Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter I Polyvinyl Chloride (PVC) Pipe

Caricato da

yesrtyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter I Polyvinyl Chloride (PVC) Pipe

Caricato da

yesrtyCopyright:

Formati disponibili

CHAPTER I - POLYVINYL CHLORIDE (PVC) PIPE

CHAPTER I

POLYVINYL CHLORIDE (PVC) PIPE

A Product of Modern Technology

© Uni-Bell PVC Pipe Association, 2001

HANDBOOK OF PVC PIPE

CHAPTER I

POLYVINYL CHLORIDE (PVC) PIPE

During the 20th century a truly revolutionary advancement in pipeline

materials engineering occurred. The revolution was born in polymer science

and has, through many decades of technological refinement, been accelerating.

The polymer that has achieved front-runner status throughout this pipe

revolution is polyvinyl chloride (PVC).

Recognized by Engineering News Record as being one of the top 125

engineering innovations, the desirable combination of chemical resistance,

long-term strength, and high stiffness accounts for PVC having become a

popular pipe material for many pressure and non-pressure applications. The use

and availability of PVC pipe has grown steadily since the 1950s. PVC has

become the dominant pipe material for such major markets as the pressure and

non-pressure sanitary sewer market and the pressure water distribution market.

In North America each year, the total installed length of PVC water and

sanitary sewer pipe exceeds that of any alternative piping material. Much of

this handbook is devoted to the proper application of PVC pipe within these

major markets.

In addition, more recent technological advancements have allowed the PVC

pipe industry to expand production to include larger pipe diameters and allow

for more efficient use of materials. As a result, PVC pipe has been

© Uni-Bell PVC Pipe Association, 2001

CHAPTER I - POLYVINYL CHLORIDE (PVC) PIPE

successfully introduced to several other buried pipe markets, which include

gravity storm sewers, highway drainage, agricultural drainage, and the large

diameter pressure transmission pipe market.

PVC: AN ENGINEERED THERMOPLASTIC

PVC is part of a large, complex, and constantly developing group of

materials known as plastics. Plastic materials, like metals and other pipeline

materials, possess a wide range of properties that lend themselves to

particular applications. Structurally, plastic materials used for pipe

fabrication can exhibit properties ranging from soft and flexible to hard and

rigid.

Plastic pipe materials may be divided into two basic groups,

thermoplastic and thermosetting. Thermoplastics, as the name implies,

soften whenever heated and harden when cooled. They can be formed and

reformed repeatedly, but the reprocessing steps must be controlled and

limited to insure retention of original performance properties. PVC is a

thermoplastic, which is manufactured using an extrusion process as

described in Chapter IV. The ability to be reheated and reformed also

enables PVC pipes to be manufactured with a post-extrusion, heat-formed

bell end for jointing. PVC fittings are generally made in an injection

molding process or fabricated through the assembly of molded or extruded

parts. Chapter IV describes both manufacturing processes.

Thermosetting plastics go through a soft plastic stage only once, then

harden irreversibly, and cannot again be softened without incurring

permanent damage. Some of the more common thermosetting plastics used

for pipe are glass-fiber-reinforced thermosetting resin and cross-linked

polyethylene.

HISTORICAL BACKGROUND

Polyvinyl chloride was discovered in the waning years of the nineteenth

century. Its birth was not particularly glamorous. Scientists observing a

newly created organic chemical gas, vinyl chloride (C2H3Cl), discovered

that when exposed to sunlight this gaseous material reacted strangely. The

chemical reaction, which ensued, resulted in the creation of an off-white ac-

cumulation of solid material in the bottom of their test tubes. The scientists

had observed simple polymerization or the basic creation of a new plastic

material, polyvinyl chloride.

© Uni-Bell PVC Pipe Association, 2001

HANDBOOK OF PVC PIPE

Subsequent investigation of the new polymer at first created great ex-

citement and, somewhat later, great disappointment. The scientists were

astonished by the incredible new plastic material, which seemed nearly inert

to most chemicals and, in fact, virtually indestructible. However, they soon

found the material so resistant to change that they were forced to concede

that it could not be easily formed or processed into useful applications. Soon

thereafter, PVC was termed another of science's great discoveries without an

apparent application, and the world forgot about the unique new plastic.

Not until the 1920s did curiosity again bring polyvinyl chloride into the

limelight. Scientists in Europe and America launched an extended

campaign, which eventually brought PVC plastics to the modern world.

Technology evolved worldwide, but particularly in Germany, for the use of

PVC in its unplasticized, rigid form. In 1931, PVC compounds were

developed by German scientists who proceeded to produce millions of

pounds, some of it for pipes. Through continued service today, several of

these earliest PVC pipelines provide testimony to PVC's outstanding

durability.

In large part, the PVC pipe industry was born out of a necessity created

by World War II. German scientists and engineers turned to PVC as a pipe

material to quickly restore essential water and wastewater pipelines in cities

damaged by Allied bombings.

In the pre-war period, and to some extent during the war, PVC

processing was largely carried out on machinery developed for rubber or

celluloid. Even immediately after the war, the technology remained fairly

primitive and the processing machinery was not engineered specifically for

PVC. In the 1950s and 1960s, the two decades following the war, there were

considerable advances in PVC technology, both in formulation and

processing. The development of more effective stabilizers, lubricants and

processing aids, together with processing machinery engineered specifically

for PVC, allowed for increasing success in the extrusion of quality, rigid

(unplasticized) PVC pipe. The result was that PVC pipe began competing

with traditional products in a number of major markets including: gas

distribution; sewer and drainage; water distribution; electrical conduit;

chemical processing; and drain, waste, and vent plumbing.

PVC pipe's success in North America parallels that which occurred in

Europe. Since its introduction in North America in 1951, PVC has become

the largest volume plastic piping material. In 1955, the year the American

© Uni-Bell PVC Pipe Association, 2001

CHAPTER I - POLYVINYL CHLORIDE (PVC) PIPE

Society for Testing and Materials (ASTM) organized a group to write

plastic pipe standards, North American plastic pipe shipments were just

under 40 million pounds. By 1968, North American PVC pipe sales

surpassed 200 million pounds annually.

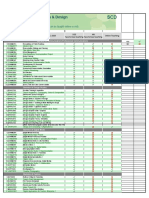

Figure 1.1 charts the PVC pipe industry's progress and growth from the

mid-seventies for North America and the world. The PVC pipe industry's

growth rate has been nothing short of phenomenal. The factors behind the

product's success and rapid growth are continuing advancements in pro-

cessing technology; improved joining materials; continuing standardization

programs; improved quality control testing; and continuing and increasing

understanding and acceptance by designers, contractors, and purchasing

agents.

FIGURE 1.1

PVC PIPE AND FITTINGS INDUSTRY GROWTH

25

PVC Pipe and Fittings Shipments (lbs)

20

Worldwide

15

(Billions)

10

5 USA & Canada

0

1975 1980 1985 1990 1995 2000

Year

A RATIONAL CHOICE

The range of useful properties afforded by PVC makes it one of the most

versatile of all pipe materials, a fact attested to by the variety of applications

and markets served by PVC pipes. The rationale for specifying or using

© Uni-Bell PVC Pipe Association, 2001

HANDBOOK OF PVC PIPE

PVC pipe is justified on the basis of any or several of the following

attributes.

Corrosion Resistance: PVC pipes are non-conductors of electricity

and immune to electrochemical reactions caused by acids, bases, and salts

that cause corrosion in metals. This characteristic exists on both the inside

and outside of PVC pipe. Consequently, PVC pipe is frequently cost

effective in applications where soil is aggressive. PVC pipe can be expected

to outlast alternative pipes without the need for protective coatings or liners.

Chemical Resistance: PVC pipes exhibit resistance to a wide range of

chemical reagents in temperatures up to 140°F and are resistant to chemicals

normally found or used in homes. Some industrial applications will warrant

an evaluation of chemical resistance. The chemical resistance quality of

PVC is further evidenced by its frequent usage as a protective liner for other

pipe materials.

Strength to Weight Ratio, Light Weight: PVC pipes offer a

tremendous weight advantage that is a particularly important safety aspect.

The material's ability to be handled more easily minimizes worker injury

and facilitates lower cost installation and transportation. A person can easily

carry two 20-foot lengths of 4-inch PVC pipe, but could carry less than 5

feet of 4-inch iron pipe with the same effort.

© Uni-Bell PVC Pipe Association, 2001

CHAPTER I - POLYVINYL CHLORIDE (PVC) PIPE

Flexibility: PVC pipe's resistance to fracture is an extremely important

performance advantage. While PVC pipes are made from rigid

(unplasticized) PVC compound, the pipe itself has the ability to yield under

loading without fracturing. The modulus of elasticity of PVC is a major

advantage for buried applications, particularly where soil movement or

vibration is anticipated. In pressure applications, PVC's modulus of

elasticity also reduces the magnitude of pressure surges (i.e., water

hammer).

Long-Term Tensile Strength: PVC pipe compounds are formulated to

attain long-term tensile strength. The long-term hydrostatic design basis

(HDB) for PVC is two or more times greater than that for other common

thermoplastic pipe materials.

Watertight Joints: A major advantage for nearly all piping

applications is joint tightness. PVC pipes are available with deep insertion,

push-together gasketed joints. Gasketed PVC pipe joints have consistently

out-performed those of traditional pipe products in actual service. They are

simple and easy to assemble and can be filled, tested, and placed in service

immediately after assembly.

Abrasion/Wear Resistance: PVC pipes exhibit outstanding resistance

to wear and abrasion. PVC pipe has proven more durable than metal,

concrete, and clay pipe for the transport of abrasive slurries.

Impact Strength: Under normal conditions, PVC pipes possess

relatively high resistance to impact damage when compared to pipes made

from clay, concrete, and most other conventional materials. Even though

PVC pipes do exhibit a reduction in impact strength at very low

temperatures, the impact strength remains more than adequate, usually

exceeding that of alternate pipe materials.

Coefficient of Friction: PVC pipes provide smoother wall surfaces that

reduce fluid friction and resistance to flow. This hydraulic smoothness

inhibits slime buildup in sewers and virtually eliminates tuberculation and

encrustation in water distribution mains. The end results are significantly

lower maintenance costs and more efficient initial pipeline design.

Longer Lengths: PVC pipe generally is available in lengths of either

13 feet or 20 feet. This reduces the number of joints required as compared

with other pipe products. Fewer joints allow for faster, more efficient

installation, less hydraulic friction, and fewer opportunities for leakage.

© Uni-Bell PVC Pipe Association, 2001

HANDBOOK OF PVC PIPE

Water Quality: PVC pipe’s non-corrosive nature and resistance to

chemical attack also renders it non-reactive with drinking water. PVC pres-

sure pipes do not adversely alter water quality. There are no corrosion by-

products with PVC pipe. PVC water pipes have been tested extensively us-

ing aggressive waters to verify their safety advantage.

Thermal Insulation: PVC has lower thermal conductivity than

traditional pipe materials. This characteristic makes PVC pipe desirable for

a variety of thermal insulation applications.

© Uni-Bell PVC Pipe Association, 2001

CHAPTER I - POLYVINYL CHLORIDE (PVC) PIPE

Flame Resistance: PVC pipe is difficult to ignite and will not continue

burning in the absence of an external ignition source. The spontaneous ig-

nition temperature is 850°F, which is well above that of most construction

materials. PVC pipe is sometimes referred to as self-extinguishing because

the products of combustion immediately combine with any available oxy-

gen, thus starving the flame.

Environmental Benefit: PVC, as a raw material, is energy efficient to

process. More than half of the raw material used in production of resin is

provided by salt, of which there is virtually unlimited supply. Similarly,

PVC pipe is efficient to manufacture and transport, using less non-

renewable resources than competing materials. However, a complete

evaluation of benefit recognizes the entire life cycle of the product, from

manufacture to disposal. Given the durable nature of the material, the long

life afforded by PVC pipe essentially eliminates the question of disposal.

Nevertheless, PVC is recyclable, with existing markets for recycled

material, and new ones continually developing.

Favorable Cost: PVC pipe is competitive with other pipes, particularly

when installation and life cycle operating costs are taken into consideration.

PVC PIPE TECHNOLOGY

Notwithstanding current advantages afforded by PVC pipe, the industry

is continuing to improve upon the technology. Through research and

development, the PVC pipe industry is striving to make the best possible

pipe and fittings products. With the ability to draw from PVC pipe's

worldwide experience, and with the opportunity to learn from the

shortcomings of predecessor pipe products, the PVC pipe industry will

maintain its product's advantages and work toward the betterment of those

advantages. PVC pipe is a product of modern technology, offering reliable

and durable service to a variety of consumers (i.e., contractors, engineers,

operators, industries, utilities, and irrigation districts). PVC pipe is a tried

and proven performer, a credit to PVC's inherently superior characteristics

and thorough engineering design.

© Uni-Bell PVC Pipe Association, 2001

HANDBOOK OF PVC PIPE

CHAPTER I

BIBLIOGRAPHY

1. American Society of Civil Engineers (ASCE), Structural Plastics Design Manual,

ASCE Manual No. 63 (1984).

2. Bulkey, Charles W., Robert G. Morin and Alan J. Stockwell, "Vinyl Polymers and

Copolymers," Modern Plastics Encyclopedia 1968, v. 45: No. 14A (Oct. 1968), p.

336.

3. Committee on Resin Statistics, the Society of the Plastics Industry (SPI), “Facts &

Figures of the U.S. Plastics Industry,” Washington, DC, (1997).

4. Henson, J. H. L. and A. Whelan, Developments in PVC Technology, National

College of Rubber Technology, London (Feb. 1973).

5. McJunkin, Frederick E. and Charles S. Pineo, Role of Plastic Pipe in Community

Water Supplies in Developing Countries, Agency for International Development,

(1971).

6. Modern Plastics, McGraw-Hill Publications, New York, (Jan. annually).

7. Penn, W. S., PVC Technology, Wiley Interscience, A Division of John Wiley and

Sons, Inc., New York (1967).

8. World PVC Demand, SRI International (1989).

9. Engineering News Record, McGraw Hill Companies, Inc. (October 18, 1999).

10

© Uni-Bell PVC Pipe Association, 2001

Potrebbero piacerti anche

- 172 Standard Weld (GHS)Documento10 pagine172 Standard Weld (GHS)yesrtyNessuna valutazione finora

- CT Fill SelectionDocumento4 pagineCT Fill SelectionkichasNessuna valutazione finora

- Penetrox HT x-1552 A (GHS)Documento10 paginePenetrox HT x-1552 A (GHS)yesrtyNessuna valutazione finora

- Safety Data Sheet: Penetrox A Oxide Inhibiting CompoundDocumento10 pagineSafety Data Sheet: Penetrox A Oxide Inhibiting CompoundyesrtyNessuna valutazione finora

- Safety Data Sheet: DuricompDocumento8 pagineSafety Data Sheet: DuricompyesrtyNessuna valutazione finora

- Small Hydent Connectors: Experience. Technology. AnswersDocumento1 paginaSmall Hydent Connectors: Experience. Technology. AnswersyesrtyNessuna valutazione finora

- Utility CapabilitiesDocumento6 pagineUtility CapabilitiesyesrtyNessuna valutazione finora

- Utility CapabilitiesDocumento6 pagineUtility CapabilitiesyesrtyNessuna valutazione finora

- Burndy Datacenter BrochureDocumento6 pagineBurndy Datacenter BrochureyesrtyNessuna valutazione finora

- Burndy Solar Solutions BrochureDocumento6 pagineBurndy Solar Solutions BrochureyesrtyNessuna valutazione finora

- Burndy Substation Catalog-Copper ProductsDocumento185 pagineBurndy Substation Catalog-Copper Productsyesrty100% (1)

- Electrical Software Tools OverviewDocumento20 pagineElectrical Software Tools OverviewPanom ParinyaNessuna valutazione finora

- Burndy Telecom Solutions BrochureDocumento6 pagineBurndy Telecom Solutions BrochureyesrtyNessuna valutazione finora

- Renewable Energy: Experience. Technology. AnswersDocumento6 pagineRenewable Energy: Experience. Technology. AnswersyesrtyNessuna valutazione finora

- Constr Esb754759Documento38 pagineConstr Esb754759yesrtyNessuna valutazione finora

- Oil Grounding AdDocumento1 paginaOil Grounding AdyesrtyNessuna valutazione finora

- Burndy Datacenter BrochureDocumento6 pagineBurndy Datacenter BrochureyesrtyNessuna valutazione finora

- Direct-Buried Installation of Fiber Optic CableDocumento9 pagineDirect-Buried Installation of Fiber Optic CableTahar HajjiNessuna valutazione finora

- 01 PrefaceDocumento2 pagine01 PrefaceHayro ArtaviaNessuna valutazione finora

- Edoc 001870Documento20 pagineEdoc 001870yesrtyNessuna valutazione finora

- Appleton Guide For Use of Electrical Products in Hazardous LocationsDocumento62 pagineAppleton Guide For Use of Electrical Products in Hazardous LocationsyesrtyNessuna valutazione finora

- Redapt Hazardous Area GuideDocumento11 pagineRedapt Hazardous Area GuidekarthipetroNessuna valutazione finora

- Burndy Braidad TedDocumento1 paginaBurndy Braidad TedyesrtyNessuna valutazione finora

- PTW V6.5 TutorialDocumento360 paginePTW V6.5 TutorialyesrtyNessuna valutazione finora

- Appendix FDocumento5 pagineAppendix FyesrtyNessuna valutazione finora

- Power System Software ListDocumento6 paginePower System Software ListyesrtyNessuna valutazione finora

- E - Electrical Engineering Design CriteriaDocumento25 pagineE - Electrical Engineering Design CriteriayesrtyNessuna valutazione finora

- Power System Software ListDocumento6 paginePower System Software ListyesrtyNessuna valutazione finora

- Corrpro Cathodic Protection CatalogueDocumento141 pagineCorrpro Cathodic Protection Catalogueyesrty100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Governance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REDocumento6 pagineGovernance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REBob SolísNessuna valutazione finora

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Documento2 pagineSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNessuna valutazione finora

- Sheet-Metal Forming Processes: Group 9 PresentationDocumento90 pagineSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyNessuna valutazione finora

- The University of The West Indies: Application For First Degree, Associate Degree, Diploma and Certificate ProgrammesDocumento5 pagineThe University of The West Indies: Application For First Degree, Associate Degree, Diploma and Certificate ProgrammesDavid Adeyinka RamgobinNessuna valutazione finora

- Transfert de Chaleur AngDocumento10 pagineTransfert de Chaleur Angsouhir gritliNessuna valutazione finora

- Atoma Amd Mol&Us CCTK) : 2Nd ErmDocumento4 pagineAtoma Amd Mol&Us CCTK) : 2Nd ErmjanviNessuna valutazione finora

- For Accuracy and Safety: Globally ApprovedDocumento4 pagineFor Accuracy and Safety: Globally ApprovedPedro LopesNessuna valutazione finora

- Waves and Ocean Structures Journal of Marine Science and EngineeringDocumento292 pagineWaves and Ocean Structures Journal of Marine Science and Engineeringheinz billNessuna valutazione finora

- Taylor Series PDFDocumento147 pagineTaylor Series PDFDean HaynesNessuna valutazione finora

- Amity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorDocumento23 pagineAmity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorMayank TayalNessuna valutazione finora

- Eccentric FootingDocumento3 pagineEccentric FootingVarunn VelNessuna valutazione finora

- Problem Solving No. 123Documento5 pagineProblem Solving No. 123Christy Joy BarboNessuna valutazione finora

- Meta100 AP Brochure WebDocumento15 pagineMeta100 AP Brochure WebFirman RamdhaniNessuna valutazione finora

- Pitch DeckDocumento21 paginePitch DeckIANessuna valutazione finora

- LG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFDocumento95 pagineLG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFplasmapete71% (7)

- Clustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaDocumento18 pagineClustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaAji LaksonoNessuna valutazione finora

- G.Devendiran: Career ObjectiveDocumento2 pagineG.Devendiran: Career ObjectiveSadha SivamNessuna valutazione finora

- Etag 002 PT 2 PDFDocumento13 pagineEtag 002 PT 2 PDFRui RibeiroNessuna valutazione finora

- Halloween EssayDocumento2 pagineHalloween EssayJonathan LamNessuna valutazione finora

- Poster-Shading PaperDocumento1 paginaPoster-Shading PaperOsama AljenabiNessuna valutazione finora

- HRM Practices in NepalDocumento22 pagineHRM Practices in NepalBodhiNessuna valutazione finora

- Consecration of TalismansDocumento5 pagineConsecration of Talismansdancinggoat23100% (1)

- "Organized Crime" and "Organized Crime": Indeterminate Problems of Definition. Hagan Frank E.Documento12 pagine"Organized Crime" and "Organized Crime": Indeterminate Problems of Definition. Hagan Frank E.Gaston AvilaNessuna valutazione finora

- PTW Site Instruction NewDocumento17 paginePTW Site Instruction NewAnonymous JtYvKt5XENessuna valutazione finora

- Superlab Manual PDFDocumento76 pagineSuperlab Manual PDFGabriela Soares100% (1)

- DLP English 10 AIRADocumento8 pagineDLP English 10 AIRAMae Mallapre100% (1)

- 5.0008786 Aluminum GrapheneDocumento11 pagine5.0008786 Aluminum GrapheneBensinghdhasNessuna valutazione finora

- Civil Rights Vocabulary Lesson PlanDocumento4 pagineCivil Rights Vocabulary Lesson PlanKati ArmstrongNessuna valutazione finora

- Types of Chemical Reactions: Synthesis and DecompositionDocumento3 pagineTypes of Chemical Reactions: Synthesis and DecompositionAlan MartínNessuna valutazione finora

- MSDS Buffer Solution PH 4.0Documento5 pagineMSDS Buffer Solution PH 4.0Ardhy LazuardyNessuna valutazione finora