Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

400 Don 4

Caricato da

DarioDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

400 Don 4

Caricato da

DarioCopyright:

Formati disponibili

Vibrational Diagnostics of Rotating Stall

in Centrifugal Compressors

by Donald E. Bently negative in normal operating conditions. labyrinth seals. The latter is called

Founder, Chairman, and CEO, The negative spring effect in the case whirl-type behavior [27-28] and can

Bently Nevada Corporation, and of rotating stall is even more profound. be associated either with fluid-film

President,

The conclusion is that during rotating bearings/seals or with rotating stall.

Bently Rotor Dynamics

Research Corporation stall the rotor dynamic stability margin Rotating stall usually results in an

e-mail: don@bently.com is reduced. appearance of a low subsynchronous

frequency component in the rotor

and Paul Goldman Introduction

vibration spectrum (frequency ratios

Manager, The interest in radial compressor are typically between 8 and 40% but

Bently Rotor Dynamics

Research Corporation

fluid-induced instabilities started in the can be as high as 80% of rotative

e-mail: paul.goldman@bently.com mid-seventies. Since then, numerous speed, [20]). The emphasis on rotor

case histories of high pressure, cen- behavior does not allow for details of

trifugal compressor instabilities have particular flow patterns but treats the

been published [1-17]. Most of the fluid (gas) “in average,” which falls in

publications report two types of rotor the scale of rotor motion.

his paper discusses the vibrational behavior: 1) High eccen-

rotating stall in centrifugal tricity, rotor first natural frequency re- Experimental compressor

compressors from vibra- excitation; and 2) Subsynchronous An experimental rig (Figure 1 and

tional diagnostics and rotor dynamics forward precession with rotative-speed- Table 1) was constructed to evaluate

standpoints. A diagnostic strategy is dependent frequency. The former is the rotor/fluid system Dynamic

suggested from the overview of the usually referred to as whip-type behavior Stiffness during rotating stall and

case history and aerodynamic research. and is normally associated with balance normal operating conditions. The rig

The literature survey shows insufficient pistons, fluid-film bearings, and consisted of a single stage, centrifugal

understanding of rotor dynamic impli-

cations of the rotating stall. Most of the

literature on the subject addresses only

aerodynamic aspects of the problem,

and only a few papers treat a compressor

as a coupled mechanical-aerodynamic

system. The latter approach is exercised

in this paper. The results of the

rotor/fluid system Dynamic Stiffness

identification are presented for the

experimental centrifugal compressor, in

rotating stall and in normal operating

conditions. It is shown that the aero-

dynamically-induced radial (direct

spring) stiffness coefficients are Figure 1. Experimental compressor.

32 ORBIT First Quarter 2000

Compressor type Centrifugal, 1 stage, vaneless diffuser

fully open, which allowed free flow

with minimum restriction. A pressure

Working fluid Air at 84.1 kPa (12.2 psi), 20° C (68° F)

transducer measured the compressor

Number of impeller blades 11

discharge pressure.

Inlet diameter 51 mm (2 in)

A constant magnitude, rotating-force

Outside diameter of impeller 108 mm (4.3 in)

perturbator, used in modal testing, was

Diffuser/Impeller radius ratio 1.8

attached to the nonrotating stub shaft.

Impeller tip/Diffuser radial clearance 380 µm (0.015 in)

It transmitted an exciting rotating force

Impeller/Diffuser axial clearance 640 µm (0.025 in) with variable frequency to the compressor

Diffuser/Shroud clearance 3 mm (0.12 in) rotor. The perturbator consisted of an

Discharge pipe dimensions 51 mm (2 in) inside diameter, outer rotating assembly supported by a

360 mm (14.2 in) length rolling element bearing attached to the

Table 1. Compressor design and operating parameters. compressor support structure. Three

radial springs with 120° angular spacing

compressor with a vaneless diffuser, An orthogonal pair of eddy current

were attached from the outer rotating

driven by a 373 W (1⁄2 hp) dc electric displacement transducers was mounted

assembly to an inner rolling element

motor. The motor speed was controlled between the air inlet and the impeller to

bearing attached to the nonrotating stub

by a high output, variable power supply, measure the displacement of the rotor.

shaft. One of the springs was tensioned

and the speed could be controlled from A spring load frame was attached to more than the other two springs, and

near zero to 17,000 rpm. The motor the nonrotating stub shaft just outboard this created a net force in the direction

was attached to the compressor rotor by of the compressor. This was used to of the most tensioned spring. As the

a flexible disk coupling. control the radial position of the perturbator outer assembly rotated, the

The compressor rotor was separated compressor rotor and to counteract the springs rotated as well, and a rotating

into two pieces: a rotating section from gravity load of the rotor. force was created. The force was

the motor to the outboard end of the

A conical exhaust valve on a lead transmitted through the inner rolling

compressor, and a nonrotating stub

screw controlled airflow through the element bearing to the stub shaft, and

shaft from the outboard compressor

compressor. The valve was located at then to the compressor rotor. A variable

bearing to the outermost support bearing.

the end of the discharge pipe from the speed motor drove the perturbator via

The rotating section was supported compressor (Figure 2). It could be a flexible belt. The perturbator drive

by two bearings: a bronze bushing type adjusted through several turns from motor was equipped with a Keyphasor®

at the inboard (motor) end, and a fully closed, which completely blocked probe to supply a phase reference and

rolling element bearing at the outboard the output flow of the compressor, to speed indication. The magnitude of the

end of the compressor. The outer race

of the bearing was installed in a collar,

which was attached to the nonrotating

outboard stub shaft. This allowed free

rotation of the compressor rotor relative

to the nonrotating stub shaft. A flexible

membrane made of stiff rubber supported

the stub shaft collar and the bearing

assembly. Another bronze bearing

supported the outboard end of the

nonrotating stub shaft.

An additional 0.8 kg (1.76 lb) disk

was attached to the shaft between the

inboard bearing and compressor to

reduce the rotor system natural

frequency. Figure 2. The experimental compressor discharge flow/pressure control.

ORBIT First Quarter 2000 33

subsynchronous vibration. The data is

presented in the form of a 1X, forward

component Bode plot and full spectrum

cascade plot (Figure 4). The Bode plot

shows the existence of two rotor modes

in the range from 0 to 17,000 rpm.

With the help of an additional set of

probes, the first mode was identified

as an almost rigid body conical mode

of the shaft, while the second was a

bending mode. The data taken during

rotating stall is shown in Figure 5.

Since the Bode plot of the 1X forward

component in this case does not differ

strongly from the previous experiment,

only a typical orbit and full spectrum

cascade are presented. The experimen-

tal compressor rotor exhibits rotating

stall whirl with a subsynchronous fre-

quency component of 0.21X in the for-

Figure 3. Experimental compressor performance chart. Ω = rotative speed. ward direction. The subsynchronous

rotating force, 1.3 N (0.3 lb), did not The first series of experiments component of the compressor rotor

change noticeably with speed, and the consisted of compressor startups with radial vibration is most likely caused

perturbator provided a variable speed, two different discharge valve positions, by the diffuser rotating stall.

constant magnitude, rotating-force while the perturbator was at rest. Valve Rotor dynamic characteristics of

excitation to the compressor rotor. positions, which were as close to each rotating stall

An experimental compressor other as possible, were chosen to The startup data does not provide

performance chart is shown in Figure 3. provide normal operating conditions and sufficient information to identify any

It also depicts the points on the rotating stall conditions. During normal changes in the Dynamic Stiffness of

performance curves where the operation, predominantly 1X forward the first mode due to rotating stall,

vibrational data was taken. vibration was observed, with no because the mode occurs at rotative

a) b)

Figure 4. Rotor lateral X and Y vibration data of the experimental compressor during startup without rotating stall: a) 1X forward

component Bode plot, b) Full spectrum cascade plot.

34 ORBIT First Quarter 2000

a) Next, the perturbation process was

repeated for perturbation in a direction

opposite the rotation of the compressor

rotor (reverse perturbation) for each

running speed Ω and valve setting. In

this case, the forward (in the direction

of perturbation) component of the

filtered-to-perturbation-frequency

response is opposite to the direction

of rotation.

The nonsynchronous Dynamic

Stiffness was calculated by taking the

ratio of the force input to the response

vectors for each speed in the databases.

(2)

b)

(3)

(4)

Since the total Dynamic Stiffness of

the compressor consists of a mechanical

and an aerodynamic part, the former

was measured by running nonsynchro-

nous perturbation on the compressor at

zero rotative speed (DS0). The differ-

ence between the Dynamic Stiffness

of the running compressor and that of

the stopped compressor represents

Figure 5. Rotor lateral X and Y vibration data of the experimental compressor rotor during aerodynamically-induced Dynamic

startup with rotating stall: a) Typical orbit/timebase, b) Full spectrum cascade. Stiffness, DSair:

speed below the onset of rotating stall Stiffness of the rotor first mode. The (5)

whirl. A series of nonsynchronous vibration signals from two orthogonal

perturbation tests were performed at eddy current displacement transducers,

each of four compressor running located at 90° to the right (X) and 0° (Y)

(6)

speeds: 11,500; 13,500; 15,000; and relative to vertical (as seen from the

17,000 rpm. At each running speed, driver), were filtered to the frequency ω

perturbation trials were performed for of the perturbation force. This yielded where Mair1, Kair, and Dair are air

the two valve positions used in the amplitudes and phases for vertical and inertia, radial stiffness, and damping,

startup tests. The constant force pertur- horizontal components of the response. respectively, generated by the air/impeller

bator generates a force of magnitude F In order to eliminate the minor interaction, Mair2 is a fluidic mass term,

with orientation δ rotating in the same influence of mechanical stiffness and T represents a tangential force

direction as the compressor rotation asymmetry, 1X vertical and coefficient.

(forward perturbation), resulting in the horizontal vectors were combined Equations 5 and 6 show the parame-

perturbation vector . The perturbator into the circular component: ters of Direct and Quadrature Stiffness

was ramped up from slow roll speed to extrapolation, that fit the data within an

3,000 rpm in order to identify Dynamic (1) accuracy of about 2% compared to actual.

ORBIT First Quarter 2000 35

The raw data and the described data Case history

identified as a surge component (3.5 Hz)

processing is illustrated in Figure 6. A 5-stage propylene compressor and rotating stall component (0.15X).

The results of all perturbation tests, provides an example of the industrial It is important to note that the half

reduced to the parameters of air-induced centrifugal compressor behavior under spectrum cascade of the thrust probe

Dynamic Stiffness (Equations 5 and 6), the conditions of surge/rotating stall. data (Figure 12) shows a strong activity

are presented in Table 2. The orbit (Figure 8) shows a typical at the surge frequency, while the rotat-

The most significant conclusion forward precession with frequency ing stall component is much smaller.

from the results in Table 2 is that aero- 0.15X. This is supported by the lateral The described behavior is a reflection

dynamic forces applied to the impeller vibration, half spectrum cascade data of the surge, which propagates axially,

generate negative spring stiffness (Figure 9). The gas pressure measured while rotating stall is mainly active in

(damping Dair and stiffness Kair at the outlet of the third stage is pre- the circumferential direction.

appear negative in all experiments). It sented in the timebase waveform for

is also important that this stiffness the steady state regime (Figure 10) and Instrumentation and diagnostics

drops even more during the rotating half spectrum cascade plot for the strategy

stall. This result is also shown in Figure startup (Figure 11). The steady state A typical machine train for a

7. Inconsistency in tangential force data shows the combination of vane centrifugal compressor unit is shown in

coefficient T suggests that it was too passing high frequency with low Figure 13. It includes an engine (in this

small in the experiment and was not frequency pulsations. Using the half case an aeroderivative gas turbine),

determined with sufficient accuracy. spectrum cascade plot, the latter are gearbox, and the compressor itself.

Different instrumentation configurations

for vibration, as well as performance

diagnostics and monitoring of the

engine, are beyond the scope of this

paper. For the centrifugal compressor,

the instrumentation package normally

includes a Keyphasor® transducer, two

sets of proximity probes in XY config-

uration installed at the inboard and out-

board bearing locations (see

Compressor DE and Compressor NDE

in Figure 13), two axial transducers,

and performance monitoring

Figure 6. Identification of the air-induced Dynamic Stiffness component.

36 ORBIT First Quarter 2000

• Pressure, temperature, flow

No With Stiffness change,

Rotative speed Parameters rotating rotating %, relative to Trend data (dc signal)

stall stall normal conditions

Indication: pressure, head, and

Kair lb/in -52.16 -63.2 flow decrease, temperature

Dair lb•s/in -3.4x10-3 -3.0x10-3 increase

11,500 rpm Mair1 lb•s2/in -2.7x10-6 -3.0x10-6 -21 Possible causes: surge, less likely

Mair2 2

lb•s /in -9.75x10 -6

-9.7x10 -6

rotating stall

T lb/in 2.83 3.6 Note: if pressure head and flow

Kair lb/in -134.6 -186.4 indicate a position on the perform-

Dair lb•s/in -7.0x10-3 -8.3x10-3 ance curve close to the surge

13,500 rpm Mair1 lb•s2/in -4.3x10-6 -7.7x10-6 -38 point, it could support rotating

Mair2 2

lb•s /in -10.0x10 -6

-7.7x10 -6 stall or surge versus fluid-induced

T lb/in -0.52 -0.07

instability

Kair lb/in -66.7 -134.1 Dynamic data

Dair lb•s/in -5.7x10-3 -5.7x10-3 Indication: vane passing frequency

15,000 rpm Mair1 lb•s2/in -4.3x10-6 -4.3x10-6 -101 amplitude modulation of pressure,

Mair2 lb•s2/in -10.0x10-6 -10.0x10-6

with constant flow

Possible cause: rotating stall

T lb/in -0.52 -0.52

Kair lb/in -63.2 -130.8

Indication: pressure vane passing

frequency amplitude modulation

Dair lb•s/in -5.2x10-3 -6.4x10-3

with correlated flow oscillations

17,000 rpm Mair1 lb•s2/in -1.5x10-6 -5.0x10-6 -107

2 -6 -6

Possible cause: surge

Mair2 lb•s /in -8.7x10 -8.3x10

As indicated above, a strong con-

T lb/in 3.6 2.7

clusion can only be reached by the

Table 2. Parameters of the aerodynamically-induced Dynamic Stiffness. correlation of vibration data with

performance information. It is important

to note that rotating stall can originate

instrumentation. As a minimum, the Indication: subsynchronous

in a particular stage of a multistage

compressor performance monitoring forward component with frequency

compressor. To localize the rotating

instrumentation is supposed to include proportional to the rotative speed

stall source, additional pressure

inlet and discharge pressures and (0.1 to 0.8X)

transducers may be required.

temperatures, and discharge flow Possible causes: rotating stall,

measurements. Using the described Conclusions

fluid-induced instability

instrumentation, the rotating stall or Although, the rotating stall aero-

surge can be identified based on the • Axial vibration dynamic effects have been investigated

following information: Steady state data: spectrum extensively [16-23], the rotor dynamic

Indication: subsynchronous implications of this phenomenon have

• Radial vibration component received much less attention [24, 27-

Steady state data: direct orbits, 29]. A direct quotation from the paper

Possible causes: rotating stall

full spectrum [26] by Colding-Jorgensen serves as an

(possible weak coupling), and

example of insufficiency of rotor

Indication: subsynchronous surge

dynamic data:

forward component

Transient data: spectrum cascade “In spite of all reservations due to

Possible causes: rotating stall, Indication: subsynchronous difficulties and lack of data, it is the

fluid-induced instability, and surge component with low constant author’s opinion that the impeller-

Transient data: direct orbits, frequency casing effect is mainly responsible for

full spectrum cascade Possible cause: surge a negative direct stiffness effect.”

ORBIT First Quarter 2000 37

Figure 8. Typical orbit of a 5-stage

propylene centrifugal compressor rotor

in rotating stall conditions.

This paper provides some practical

recommendations on the rotating stall

Figure 7. Aerodynamically-induced radial stiffness of experimental compressor.

diagnostics as well as some insight into

rotor dynamic implications of the

phenomenon. In short, the conclusions

can be formulated as follows:

• The rotating stall conditions

manifest in the rotor vibration

signature as rotor forward pre-

cession with subsynchronous fre-

quency, which tracks the rotor

speed. This behavior is referred

to as a rotating stall whirl.

• From the diagnostic standpoint,

rotating stall differs from the

other instabilities of the whirl

type in its strong dependence on

Figure 9. Half spectrum cascade plot of the vertical inboard lateral vibrations of the rotor

the compressor operating condi-

at the outboard bearing of the 5-stage propylene compressor during startup. tions; it should disappear with

increased flow. It differs from

surge by its frequency propor-

tionality to the rotative speed as

well as by the predominantly

axial character of surge-caused

vibrations.

• The parameter clearly identified

by nonsynchronous perturbation

tests is aerodynamically-induced

direct spring stiffness. In all

conditions it was negative. From

Figure 10. Gas pressure oscillations measured at the outlet of the third stage of 5-stage the practical standpoint, it means

propylene compressor in steady state regime. Note high vane passing frequency that even in normal operating

modulated by the low frequency of rotating stall/surge. conditions, centrifugal compressors

38 ORBIT First Quarter 2000

have lower natural frequencies

than follows from purely

mechanical calculations.

• The aerodynamically-induced

Direct Stiffness during rotating

stall drops dramatically and ulti-

mately can make a compressor

unstable.

• Altogether, aerodynamic forces

may have a significant desta-

bilizing effect on the compressor.

In the case of a flexible rotor

Figure 11. Half spectrum cascade plot of gas pressure oscillations at the outlet of the and/or soft bearings, they are able

third stage of 5-stage propylene compressor during startup. to create a rotor dynamic instability

of whirl type.

References

1. Fowlie, D. W., Miles, D. D., “Vibration

Problems With High Pressure Centrifugal

Compressors,” ASME Paper 75-Pet-28,

Petroleum Mechanical Engrg. Conf., Tulsa,

Oklahoma, 1975.

2. Smith, K. J., “An Operation History of

Fractional Frequency Whirl,” Proceedings of

Fourth Turbomachinery Symposium, 1975.

3. Wachel, J. C., “Nonsynchronous Instability

of Centrifugal Compressors,” ASME Paper

75-Pet-22, Petroleum Mechanical Engrg.

Conf., Tulsa, Oklahoma, 1975.

4. Ferrara, P., “Vibrations in Very High Pressure

Centrifugal Compressors,” ASME Paper 77-

Figure 12. Half spectrum cascade plot of the rotor axial vibrations of the 5-stage

Det-15, Design Engrg. Technical Conf.,

propylene compressor during startup, showing surge component. Chicago, Illinois, 1977.

Figure 13. Typical compressor train diagram.

ORBIT First Quarter 2000 39

5. Kaneki, T., Eino, T., “Centrifugal Carbon 14. Fulton, J. W., “Subsynchronous Vibration of a 22. Tsujimoto, Y., Acosta, A. J., “Theoretical

Dioxide Compressor for Urea Synthesis Multistage Centrifugal Compressor Forced Study of Impeller and/or Vaneless Diffuser

Plant,” Hitachi Review, Vol. 28, No. 6, 1979. by Rotating Stall,” Turbomachinery Attributed Rotating Stalls and Their Effects

6. Ek, M. C., “Solution of the Subsynchronous Technology Seminar 1986, Solar Turbines, on Whirling Instability of a Centrifugal

Whirl Problem in the High Pressure Inc., San Diego, California, February 1986. Impeller,” Work Group of Hydraulic

Hydrogen Turbomachinery of the Space 15. Emmons, H. W., Pearson, C. E., Grant, H. P., Machinery Under Steady Oscillatory

Shuttle Main Engine,” AIAA/SAE 14th Joint “Compressor Surge and Stall Propagation,” Conditions, Lille, France, 1987.

Propulsion Conference, Las Vegas, Nevada, Trans. ASME, Vol. 79, 1955. 23. Pampreen, R. C., “Compressor Surge and

1978. 16. Lennemann, E., Howard, J. H. G., “Unsteady Stall,” Concepts ETI, Inc., Norwich,

7. Geary, C. H., Damratowsky, L. P., Seyer, C., Flow Phenomena in Rotating Centrifugal Vermont, 1993.

“Design and Operation of the World’s Impeller Passages,” ASME 69-GT-35, ASME 24. Bently, D. E., Muszynska, A., “Role of

Highest Pressure Gas Injection Centrifugal Journal of Engrg. for Power, Vol. 108, 1970. Circumferential Flow in the Stability of

Compressor,” No. 0TC 2485, Offshore 17. Frigne, P., Van den Braembusse, R., Fluid-Handling Machine Rotors,” The Fifth

Technology Conference, Houston, Texas, “Distinction Between Different Types of Workshop on Rotordynamic Instability

1976. Impeller and Diffuser Rotating Stall in a Problems in High Performance

8. Sabella, D., Terrinoni, L., Timori, A., “Full Centrifugal Compressor With Vaneless Turbomachinery, Texas A&M University,

Load Testing of Centrifugal Natural Gas Diffuser,” ASME Journal of Engrg. for Gas College Station, Texas, NASA CP 3026,

Injection Compressors,” Inst. Mech. Ing. Turbines and Power, Vol. 106, No. 2, 1984. 1988.

Conference Publications, March 3, 1981. 18. Van den Braembusse, R., “Rotating Stall in 25. Muszynska, A., Bently, D. E., “Frequency

9. Coletti, N. J., Crane, M. E., “Centrifugal Centrifugal Compressors,” von Karman Swept Rotating Input Perturbation

Compression on the Arun High Pressure Institute for Fluid Dynamics, Preprint 1987- Techniques and Identification of the Fluid

Injection Project,” Inst. Mech. Ing. 16, March 1987, Belgium. Force Models in Rotor/Bearing/Seal Systems

Conference Publications, March 3, 1981. and Fluid-Handling Machines,” Journal of

19. Haupt, U., Seidel, U., Abdel-Hamid, A. N.,

Sound and Vibration, Vol. 143, No. 1, 1990.

10. Bonciani, L., Ferrara, P. L., Timori, A., Rautenberg, M., “Unsteady Flow in a

“Aero-Induced Vibrations in Centrifugal Centrifugal Compressor With Different Types 26. Colding-Jorgensen, J., “Rotordynamic Effects

Compressors,” Workshop on Rotordynamic of Vaned Diffusers,” ASME Paper 88-GT-22, of Impeller Flow in Centrifugal

Instability at Texas A&M University, College Gas Turbine and Aeroengine Congress and Compressors,” VDI Bevichte, No. 1082, 1993.

Station, Texas, 1980. Exposition, Amsterdam, The Netherlands, 27. Bently, D. E., Goldman, P., “Destabilizing

11. Bonciani, L., Terrinoni, L., Tesei, A., 1988. Effect of Aerodynamic Forces in Centrifugal

“Unsteady Flow Phenomena in Industrial 20. Jin, D., Haupt, U., Hasemann, H., Compressors,” ISROMAC-7, Honolulu,

Compressor Stage,” NASA Conference Rautenberg, M., “Blade Excitation by Hawaii, February 1998.

Publication 2250, 1982. Circumferentially Asymmetric Rotating Stall 28. Sorokes, J. M., Marshall D. F., “A Review of

12. Excerpts From Turbomachinery Technology in Centrifugal Compressors,” ASME Paper Aerodynamically Induced Forces Acting on

Seminar, March 11-14, 1984, Coronado, 92-GT-148. Centrifugal Compressors, and Resulting

California. 21. Chen, J., Huang, X., Hasemann, H., Seidel, Vibration Characteristics of Rotors,”

U., Jin, D., Rautenberg, M., “The Proceedings of the 27th Turbomachinery

13. Wendt, P. G., “Forced Low Frequency

Interpretation of Internal Pressure Patterns of Symposium, Texas A&M, September 1998.

Vibration Due to Aerodynamic Flow

Instability (Rotating Stall),” Solar Turbines, Rotating Stall in Centrifugal Compressor

Inc., Engineering Report 2832, January 23, Impellers,” ASME Paper 93-GT-192.

1985.

Bently Rotor Dynamics Research Corporation

Appoints New Manager

Paul Goldman, Ph.D., was promoted to A native of St. Petersburg, Russia, Paul joined BRDRC in

Bently Rotor Dynamics Research 1990. He earned an M.S.M.E. and Ph.D. in Applied

Corporation (BRDRC) Manager on 15 Mathematics from State Technical University of St. Petersburg.

December 1999. He had been Acting He has conducted research in rotating machinery dynamics-

Research Manager for six months prior to related topics, including loose pedestal effect, rotor-to-stator

his promotion, and, before that, he was a rubbing, lateral/torsional cross-coupling, fluid dynamics of

Senior Research Scientist. Paul’s new responsibilities oil film bearings, rotating stall, and cracked shaft. He has

include providing major research directions, visions, and authored or co-authored over 45 technical papers and

plans for BRDRC. reports.

40 ORBIT First Quarter 2000

Potrebbero piacerti anche

- Chapter 10Documento63 pagineChapter 10Hosam Abd Elkhalek100% (1)

- Effects of Clearance On Damping in Fluid Film Bearing: Spectra Quest, IncDocumento10 pagineEffects of Clearance On Damping in Fluid Film Bearing: Spectra Quest, IncjamariekoniNessuna valutazione finora

- 96-vfd Torsional - Turbo 2008 PDFDocumento12 pagine96-vfd Torsional - Turbo 2008 PDFwaj1Nessuna valutazione finora

- Torsional Vibration Analysis of Reciprocating Compressor Trains Driven B...Documento11 pagineTorsional Vibration Analysis of Reciprocating Compressor Trains Driven B...fuzhi2016Nessuna valutazione finora

- The Effect of Unbalance On Bearing LifeDocumento8 pagineThe Effect of Unbalance On Bearing Lifemans2014100% (2)

- Axial Thrust Position MonitoringDocumento3 pagineAxial Thrust Position MonitoringSeindahNyaNessuna valutazione finora

- Vibration AnalysisDocumento22 pagineVibration Analysisvenkat chakNessuna valutazione finora

- SMP 7Documento5 pagineSMP 7gullipalli srinivasa raoNessuna valutazione finora

- Basic Training Program On Vibration AnalysisDocumento24 pagineBasic Training Program On Vibration AnalysisMohamed Al-OdatNessuna valutazione finora

- BearingDocumento41 pagineBearingM.IBRAHEEMNessuna valutazione finora

- The New Professor Coyle-METRICDocumento3 pagineThe New Professor Coyle-METRICMarcelo MoraesNessuna valutazione finora

- Practical Use of Dynamic Vibration AbsorbersDocumento4 paginePractical Use of Dynamic Vibration AbsorbersDan-jones TudziNessuna valutazione finora

- Orbit V33N3 2013 Q3Documento64 pagineOrbit V33N3 2013 Q3Adhitya DwijayanthoNessuna valutazione finora

- Vibrations in A Francis Turbine A Case StudyDocumento4 pagineVibrations in A Francis Turbine A Case Studybukit_guestNessuna valutazione finora

- Resonance - : A Condition Where The Natural Freq. of A Part Matches With Exciting Freq. and Creates Large VibrationsDocumento8 pagineResonance - : A Condition Where The Natural Freq. of A Part Matches With Exciting Freq. and Creates Large Vibrationsrashm006ranjanNessuna valutazione finora

- Centrifugal Compressor Vibrations: Oil & Gas Customer Training CenterDocumento44 pagineCentrifugal Compressor Vibrations: Oil & Gas Customer Training CenterBrahim Rostane100% (1)

- Axial Thrust Position Sensor PDFDocumento3 pagineAxial Thrust Position Sensor PDFmanteghNessuna valutazione finora

- Gearbox Spectral Components Presentation V2Documento29 pagineGearbox Spectral Components Presentation V2Asha Venkataram100% (1)

- Torsional Vibration Analysis of Synchronous Motor Driven TCDocumento16 pagineTorsional Vibration Analysis of Synchronous Motor Driven TCBharath Chandra ReddyNessuna valutazione finora

- Mode Shapes of Centrifugal Pump Impeller PDFDocumento4 pagineMode Shapes of Centrifugal Pump Impeller PDFhachanNessuna valutazione finora

- VFD PDFDocumento26 pagineVFD PDFKamal ArreazaNessuna valutazione finora

- Coupling Failures in VFD Motor Fan: Torsional VibrationDocumento15 pagineCoupling Failures in VFD Motor Fan: Torsional VibrationCairo Oil Refining Co.100% (1)

- Oil Whirl Whip PDFDocumento9 pagineOil Whirl Whip PDFbwelz100% (2)

- Flexible Pin Bush CouplingsDocumento3 pagineFlexible Pin Bush CouplingsMAYURANDULKARNessuna valutazione finora

- Design Charts For Finite-Length Journal BearingsDocumento35 pagineDesign Charts For Finite-Length Journal Bearingsgao379100% (2)

- VibrationDocumento4 pagineVibrationzhyhh100% (1)

- Soal Analisa VibrasiDocumento15 pagineSoal Analisa VibrasiAdi FirmantoNessuna valutazione finora

- Machinery Malfunction Diagnosis and Correction - Constant ContactDocumento2 pagineMachinery Malfunction Diagnosis and Correction - Constant ContactLisan YanNessuna valutazione finora

- M14Cent Pump VibDocumento49 pagineM14Cent Pump VibBhargav Chaudhari100% (1)

- BalancingDocumento138 pagineBalancingJeinnerCastroNessuna valutazione finora

- Dynamic Vibration AbsorbersDocumento7 pagineDynamic Vibration AbsorberstmacspamNessuna valutazione finora

- Roots BlowerDocumento2 pagineRoots Blowereko bagus sunaryoNessuna valutazione finora

- Rotordynamic Stability Case StudiesDocumento9 pagineRotordynamic Stability Case StudiesYong LiNessuna valutazione finora

- Rotordynamic Insatability Problems in High-Performance TurbomachineryDocumento454 pagineRotordynamic Insatability Problems in High-Performance TurbomachineryMounicaRasagyaPalla100% (2)

- Identification of Torsional Vibration Features in Electrical Powered Rotating EquipmentDocumento9 pagineIdentification of Torsional Vibration Features in Electrical Powered Rotating EquipmentHasan PashaNessuna valutazione finora

- Vibration Basics 2Documento82 pagineVibration Basics 2AbdulNessuna valutazione finora

- Vibration Analysis of Gear Box.5-MilosprokoDocumento3 pagineVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Orbit v27n207 SlowrollDocumento13 pagineOrbit v27n207 SlowrollAyman ElsebaiiNessuna valutazione finora

- SCHROEDER Automatic Recirculation Check ValveDocumento14 pagineSCHROEDER Automatic Recirculation Check ValveAli Bari100% (1)

- Engine Pedestal Vibration - A New Solution Approach Using A Tuned-Mass Damper - R00Documento22 pagineEngine Pedestal Vibration - A New Solution Approach Using A Tuned-Mass Damper - R00Kelly EberleNessuna valutazione finora

- Monitoring and Analysis of Machine VibrationDocumento6 pagineMonitoring and Analysis of Machine VibrationAvinashNessuna valutazione finora

- How To Bump Test With MicrologDocumento2 pagineHow To Bump Test With MicrologYuda SatriaNessuna valutazione finora

- Iso TC 108 SC 2 N 666Documento58 pagineIso TC 108 SC 2 N 666Rahul B. WaghaleNessuna valutazione finora

- Format Final Report - Balancing ISODocumento68 pagineFormat Final Report - Balancing ISOAdeImanudin100% (1)

- Vibration Report For The Vapor Compressor of Desalination Unit B (59ML04B-MJ01)Documento8 pagineVibration Report For The Vapor Compressor of Desalination Unit B (59ML04B-MJ01)FadooollNessuna valutazione finora

- Axial PositionDocumento23 pagineAxial PositionArif Insurgent67% (3)

- Methodical Phase AnalysisDocumento31 pagineMethodical Phase Analysisturboconch100% (1)

- Effect of Fluid Forces On Vertical Pump Vibrations: Condition Monitoring Technical Services (TS)Documento3 pagineEffect of Fluid Forces On Vertical Pump Vibrations: Condition Monitoring Technical Services (TS)JAY PARIKHNessuna valutazione finora

- Application of Full Spectrum of Rotating Machinery DiagnosticsDocumento5 pagineApplication of Full Spectrum of Rotating Machinery DiagnosticsMajid SattarNessuna valutazione finora

- EM 67 - Recommended Practices For A Bump TestDocumento4 pagineEM 67 - Recommended Practices For A Bump TestChad Hunt100% (2)

- Monitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005Documento60 pagineMonitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005eko bagus sunaryo100% (2)

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocumento10 pagineCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Hydrostatic Journal BearingDocumento18 pagineHydrostatic Journal Bearingapi-19775783100% (1)

- Torsional Natural Frequencies PDFDocumento32 pagineTorsional Natural Frequencies PDFdavih007Nessuna valutazione finora

- Rotating Machinery Reliability for Technicians and EngineersDa EverandRotating Machinery Reliability for Technicians and EngineersNessuna valutazione finora

- Forsthoffer’s Component Condition MonitoringDa EverandForsthoffer’s Component Condition MonitoringValutazione: 4 su 5 stelle4/5 (2)

- Mechanism of Stall and Surge in A Centrifugal Compressor With A Variable Vaned DiffuserDocumento10 pagineMechanism of Stall and Surge in A Centrifugal Compressor With A Variable Vaned DiffuserIsmail SakrNessuna valutazione finora

- SPE 144416 Drilling Performance Improvements in Gas Shale Plays Using A Novel Drilling Agitator DeviceDocumento9 pagineSPE 144416 Drilling Performance Improvements in Gas Shale Plays Using A Novel Drilling Agitator DeviceJulio Alejandro Rojas BarbaNessuna valutazione finora

- Vibration Formulas PDFDocumento1 paginaVibration Formulas PDFmasanegraNessuna valutazione finora

- Vibration Formulas PDFDocumento1 paginaVibration Formulas PDFmasanegraNessuna valutazione finora

- Failure ModeDocumento13 pagineFailure ModeDarioNessuna valutazione finora

- Rexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDocumento24 pagineRexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDarioNessuna valutazione finora

- Milwaukee Cylinder Series H Hydraulic CylindersDocumento32 pagineMilwaukee Cylinder Series H Hydraulic Cylindersnvkjayanth100% (1)

- 1q05 FlametrackerDocumento7 pagine1q05 FlametrackerDarioNessuna valutazione finora

- Welding Procedure SpecificationDocumento1 paginaWelding Procedure SpecificationDarioNessuna valutazione finora

- Centr Compr StallDocumento3 pagineCentr Compr StallDarioNessuna valutazione finora

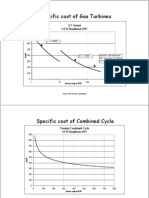

- Specific Cost of Gas Turbines: GT Genset GTW Handbook 1997Documento5 pagineSpecific Cost of Gas Turbines: GT Genset GTW Handbook 1997DarioNessuna valutazione finora

- 2005 PlantOperT&C ProgDocumento28 pagine2005 PlantOperT&C ProgDarioNessuna valutazione finora

- NOx Permit LimitDocumento15 pagineNOx Permit LimitTrung Quan VoNessuna valutazione finora

- An 01 013 Ctrls & Process ValvingDocumento2 pagineAn 01 013 Ctrls & Process ValvingAKSHEYMEHTANessuna valutazione finora

- Anti Surge ControllersDocumento6 pagineAnti Surge Controllersalimohebbi1361100% (1)

- Airplane Turbofan Engine Operation and Malfunctions Basic Familiarization For Flight CrewsDocumento38 pagineAirplane Turbofan Engine Operation and Malfunctions Basic Familiarization For Flight CrewstheevanraoNessuna valutazione finora

- 02 05 01 MB OkDocumento35 pagine02 05 01 MB OkdadrahimNessuna valutazione finora

- Section 10 - CompressorsDocumento69 pagineSection 10 - CompressorsChakerZagroubaNessuna valutazione finora

- Class Room Notes of PropulsionDocumento30 pagineClass Room Notes of PropulsionVaibhav SinghNessuna valutazione finora

- SIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2Documento39 pagineSIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2kenji roberto santanaNessuna valutazione finora

- F-86F Sabre: Dcs GuideDocumento91 pagineF-86F Sabre: Dcs GuideChristophe JourjonNessuna valutazione finora

- Compressor PDFDocumento57 pagineCompressor PDFAhmad Wildan ZakawaliNessuna valutazione finora

- Procidia Control Solutions Compressor Surge Control: Application DataDocumento3 pagineProcidia Control Solutions Compressor Surge Control: Application DataAto AnsoriNessuna valutazione finora

- Scramjet Problem OccurDocumento49 pagineScramjet Problem OccursakthiNessuna valutazione finora

- 02.understanding Process Equipment For Operators & Engineers-69Documento5 pagine02.understanding Process Equipment For Operators & Engineers-69rahulNessuna valutazione finora

- Introduction To Gas Turbine: 1. Operating PrincipleDocumento6 pagineIntroduction To Gas Turbine: 1. Operating PrincipleMuhammad Ridhwan100% (2)

- Beginner's Guide To Centrifugal CompressorsDocumento36 pagineBeginner's Guide To Centrifugal CompressorsShabir MansuriNessuna valutazione finora

- CT Oct 2015 PDFDocumento6 pagineCT Oct 2015 PDFDanish AlamNessuna valutazione finora

- Technical Training ManualDocumento607 pagineTechnical Training ManualIonut Marian Penciu100% (8)

- A4GpilotDaveRamsayPages MINDocumento57 pagineA4GpilotDaveRamsayPages MINSpazSinbadNessuna valutazione finora

- C-141C Dash 1 002 1 - 1-50Documento50 pagineC-141C Dash 1 002 1 - 1-50bkaplan452100% (1)

- Surge Detection in An Industrial Axial Flow Compressor by David H. Linden and Charles A. ParkerDocumento6 pagineSurge Detection in An Industrial Axial Flow Compressor by David H. Linden and Charles A. ParkerJoy BhattacharyaNessuna valutazione finora

- 4 2 1Documento105 pagine4 2 1emadNessuna valutazione finora

- Understanding Centrifugal Compressor - Equipment InteractionDocumento12 pagineUnderstanding Centrifugal Compressor - Equipment Interactionsoumya19800000000Nessuna valutazione finora

- AA007 Aircraft Propulsion Question BankDocumento15 pagineAA007 Aircraft Propulsion Question BankZubaran Bautista JuanNessuna valutazione finora

- Surge ControlDocumento16 pagineSurge ControlSANTOSH KUMARNessuna valutazione finora

- Compressor ControlsDocumento167 pagineCompressor ControlsAnonymous 70lCzDJvNessuna valutazione finora

- Severe Surge Incidents at Process Air Compressor, Their After Effects and Problem ResolutionDocumento15 pagineSevere Surge Incidents at Process Air Compressor, Their After Effects and Problem ResolutionAbhimanyu SharmaNessuna valutazione finora

- CompressorsDocumento19 pagineCompressorsVinoth Kumar100% (1)

- TFE 731 Chap 75Documento18 pagineTFE 731 Chap 75Egor85Nessuna valutazione finora

- Verification of High Altitude Performance and Characteristics For HF120 Turbofan EngineDocumento8 pagineVerification of High Altitude Performance and Characteristics For HF120 Turbofan EngineSam JacobNessuna valutazione finora

- 134849Documento3 pagine134849Elbahi DjaalabNessuna valutazione finora

- Hal 24 HP Recoup PDFDocumento34 pagineHal 24 HP Recoup PDFRendi Potenk100% (1)