Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Brochure Amylomer

Caricato da

mauriardDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Brochure Amylomer

Caricato da

mauriardCopyright:

Formati disponibili

Hair Care

intelligence behind beauty

LIQUID HAIR & SKIN CONDITIONERS MADE FROM STARCH

IMPROVING THE PERFORMANCE OF

COSMETIC PRODUCTS

The essence of a successful cosmetic product lies in the

Repeated conditioning and clarifying

cosmetic performance it delivers to the consumer’s skin or

00

hair. The sensual experience depends on various factors like

perfume, texture, skin feel of oil components and emulsifiers -0,1

-10

combing force reduction in %

or the performance of active ingredients. And there are -20

-0,2

ingredients that can still improve products that already are -30

-0,3

close to perfect. Our Amylomer range of conditioners has

-40

-0,4

been designed to improve and refine the skin feel in skin care

products and the hair conditioning performance in shampoos -50

-0,5

and conditioners. The basic ingredient of these raw materials -60

-0,6

is Amylose, which is a natural polymer from starch. Thus

-70

-0,7

the brand name Amylomer explains the nature of this

-80

-0,8

class of compounds. Produced on the basis of renewable

materials and chemically modified to obtain hig performance, -90

-0,9

Amylomer is an ideal compromise between natural sourcing

2

cle

po

o

o

po

po

am

cy

and chemical engineering for the improvement of the

am

am

h

sh

as

sh

sh

cosmetic performance. A variation in molecular size and

g

w

n

g

g

ni

ng

in

in

itio

ify

ify

degree of quaternization makes Amylomer a versatile concept

ni

tio

r

nd

cla

cla

di

co

of specialized conditioners for different hair qualities. The

n

co

5

second generation of conditioners for hair and skin carries the

5

name . This stands for the symbiosis between

Amylomer Blend Polyquaternium -10

different types of Amylomer, which have been blended for best

results on all types of hair and on the skin. is an

Fig.1: Comparison of and Polyquaternium-10. The

easy to use, all purpose conditioner, that truly combines ease

reduction of combing forces after 5 washing procedures is comparable.

of application and a balanced cosmetic profile of conditioning A significant difference is seen in the adhesion to the hair. A neutral

with minimum build-up. shampooing can not significantly remove Polyquaternium-10 from the hair.

After a second cycle the effect is even more pronounced.

Hair conditioning has been the main target in the

development of Amylomer products. The use of different A too pronounced substantivity is normally not desired since it

molecular sizes of amylose and the chemical modification to interferes with styling possibilities. An overload of conditioner

form this class of raw materials guarantees a high flexibility as usually seen with Polyquaternium-10 also decreases

in designing valuable hair conditioners for shampoos. volume, particularly in fine hair. Therefore many hair care

Compounds with different properties are created by this professionals try to avoid accumulation of conditioners on hair

variation and we have developed perfect conditioners for because the manageability, volume and structure is reduced.

different types of hair. A combination of different Amylomer

grades in or the addition of other conditioners

open new possibilities for specialized hair care for every type Positive evaluation by hair care professionals

of hair. The balance between substantivity and removability is

0,9

90 Shampoo L021-3 & 0,3% JR 400

one key to optimization of hair care products.

0,8

80 Shampoo L021-3 & 0,3% Amylomer MIX

0,7

70

We have obtained it by combining different types of Amylomer

0,6

60

in . According to their size and chemical

%

0,5

50

modification they target different sites at the hair. This is

0,4

40

necessary, because from the follicles to the tip of the hair

0,3

30

there has been – depending on the length – a varying degree 0,2

20

of treatments and probably damage to the hair. The balance 0,1

10

between high performance and better manageability of the 00

hair is best seen when is compared with a

ir

ty

ir

ir

ir

ir

e

ha

ha

ha

ha

ha

um

tio

ali

market standard like Polyquaternium-10. The reduction of

ica

qu

on

et

et

et

ol

dr

lv

w

w

pl

am

ss

of

ap

a

of

of

of

combing forces is comparable between both raw materials.

fin

ne

fo

el

ng

el

g

th

fe

n

fe

in

bi

bi

oo

ur

A significant difference can be seen in an attempt to remove

ld

sm

co

co

e

fe

&

st

d

2n

1r

ss

the conditioner with a neutral shampoo. Polyquaternium-10

e

tn

f

so

remains too strongly on the hair strongly reducing combing

forces, but creating film, that reduces the natural structure of

the hair. Fig. 2: Evaluation of two test shampoos by hair care professionals. The

same basic shampoo was formulated with Polyquaternium-10 and

, respectively.

drstraetmans · intelligence behind beauty

Skin conditioning is the second application that has Energy consumption by heating for the incorporation of

been targeted with our Amylomer. The assessment of several Polyquaternium types is another step that many producers

sample products showed us that the skin feel of cosmetics may like to avoid. Therefore cosmetic manufacturers will

and toiletries is improved by addition of certain Amylomer appreciate that Amylomer products are liquid and easy to

types. Smooth and silky skin is the result of formulations with apply. Just add the required amount of Amylomer to the

starch based . This effect can be used in rinse formulation and proceed with your common procedure. No

off products for a rich and velvety afterfeel, as well as in leave heating or hydrating is necessary. With our unique process of

on products, where a luxurious skin feel is achieved. modification and solubilization the resulting liquid is ready to

use.

Shower Gel evaluation with and without Amylomer

Proven efficacy is the ground for a successful application.

1

milder better feel better wash performance performance in total

Therefore we have extensive test protocols for our raw

0,9

88%

materials. We incorporate the different types in various state

0,8 82% of the art formulations to test the performance with our In-

76%

0,7 house facilities. Combing force measurements, curl retention

% of all testpersons

65%

0,6 experiments, Rubin-Dye-tests, UV-resistance and other

0,5 tests are done to carefully evaluate the performance of our

0,4 Amylomer materials in your products. Therefore we can not

0,3 only supply valuable data for your development, but also

0,2 support you with experience and experimental work to support

0,1 12% 12% your developments in our application lab.

6% 6%

0

Placebo Amylomer

Natural materials are the basis for Amylomer products.

Renewable sources like potatoes and tapioca provide the

Fig. 3: Evaluation of the cosmetic performance of a basic shower gel, starch used for the production. The raw starch is refined and

formulated with and without the skin conditioner (n=17, chemically modified to yield cosmetic ingredients with the

non trained individuals)

desired functionalities. A 100% natural conditioning agent is

the Ecocert listed dermofeel® P-30. For the production of

Ease of application is something hardly found in starch this ingredient only chemical modifications accepted by natural

based conditioner products. Also many Polyquaternium cosmetics standards are used. It binds to the hair cuticle

types are solids, that require hydration and time to restore the natural lubrication on the hairs’ surface, thus

consuming procedures to dissolve them in the formulation. decreasing the combing force and improving the hair condition.

Active

Name INCI Source

substance

Amylomer H-NI Aqua, Sodium Hydroxypropyl Oxidized Starch

26% - 28% Potato

Succinate

Amylomer 50 M Aqua, Starch Hydroxypropyltrimonium

19% - 21% Potato

Chloride

Amylomer CAS 50 M Aqua, Hydroxypropyl Oxidized Starch

24% - 26% Cassava

PG-Trimonium Chloride

Amylomer H 75 M Aqua, Hydroxypropyl Oxidized Starch

27,5% - 29,5% Potato

PG-Trimonium Chloride

Aqua; Starch Hydroxypropyltrimonium Chloride,

Hydroxypropyl Oxidized Starch 17% – 19% Potato

PG-Trimonium Chloride

dermofeel® P-30 PCA Glyceryl Oleate 100% Vegetable

drstraetmans · intelligence behind beauty

OUR REPRESENTATIVES ABROAD

Europe Asia/Pacific Americas

Benelux China Argentina/Brazil

Jan van Laarhoven-Waalwijk b.v. Shanghai Hope-Tec Biotechnology Inc nordest nova s.a..

E-Mail: laarhoven@planet.nl E-Mail: shanghai@htchem.com.cn E-Mail: sergio.engrassi@nordest-nova.com

www.htchem.com.cn www.nordest-nova.com

Bulgaria

Biesterfeld Pro Specialty Chemicals Iran USA

E-Mail: pavel.makedonski@biesterfeldpro.com Tooska-E-Khorasan Trading Co. Kinetik Technologies, Inc.

www.biesterfeldpro.com E-Mail: hrt@tooskaco.com E-Mail: chj@kinetiktech.com

www.tooskaco.com Web: www.kinetiktech.com

Croatia

Biesterfeld Spezialchemie d.o.o. Israel Chile

E-Mail: gordana.peric@biesterfeld.hr Efal chemical industries ltd. Maprin Representaciones Ltda.

www.biesterfeld.hr E-Mail: roni@efal.com E-Mail: JCroxatto@Maprin.cl

www.efal.com

Czech Republic Colombia

Biesterfeld Silcom s.r.o. Korea Cromaroma Ltda

E-Mail: terezie.sestakova@bisi.cz HANA Trading Company E-Mail: cromaroma@etb.net.co

www.bisi.cz E-Mail: Hoffnung@hitel.net

Denmark/Iceland/Norway Malaysia

Bionord A/S Ingredients Plus Africa

E-Mail: info@bionord.dk E-Mail: chaist@ingredientsplus.com.my

www.bionord.dk http://www.ingredientsplus.com.au/ South Africa

Meganede

France Phillippines E-Mail: megan.jones@meganede.com

Lucas Meyer Cosmetics S.A. CTC Far East Phils. Inc. www.meganede.com

E-Mail: info@lucasmeyercosmetics.com E-Mail: faith@ctcfareastphils.com

www.lucasmeyercosmetics.com www.ctc-group.com

Great Britain Thailand

Gemro Products Ltd. Adinop Co. Ltd.

E-Mail: stephen.blech@gemroproducts.com E-Mail: mail@adinop.co.th

www.gemroproducts.com www.adinop.co.th

Greece Turkey

Cellco Chemicals Ltd. Kalekimya

E-Mail: paraskevopoulos@cellco.gr E-Mail: birgen.kaleagasi@kalekimya.com

www.kalekimya.com

Hungary

Biesterfeld Special Chemicals Hungary Ltd. Australia/New Zealand

E-Mail: l.vereckei@biesterfeld.hu RejuvaCare

www.biesterfeld.hu E-Mail: smorse@rejuvacare.com.au

www.rejuvacare.com.au

Italy

Pharma Cosm Polli srl

E-Mail: info@pharmacosm.it

www.pharmacosm.it

Poland

Biesterfeld Polska Sp.z.o.o.

E-Mail: r.borzyminska@biesterfeld.com.pl

www.chemia.biesterfeld.com.pl

Romania

Biesterfeld Spezialchemie Romania S.R.L.

E-Mail: cmicu@biesterfeld.ro

www.biesterfeld-spezialchemie.ro

Spain

Comercial Quimica Jover, S.L.

E-Mail: comercial@cqjover.com

www.cqjover.com

Sweden/Finland

Bionord AB

E-Mail: lena@bionord.se

www.bionord.se

Dr. Straetmans Chemische Produkte GmbH

Switzerland

Rahn AG Merkurring 60–62 · D-22143 Hamburg

E-Mail: schulerg@rahn-group.com Phone: +49 40-66 93 56 0 · Fax: +49 40-66 93 56 310

www.rahn.ch email: info@dr-straetmans.de · www.dr-straetmans.de

Potrebbero piacerti anche

- February Monthly Collection, Grade 5Da EverandFebruary Monthly Collection, Grade 5Valutazione: 3 su 5 stelle3/5 (1)

- PT Orindo Eratec Company Profile and Product CatalogDocumento16 paginePT Orindo Eratec Company Profile and Product CatalogHSE Wana Dirga NusantaraNessuna valutazione finora

- August & September Monthly Collection, Grade 1Da EverandAugust & September Monthly Collection, Grade 1Nessuna valutazione finora

- Dominator 15W-50 Racing OilDocumento2 pagineDominator 15W-50 Racing OilBruce WappmanNessuna valutazione finora

- Microbial fermentation of seaweed biomass and possible industrial and food applicationsDocumento1 paginaMicrobial fermentation of seaweed biomass and possible industrial and food applicationsPlainexus MyNessuna valutazione finora

- Corrguard - 95: Key Performance AdvantagesDocumento3 pagineCorrguard - 95: Key Performance AdvantagesTRUNG PHẠM TIẾNNessuna valutazione finora

- ARLANXEO Product Brochure PVC Modification Baymod N XL 33.61Documento6 pagineARLANXEO Product Brochure PVC Modification Baymod N XL 33.61ahmetNessuna valutazione finora

- India HPCI2013 Merquat SoapBar PosterDocumento1 paginaIndia HPCI2013 Merquat SoapBar PostermikocorpusNessuna valutazione finora

- Plaschem Investment Booklet- Final EnglishDocumento29 paginePlaschem Investment Booklet- Final EnglishSwastic SinghNessuna valutazione finora

- Chemistry G Homologous & Denaturing To: CarbonylDocumento7 pagineChemistry G Homologous & Denaturing To: CarbonyljfdhkskfNessuna valutazione finora

- Biochemistry - ProteinsDocumento6 pagineBiochemistry - ProteinsPrem ShankerNessuna valutazione finora

- OEE - Fine-Blanking (May-2011)Documento41 pagineOEE - Fine-Blanking (May-2011)bluerosebachNessuna valutazione finora

- Chapter 11Documento85 pagineChapter 11malik2010Nessuna valutazione finora

- Design of Solar PVFuel Cell Hybrid Microgrid Power SystemDocumento1 paginaDesign of Solar PVFuel Cell Hybrid Microgrid Power Systemlaithismail200018Nessuna valutazione finora

- Potato 2Documento11 paginePotato 2Soumya ChakrabortyNessuna valutazione finora

- Bechem AutomotiveDocumento13 pagineBechem AutomotiveRajib DuttaNessuna valutazione finora

- Attachments for Every Requirement: Quality Management SystemDocumento3 pagineAttachments for Every Requirement: Quality Management SystemMahendra Tyre Works RaigarhNessuna valutazione finora

- D&L Industries Investor Deck 9M14Documento24 pagineD&L Industries Investor Deck 9M14Giang NguyenNessuna valutazione finora

- Plastic OnDocumento16 paginePlastic OnbilalaimsNessuna valutazione finora

- Sample PosterDocumento1 paginaSample PosterAlrayyan RashidNessuna valutazione finora

- Exxelor PE1040 DatasheetDocumento2 pagineExxelor PE1040 DatasheetmaheshgupteNessuna valutazione finora

- Spain CDR 2019Documento33 pagineSpain CDR 2019Spike BikeNessuna valutazione finora

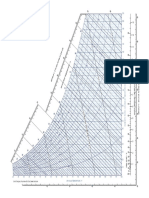

- PDF Ashrae Psychrometricchart CompressDocumento2 paginePDF Ashrae Psychrometricchart CompressSjsinssjNessuna valutazione finora

- France CDR 2019 0Documento33 pagineFrance CDR 2019 0Brandon MaNessuna valutazione finora

- Bimodal BlowMoldingBrochure PDFDocumento4 pagineBimodal BlowMoldingBrochure PDFarjun rawat100% (1)

- Toyox-ENGDocumento69 pagineToyox-ENGthu12a1thpthongthaiNessuna valutazione finora

- Arkema - Polymer Selection Guide For Liquid ResinsDocumento28 pagineArkema - Polymer Selection Guide For Liquid ResinsYoNessuna valutazione finora

- Psychrometric ChartDocumento1 paginaPsychrometric ChartJawBone YtNessuna valutazione finora

- Psychrometric Chart 29inhgDocumento1 paginaPsychrometric Chart 29inhgDickcy BenedictNessuna valutazione finora

- Psychrometric Chart 29inhgDocumento1 paginaPsychrometric Chart 29inhgGunnar Leonardo Gutiérrez QuisbertNessuna valutazione finora

- Drying & Cooling SolutionsDocumento9 pagineDrying & Cooling SolutionsDeepakNessuna valutazione finora

- Hallite CatalogueDocumento374 pagineHallite Cataloguegeovane cardosoNessuna valutazione finora

- Psychrometric Chart: Sea LevelDocumento1 paginaPsychrometric Chart: Sea LevelluisNessuna valutazione finora

- Redkite ExamplesDocumento2 pagineRedkite ExamplesIan LeaperNessuna valutazione finora

- Proposed Residential Apartments. 01Documento2 pagineProposed Residential Apartments. 01Daniel OkereNessuna valutazione finora

- Predicting Phase Behavior of Condensate/Crude-Oil Systems Using Methane Interaction CoefficientsDocumento7 paginePredicting Phase Behavior of Condensate/Crude-Oil Systems Using Methane Interaction Coefficientskmilo04Nessuna valutazione finora

- Pam 240 ADocumento16 paginePam 240 Adguruge8Nessuna valutazione finora

- BASF Coagulant and Flocculant KitDocumento6 pagineBASF Coagulant and Flocculant KitPrototype100% (2)

- BASF Coagulant and Flocculant KitDocumento6 pagineBASF Coagulant and Flocculant KitPrototypeNessuna valutazione finora

- ALI - Industrialists-2010Documento2 pagineALI - Industrialists-2010hassankouraniNessuna valutazione finora

- Brochure Elevast ElastomerDocumento5 pagineBrochure Elevast ElastomermaheshgupteNessuna valutazione finora

- New Products - Air operated 2 port valve (cylinder valve) SAB/SVB SeriesDocumento58 pagineNew Products - Air operated 2 port valve (cylinder valve) SAB/SVB SeriesvanNessuna valutazione finora

- 620 enDocumento3 pagine620 enJoseph wheelerNessuna valutazione finora

- New Trends in On-Line Rheometry To Study The Rheological Properties of NanocompositesDocumento1 paginaNew Trends in On-Line Rheometry To Study The Rheological Properties of NanocompositesSemana de Engenharia '2010Nessuna valutazione finora

- Sample PosterDocumento1 paginaSample PosterAlrayyan RashidNessuna valutazione finora

- Ju202as-202 Facade Structure Submittal 051200-3aDocumento1 paginaJu202as-202 Facade Structure Submittal 051200-3aMoises GaytanNessuna valutazione finora

- (Coco) Remember Me TABDocumento4 pagine(Coco) Remember Me TABmiromarko100% (1)

- Roof DetailsDocumento1 paginaRoof DetailsAwadhi SuleimanNessuna valutazione finora

- Charmor: Protecting People & PropertyDocumento8 pagineCharmor: Protecting People & Propertytivi boxNessuna valutazione finora

- WCB 061.20.0644 Swing Circle Gear Turntable Slewing Ring BearingDocumento1 paginaWCB 061.20.0644 Swing Circle Gear Turntable Slewing Ring BearingWCB BEARINGNessuna valutazione finora

- Poster ONTA 2010 v3Documento1 paginaPoster ONTA 2010 v3Christian ChabrierNessuna valutazione finora

- Sizing Chemicals - Sizing of Warp Yarns, Sizing Chemicals For Textile WeavingDocumento2 pagineSizing Chemicals - Sizing of Warp Yarns, Sizing Chemicals For Textile WeavingTholkappiyan GanesanNessuna valutazione finora

- Ba 19 FaDocumento1 paginaBa 19 FaLuis SánchezNessuna valutazione finora

- Serie A MOUVEX PDFDocumento3 pagineSerie A MOUVEX PDFrasottoNessuna valutazione finora

- Psychrometric chart essentialsDocumento1 paginaPsychrometric chart essentialsMUHAMMAD FAHRI RAMADHANNessuna valutazione finora

- 1046 Freshening Hair MistDocumento1 pagina1046 Freshening Hair MistMARTHA VALLENessuna valutazione finora

- Do An Be Tong Hoan Chinh-Model - pdf2Documento1 paginaDo An Be Tong Hoan Chinh-Model - pdf2Huy LêNessuna valutazione finora

- HSE Product PromoDocumento1 paginaHSE Product PromoProject Sales CorpNessuna valutazione finora

- Paint Additives: Product Guide L-G 1Documento16 paginePaint Additives: Product Guide L-G 1محمد عزتNessuna valutazione finora

- Ylang Ylang Essential Oil Benefits Sensual Relaxing ScentDocumento2 pagineYlang Ylang Essential Oil Benefits Sensual Relaxing ScentmauriardNessuna valutazione finora

- Rose OilDocumento2 pagineRose OilRakeshKumarNessuna valutazione finora

- Essential Oils - JulienDocumento14 pagineEssential Oils - JulienAnne-Sophie VilleNessuna valutazione finora

- Essential Oils - JulienDocumento14 pagineEssential Oils - JulienAnne-Sophie VilleNessuna valutazione finora

- Hairdressing CGDocumento29 pagineHairdressing CGlea bendijo100% (1)

- T.L.E - Hairdressing 10/written Test Name: - Section: - CP#Documento2 pagineT.L.E - Hairdressing 10/written Test Name: - Section: - CP#Jake Peñano0% (1)

- Clinic Plus Vs Meera ShampooooooooooDocumento10 pagineClinic Plus Vs Meera ShampooooooooooPawan KumarNessuna valutazione finora

- Best Fruits For Hair GrowthDocumento19 pagineBest Fruits For Hair Growthfakrul hasanNessuna valutazione finora

- Hair Shine, Hydration and Health PDFDocumento16 pagineHair Shine, Hydration and Health PDFrafaeldelperuNessuna valutazione finora

- Bus 620 AssignmentDocumento21 pagineBus 620 AssignmentPrayag DasNessuna valutazione finora

- Catalog Remington 2014Documento118 pagineCatalog Remington 2014Humberto FartoNessuna valutazione finora

- Biocosmethic - Product List 01.05.2016 - 3acDocumento4 pagineBiocosmethic - Product List 01.05.2016 - 3acMasneli MasriNessuna valutazione finora

- LUSH: Fresh Handmade Cosmetics Company ProfileDocumento34 pagineLUSH: Fresh Handmade Cosmetics Company ProfileElizabeth Aquiño JaimesNessuna valutazione finora

- Ultimate Guide To Managing Frizzy Hair - SkinKraftDocumento7 pagineUltimate Guide To Managing Frizzy Hair - SkinKraftPriya PatelNessuna valutazione finora

- 10 Hair Growth Oils That Can Actually Work Wonders - SkinKraftDocumento7 pagine10 Hair Growth Oils That Can Actually Work Wonders - SkinKraftPriya PatelNessuna valutazione finora

- 18 Ways To Glow Up Mentally and PhysicallyDocumento7 pagine18 Ways To Glow Up Mentally and PhysicallyRemy BedañaNessuna valutazione finora

- Hair Care and Foot CareDocumento6 pagineHair Care and Foot CareKelsey MacaraigNessuna valutazione finora

- The Importance of Branding in the Hair Care IndustryDocumento51 pagineThe Importance of Branding in the Hair Care IndustryVatsal MehtaNessuna valutazione finora

- India Hair Care Market Outlook, 2023Documento8 pagineIndia Hair Care Market Outlook, 2023Bonafide ResearchNessuna valutazione finora

- Hair Care 2017 v-1 PDFDocumento202 pagineHair Care 2017 v-1 PDFahmed hassanNessuna valutazione finora

- COSMETOLOGY 10 - Q1 - W3 - Mod3Documento18 pagineCOSMETOLOGY 10 - Q1 - W3 - Mod3Rosalie RebayNessuna valutazione finora

- Silicones & Sulfates: by Hair Growth LabDocumento28 pagineSilicones & Sulfates: by Hair Growth Labcreem sodahNessuna valutazione finora

- Top 18 Homeopathic Medicines & Treatments For Hair LossDocumento23 pagineTop 18 Homeopathic Medicines & Treatments For Hair LossSekarVel100% (1)

- Formula Botanica School Prospectus 2019-2020Documento54 pagineFormula Botanica School Prospectus 2019-2020Mayada Ahmad100% (2)

- Best Shampoo For Black MenDocumento11 pagineBest Shampoo For Black MenNadira Islam NilaNessuna valutazione finora

- QuestionnaireDocumento3 pagineQuestionnairebangalore_vineet100% (1)

- Examples of Fast-Moving Consumer Goods: DiscountsDocumento3 pagineExamples of Fast-Moving Consumer Goods: Discountstejaswi mhatreNessuna valutazione finora

- Silk Protein Improves Skin & Hair MoistureDocumento1 paginaSilk Protein Improves Skin & Hair MoistureJohana Ibarra JaramilloNessuna valutazione finora

- Ayurvedic Skin & Hair Care RangeDocumento45 pagineAyurvedic Skin & Hair Care Rangepratik12188Nessuna valutazione finora

- Jchps 8 (4) 70 Diana PearlineDocumento5 pagineJchps 8 (4) 70 Diana PearlineSheramae Sulde OngNessuna valutazione finora

- Amla-Indian Secret of Healthy, Lustrous HairDocumento4 pagineAmla-Indian Secret of Healthy, Lustrous HairShubham BhardwajNessuna valutazione finora

- AyurDocumento23 pagineAyurSubhojit RoyNessuna valutazione finora

- A DIY Guide For All Things Natur PDFDocumento107 pagineA DIY Guide For All Things Natur PDFJulian Martinez100% (3)