (Notes)kkalvi91% (69)

- Nebosh IGC Element 7 Monitoring, Review & Audit (Notes)Documento4 pagineNebosh IGC Element 7 Monitoring, Review & Audit (Notes)kkalvi88% (8)

- Nebosh IGC Element 6 Principles of Control (Notes)Documento6 pagineNebosh IGC Element 6 Principles of Control (Notes)kkalvi100% (26)

- Nebosh IGC Element 1. Foundations in Health and Safety (Notes)Documento7 pagineNebosh IGC Element 1. Foundations in Health and Safety (Notes)kkalvi92% (204)

- Nebosh IGC Element 3. Organizing Health and Safety (Notes)Documento3 pagineNebosh IGC Element 3. Organizing Health and Safety (Notes)kkalvi95% (58)

- Nebosh IGC Element 5. Rish Assessment (Notes)Documento6 pagineNebosh IGC Element 5. Rish Assessment (Notes)kkalvi96% (25)

- Nebosh Igc Element 4 Promoting Positive Health and Safety NotesDocumento6 pagineNebosh Igc Element 4 Promoting Positive Health and Safety Notesims1100% (1)

- Nebosh IGC Element 1. Foundations in Health and Safety (Notes)Documento7 pagineNebosh IGC Element 1. Foundations in Health and Safety (Notes)kkalvi92% (204)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocumento4 pagineJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- SRB-02-2011 - (Welding of Pipes) For Thrust BoringDocumento4 pagineSRB-02-2011 - (Welding of Pipes) For Thrust BoringkkalviNessuna valutazione finora

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Documento9 pagineSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Near Miss Report Form DetailsDocumento1 paginaNear Miss Report Form Detailskkalvi100% (1)