Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fabrication Procedure

Caricato da

Ajay G GopalDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fabrication Procedure

Caricato da

Ajay G GopalCopyright:

Formati disponibili

Number: MOP – 002

Revision: 042110

Date: April 21, 2010

Page 1 of 3

QUALITY MANAGEMENT SYSTEM DOCUMENT

TITLE: Fabrication Procedure

PURPOSE

The Purpose of this procedure is to control the fabrication processes. This

procedure provides for the communication of customer requirements to the shop,

and inspection of product to the customer requirements.

APPLICABLE DOCUMENTS

FORM-015 Fabrication Traveler

QAP-003 Control of Nonconforming Product

“Rejected” Tag

Customer Drawing

RESPONSIBILITIES

It is the responsibility of the shop supervisor to maintain this procedure. The Shop

supervisor is responsible to assign and train inspectors. It is the responsibility of

the welder to fabricate the part to the customer drawing and to follow this

procedure and not move on to another step without inspection. The inspector must

inspect the parts to the customer drawing.

PROCEDURE

1.1 The fabrication shop is given a Job Pack to fabricate a product.

1.2 The Shop Lead man looks at the drawings, bills of material, and cut

sheets to verify that there is adequate information to fabricate the

part.

1.3 The shop lead man gets the materials from the storage area and

verifies that they are correct to the BOM and Cut sheet requirements

and signs the fabrication traveler (FORM-015).

1.4 The shop lead man gives the materials and job pack to a welder to

fabricate the parts to the drawings. The welder completes the layout.

Approved By: _________________________________________________Date:

___________________

Controlled Copy, Do Not Duplicate

Number: MOP – 002

Revision: 042110

Date: April 21, 2010

Page 2 of 3

QUALITY MANAGEMENT SYSTEM DOCUMENT

1.5 The shop supervisor or lead man inspects the layout of the part to the

drawing and signs the fabrication traveler (FORM-015).

1.6 The welder cuts the material to match the drawing. The welder or cuts

or drills holes in the material to match the drawing.

1.7 The welder fits up the parts as described on the drawing. If the welder

does not understand the drawing, the welder is to ask the supervisor.

If the drawing is still unclear, the QA Manager or Plant Manager is

contacted to resolve the question with the customer in accordance

with QAP-003.

1.8 The shop supervisor or lead man inspects the fit-up of the part to the

drawing and signs the fabrication traveler (FORM-015).

1.9 The weld is completed by the welder.

1.10 The shop supervisor or lead man inspects the weld of the part to the

drawing and signs the fabrication traveler (FORM-015).

1.11 If necessary steps 4.7 to 4.10 are repeated until the part is completed.

1.12 When completed the part and job pack are moved to paint or to Final

Inspection.

Approved By: _________________________________________________Date:

___________________

Controlled Copy, Do Not Duplicate

Number: MOP – 002

Revision: 042110

Date: April 21, 2010

Page 3 of 3

QUALITY MANAGEMENT SYSTEM DOCUMENT

FLOWCHART

REVISION HISTORY

042110 Initial Trial Release.

Approved By: _________________________________________________Date:

___________________

Controlled Copy, Do Not Duplicate

Potrebbero piacerti anche

- 03-01 Material TraceabilityDocumento1 pagina03-01 Material TraceabilityAngel AngeleyeNessuna valutazione finora

- Dimensional Control ProcedureDocumento12 pagineDimensional Control ProcedureBethel NdifonNessuna valutazione finora

- QIR 121 Bolts Torque ReportDocumento1 paginaQIR 121 Bolts Torque ReportSamer BayatiNessuna valutazione finora

- Piping Fabrication Installation QCP On SiteDocumento1 paginaPiping Fabrication Installation QCP On SiteTarun PatelNessuna valutazione finora

- Method Statement For Fabrication, Installation and Testing of PipeworkDocumento31 pagineMethod Statement For Fabrication, Installation and Testing of PipeworkNaveed Ahmed Get-Info100% (1)

- Fabrication Division QMDDocumento11 pagineFabrication Division QMDRakesh RanjanNessuna valutazione finora

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocumento1 paginaFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNessuna valutazione finora

- Welding Consumables Control RegisterDocumento5 pagineWelding Consumables Control RegisterAli Mhaskar100% (2)

- Welding Consumable Control ProcedureDocumento15 pagineWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- Fabrication and Installation of PipingDocumento26 pagineFabrication and Installation of PipingAlin TomozeiNessuna valutazione finora

- Material Receiving Inspection ChecklistDocumento1 paginaMaterial Receiving Inspection ChecklistRonnel LeanoNessuna valutazione finora

- Welding Procedure SpecificationDocumento6 pagineWelding Procedure SpecificationJorge SanchezNessuna valutazione finora

- Wps For Smaw06-001 (Pipe 6g CS)Documento10 pagineWps For Smaw06-001 (Pipe 6g CS)walitedisonNessuna valutazione finora

- O - (TOC) - SOP - 019 - R0 - SOP For Steel Structure Fabrication and ErectionDocumento8 pagineO - (TOC) - SOP - 019 - R0 - SOP For Steel Structure Fabrication and ErectionMDhana SekarNessuna valutazione finora

- Welding Control ProcedureDocumento9 pagineWelding Control ProcedureRomi Abdul RahmanNessuna valutazione finora

- Weekly Welder Repair Rate MonitoringDocumento15 pagineWeekly Welder Repair Rate MonitoringSiddiqui Abdul Khaliq100% (1)

- Consumable Spec Rev 12Documento24 pagineConsumable Spec Rev 12megastar0604Nessuna valutazione finora

- B2020-TDC-VF-009 Vessel Fabrication R0Documento5 pagineB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNessuna valutazione finora

- Fabrication Procedure SA-4200-70621Documento24 pagineFabrication Procedure SA-4200-70621mohd as shahiddin jafriNessuna valutazione finora

- Material Inspection Report Steel FormDocumento1 paginaMaterial Inspection Report Steel Formtuan mai vanNessuna valutazione finora

- Preparation and Control of WeldingDocumento3 paginePreparation and Control of Weldingbalakumar rajaramNessuna valutazione finora

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDocumento1 paginaFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNNessuna valutazione finora

- D-Erection Manual MAGHREB-SP-SMPDocumento357 pagineD-Erection Manual MAGHREB-SP-SMPYoussef EL HamraouiNessuna valutazione finora

- Fabrication ProcedurDocumento7 pagineFabrication ProcedurHarry PangestuNessuna valutazione finora

- QMS Audit ChecklistDocumento8 pagineQMS Audit ChecklistAmb Patrick OghateNessuna valutazione finora

- Welding Control ProcedureDocumento4 pagineWelding Control Procedurevenkatesh100% (2)

- WI Dimensional Control Sign1Documento6 pagineWI Dimensional Control Sign1gusyahri001Nessuna valutazione finora

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessDocumento1 paginaInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiNessuna valutazione finora

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Documento19 pagineHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNessuna valutazione finora

- QAQC Procedure For FabricationDocumento7 pagineQAQC Procedure For FabricationRajesh K Pillai100% (6)

- Welding Consumable Receiving LogDocumento11 pagineWelding Consumable Receiving LogKandula Raju100% (1)

- Responsibility Matrix For Shop Piping WorksDocumento5 pagineResponsibility Matrix For Shop Piping WorksRenny DevassyNessuna valutazione finora

- 01 Procedure For Structural SteelDocumento9 pagine01 Procedure For Structural Steelpunitg_2Nessuna valutazione finora

- Welding Procedure SpecificationsDocumento2 pagineWelding Procedure SpecificationsGerhard Kemp0% (1)

- Dimensional-Control Procedure PDFDocumento57 pagineDimensional-Control Procedure PDFJohn Terry100% (2)

- Welding Inspector Job and ResponsilbilitiesDocumento5 pagineWelding Inspector Job and ResponsilbilitiesFelix GomintongNessuna valutazione finora

- Quality Control Checklist: Steel RepairDocumento2 pagineQuality Control Checklist: Steel RepairDilhara WickramaarachchiNessuna valutazione finora

- Fit-Up Preparation and Acceptance Criteria As Per Project RequirementsDocumento6 pagineFit-Up Preparation and Acceptance Criteria As Per Project RequirementsAbdülHak ÖZkaraNessuna valutazione finora

- 03 Welding Control Procedure - Asf QC WCP 001Documento7 pagine03 Welding Control Procedure - Asf QC WCP 001el_sharkawy2011100% (1)

- Alignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / DateDocumento6 pagineAlignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / Dateคุณพ่อน้อง บิ๊กบอส100% (1)

- MS For Lead LiningDocumento19 pagineMS For Lead LiningJervino RuahNessuna valutazione finora

- F-Qa-03 Material Inspection ReportDocumento2 pagineF-Qa-03 Material Inspection ReportHilal mohamedNessuna valutazione finora

- Weld MapDocumento4 pagineWeld MapSatish Keskar50% (2)

- Electrode Handling Procedure - Simple - SMAWDocumento7 pagineElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Cold Forming ProcedureDocumento5 pagineCold Forming ProcedureMassimo FumarolaNessuna valutazione finora

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Documento2 pagineSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNessuna valutazione finora

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocumento1 paginaPunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNessuna valutazione finora

- Approved Welding Procedures List RegioDocumento2 pagineApproved Welding Procedures List Regiogabriel__regio100% (1)

- Responsibilities of QA QC Welding SupervisorDocumento1 paginaResponsibilities of QA QC Welding SupervisorAnonymous VohpMtUSN100% (1)

- Dimensional Inspection ReportDocumento2 pagineDimensional Inspection Reportshabbir626Nessuna valutazione finora

- SOP - 06 - Visual and Dimensional ProcedureDocumento22 pagineSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNessuna valutazione finora

- Steel Structure Fabrication Procedure: Tz.O.R.C R.O. ProjectDocumento12 pagineSteel Structure Fabrication Procedure: Tz.O.R.C R.O. Projectbehzad mohammadiNessuna valutazione finora

- ITP For Hydraulic BarrierDocumento4 pagineITP For Hydraulic Barriermoytabura96Nessuna valutazione finora

- WPS Pipe 08'' SHD 40 SMAW REV02Documento2 pagineWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNessuna valutazione finora

- The Welding Inspection Services Are Define in Three Stages As BelowDocumento9 pagineThe Welding Inspection Services Are Define in Three Stages As BelowdeliNessuna valutazione finora

- Release For GroutingDocumento1 paginaRelease For GroutingUmair AwanNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocumento15 pagineSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNessuna valutazione finora

- Fabrication Procedure FlowDocumento3 pagineFabrication Procedure FlowtrikjohNessuna valutazione finora

- Fabrication ProcedureDocumento3 pagineFabrication ProcedureAndreMarcel100% (1)

- P 7.2-01 Prosedür - Müşteri İle İlişkili Prosesler Prosedürü - EngDocumento4 pagineP 7.2-01 Prosedür - Müşteri İle İlişkili Prosesler Prosedürü - Engfaruk öztürkNessuna valutazione finora

- IDEMDocumento15 pagineIDEMjayand_net100% (4)

- ISO 14001:2015 CQI/IRCA Approved Lead Auditor: Course ContentsDocumento1 paginaISO 14001:2015 CQI/IRCA Approved Lead Auditor: Course ContentsAjay G GopalNessuna valutazione finora

- ISO 14001 Lead Auditor Training Brouchre-EASDocumento2 pagineISO 14001 Lead Auditor Training Brouchre-EASAjay G GopalNessuna valutazione finora

- Steps To Install Anaconda and Packges in EnvDocumento8 pagineSteps To Install Anaconda and Packges in EnvAjay G GopalNessuna valutazione finora

- Non Conformance ProcedureDocumento3 pagineNon Conformance ProcedureAjay G GopalNessuna valutazione finora

- 10.50am (B) Work Site Induction For New Employees - Best PraDocumento16 pagine10.50am (B) Work Site Induction For New Employees - Best PraAkil ParkarNessuna valutazione finora

- © 2013 Eaton, All Rights ReservedDocumento95 pagine© 2013 Eaton, All Rights ReservedAjay G GopalNessuna valutazione finora

- Transition Checklist - FDIS 9001Documento13 pagineTransition Checklist - FDIS 9001rwillestoneNessuna valutazione finora

- AD EHSMS RF - Manual - V2.0-EnglishDocumento32 pagineAD EHSMS RF - Manual - V2.0-EnglishNaeem IqbalNessuna valutazione finora

- DAC Approval ListDocumento28 pagineDAC Approval ListAjay G GopalNessuna valutazione finora

- Fispoi Qual Compliance Work Wcappmce 1419884410775 Eng PDFDocumento2 pagineFispoi Qual Compliance Work Wcappmce 1419884410775 Eng PDFAjay G GopalNessuna valutazione finora

- Kerala - SocioReligious Leaders - 100 IMPORTANT QUESTIONSDocumento22 pagineKerala - SocioReligious Leaders - 100 IMPORTANT QUESTIONSuma149Nessuna valutazione finora

- The Management Environment: LIS 580: Spring 2006 Instructor-Michael CrandallDocumento22 pagineThe Management Environment: LIS 580: Spring 2006 Instructor-Michael CrandallAbhishek RaveendranNessuna valutazione finora

- Insert Company Name/Logo Here: ISO 9001:2015 Quality Management Systems - The Gap Analysis ChecklistDocumento4 pagineInsert Company Name/Logo Here: ISO 9001:2015 Quality Management Systems - The Gap Analysis ChecklistAjay G GopalNessuna valutazione finora

- Audit Iso9001 2015 ChecklistDocumento23 pagineAudit Iso9001 2015 ChecklistLa Metalurgica100% (5)

- Determining The Root Cause of A Problem: Approved For Public ReleaseDocumento22 pagineDetermining The Root Cause of A Problem: Approved For Public ReleaseLucia M. AceroNessuna valutazione finora

- 03 HSP Canada Full Line 2013 North EFDocumento28 pagine03 HSP Canada Full Line 2013 North EFAjay G GopalNessuna valutazione finora

- Audit DocsDocumento6 pagineAudit DocsAjay G GopalNessuna valutazione finora

- Sample Internal Audit Engagement Letter - Doc - FinalDocumento2 pagineSample Internal Audit Engagement Letter - Doc - FinalMohamoud A. Nour71% (7)

- QMDocumento36 pagineQMAjay G GopalNessuna valutazione finora

- Traffic Safety in Bad Weather ConditionsDocumento2 pagineTraffic Safety in Bad Weather ConditionsAjay G GopalNessuna valutazione finora

- 23.0 - Working at Heights v3.0 EnglishDocumento26 pagine23.0 - Working at Heights v3.0 EnglishAjay G Gopal100% (4)

- CV Template Building SurveyorDocumento3 pagineCV Template Building SurveyorAjay G GopalNessuna valutazione finora

- K. Ravikumar: Mobile: 050 8796794 AbudhabiDocumento3 pagineK. Ravikumar: Mobile: 050 8796794 AbudhabiAjay G GopalNessuna valutazione finora

- Khalid Bin Al Waleed Metro Station 1 To Dubai Dolphinarium - Google MapsDocumento1 paginaKhalid Bin Al Waleed Metro Station 1 To Dubai Dolphinarium - Google MapsAjay G GopalNessuna valutazione finora

- ARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpDocumento1 paginaARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpArun SonejiNessuna valutazione finora

- Supreme Court Case Analysis-Team ProjectDocumento5 pagineSupreme Court Case Analysis-Team ProjectJasmineA.RomeroNessuna valutazione finora

- SSC 211 ED Activity 4.1Documento4 pagineSSC 211 ED Activity 4.1bernard bulloNessuna valutazione finora

- Policy Implementation NotesDocumento17 paginePolicy Implementation NoteswubeNessuna valutazione finora

- ETSI EG 202 057-4 Speech Processing - Transmission and Quality Aspects (STQ) - Umbrales de CalidaDocumento34 pagineETSI EG 202 057-4 Speech Processing - Transmission and Quality Aspects (STQ) - Umbrales de Calidat3rdacNessuna valutazione finora

- 7540 Physics Question Paper 1 Jan 2011Documento20 pagine7540 Physics Question Paper 1 Jan 2011abdulhadii0% (1)

- Study of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaDocumento8 pagineStudy of Subsonic Wind Tunnel and Its Calibration: Pratik V. DedhiaPratikDedhia99Nessuna valutazione finora

- Body Temperature PDFDocumento56 pagineBody Temperature PDFBanupriya-Nessuna valutazione finora

- Industry GeneralDocumento24 pagineIndustry GeneralilieoniciucNessuna valutazione finora

- Application of The Ritz Method To The Analysis of Non-Linear Free Vibrations of BeamsDocumento12 pagineApplication of The Ritz Method To The Analysis of Non-Linear Free Vibrations of BeamsKuldeep BhattacharjeeNessuna valutazione finora

- KPJ Healthcare Berhad (NUS ANalyst)Documento11 pagineKPJ Healthcare Berhad (NUS ANalyst)noniemoklasNessuna valutazione finora

- Al-Farabi Fusul Al MadaniDocumento107 pagineAl-Farabi Fusul Al MadaniDaniel G.G.100% (1)

- SST Vs BBTDocumento7 pagineSST Vs BBTFlaxkikare100% (1)

- ADP G2 Spreadsheet Loader Data Entry: End-User GuideDocumento48 pagineADP G2 Spreadsheet Loader Data Entry: End-User Guideraokumar250% (2)

- Detailed Lesson Plan in Mathematics (Pythagorean Theorem)Documento6 pagineDetailed Lesson Plan in Mathematics (Pythagorean Theorem)Carlo DascoNessuna valutazione finora

- DOMESDocumento23 pagineDOMESMukthesh ErukullaNessuna valutazione finora

- Chapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDocumento123 pagineChapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNessuna valutazione finora

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDocumento11 pagineDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNessuna valutazione finora

- Higher Vapor Pressure Lower Vapor PressureDocumento10 pagineHigher Vapor Pressure Lower Vapor PressureCatalina PerryNessuna valutazione finora

- List of Practicals Class Xii 2022 23Documento1 paginaList of Practicals Class Xii 2022 23Night FuryNessuna valutazione finora

- 8A L31 Phiếu BTDocumento7 pagine8A L31 Phiếu BTviennhuNessuna valutazione finora

- Aluminium PasteDocumento11 pagineAluminium PasteGovindanayagi PattabiramanNessuna valutazione finora

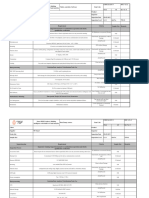

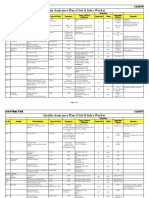

- Quality Assurance Plan-75FDocumento3 pagineQuality Assurance Plan-75Fmohamad chaudhariNessuna valutazione finora

- 1Documento14 pagine1Cecille GuillermoNessuna valutazione finora

- Unit 6B - PassiveDocumento18 pagineUnit 6B - PassiveDavid EstrellaNessuna valutazione finora

- Quality Assurance Plan - CivilDocumento11 pagineQuality Assurance Plan - CivilDeviPrasadNathNessuna valutazione finora

- Class 12 Unit-2 2022Documento4 pagineClass 12 Unit-2 2022Shreya mauryaNessuna valutazione finora

- 1 s2.0 S0378432004002465 MainDocumento20 pagine1 s2.0 S0378432004002465 MainMuhammad JameelNessuna valutazione finora

- A List of 142 Adjectives To Learn For Success in The TOEFLDocumento4 pagineA List of 142 Adjectives To Learn For Success in The TOEFLchintyaNessuna valutazione finora

- Unit 7 - Evolution and Classification: Regents BiologyDocumento24 pagineUnit 7 - Evolution and Classification: Regents BiologyTalijah JamesNessuna valutazione finora