Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ProFloSE DF Use & Care Guide

Caricato da

Greg ReynekeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ProFloSE DF Use & Care Guide

Caricato da

Greg ReynekeCopyright:

Formati disponibili

ProFloSE ProFloSE Use & Care Guide

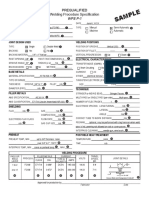

Control Valve Assembly Installation Data - Please fill out for future reference

General Data:

Installation Date _________________________________________________

Installer’s Name _________________________________________________

Equipment Model ________________________________________________

Water Hardness _______ US gr/gallon ________mg/l(g/m3) _______meq/l

Water Pressure ___________________ Water Temperature________________

Salt Dosage ____________ lbs of NaCl/ft3 _______________ g of NaCl/liter

Type of Media___________________________________________________

Resin Volume ___________ ft3 ____________ liters ________________m3

System Capacity ______ US gr/Regen. ______ meq/Regen. ______ g/Regen.

Regeneration:______ Downflow (Co-current) ______ Upflow (Counter-current)

3 Flow Controllers:

1 Brining System 1610

2 Injector # _________________________________

Drain Line Flow Control (DLFC)________________ gpm

Brine Line Flow Control (BLFC)________________ gpm

Controller Program:

Display Format: ❏ US/gallons (U-1), ❏ metric/ liters (U-2), ❏ metric/m3 (U-4)

Regeneration Type: ❏ (7-1), ❏ (7-2), ❏ (7-3)

Treated Water Capacity _________ gallons _________ liters ___________ m3

Regeneration Time__________________

Regeneration Day (Override) A-

Downflow Upflow

(1) Backwash _______________ minutes Brining & Slow Rinse

(2) Brining SR _______________ minutes Backwash

(3) Rapid Rinse______________ minutes Rapid Rinse

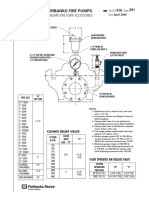

PARTS LIST

(4) BrineTank Refill_________________ Refill

Item No. Quantity Part No. Description (5) Off Off

1 . . . . . . . . . . . . 1 . . . . . . . . . 18277 . . . . . . . . . .Cover Flow Meter Size ❏ (F131) ❏ (F34.6)

2 . . . . . . . . . . . . 2 . . . . . . . . . 18262 . . . . . . . . . .Screws

Valve Type: (O-1)

3 . . . . . . . . . . . . 1 . . . . . . . . . 18271 . . . . . . . . . .Screen

Line Frequency (Hertz) ❏ (LF60) ❏ (LF50)

Page 4 Page 1

Printed in U.S.A. Printed in U.S.A.

P/N 40277 Rev. 1 4/00

ProFloSE ProFloSE

Time of Day/Manual Start of Regeneration Troubleshooting

SYMPTOM CAUSE CORRECTION

Service Indicator:

Valve In Service - Dot On Flow Indicator:

Extra Cycle Tonight - Flashing Dot Flashing Dot With Water Flow 1. Hard water to A. Softener failed to A. Electrical service

service. regenerate. interrupted, assure

permanent electrical

Service Flow

service.

P.M. Indicator

B. Defective timer B. Call equipment supplier

Program P.M.

Set Up

for replacement.

Button C. Open bypass. C. Close bypass valve.

Extra Cycle

Button

D. Low salt level in D. Keep salt level above

brine tank. water at all time.

Set Down

Button E. Injector screen E. See attached valve

Regeneration Display

plugged. assembly. Remove the

Step 1 - Rinse Step 3 - Brine/Rinse 2 screws (2), lift cover

Step 2 - Backwash Step 4 - Brine Refill (1), pull screen (3) out

to clean. Reinstall. Call

your equipment

supplier if problem

persists.

Your 5000SE has been programmed for your system. If required to change the 2. Salty water to A. Injector screen A. See attached valve

program, contact your equipment supplier for assistance. service. plugged. assembly. Remove the

2 screws (2), lift cover

To access the valve controller, remove the front cover of your water softener.

(1), pull screen (3) out

If the electricity fails, the electronic controller will keep in memory the pre set program. to clean. Reinstall. Call

Use the up and down arrows to set the correct time of day. your equipment

supplier if problem

If you need to manually initiate a regeneration, push and hold the “extra cycle button” persists.

for five seconds. The unit will then proceed to regenerate automatically.

OPERATING TIPS 3. Valve leaking to A. Internal valve leak. A. Call your equipment

drain at service. supplier for assistance.

• Keep the bypass closed at all times. Open the bypass to service the 5000SE valve

and to allow hard water to service.

• Keep the salt level at all times above the water in the brine tank.

Page 2 Page 3

Printed in U.S.A. Printed in U.S.A.

Potrebbero piacerti anche

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)Da EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)Nessuna valutazione finora

- Target Cleanliness WorksheetDocumento6 pagineTarget Cleanliness WorksheetMauricio Marin PinedaNessuna valutazione finora

- Rupture Disc Sizing Capacity FormDocumento1 paginaRupture Disc Sizing Capacity Formjeaneth_e173Nessuna valutazione finora

- Vog0038 PDFDocumento99 pagineVog0038 PDFjorge castilloNessuna valutazione finora

- Form N 3 Sample Procedure Qualification RecordDocumento1 paginaForm N 3 Sample Procedure Qualification RecordViswanath SreepadaNessuna valutazione finora

- Mesin 2KD PDFDocumento22 pagineMesin 2KD PDFfahriNessuna valutazione finora

- 05TA Service ManualDocumento111 pagine05TA Service ManualPTY EntertainmentNessuna valutazione finora

- L3 PQRforQualificationDocumento1 paginaL3 PQRforQualificationBernardo LeorNessuna valutazione finora

- 03TA Service ManualDocumento108 pagine03TA Service ManualPTY EntertainmentNessuna valutazione finora

- BcadDocumento2 pagineBcadAshwani Prabha BhardwajNessuna valutazione finora

- "CESSNA C182T G1000" "Cc-Ahm / Cc-Ahl ": Departamento "Seguridad Operacional" "Subdepartamento "Licencias"Documento4 pagine"CESSNA C182T G1000" "Cc-Ahm / Cc-Ahl ": Departamento "Seguridad Operacional" "Subdepartamento "Licencias"CHRISTOPHERNessuna valutazione finora

- 2G Rev-0-D1 - 2 - AL - PQRDocumento2 pagine2G Rev-0-D1 - 2 - AL - PQRAhmed GomaaNessuna valutazione finora

- PC Nirvana Contact Cooled - FormDocumento1 paginaPC Nirvana Contact Cooled - Formjohn vickers100% (1)

- PC Rotary - Oil Free NirvanaDocumento1 paginaPC Rotary - Oil Free NirvanaBùi ViệtNessuna valutazione finora

- D1.5M D1.5 2015 AMD1 Form O 3 FillableDocumento1 paginaD1.5M D1.5 2015 AMD1 Form O 3 FillableNavanitheeshwaran SivasubramaniyamNessuna valutazione finora

- VTSDocumento1 paginaVTSДанил ЗябловNessuna valutazione finora

- Sid 1038997332 1Documento3 pagineSid 1038997332 1Adryan MarstyaNessuna valutazione finora

- Aws N-1 WPS-PQR FormDocumento2 pagineAws N-1 WPS-PQR FormEdwin MariacaNessuna valutazione finora

- JushDocumento2 pagineJushg6vhdytsyzNessuna valutazione finora

- Sample: Exhibit 1 Exhibit 1Documento1 paginaSample: Exhibit 1 Exhibit 1jessy eghNessuna valutazione finora

- 3G Rev-0-D1 - 2 - AL-PQRDocumento2 pagine3G Rev-0-D1 - 2 - AL-PQRAhmed GomaaNessuna valutazione finora

- A11 Rig Move PDFDocumento21 pagineA11 Rig Move PDFMarshal RichesNessuna valutazione finora

- HVAC Performance Test Quality Control and Inspection Report FormDocumento6 pagineHVAC Performance Test Quality Control and Inspection Report Formhasan_676489616100% (1)

- TCM Forklift Inspection ChecklistDocumento1 paginaTCM Forklift Inspection Checklistnelson moratallaNessuna valutazione finora

- Welding Procedure Specification (WPS) : BackingDocumento1 paginaWelding Procedure Specification (WPS) : BackingtimkemperNessuna valutazione finora

- Er-10 4 0Documento6 pagineEr-10 4 0Dibyendu ChakrabortyNessuna valutazione finora

- OutspeedDocumento12 pagineOutspeedklemencicvinkoNessuna valutazione finora

- Alere Cholestech LDX Quality Control Optics LogDocumento1 paginaAlere Cholestech LDX Quality Control Optics LogRoberto NutiNessuna valutazione finora

- Arr. & Dep. Condition FormDocumento3 pagineArr. & Dep. Condition FormRay Audiophile666Nessuna valutazione finora

- Form Operasional Genset Kemenko Marves Perkins 1500 KvaDocumento1 paginaForm Operasional Genset Kemenko Marves Perkins 1500 KvaArdee LEDNessuna valutazione finora

- Dimensioning Sheet Oxistop Oxs Unit: ProjectDocumento1 paginaDimensioning Sheet Oxistop Oxs Unit: Projectjean bouNessuna valutazione finora

- Rifts - Robot Combat & Vehicle Log PDFDocumento1 paginaRifts - Robot Combat & Vehicle Log PDFTess MercerNessuna valutazione finora

- Boiler Make Up Water Pump Data SheetDocumento6 pagineBoiler Make Up Water Pump Data SheetGunturMudaAliAkbarNessuna valutazione finora

- Pre-Recorded Information: X X X X X XDocumento3 paginePre-Recorded Information: X X X X X XNancy Perez MendezNessuna valutazione finora

- Ariel Start-Up Check List (Er-10.4.0)Documento6 pagineAriel Start-Up Check List (Er-10.4.0)Jose RattiaNessuna valutazione finora

- DWD Operations Manual-Revised1Documento168 pagineDWD Operations Manual-Revised1Gerald A. DelfinNessuna valutazione finora

- OFITE - Portable Roller OvenDocumento1 paginaOFITE - Portable Roller OvenLuisAlbertoVazquezNessuna valutazione finora

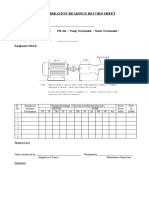

- Pump Vibration Reading Record SheetDocumento1 paginaPump Vibration Reading Record SheetSamuel MathumaranNessuna valutazione finora

- D - 16 Master - Pilot Exchange EditedDocumento5 pagineD - 16 Master - Pilot Exchange EditedYamada NorringtonNessuna valutazione finora

- 36e77619b0019 078Documento550 pagine36e77619b0019 078Omer Ghassan Abdulkareem Hassan AlsultanNessuna valutazione finora

- Dive No. - Date - Area - Location - Boat - Time in - : - Time OutDocumento2 pagineDive No. - Date - Area - Location - Boat - Time in - : - Time OutpedrocabiyaNessuna valutazione finora

- Er-10 4 0 PDFDocumento6 pagineEr-10 4 0 PDFANKIT DUBEYNessuna valutazione finora

- DEBEG 3400 Form For ParametersDocumento4 pagineDEBEG 3400 Form For ParametersHenry DengNessuna valutazione finora

- Compressor Start-Up Check ListDocumento6 pagineCompressor Start-Up Check ListCokro YudhaNessuna valutazione finora

- 580 Hc107r O&mmanengDocumento193 pagine580 Hc107r O&mmanengMario Garcia67% (6)

- Application Worksheet PROCAP Capacitance Probes & Vibrating Rod Point Level IndicatorDocumento1 paginaApplication Worksheet PROCAP Capacitance Probes & Vibrating Rod Point Level IndicatorJavier RamirezNessuna valutazione finora

- ProFloSe UF UseDocumento2 pagineProFloSe UF UseintermountainwaterNessuna valutazione finora

- PSV Servicing & Calibration SheetDocumento2 paginePSV Servicing & Calibration SheetKaisar JamilNessuna valutazione finora

- Iadc Wellcap Well Control Worksheet Bullhead: C W M MDocumento3 pagineIadc Wellcap Well Control Worksheet Bullhead: C W M MNirwan Purwa Lahardi100% (1)

- CFM56 3book2t Shoot PDFDocumento10 pagineCFM56 3book2t Shoot PDFDiniswari Alrino100% (1)

- Liebherr R 944 C Tunnel LitronicDocumento6 pagineLiebherr R 944 C Tunnel LitronicForomaquinas100% (1)

- PDI Inspection Form July 2005Documento4 paginePDI Inspection Form July 2005Chris. B.Nessuna valutazione finora

- SECTION 04 After Sales Service PolicyDocumento14 pagineSECTION 04 After Sales Service PolicyRFamDamilyNessuna valutazione finora

- 22.ecr LR9Documento5 pagine22.ecr LR9Abhimanyu Singh ChundawatNessuna valutazione finora

- Ops Plan TempDocumento21 pagineOps Plan TempTiago HenriquesNessuna valutazione finora

- Cargo Pumping RecordDocumento1 paginaCargo Pumping RecordU NaingNessuna valutazione finora

- Work Sheet PneumaticDocumento130 pagineWork Sheet PneumaticDimas WibisonoNessuna valutazione finora

- PPA31Chieftain MutualDocumento4 paginePPA31Chieftain MutualJuanNessuna valutazione finora

- Asset-backed Securitization and the Financial Crisis: The Product and Market Functions of Asset-backed Securitization: Retrospect and ProspectDa EverandAsset-backed Securitization and the Financial Crisis: The Product and Market Functions of Asset-backed Securitization: Retrospect and ProspectNessuna valutazione finora

- A Sewer Catastrophe CompanionDocumento24 pagineA Sewer Catastrophe CompanionMolly Danielsson50% (2)

- Are You Ready: An In-Depth Guide To Citizen PreparednessDocumento204 pagineAre You Ready: An In-Depth Guide To Citizen PreparednessAndrew Mack100% (2)

- Erie 541 Programming GuideDocumento1 paginaErie 541 Programming GuideGreg ReynekeNessuna valutazione finora

- How To Make An IglooDocumento2 pagineHow To Make An Iglooaquila_81Nessuna valutazione finora

- Robert Slovak - Alkalinity - WQA Aquatech 2012 - HandoutsDocumento11 pagineRobert Slovak - Alkalinity - WQA Aquatech 2012 - HandoutsGreg ReynekeNessuna valutazione finora

- 2011 EWG Cereals ReportDocumento23 pagine2011 EWG Cereals ReportpeanutmilkNessuna valutazione finora

- Robert Slovak - Alkalinity - WQA Aquatech 2012 - HandoutsDocumento11 pagineRobert Slovak - Alkalinity - WQA Aquatech 2012 - HandoutsGreg ReynekeNessuna valutazione finora

- Target Left HandedDocumento1 paginaTarget Left HandedGreg ReynekeNessuna valutazione finora

- Short Range Scope TargetDocumento1 paginaShort Range Scope TargetGreg ReynekeNessuna valutazione finora

- XLong Range Grid ADocumento1 paginaXLong Range Grid AGreg ReynekeNessuna valutazione finora

- Targets With BlockDocumento1 paginaTargets With BlockGreg ReynekeNessuna valutazione finora

- Targets SquareDocumento1 paginaTargets SquareGreg ReynekeNessuna valutazione finora

- XLong Range Scope TargetDocumento1 paginaXLong Range Scope TargetGreg ReynekeNessuna valutazione finora

- Target Right HandedDocumento1 paginaTarget Right HandedMark RossNessuna valutazione finora

- Targets CircledDocumento1 paginaTargets CircledGreg ReynekeNessuna valutazione finora

- PDF Created With Fineprint Pdffactory Trial VersionDocumento1 paginaPDF Created With Fineprint Pdffactory Trial VersionGreg ReynekeNessuna valutazione finora

- SM Scope GridDocumento1 paginaSM Scope GridGreg ReynekeNessuna valutazione finora

- PDF Created With Fineprint Pdffactory Trial VersionDocumento1 paginaPDF Created With Fineprint Pdffactory Trial VersionGreg ReynekeNessuna valutazione finora

- PDF Created With Fineprint Pdffactory Trial VersionDocumento1 paginaPDF Created With Fineprint Pdffactory Trial VersionGreg ReynekeNessuna valutazione finora

- Rifle TargetDocumento1 paginaRifle TargetGreg ReynekeNessuna valutazione finora

- Shotgun Shooting: Merit Badge WorkbookDocumento5 pagineShotgun Shooting: Merit Badge WorkbookGreg ReynekeNessuna valutazione finora

- PDF Created With Fineprint Pdffactory Trial VersionDocumento1 paginaPDF Created With Fineprint Pdffactory Trial VersionGreg ReynekeNessuna valutazione finora

- Rifle Shooting: Merit Badge WorkbookDocumento6 pagineRifle Shooting: Merit Badge WorkbookGreg ReynekeNessuna valutazione finora

- LR Scope Target ADocumento1 paginaLR Scope Target AGreg ReynekeNessuna valutazione finora

- Large TargetDocumento1 paginaLarge TargetGreg ReynekeNessuna valutazione finora

- Midway PistolDocumento1 paginaMidway PistolSergiotfNessuna valutazione finora

- Reloading Data Log: Bullet Powder Primer CaseDocumento1 paginaReloading Data Log: Bullet Powder Primer CaseGreg ReynekeNessuna valutazione finora

- Medium Distance Scope TargetDocumento1 paginaMedium Distance Scope TargetGreg ReynekeNessuna valutazione finora

- LR Scope Target BDocumento1 paginaLR Scope Target BGreg ReynekeNessuna valutazione finora

- CircleTarget 3inchDocumento1 paginaCircleTarget 3inchGreg ReynekeNessuna valutazione finora

- Minor ProjectDocumento49 pagineMinor Projectapi-334907813Nessuna valutazione finora

- Bohol HRMD Plan 2011-2015Documento233 pagineBohol HRMD Plan 2011-2015Don Vincent Bautista Busto100% (1)

- Practice - Creating A Discount Modifier Using QualifiersDocumento37 paginePractice - Creating A Discount Modifier Using Qualifiersmadhu12343Nessuna valutazione finora

- The Effectiveness of Acceptance and Commitment-BasDocumento18 pagineThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiNessuna valutazione finora

- USA Cutter Suction Dredger Simulator TrainingDocumento2 pagineUSA Cutter Suction Dredger Simulator TrainingAbdullah Badawi BatubaraNessuna valutazione finora

- Technics Su-7200 SMDocumento21 pagineTechnics Su-7200 SMF_E_TermanNessuna valutazione finora

- Absolute ValueDocumento19 pagineAbsolute Valueapi-70433300Nessuna valutazione finora

- India International Centre India International Centre QuarterlyDocumento15 pagineIndia International Centre India International Centre QuarterlySruti UNessuna valutazione finora

- P3Documento39 pagineP3venkatNessuna valutazione finora

- 6.9. How To Send SSL-Encrypted EmailDocumento3 pagine6.9. How To Send SSL-Encrypted EmailJoxNessuna valutazione finora

- BRO MAHA Alle Fahrwerkstechnik ENDocumento8 pagineBRO MAHA Alle Fahrwerkstechnik ENFranco DiacNessuna valutazione finora

- Mechanics Guidelines 23 Div ST Fair ExhibitDocumento8 pagineMechanics Guidelines 23 Div ST Fair ExhibitMarilyn GarciaNessuna valutazione finora

- RFQ - Printer Cartridge HP - A0066Documento1 paginaRFQ - Printer Cartridge HP - A0066منتظر عليNessuna valutazione finora

- Aksesoris PumpDocumento10 pagineAksesoris PumpDido AlexanNessuna valutazione finora

- Essay On The Traffic Conditions in Big CitiesDocumento3 pagineEssay On The Traffic Conditions in Big CitiesCeciliaNessuna valutazione finora

- DER11001 Reference DrawingsDocumento2 pagineDER11001 Reference DrawingsPrime Energy Warehouse-YemenNessuna valutazione finora

- BC-2800 - Service Manual V1.1 PDFDocumento109 pagineBC-2800 - Service Manual V1.1 PDFMarcelo Ferreira CorgosinhoNessuna valutazione finora

- COVID-19 Vaccination Appointment Details: CenterDocumento1 paginaCOVID-19 Vaccination Appointment Details: CenterMohit MittalNessuna valutazione finora

- Intro To Computing SyllabusDocumento7 pagineIntro To Computing SyllabusAireen Rose Rabino ManguiranNessuna valutazione finora

- Accenture Global Pharmaceutical and Company Planning Forecasting With Oracle HyperionDocumento2 pagineAccenture Global Pharmaceutical and Company Planning Forecasting With Oracle HyperionparmitchoudhuryNessuna valutazione finora

- 90-Day Performance ReviewDocumento2 pagine90-Day Performance ReviewKhan Mohammad Mahmud HasanNessuna valutazione finora

- Humboldt Triaxial Equipment Guide-LR0417Documento21 pagineHumboldt Triaxial Equipment Guide-LR0417Dilson Loaiza CruzNessuna valutazione finora

- Poster BC - Bored PileDocumento1 paginaPoster BC - Bored PileZaim Adli100% (1)

- Gitlab CICDDocumento15 pagineGitlab CICDdeepak bansal100% (1)

- Hydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesDocumento7 pagineHydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesMiguel VlntìnNessuna valutazione finora

- How To Find MAC Address On A Mobile PhoneDocumento11 pagineHow To Find MAC Address On A Mobile PhoneEyiwin WongNessuna valutazione finora

- DjikstraDocumento5 pagineDjikstramanoj1390Nessuna valutazione finora

- IP10G-CLI User Guide Version 6.7 March2011Documento124 pagineIP10G-CLI User Guide Version 6.7 March2011JorgIVariuS100% (1)

- 2Z140002 SV enDocumento21 pagine2Z140002 SV enBob AndreiNessuna valutazione finora

- Ivd Symbols FinalDocumento14 pagineIvd Symbols FinalDennis ChenNessuna valutazione finora