Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Curriculum Vitae - Vy Minh Loc PDF

Caricato da

Kolusu SivakumarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Curriculum Vitae - Vy Minh Loc PDF

Caricato da

Kolusu SivakumarCopyright:

Formati disponibili

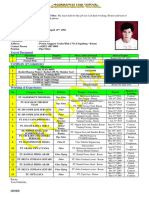

CURRICULUM VITAE VY MINH LOC

CURRICULUM VITAE

Personal informations

Name : VY MINH LOC

Location : Quang Ngai, Vietnam

Date of birth : Oct 30, 1989

Designation : Supervisor & Inspector

Education Qualification : Bachelor's degree of Naval Architecture and Marine

Engineering

Professional Qualification : NACE CIP LEVEL 1& 2

Experience in Years : 9 years

Language : Vietnam & English

Hand Phone : +84949046427

Email : minhloc89ntu@gmail.com

CAREER SUMMARY

I have more 9 years of working experience in Engineer, Supervisor and Quality control gained

whilst working in Oil & Gas and various engineering environments for major, international

projects, worked for both foreign & domestic Contractor & Owner. Position held have included

Painting Engineer, Painting Supervisor; Painting Inspector, Structural Engineer, Structural

Inspector. This involved shop fabrication to site construction, quality control for steel works

and painting works as material receiving inspection, prefabrication, Blasting & Painting and

Packing.

EDUCATION

2011: Bachelor's degree of Naval Architecture and Marine Engineering of Nha Trang University

INTERNATIONAL CERTIFICATES

Description Certificate No Expires

NACE CIP Level 1 #72878 Nov 20,2020

NACE CIP Level 2 #72878 Oct 8, 2022

EMPLOYMENT HISTORY

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

No Employer/Agency Position Duration Employer/Agency’s Logo

June~Sep,

1 PV Gas/ Technip FMC Coating Inspector

2020

Steel Structure

2 LSP/Technip FMC Nov~May, 2020

/Coating Inspector

Baltec IES/

3 Coating Inspector May~Dec, 2019

PTSC Quang Ngai

Binh Son Refinery/ Coating Supervisor

4 May~Nov, 2018

PTSC Quang Ngai CUM Inspector

Dongyang/ Steel Structure

5 July~Nov 2017

PTSC Quang Ngai /Coating Engineer

Steel Structure

Long Phu/ Feb ~June

6 /Coating Quality

PTSC Quang Ngai 2017

Control Engineer

JGC and SK E&C/ Coating/Insulation July 2015

7

PTSC Quang Ngai Inspector ~ Dec 2016

Steel Structure

SK E&C/ May 2014~

8 /Coating Quality

PTSC Quang Ngai June 2016

Control Engineer

JNK Heater/

Coating Quality Jan~April

9 POSCO E&C

Control Engineer 2014

Vietnam

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

No Employer/Agency Position Duration Employer/Agency’s Logo

Central Mare

Painting QC Feb~Aug

10 /Hyundai Vietnam

Engineer 2013

Shipyard

PREVIOUS ASSIGNMENT

Items Vendor/

No Client/Agency Project Position Duration

Inspection Location

PLEM

PV POS

Nam Con Son Structure/3LPE

1 Gas/Technip Coating Inspector June~Sep,2020 Company/

Gas Pipeline coating & FJC

FMC Vung Tau

for Piping

Steel Structure

LSP/Technip Long Son Piperack ATAD/Dong

2 /Coating Nov~May, 2020

FMC Petrochemical Structure Nai

Inspector

Baltec IES/ Independent Duct, Casing,

PTSC

3 PTSC Quang Power OKPAI Coating Inspector Diverter May~Dec, 2019

Quang Ngai

Ngai Phase II damper

Lining Coating

Binh Son

Refinery/ Maintenance for Coating Tank Floating Binh Son

4 May~Nov, 2018

PTSC Quang Tank Floating Supervisor CUM Roof Refinery

Ngai Inspector

Roof

Baltec IES/ Duct, Casing,

Dec 2017 PTSC

5 PTSC Quang RENAISSANCE Coating Inspector Diverter

April 2018 Quang Ngai

Ngai Damper

Dongyang/ SEC2101X150W

Steel Structure PTSC

6 PTSC Quang Coal Fired Steel Structure July~Nov 2017

/Coating Engineer Quang Ngai

Ngai Power

Long Phu/ Long Phu 1 Steel Structure

Feb ~June PTSC

7 PTSC Quang Thermal Power /Coating Quality Steel Structure

2017 Quang Ngai

Ngai Plant Project Control Engineer

JGC and SK Tank 4 Package Tanks Coating PTSC Quang

E&C/ Coating/Insulation July 2015

8 Nghi Son and Ngai/

PTSC Quang Inspector ~ Dec 2016

Refinery Project Insulation Thanh Hoa

Ngai

Piperack Steel

SK E&C/ Structure Steel Structure

Piperack May 2014~ PTSC

9 PTSC Quang Package- /Coating Quality

Structure June 2016 Quang Ngai

Ngai Control Engineer

Nghi Son

Refinery Project

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

Items Vendor/

No Client/Agency Project Position Duration

Inspection Location

Posco E&C

JNK Heater/

Coating Quality Jan~April Vietnam/

10 POSCO E&C ERC Project Heater

Control Engineer 2014 Nhon Trach –

Vietnam

Dong Nai

Formosa Ha Posco E&C

Gas Treatment Steel Structure

Tinh/ Aug~Dec Vietnam/

11 /Coating Quality Steel Structure

POSCO E&C Plant 2013 Nhon Trach –

Control Engineer

Vietnam Dong Nai

Central Mare Huyndai

/Hyundai Cargo Tanker Painting QC New Ship Feb~Aug Vinashin

12

Vietnam Ship Engineer Building 2013 Shipyard/

Shipyard Khanh Hoa

Huyndai

Geden/Hyundai

New Ship June 2011 Vinashin

13 Vinashin Bulk Carrier Ship Painting Engineer

Building ~Feb 2013 Shipyard/

Shipyard

Khanh Hoa

DETAILS FOR PROFESSIONAL EXPERIENCES, DUTIES AND RESPONSIBILITIES

As a Coating inspection for PLEMs Structure /3LPE coating & FJC for Piping

1. Interface actively with other discipline engineer/inspector to ensure consistency

of the work.

2. Review and understand the requirement of the Project Coating Specifications,

ITPs, QCPs, MS, i.e.

3. Inspection & Testing of the in-progress work to ensure compliance with the

Project Specification requirements.

4. Ensure effective implementation of ITPs or ITRs by the contractor and client

attendance at witness and/or hold points.

5. To Review regularly Quality Records, Contractor’s Procedures, Contracts and

Estimation Documents for the Painting/Coating requirements.

6. Review of coating materials data Sheets, abrasive, and batch Certificates.

7. Monitoring, verifying and witness blasting quality issues i.e. measuring weather

conditions, surface profile, cleanliness of blasting surface (dust & salt test),

paint thickness, adhesion test, holiday detection test to ensure compliance with

relevant project specification.

8. Check the HDG coating for steel structure and grating.

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

9. Carried out Wrappers qualification test, Pre production test for Polyethylene (3

LPE) and poly propylene (3 LPP) HSS- Canusa for Field Joint Coating.

10. Carried out incoming material inspection for FJC 3LPE; 3LPP consumable and

batch certificates.

11. Carried out chloride content of abrasive, FJC Blasting/Grinding visual

inspection, Surface profile, Dust level inspection, Salt test, check the Pre-

heating temperature, Sleeve DFT and Visual inspection, Impact test, Peel

strength test as per ITP.

12. I liaised with the Authorized Inspector, Certification Authorized and Client’s

QA/QC Inspector requested the timely execution of inspection and document

reviewed following in ITP Submitted all supplementary procedures to CA and

Client for them review and acceptance.

As a Steel Structure /Coating Inspector

1. Interface actively with other discipline engineer/inspector to ensure

consistency of the work.

2. Review and understand the requirement of the Project Coating Specifications,

ITPs, MS, i.e.

3. Inspection & Testing of the in-progress work to ensure compliance with the

Project Specification requirements.

4. To Review regularly Quality Records, Contractor’s Procedures, Contracts and

Estimation Documents for the Steel Structure/Painting/Coating requirements

5. Perform frontline welding inspections at fabrication Shop.

6. Make required replacement, Inspection and test plans as per Class and Code

requirements.

7. Reviewing MTC’s, Welding consumable certificates as per the approved

specification/Client requirement and welding equipment calibration certificate

and their condition.

8. Ensure that the approved procedures are followed.

9. Witness/Monitoring of various fabrication, Fit-up check, Dimension Check,

Visual inspection of completed welds as per the Specification.

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

10. Ensure that all Welding, Heat treatment, and Non-Destructive testing are in

compliance with relevant codes and Specification.

11. Review of coating materials data Sheets, abrasive, and batch Certificates.

12. Monitoring, verifying and witness blasting quality issues i.e. measuring

weather conditions, surface profile, cleanliness of blasting surface (dust & salt

test), paint thickness, adhesion test, holiday detection test to ensure

compliance with relevant Project Specification.

13. Check the HDG coating for steel structure and grating.

As a Coating Supervisor Cum Inspector

1. Review and understand the requirement of the Project Coating Specifications.

2. Make working procedure, Working Method Statement, ITP comply with Project

Coating Specification.

3. Carry out to calculate paint material, man power, equipment used to project.

4. Make schedule to rely on: Working amount and Working progress.

5. Distribution the man power (Blaster, painter & helper) as per planed schedule.

6. Arrange the qualification test for Blaster/Painter and certify them. Keep

permanent record also.

7. Ensure the Blasting and Painting activities carried out as per the specification.

8. Check the delivered paint materials with batch numbers; ensure the paint

come across the specification.

9. Check the calibration date for the measuring devices before commencing the

project and arrange for re-calibration if it expires.

10. Maintain the measuring tools safe and tidy.

11. Ensure the Blasting and Painting activities carried out as per the specification.

12. Pre-inspect the module at each stage prior to request client inspection and

ensure the quality meets the Specification prior to contacting clients.

13. Carrying out the inspection activities as Relative Humidity, Profile Test, Salt

Test, DFT Test, Pull of test, Adhesion Test, Holiday Test.

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

14. To carry out joint inspections with Client and painting Representatives for all

painting inspections.

15. All the non-conformance, observations should be closed and get Client

approval.

16. Making painting reports on time and gets Client approval.

17. Coordinate with project team drawing consultation phase.

As a Coating/Insulation Inspector for Tanks

Tanks Coating & Lining Inspection

1. Interface actively with other discipline Engineer/Inspector to ensure

consistency of the work.

2. Check, understand and review the Tank coating & Lining Coating Project

Specification and ITP which will follow according to the work in the Project.

3. Ensure that paint materials are used from approved paint manufacturers with

valid pot life.

4. Carry out inspection of surface profile, chloride contamination test as per

applicable standards.

5. Monitor weather and equipment condition during painting, coating operation.

6. Ensure that the application of coating is carried out as per technical data sheet

of the manufacturer and approved painting Specification.

7. Ensure the proper time intervals between intermediate coats for proper

chemical and mechanical bonding.

8. Witness / checking of DFT (dry film thickness) and Holiday, Pull off Adhesion

test and Ensure the calibrated testing equipment is used.

Tanks Hot/Cold Insulation Inspection

1. Check, understand and review the Hot/Cold insulation Project Specification

and ITP which will follow according to the work in the project.

2. Check the isometric drawing and proper documents to be insulated and correct

Code system.

3. Monitor weather condition before the work starts as per Specification.

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

4. Ensure that the equipment or tools to be used and insulation materials

Polyisocyanurate (PIR), Rock wool and cellular glass, type of jacketing are

used from approved manufacturers with approved banding, sealant, screws,

rivet, cold shoe, vapor etc. to be used in the project.

5. Ensure that the application of insulation is carried out as per ITP and approved

Project Specification.

6. Ensure the Surface preparation is free from dust, oil and other contaminants

before to start.

7. Monitor and check layer by layer during application of insulation and correct

thickness.

8. Check the completeness of the insulation and final cladding with complete

sealant.

KEY STRENGTHS

- Adequate knowledge in NACE, SSPC, ISO, PSPC, AS/NZ standards.

- Survey of the Coating material & Object.

- Preparing the surface for specified standards.

- Verify inspection records compliance.

- Verify proper documentations compliance.

- Good negotiation, strong interpersonal skills and the ability to deal with all

levels of people, often in complex and difficult situation.

- Prepared to work under pressure and within schedule and able to work under

minimum supervision.

- Capable of handling multiple projects simultaneously.

REFERENCE PERSON

1.Mr Gokulnath Jambulingam - Project QA QC Manager /NCS2 and SVDN Project

Email : gokulnath.jambulingam@technipfmc.com

Hand phone : +60 11 2315 1547

2. Mr Alfonso Muze Anak Jerol – Site Manager NCS Gas Pipeline Project

Email : alfonsomuze.anakjerol@technipfmc.com

Hand phone : +60 01 63900 451

3. Mr Le Van Hai Bang – Structure/Piping Inspector – NCS Gas Pipeline Project

Email : banglvh@gmail.com

Hand phone : +84 934 752 182

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

CURRICULUM VITAE VY MINH LOC

4. Mr Pham Cong Vuong – Painting Manager – Binh Son Refining and Petrochemical J.S.C

Email : vuongpc@bsr.com.vn

Hand phone: +84 943 277 253

5. Nguyen Tan Thuat – Technical Manager – PTSC Quang Ngai J.S.C

Email : thuatnguyen@ptsc.com.vn

Hand phone: +84 901 156 349

6. Ngo Tan Quang - Project Director – PTSC Quang Ngai J.S.C

Email : quangngo@ptsc.com.vn

Hand Phone : +84 901 973 666

Mobile: +84949046427 Email: minhloc89ntu@gmail.com

Potrebbero piacerti anche

- Request For Inspection: (Client Name)Documento1 paginaRequest For Inspection: (Client Name)Adi QC100% (1)

- Qcmechinspec7cv DocsDocumento22 pagineQcmechinspec7cv DocsMinhaj AkbarNessuna valutazione finora

- CV Hotrungtinh QC-NDT PDFDocumento6 pagineCV Hotrungtinh QC-NDT PDFTrung Tinh HoNessuna valutazione finora

- Approved CV FormatDocumento7 pagineApproved CV FormatEdison WalitNessuna valutazione finora

- TRAN ANH VAN Piping Mechanical EngineerDocumento11 pagineTRAN ANH VAN Piping Mechanical EngineerAnh Vân TrầnNessuna valutazione finora

- Curriculum Vitae-Nguyen Ngoc KhaiDocumento7 pagineCurriculum Vitae-Nguyen Ngoc KhaiBùi Văn TấnNessuna valutazione finora

- CV - Nguyen Dinh ThuyDocumento4 pagineCV - Nguyen Dinh ThuyHoàng TrầnNessuna valutazione finora

- Personal Data: Makhfud Edy SupraptoDocumento5 paginePersonal Data: Makhfud Edy SupraptoMakhfud EdyNessuna valutazione finora

- Bernath Turnip, ST: Address: Jl. Sutomo 3, No 29 RT 05/Rw 06 Kel. Kebon Pala Kec. Makasar JaktimDocumento4 pagineBernath Turnip, ST: Address: Jl. Sutomo 3, No 29 RT 05/Rw 06 Kel. Kebon Pala Kec. Makasar JaktimBernathTurnipNessuna valutazione finora

- CV + Cert Iyon MulyonoDocumento9 pagineCV + Cert Iyon MulyonoGunawanNessuna valutazione finora

- TUV CV FormatDocumento7 pagineTUV CV Formatmohd as shahiddin jafriNessuna valutazione finora

- Kresno Dani Kurniawan: ProfileDocumento1 paginaKresno Dani Kurniawan: ProfileDani KurniawanNessuna valutazione finora

- Interͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 OwnerDocumento11 pagineInterͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 Ownerramadh diyyazNessuna valutazione finora

- 4511345Documento12 pagine4511345taufiq.akbarNessuna valutazione finora

- Kalai CVDocumento5 pagineKalai CVkalaichelvamNessuna valutazione finora

- Abroad CV Hammad ShortDocumento3 pagineAbroad CV Hammad Shortnadeem.ahmad45897Nessuna valutazione finora

- CV Hariadi Coating Inspector-1Documento13 pagineCV Hariadi Coating Inspector-1zamri.rahmat4848Nessuna valutazione finora

- Resume MayDocumento4 pagineResume MayBernathTurnipNessuna valutazione finora

- Cathodic Protection Professional "NACE International-The Corrosion Society (USA) Certified Cathodic Protection Level-IIDocumento5 pagineCathodic Protection Professional "NACE International-The Corrosion Society (USA) Certified Cathodic Protection Level-IIkrishnakumar rNessuna valutazione finora

- Site CVDocumento10 pagineSite CVRamsey RasmeyNessuna valutazione finora

- G. Work Experience ListDocumento58 pagineG. Work Experience ListRiyonda SuhalisNessuna valutazione finora

- Curriculum Vitae: Permanent AddressDocumento6 pagineCurriculum Vitae: Permanent AddressYan NesiaNessuna valutazione finora

- CV - Alvindo Satria Nabariba - Admin GADocumento1 paginaCV - Alvindo Satria Nabariba - Admin GASatugaris HumanNessuna valutazione finora

- Muhammad Zikril HafizDocumento8 pagineMuhammad Zikril HafizPrabhuNessuna valutazione finora

- Form: Curriculum Vitae (CV) For Proposed Key Staff: Abid Hussain - Material EngineerDocumento5 pagineForm: Curriculum Vitae (CV) For Proposed Key Staff: Abid Hussain - Material Engineermunir HussainNessuna valutazione finora

- Iyappan Balu - PeiDocumento3 pagineIyappan Balu - PeiIyappan BaluNessuna valutazione finora

- CV Ho Trung TinhDocumento4 pagineCV Ho Trung TinhTĩnh Hồ TrungNessuna valutazione finora

- Qaqc Engineer (Ajinsathyababu) CVDocumento6 pagineQaqc Engineer (Ajinsathyababu) CVAjin SNessuna valutazione finora

- LAB121-2020-031 RFI Inspection For Rebound Test of Precast Segment V1-P53-P52-8#Documento1 paginaLAB121-2020-031 RFI Inspection For Rebound Test of Precast Segment V1-P53-P52-8#bojun liNessuna valutazione finora

- Mechanical Engineer - Bui Van DiepDocumento5 pagineMechanical Engineer - Bui Van DiepHieuNessuna valutazione finora

- CV. Ario MulyadiDocumento2 pagineCV. Ario MulyadiRamadhanNessuna valutazione finora

- (Comp.) 293. RFI of S-Curve Revision No. 3Documento6 pagine(Comp.) 293. RFI of S-Curve Revision No. 3Johan JasmadiNessuna valutazione finora

- S TelerDocumento21 pagineS TelerRyandhika PratamaNessuna valutazione finora

- SMN J PR 00 153 Rev1 Precom Commissioning Execution Plan APPDocumento26 pagineSMN J PR 00 153 Rev1 Precom Commissioning Execution Plan APPramadh diyyazNessuna valutazione finora

- Bernath Turnip, ST: Address: Jl. Sutomo 3, No 29 RT 05/Rw 06 Kel. Kebon Pala Kec. Makasar JaktimDocumento4 pagineBernath Turnip, ST: Address: Jl. Sutomo 3, No 29 RT 05/Rw 06 Kel. Kebon Pala Kec. Makasar JaktimBernath TurnipNessuna valutazione finora

- Interͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 OwnerDocumento21 pagineInterͳdiscipline Check (Idc) : Civil Engineer LS Construction Engineer KRH 08Ͳ12Ͳ21 Ownerramadh diyyazNessuna valutazione finora

- 1939-Coal Tar Epoxy-Berger PaintsDocumento1 pagina1939-Coal Tar Epoxy-Berger Paintsdeepak925Nessuna valutazione finora

- Balu Resume - 2017Documento4 pagineBalu Resume - 2017HeartyscorpionNessuna valutazione finora

- Contoh CV RizanDocumento8 pagineContoh CV RizanMohd AzwanNessuna valutazione finora

- Contoh RfiDocumento1 paginaContoh Rfiandri yantoNessuna valutazione finora

- Pravesh Tiwari Solar Quality Engineers-Civil-B.Tech-1Documento2 paginePravesh Tiwari Solar Quality Engineers-Civil-B.Tech-1pravesh tiwariNessuna valutazione finora

- CV MartinDocumento16 pagineCV MartinMartin SultanAhsan AlNaafiNessuna valutazione finora

- Curriculum Vitae Update Rev - 10, February 2021Documento14 pagineCurriculum Vitae Update Rev - 10, February 2021Yusnal KasirunNessuna valutazione finora

- Curiculum Vitae - Bagus Handika Yuda - Inspector & EngineerDocumento12 pagineCuriculum Vitae - Bagus Handika Yuda - Inspector & EngineerPRIMA JAYANessuna valutazione finora

- Hashik CV NewDocumento4 pagineHashik CV NewHashik MohammedNessuna valutazione finora

- ONGC Format Mahesh Kumar K BDocumento4 pagineONGC Format Mahesh Kumar K BMahesh Kumar K BNessuna valutazione finora

- CV PDFDocumento3 pagineCV PDFSanket GuptaNessuna valutazione finora

- 3) Method Statement For Formwork Steel & Concrete WorkDocumento9 pagine3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatNessuna valutazione finora

- ITP For Steel ReinforcementDocumento4 pagineITP For Steel ReinforcementShaarun M RamannNessuna valutazione finora

- 1 RfiDocumento2 pagine1 RfiPrasanna S KulkarniNessuna valutazione finora

- Resume: Shashikant Pandey Mob. No +91 9621693439 +91 6269206327 Job ObjectiveDocumento3 pagineResume: Shashikant Pandey Mob. No +91 9621693439 +91 6269206327 Job ObjectiveShashi Kant PandeyNessuna valutazione finora

- CV2019Documento7 pagineCV2019Shahiddin JafriNessuna valutazione finora

- Vimal Resume For Tunnel SupervisorDocumento5 pagineVimal Resume For Tunnel SupervisorTamil AlaganNessuna valutazione finora

- Ashik P.A (CV) Welding InspectorDocumento3 pagineAshik P.A (CV) Welding InspectorNATIONAL BASICS COMPANYNessuna valutazione finora

- TranPhucCuong FieldOperator 07101996 0889720609 PDFDocumento7 pagineTranPhucCuong FieldOperator 07101996 0889720609 PDFTrần Phúc CườngNessuna valutazione finora

- CV DODI Pipe FitterDocumento26 pagineCV DODI Pipe Fitterfauzan alawyNessuna valutazione finora

- Irshad Khan CVDocumento4 pagineIrshad Khan CVGood GamerNessuna valutazione finora

- MD Nazim: Profile SummaryDocumento3 pagineMD Nazim: Profile SummaryNazim HaiderNessuna valutazione finora

- CV of Muhammad Ashfaq HussainDocumento5 pagineCV of Muhammad Ashfaq HussainIshfaq UrrehmanNessuna valutazione finora

- KLM Employment Application: Applicant InformationDocumento3 pagineKLM Employment Application: Applicant InformationKolusu SivakumarNessuna valutazione finora

- Painting, Painting ProcessDocumento4 paginePainting, Painting ProcessKolusu SivakumarNessuna valutazione finora

- 3Uhvvxuh5Holhi9Doyh $Lu6Xsso/%Doo9Doyhv: 3U HV VX UH 5 HO LH I 9D OY HDocumento1 pagina3Uhvvxuh5Holhi9Doyh $Lu6Xsso/%Doo9Doyhv: 3U HV VX UH 5 HO LH I 9D OY HKolusu SivakumarNessuna valutazione finora

- D.VASANTHAN, B.E (Mechanical) Senior Engineer - Quality Total Experience - 7 YearsDocumento3 pagineD.VASANTHAN, B.E (Mechanical) Senior Engineer - Quality Total Experience - 7 YearsKolusu SivakumarNessuna valutazione finora

- Operating Instructions The New Elcometer 130 Salt Contamination MeterDocumento63 pagineOperating Instructions The New Elcometer 130 Salt Contamination MeterKolusu SivakumarNessuna valutazione finora

- The Argon Beam Coagulator Provides Rapid Hemostasis of Experimental Hepatic and Splenic Hemorrhage in Anticoagulated Dogs - PubMedDocumento2 pagineThe Argon Beam Coagulator Provides Rapid Hemostasis of Experimental Hepatic and Splenic Hemorrhage in Anticoagulated Dogs - PubMedKolusu SivakumarNessuna valutazione finora

- Cold Applied TapeDocumento3 pagineCold Applied TapeKolusu SivakumarNessuna valutazione finora

- Radiography Testing - NDT Inspection - TWIDocumento5 pagineRadiography Testing - NDT Inspection - TWIKolusu SivakumarNessuna valutazione finora

- Radiography - TWIDocumento7 pagineRadiography - TWIKolusu SivakumarNessuna valutazione finora

- Industrial Member Report Summary - Key Findings For IndustryDocumento1 paginaIndustrial Member Report Summary - Key Findings For IndustryKolusu SivakumarNessuna valutazione finora

- Radiography Testing - NDT Inspection - TWIDocumento5 pagineRadiography Testing - NDT Inspection - TWIKolusu SivakumarNessuna valutazione finora

- LIST OF HOTELS - Nearby IQCDocumento1 paginaLIST OF HOTELS - Nearby IQCKolusu SivakumarNessuna valutazione finora

- Surface Preparation - Blasting: Blast Nozzle GaugeDocumento1 paginaSurface Preparation - Blasting: Blast Nozzle GaugeKolusu SivakumarNessuna valutazione finora

- Radiography Part 3 - TWIDocumento6 pagineRadiography Part 3 - TWIKolusu SivakumarNessuna valutazione finora

- Radiography Part 2 - TWIDocumento8 pagineRadiography Part 2 - TWIKolusu SivakumarNessuna valutazione finora

- Radiography Part 3 - TWIDocumento6 pagineRadiography Part 3 - TWIKolusu SivakumarNessuna valutazione finora

- Radiography Part 2 - TWIDocumento8 pagineRadiography Part 2 - TWIKolusu SivakumarNessuna valutazione finora

- The Principles of Radiography in Non-Destructive Examination - TWIDocumento3 pagineThe Principles of Radiography in Non-Destructive Examination - TWIKolusu SivakumarNessuna valutazione finora

- Radiography of Thin Section Welds - Part 1 Practical Approach - TWIDocumento11 pagineRadiography of Thin Section Welds - Part 1 Practical Approach - TWIKolusu SivakumarNessuna valutazione finora

- Definition and Contrast Factors in Radiographic NDT - TWIDocumento4 pagineDefinition and Contrast Factors in Radiographic NDT - TWIKolusu SivakumarNessuna valutazione finora

- COVID 19 Management InformationDocumento2 pagineCOVID 19 Management InformationKolusu SivakumarNessuna valutazione finora

- The Principles of Radiography in Non-Destructive Examination - TWIDocumento3 pagineThe Principles of Radiography in Non-Destructive Examination - TWIKolusu SivakumarNessuna valutazione finora

- Thermal Insulation Design-L-101 - Rev.01 PDFDocumento65 pagineThermal Insulation Design-L-101 - Rev.01 PDFzulfikar bamneNessuna valutazione finora

- TDS Fosroc Nitofoam 45 India PDFDocumento2 pagineTDS Fosroc Nitofoam 45 India PDFTarun KumarNessuna valutazione finora

- Fabrication Standard of Duct-AcDocumento5 pagineFabrication Standard of Duct-AcVicky KumarNessuna valutazione finora

- Polyurethane ProductsDocumento47 paginePolyurethane ProductsAdnan JadoonNessuna valutazione finora

- Aluminum Cladding Part 03Documento7 pagineAluminum Cladding Part 03Anonymous ELujOV3Nessuna valutazione finora

- TDS - CRYOPIR50f - 202004-1Documento1 paginaTDS - CRYOPIR50f - 202004-1Nguyen Thi Bich ThuyNessuna valutazione finora

- A Fire Rating p225Documento12 pagineA Fire Rating p225AhmedNessuna valutazione finora

- Katalog Techniczny ENG PDFDocumento136 pagineKatalog Techniczny ENG PDFJoseph Cloyd L. LamberteNessuna valutazione finora

- Sandwich Panel - BONDOR INDONESIA PDFDocumento27 pagineSandwich Panel - BONDOR INDONESIA PDFSaor PakpahanNessuna valutazione finora

- PRODUCT CATALOG 2020 - BONDOR INDONESIA BaruDocumento27 paginePRODUCT CATALOG 2020 - BONDOR INDONESIA Baruproduksi.iusNessuna valutazione finora

- Analysis of ASTM D6226 and ISO 4590Documento8 pagineAnalysis of ASTM D6226 and ISO 4590SameerKhanNessuna valutazione finora

- E 1730 - 99 - Rte3mzatotkDocumento4 pagineE 1730 - 99 - Rte3mzatotkEric GozzerNessuna valutazione finora

- Cold Storage SlidesDocumento37 pagineCold Storage Slidesbal singh ranaNessuna valutazione finora

- 1 57Documento23 pagine1 57Ricardo Argentton FicanhaNessuna valutazione finora

- Export PIR Product Range ListDocumento20 pagineExport PIR Product Range ListDaniela FlorescuNessuna valutazione finora

- Technical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesDocumento117 pagineTechnical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesJankoNessuna valutazione finora

- Dana Composite Panels Cladding ProfilesDocumento48 pagineDana Composite Panels Cladding Profilesadam150161Nessuna valutazione finora

- BTR Company Profile 2019Documento19 pagineBTR Company Profile 2019zahidhssn1Nessuna valutazione finora

- Design Specification ColdroomDocumento28 pagineDesign Specification ColdroomRupak PatilNessuna valutazione finora

- As 1366.2-1992 Rigid Cellular Plastics Sheets For Thermal Insulation Rigid Cellular Polyisocyanurate (RC PIR)Documento6 pagineAs 1366.2-1992 Rigid Cellular Plastics Sheets For Thermal Insulation Rigid Cellular Polyisocyanurate (RC PIR)SAI Global - APACNessuna valutazione finora

- Kingspan Isoeste FM Global 4880-4881-4471 - Approval ReportDocumento10 pagineKingspan Isoeste FM Global 4880-4881-4471 - Approval ReportJoaquin VieraNessuna valutazione finora

- Cold Store Catalogue 20-01-2017Documento23 pagineCold Store Catalogue 20-01-2017robertaNessuna valutazione finora

- Polyurethane Foam (PUF) Technical Information - Piping Technology & Products, Inc - PDFDocumento9 paginePolyurethane Foam (PUF) Technical Information - Piping Technology & Products, Inc - PDFvaratharajan g rNessuna valutazione finora

- Eil Insulation TableDocumento9 pagineEil Insulation TablePradeep PatilNessuna valutazione finora

- Chilled Water CatalogueDocumento12 pagineChilled Water CatalogueAhmed HathoutNessuna valutazione finora

- Process Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)Documento76 pagineProcess Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)satishchemeng75% (4)

- Insulation MaterialsDocumento18 pagineInsulation MaterialsChona ManliguisNessuna valutazione finora

- PIR Dämmung - ENDocumento2 paginePIR Dämmung - ENBorisNessuna valutazione finora

- Hot and Cold Thermal Insulation For Piping Calculation of Thermal Insulation Thickness PDFDocumento8 pagineHot and Cold Thermal Insulation For Piping Calculation of Thermal Insulation Thickness PDFYudha Andrie Sasi ZenNessuna valutazione finora

- DCT Pir: White Silver TissueDocumento4 pagineDCT Pir: White Silver TissueHenky MantophaniNessuna valutazione finora