Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AN3481

Caricato da

rosarioantonyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AN3481

Caricato da

rosarioantonyCopyright:

Formati disponibili

Freescale Semiconductor Document Number: AN3481

Rev. 0, 02/2008

Application Note

Ultrasonic Distance Measurer

Implemented with the MC9RS08KA2

by: Luis Puebla Palma

RTAC Americas

1 Introduction Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Linear measurement is a problem that a lot of 2 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Sound and Ultrasound Principles . . . . . . . . . . . . . . 2

applications in the industrial and consumer market 2.2 Speed of Sound. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

segment have to contend with. Ultrasonic technology is 2.3 Sound Reflection . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

one of the solutions used by the industry. However, an 2.4 General Description. . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Freescale Tools Used . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

optimized balance between cost and features are a must 3.1 CodeWarrior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

for almost all target applications. The ultrasonic distance 4 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 The MC9RS08KA2 Microcontroller . . . . . . . . . . . . 6

measurer (UDM) is used mainly when a non-contact 4.2 Other Components . . . . . . . . . . . . . . . . . . . . . . . . . 7

measurer is required. This is the type of solution this 5 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

document explains using a simple robot toy 6 Software Implementation. . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 Resources: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

implementation. 7 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

This demo is developed using Freescale’s ultra low cost 9 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MC9RS08KA2. 10 Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix A Time analysis ....................................................13

© Freescale Semiconductor, Inc., 2008. All rights reserved.

Background

2 Background

2.1 Sound and Ultrasound Principles

Sound is a mechanical vibration transmitted by an elastic medium. The range of frequencies that humans

can hear are approximately between 20 Hz and 20,000 Hz. This range is by definition the audible spectrum

and varies by individual and generally reduces with age. The ear is most sensitive to frequencies around

3,500 Hz. Sound above 20,000 Hz is known as ultrasound, and sound below 20 Hz as infrasound.

2.2 Speed of Sound

The speed which sound travels depends on the medium which it passes through. In general, the speed of

sound is proportional (the square root of the ratio) to the stiffness of the medium and its density. This is a

fundamental property of the medium. Physical properties and the speed of sound change with the

conditions in the environment. The speed of sound in the air depends on the temperature. In the air speed

is approximately 345 m/s, in water 1500 m/s and in a bar of steel 5000 m/s.

A common use of ultrasound is for range finding. This use is also called sonar. Sonar works similarly to

radar. An ultrasonic pulse is generated in a particular direction. If there is an object in the way of this pulse,

the pulse is reflected back to the sender as an echo and is detected. Measuring the difference in time

between the pulse transmitted and the echo received, it is possible to determine how far away the object

is. Bats use a variety of ultrasonic ranging (echolocation) to detect their prey.

2.3 Sound Reflection

To measure the distance of a sound signal transmitted, it needs to be reflected. This sound signal is a

longitudinal sound wave that strikes a flat surface. Sound is then reflected, provided that the dimension of

the reflective surface is large compared to the wavelength of the sound. See Figure 1.

Surface

An ideal target surface is hard and smooth. This surface reflects a greater amount of signal than a soft,

rough surface. A weak echo is the result of a small or soft object. This reduces the operating distance

of an ultrasonic sensor and decreases its accuracy.

Distance

The shorter the distance from the ultrasonic sensor to an object, the stronger the returning echo is.

Therefore, as the distance increases, the object requires better reflective characteristics to return a

sufficient echo.

Size

A large object has more surface to reflect the signal than a small one. The surface area recognized as

the target is generally the area closest to the sensor.

Ultrasonic Distance Measurer, Rev. 0

2 Freescale Semiconductor

Background

Angle

The inclination of an objects’ surface facing the ultrasonic sensor affects how the object reflects. The

portion perpendicular to the sensor returns the echo. If the entire object is at a greater angle, the signal

is then reflected away from the sensor and no echo is detected.

Surface Distance Size Angle

Good Good Good Good

Better Better Better Better

Figure 1. Sound Reflection Cases

2.4 General Description

The UDM is a demo that shows capability and performance of the MC9RS08KA2 and the ultrasonic

sensor to build a distance measurer.

Figure 2 shows the basic building block of this project.

Tx

MCU

Rx

Amplifier

Figure 2. UDM Basic Building Block

The firmware generates a 40 kHz burst signal. After the 10 cycle burst is completed, a variable that

measures the distance is activated. This variable measures the time sound takes to rebound and is used for

distance calculation.

Ultrasonic Distance Measurer, Rev. 0

3 Freescale Semiconductor

Background

The burst signal goes to the ultrasonic transmitter (US Tx) and is transmitted as ultrasound through the air

Figure 2. When the wave is reflected off an object, this wave is captured by the ultrasonic receiver (US

Rx.) This received signal is amplified because it attenuates as it travels. Afterwards, the signal goes back

to the microcontroller unit (MCU), filters it and calculates the distance.

A 40 kHz interrupt is generated by the timer in the MCU. To perform this, the keyboard interrupt (KBI) is

enabled and detects the external signal. Every time the MCU is interrupted the counter is increased by

three. And the variable used as a counter is decreased by one for the entrances to the modulus timer module

(MTIM) interrupt service routine (ISR). When this variable is bigger than eight the ECHO signal is

activated. The distance variable is then set to 0. Refer to Figure 3 for timing diagram.

For detailed information about the firmware see Figure 3.

PTA0

PTA1

Ultrasonic

Signal

High Level

PTA4

Low Level

Echo Signal

Time

Distance

Filter behavior

Figure 3. Timing Diagram

Ultrasonic Distance Measurer, Rev. 0

4 Freescale Semiconductor

Background

Filter Flag Check

Start SCI Flag

2 which Flag 3

is active?

Initialize MCU

Configure MTIM 100 ms

Configure I/O

1 No

Has it passed 100 ms?

Configure and start MTIM (1 kHz)

Configure MTIM 80 kHz

Wait Generate a 40 kHz burst

Increment cycles

Is an MTIM

Yes

interrupt

pending?

Have 10

No

cycles

passed?

Is a KBI

No Yes

interrupt

pending? 1

Yes

Increments in 3 filter_count

2 3

1

Configure MTIM (40 kHz) SCI Service

Increment count_ timer 1

filter_ count > N or Is filter_

Count timer > Max? count >0?

Yes

Distance = count_ timer Decrement filter_ count

1 1

Figure 4. UDM Flow Chart Diagram

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 5

Freescale Tools Used

For detailed information refer to the software AN3481SW.

3 Freescale Tools Used

3.1 CodeWarrior

CodeWarrior is a professional integrated development environment (IDE) for fast and easy MCU

development. This application is developed in assembly language using Freescale CodeWarrior

Version 5.1.

4 Components Used

4.1 The MC9RS08KA2 Microcontroller

The MC9RS08KA21 MCU is a small pin count device at an extremely low cost. It has the ability for low

voltage programming, system protection and analog control.

This device is composed of standard on-chip modules, including a very small and highly efficient

RS08CPU. This is a list of some features of the device:

• 63 bytes of RAM

• 2 Kb of flash

• 8 bit module timer

• Keyboard interrupt (KBI)

• Analog comparator

• Real-time interrupt trigger with a 3-bit prescaler

• System protection with low voltage detection

• Background debugging system

• 4 bidirectional I/O pins

Ultrasonic Distance Measurer, Rev. 0

6 Freescale Semiconductor

Components Used

RS08 Core

5-bit Keyboard 5/

BDC CPU Interrupt Module

(KBI)

ACMP+

PTA0 / KBIP0 / ACMP+(1)

Analog ACMP–

RS08 System Control PTA0 / KBIP1 / ACMP–(1)

Comparator TCLK

PTA2 / KBIP2 / TCLK / RESET/ Vpp(1), (2)

Module (ACMP)

Reset and Stop Wakeup ACMPO

PTA3 / ASMP0 / BKGD /MS

Modes of Operation

Power Management

Module Timer PTA4 / KBIP4(1), (3)

Module

RTI COP PTA5 / KBIP5(1), (3)

(MTIM)

Wakeup LVD

User Flash — 2,048 bytes

User RAM — 63 bytes

Internal Clock Source

(ICS)

Notes:

(1) Pins are software configurable with pullup/pulldown device if input port.

VSS (2) Intergrated pullup device enabled if reset enabled (RSTPE=).

Power and Internal

(3) These pins are not available in 6-pin package.

VDD Regulator

Figure 5. MC9RS08KA2 Block Diagram

4.2 Other Components

4.2.1 Ultrasonic Transducers

Ultrasonic transducers are devices that send and receive ultrasonic waves commonly used on many types

of sensing. These devices include proximity counting, level measurement, and security applications.

For this demo, an ultrasonic sensor 2 (part number 255-400ET18-RO) is used.

• Center frequency: 40.0 kHz ± 1 kHz

• SPL 115 dB

• Bandwidth: 1.5 kHz (–6 dB)

• Input voltage: 20 V max

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 7

Hardware Description

• Allowable input power: 0.2 W

5 Hardware Description

The ultrasonic distance measurer (UDM) is implemented with an MC9RS08KA2, a transmitter, receiver

and an array of three operational amplifiers. These are used to amplify the wave signal and square it.

BKG 1 2 GND

3 4 VPP

5 6 VDD

BDM U1 US Tx

1 PTA2/reset/Vpp/Tclk/KBI PTA0/KBIP0/ACM 8

Vcc BKGD 2 PTA3/ACMP0/BKGD/M PTA1/KBIP1/ACM 7

3 VDD PTA4/KBIP4 6 Tx

4 VSS PTA5/KBIP5 5

0.1 R1

400

MC9RS08KA

2

R11 22K

22K

22K

Vcc R13

0.1 U8/A R18

2.2 4 0.1 U8/B

2 - 2.2 U8/C

1 6 2.2

R8 - 7 1

C6 3 + + 8 Rx Out

1 R12 C7 5 + R14 9

US Rx 4342UA -

J1

Vcc

VDD 1

GND 2

1K Tx 3

R15 R16 4

1K

0.1

Figure 6. Ultrasonic Distance Measurer Schematic

Two signals from the MCU are used to produce an alternating current to generate a 40 kHz signal. These

signals go to the US Tx which transmits the signal in the air. When the signal rebounds, it is received by

the US Rx and amplified to obtain a logical signal. This signal goes to a KBI input of the MCU. Figure 2.

This system functions within a range of 3–5 V.

Ultrasonic Distance Measurer, Rev. 0

8 Freescale Semiconductor

Software Implementation

The system also has a background debug mode (BDM) connector. It is used for programming and

debugging the MCU and the firmware code.

Because the MCU does not have an implemented Serial Communication Interface (SCI) module, an

emulated SCI uses the port A pin 4 (PTA4) to output the distance value.

6 Software Implementation

The functions required to implement this UDM are:

• Time base of 1 millisecond

• 40 kHz 10 cycle burst is generated every 100 milliseconds. The MTIM is configured at 80 kHz to

generate a signal at 40 kHz (80 kHz / 2).

• Filter of the reflected signal (echo signal)

• Measure the time (distance) between the burst Tx and the echo signal

• Conversion of time into distance

• Send the distance through an emulated SCI

6.1 Resources

Table 1 the resources used by the UDM are shown in this table.

Table 1. Resource Usage

US Distance

MC9RS08KA2

Measurer

I/O 6 6

Flash 2 Kbytes 623 bytes

RAM 63 bytes 14 bytes

Analog 1

Comparator

KBI 5 1

Bus Clock Up to 10 MHz 8 MHz

MTIM 1 1

RTI 1

Package 8 SOIC 8 SOIC

6 DFN

8 DIP

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 9

Test

7 Test

The basic testing demo includes, taking time measurements vs. distance. Figure 7. The time period

measured is displayed in the Hyper Terminal program of the computer.

Figure 7. Distance Measurements

There are measurements taken using an oscilloscope to monitor the behavior of the signals before inputting

them on the MCU, Figure 8. The plot on the top represents the 10 cycle 40 kHz burst. The echo response

is the plot on the bottom view.

These results are plotted using a worksheet. This is done to understand the behavior on all the specified

ranges. Figure 9 are the results obtained in the test plotted in the XY axis (time measured in timer counts

vs. distance measured in cm).

Ultrasonic Distance Measurer, Rev. 0

10 Freescale Semiconductor

Conclusions

Figure 8. Behavior of Burst Signal and ECHO Signal

Tics vs distance

5500

5000

4500

4000

tics

3500

3000

2500

2000

1500

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

cm

Figure 9. Tics vs. Distance

8 Conclusions

This demo shows the viability of implementing distance measurements using the MC9RS08KA2.

This type of implementation is optimized for reading distances above 5 cm. A hardware/software filter

must be implemented when measuring distances shorter than 5 cm.

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 11

Conclusions

The time analysis is included in Appendix A. This section explains the restrictions that this demo has for

time and cycles available to implement the filter.

The design uses a 3.3 V power supply. This limits the measurement up to 34 cm.

The transmitter is tested to a max of 20 Vrms. It is possible to drive it at a higher voltage to enable more

distance.

This range of distance can be used for proximity sensors on all kind of consumer and industrial

applications.

The scope of this document does not include temperature compensation. However; Appendix A can be

used as a base for the conversions between tics and distances, at different temperatures.

Ultrasonic Distance Measurer, Rev. 0

12 Freescale Semiconductor

References

9 References

Reference 1:

http://www.freescale.com/files/microcontrollers/doc/data_sheet/MC9RS08KA2.pdf.

(MC9RS08KA2.pdf datasheet).

Reference 2:

http://www.mouser.com. 255-400ER18 Ultrasonic sensor datasheet.

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 13

References

Appendix A Time Analysis

The frequency of the ultrasonic sensor is 40 kHZ.

t = 25 microseconds,

Using a burst of 8 cycles

Tburst = 25*8 = 200 microseconds.

Table A-1. Speed of Sound vs. Temperature

Speed of Sound C in Density of Air in Acoustic Impedance of

Temperature of Air °C

m/s kg/m3 Air Z in N- s/m3

–10 325.4 1.341 436.5

–5 328.5 1.316 432.4

0 331.5 1.293 428.3

5 334.5 1.269 424.5

10 337.5 1.247 420.7

15 340.5 1.225 417.0

20 343.4 1.204 413.5

25 346.3 1.184 410.0

30 349.2 1.164 406.6

The speed of sound in the air is given approximately by:

c = 331 + 0.6 g

Taken the speed of sound at 20°C = 343.4 m/s

Table A-2. Time Analysis

Frequency 40000 Hz

Period 0.000025 Seconds

Period (micro) 25 Microseconds

Burst Cycles 8

Burst Period 200 Microseconds

Speed of sound in the air 343.5 m/s Speed of sound

(20°C)

Measured time 2.50E-02 sec

Measured time 1.00E-04 Microseconds

(microseconds)

D 8.5875 m

Rd 4.29375 m

rd (centimeters) 429.375 cm

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 14

References

Measured distances at different temperatures:

Table A-3. Time vs. Distance

Air Temperature 10 20 30

Speed of sound 337 343 349

Time (milliseconds) Measured Distance (cm) Measured Distance (cm) Measured Distance (cm)

0.1 1.7 1.7 1.7

0.2 3.4 3.4 3.5

0.5 8.4 8.6 8.7

1 16.9 17.2 17.5

2 33.7 34.3 34.9

5 84.3 85.8 87.3

10 168.5 171.5 174.5

20 337.0 343.0 349.0

50 842.5 857.5 872.5

100 1685.0 1715.0 1745.0

As shown in Table A-3, 20 ms is the time needed to reach 345 cm (3.45 mts).

The minimum distance resolution depends on the time resolution required by the application. If a time

resolution of 100 microseconds is selected, the minimum distance measured is 1.7 cm.

The filter has a time restriction of 1/ (2*40K), this means 12.5 microseconds. Therefore; if further time is

needed to filter the signals, then a change in the overall algorithm is required.

If there is an 8 MHz bus clock frequency there are 125 nanoseconds by cycle.

12.5 micro/125 nanosec = 200 cycles to do the filter. This is the maximum number of cycles available to

generate the filter in the MCU.

Ultrasonic Distance Measurer, Rev. 0

Freescale Semiconductor 15

How to Reach Us: Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

Home Page: implied copyright licenses granted hereunder to design or fabricate any integrated

www.freescale.com circuits or integrated circuits based on the information in this document.

Web Support:

http://www.freescale.com/support Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

USA/Europe or Locations Not Listed: guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor, Inc. Freescale Semiconductor assume any liability arising out of the application or use of any

Technical Information Center, EL516 product or circuit, and specifically disclaims any and all liability, including without

2100 East Elliot Road

Tempe, Arizona 85284 limitation consequential or incidental damages. “Typical” parameters that may be

+1-800-521-6274 or +1-480-768-2130 provided in Freescale Semiconductor data sheets and/or specifications can and do vary

www.freescale.com/support in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

Europe, Middle East, and Africa: customer’s technical experts. Freescale Semiconductor does not convey any license

Freescale Halbleiter Deutschland GmbH under its patent rights nor the rights of others. Freescale Semiconductor products are

Technical Information Center not designed, intended, or authorized for use as components in systems intended for

Schatzbogen 7 surgical implant into the body, or other applications intended to support or sustain life,

81829 Muenchen, Germany

+44 1296 380 456 (English) or for any other application in which the failure of the Freescale Semiconductor product

+46 8 52200080 (English) could create a situation where personal injury or death may occur. Should Buyer

+49 89 92103 559 (German) purchase or use Freescale Semiconductor products for any such unintended or

+33 1 69 35 48 48 (French) unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

www.freescale.com/support its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

Japan: directly or indirectly, any claim of personal injury or death associated with such

Freescale Semiconductor Japan Ltd. unintended or unauthorized use, even if such claim alleges that Freescale

Headquarters

ARCO Tower 15F Semiconductor was negligent regarding the design or manufacture of the part.

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064 RoHS-compliant and/or Pb-free versions of Freescale products have the functionality

Japan and electrical characteristics as their non-RoHS-compliant and/or non-Pb-free

0120 191014 or +81 3 5437 9125

support.japan@freescale.com counterparts. For further information, see http://www.freescale.com or contact your

Freescale sales representative.

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd. For information on Freescale’s Environmental Products program, go to

Technical Information Center

2 Dai King Street http://www.freescale.com/epp.

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

+800 2666 8080 All other product or service names are the property of their respective owners.

support.asia@freescale.com

© Freescale Semiconductor, Inc. 2008. All rights reserved.

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Document Number: AN3481

Rev. 0

02/2008

Potrebbero piacerti anche

- Practical Machinery Vibration Analysis and Predictive MaintenanceDa EverandPractical Machinery Vibration Analysis and Predictive MaintenanceValutazione: 4.5 su 5 stelle4.5/5 (10)

- Ultrasonic Distance Measurement With The MSP430: Murugavel Raju Mixed Signal ProcessorsDocumento18 pagineUltrasonic Distance Measurement With The MSP430: Murugavel Raju Mixed Signal Processorsbadu51Nessuna valutazione finora

- Spectrum Requirement Planning in Wireless Communications: Model and Methodology for IMT - AdvancedDa EverandSpectrum Requirement Planning in Wireless Communications: Model and Methodology for IMT - AdvancedHideaki TakagiNessuna valutazione finora

- msp430 Controller Ultrasonic Distance MeasurmentDocumento45 paginemsp430 Controller Ultrasonic Distance Measurmentchandre100% (3)

- Deep Space Optical CommunicationsDa EverandDeep Space Optical CommunicationsHamid HemmatiNessuna valutazione finora

- Ultrasonic Distance Measurement With The MSP430Documento18 pagineUltrasonic Distance Measurement With The MSP430lgrome73Nessuna valutazione finora

- GSM - Architecture, Protocols and ServicesDa EverandGSM - Architecture, Protocols and ServicesValutazione: 1 su 5 stelle1/5 (1)

- Superheterodyne PDFDocumento21 pagineSuperheterodyne PDFThế Dân TrầnNessuna valutazione finora

- Mehr FatimaDocumento18 pagineMehr FatimaDavi NathanNessuna valutazione finora

- Acoustic SensorsDocumento106 pagineAcoustic Sensorshamadaxx2000Nessuna valutazione finora

- Experiment 1 Spectrum AnalyzerDocumento23 pagineExperiment 1 Spectrum AnalyzerTumzangwanaNessuna valutazione finora

- Echolocation and Blind Navigation System: Mini Project ReportDocumento29 pagineEcholocation and Blind Navigation System: Mini Project Reportlekshmidevi mNessuna valutazione finora

- Super-Regenerative Receiver For UWB-FM Rui - Hou - 2008 PDFDocumento136 pagineSuper-Regenerative Receiver For UWB-FM Rui - Hou - 2008 PDFjbranthooverNessuna valutazione finora

- High Performance Multi-Channel High-Speed IO Circuits PDFDocumento91 pagineHigh Performance Multi-Channel High-Speed IO Circuits PDFVăn CôngNessuna valutazione finora

- Autocorrelation of An Ultrashort Laser Pulse To Determine Its DurationDocumento26 pagineAutocorrelation of An Ultrashort Laser Pulse To Determine Its DurationMirelly FerreiraNessuna valutazione finora

- ITU Spec-PsophometerDocumento17 pagineITU Spec-PsophometerWerner JakobusNessuna valutazione finora

- Design of A Metal DetectorDocumento56 pagineDesign of A Metal DetectorKireNessuna valutazione finora

- Radar Systems & Applications: Department of Ece, Pesit-BscDocumento18 pagineRadar Systems & Applications: Department of Ece, Pesit-BscvivekallcoolNessuna valutazione finora

- Evaluation of Real-Time Noise Classifier Based On CNN-LSTM and MFCC For SmartphonesDocumento66 pagineEvaluation of Real-Time Noise Classifier Based On CNN-LSTM and MFCC For SmartphonesWin RoedilyNessuna valutazione finora

- Atcor3 Manual PDFDocumento263 pagineAtcor3 Manual PDFAnonymous cC2VeA9MBNessuna valutazione finora

- ISC NIRScan User Manual - EN - V1.1Documento55 pagineISC NIRScan User Manual - EN - V1.1bexepac929100% (1)

- CAS Beam Instrumentation BookletDocumento186 pagineCAS Beam Instrumentation Bookletabr6ls4heNessuna valutazione finora

- ECE 5525FinalProjectDocDocumento12 pagineECE 5525FinalProjectDocRamkumar ThiruvenkadamNessuna valutazione finora

- Project Review On Ultrasonic Distance Measurement: Prakhar Shrivastava, Praveen Kumar, Ankit TiwariDocumento3 pagineProject Review On Ultrasonic Distance Measurement: Prakhar Shrivastava, Praveen Kumar, Ankit TiwariSuraj UpadhyayNessuna valutazione finora

- LT-2900 - Double Beam Instruction ManualDocumento23 pagineLT-2900 - Double Beam Instruction Manualsaurabh shukla100% (1)

- Low-Noise Amplifier Design and Optimization: Master'S ThesisDocumento0 pagineLow-Noise Amplifier Design and Optimization: Master'S Thesisjitu123456789Nessuna valutazione finora

- Ultrasonic Sensing BasicsDocumento15 pagineUltrasonic Sensing BasicsEdsonNessuna valutazione finora

- UV-2800 Series Spectrophotometer: User's ManualDocumento47 pagineUV-2800 Series Spectrophotometer: User's ManualAngelaNessuna valutazione finora

- Carey Thesis 2017Documento70 pagineCarey Thesis 2017atalasa-1Nessuna valutazione finora

- Distributed Rayleigh Sensing: Xinyu FanDocumento50 pagineDistributed Rayleigh Sensing: Xinyu FanFelipe Alejandro Muñoz CarmonaNessuna valutazione finora

- Acquisition of Seismic Data Using Wiener FilterDocumento26 pagineAcquisition of Seismic Data Using Wiener FilterVijay Seshu RNessuna valutazione finora

- Interference Rejection Combining System PerformanceDocumento73 pagineInterference Rejection Combining System PerformanceumeraftabranaNessuna valutazione finora

- Ultrasonic Sensing Basics: Application ReportDocumento15 pagineUltrasonic Sensing Basics: Application Reportkundu.banhimitraNessuna valutazione finora

- MatlabDocumento113 pagineMatlabMadhumitha MNessuna valutazione finora

- 00849A Spectrum Monitoring Techniques ANDocumento28 pagine00849A Spectrum Monitoring Techniques ANchuzv11Nessuna valutazione finora

- Atcor3 Tutorial PDFDocumento36 pagineAtcor3 Tutorial PDFGongNessuna valutazione finora

- SES 2000 Instruction ManualDocumento38 pagineSES 2000 Instruction Manualxuantruong0212Nessuna valutazione finora

- Mazin ThesisDocumento179 pagineMazin ThesisAndrew JaffeNessuna valutazione finora

- IC-TGD-100 User's ManualDocumento29 pagineIC-TGD-100 User's ManualJboy SchlossNessuna valutazione finora

- Book Title: Cognitive Radio NetworksDocumento37 pagineBook Title: Cognitive Radio NetworkslaerciomosNessuna valutazione finora

- Di Trocchio SpecialisticaDocumento101 pagineDi Trocchio SpecialisticabaymanNessuna valutazione finora

- Ultrasonic Transducers Technical NotesDocumento11 pagineUltrasonic Transducers Technical NotesBelaliaNessuna valutazione finora

- Manual 25 RadarDocumento54 pagineManual 25 RadarKalashnikov GCG GeofísicaNessuna valutazione finora

- MATLAB BASED SPECAN AlgorithmDocumento91 pagineMATLAB BASED SPECAN Algorithmnaivedya_mishra0% (1)

- Multilayer Integrated Film Bulk Acoustic Resonators - Yafei Zhang, Da ChenDocumento158 pagineMultilayer Integrated Film Bulk Acoustic Resonators - Yafei Zhang, Da ChenSasaNessuna valutazione finora

- Dark Fiber: Evaluation With OTDRDocumento17 pagineDark Fiber: Evaluation With OTDRАлексей Лагунов100% (1)

- Sound CaptureDocumento278 pagineSound CaptureJulio Gándara GarcíaNessuna valutazione finora

- Aer403 Lab Manual Rev1.3Documento34 pagineAer403 Lab Manual Rev1.3Urshia Likes CookiesNessuna valutazione finora

- Final Report Complete PDFDocumento26 pagineFinal Report Complete PDFsudeendraNessuna valutazione finora

- Project Report. DSDocumento9 pagineProject Report. DSHassaan YousafNessuna valutazione finora

- Pfeiffer DRDocumento105 paginePfeiffer DRloaizaleoNessuna valutazione finora

- Wu2013 PDFDocumento198 pagineWu2013 PDFKarima Ben salahNessuna valutazione finora

- An 1405-1 PDFDocumento28 pagineAn 1405-1 PDFjinterpaulNessuna valutazione finora

- Acoustic SensorsDocumento107 pagineAcoustic SensorsSuman MandalNessuna valutazione finora

- AN Spectrum Analyzers For EMC TestingDocumento18 pagineAN Spectrum Analyzers For EMC Testingchuku7Nessuna valutazione finora

- UTG-2800 2018 BookletDocumento31 pagineUTG-2800 2018 BookletQAMAR ALI KHANNessuna valutazione finora

- Project Ultrasonic Range FinderDocumento7 pagineProject Ultrasonic Range FinderSufiyan SiddiqueNessuna valutazione finora

- ThesisDocumento59 pagineThesiseuler.amNessuna valutazione finora

- STEPS User ManualDocumento53 pagineSTEPS User ManualAndres PaezNessuna valutazione finora

- User's Manual: Riga 2017Documento70 pagineUser's Manual: Riga 2017sinyor deliNessuna valutazione finora

- MHDV2262-04 Fuente Ob2273Documento64 pagineMHDV2262-04 Fuente Ob2273Andres AlegriaNessuna valutazione finora

- Module4.Etching - Ee143 f14.CtnDocumento20 pagineModule4.Etching - Ee143 f14.CtnstansilawNessuna valutazione finora

- TM1651 V1.1 enDocumento12 pagineTM1651 V1.1 enPriyanka ShanmugamNessuna valutazione finora

- Vlsi Physical Design PDFDocumento41 pagineVlsi Physical Design PDFParul TrivediNessuna valutazione finora

- ECE 372 - Chap14Documento65 pagineECE 372 - Chap14amritaeceNessuna valutazione finora

- Exam Questions-Section 1Documento38 pagineExam Questions-Section 1Gecca VergaraNessuna valutazione finora

- CatalogDocumento34 pagineCatalogccvvbbnnNessuna valutazione finora

- CG-428 - 06 TransistorsDocumento17 pagineCG-428 - 06 TransistorsMark ClementsNessuna valutazione finora

- Project Report On Speed Control of DC Motor by Using PWM TechniqueDocumento75 pagineProject Report On Speed Control of DC Motor by Using PWM Techniquepandyamech80% (15)

- Intrinsic Safety MaintenanceDocumento2 pagineIntrinsic Safety MaintenanceRoadieNessuna valutazione finora

- Quantification of Ion Migration in CH NH Pbi Perovskite Solar Cells by Transient Capacitance MeasurementsDocumento37 pagineQuantification of Ion Migration in CH NH Pbi Perovskite Solar Cells by Transient Capacitance MeasurementsAbhinav PaikNessuna valutazione finora

- TH-42PD50U Plasma Training CourseDocumento85 pagineTH-42PD50U Plasma Training CourseElmer ChristoperNessuna valutazione finora

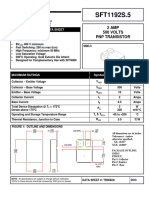

- SFT1192S.5: Solid State Devices, IncDocumento2 pagineSFT1192S.5: Solid State Devices, IncIPUNK PURNOMONessuna valutazione finora

- Philips Lumileds: IESNA LM-80 Test ReportDocumento25 paginePhilips Lumileds: IESNA LM-80 Test ReportR A ArunkrishnanNessuna valutazione finora

- Max1909 Max8725Documento30 pagineMax1909 Max8725Juan CarlosNessuna valutazione finora

- Polycab Wires PVT LTD: HT Xlpe CablesDocumento18 paginePolycab Wires PVT LTD: HT Xlpe Cablesmohit616Nessuna valutazione finora

- Wharfedale TITAN SUB-A12 - 1-400wDocumento13 pagineWharfedale TITAN SUB-A12 - 1-400wNguyễn Quang TrânNessuna valutazione finora

- PAL007A Pioneer PDFDocumento1 paginaPAL007A Pioneer PDFWillian Jose Rosas MartinezNessuna valutazione finora

- Analog Communications Laboratory (Documento5 pagineAnalog Communications Laboratory (shivam007Nessuna valutazione finora

- Diode Resistance & Diode Equivalent CircuitsDocumento42 pagineDiode Resistance & Diode Equivalent Circuitsgirishkumardarisi254Nessuna valutazione finora

- Basic Silicone Chemistry P 1Documento21 pagineBasic Silicone Chemistry P 1Rahul Yadav100% (1)

- LM 395Documento20 pagineLM 395Baixista Sapiens NeanderthalensisNessuna valutazione finora

- Slim TV Service Manual - Sy33 ChassisDocumento45 pagineSlim TV Service Manual - Sy33 ChassisUmar MajeedNessuna valutazione finora

- Jinko Mono 340wDocumento2 pagineJinko Mono 340wDiego Alejandro CampoNessuna valutazione finora

- Aluminum Lithium Alloy Welding Process FeaturesDocumento82 pagineAluminum Lithium Alloy Welding Process FeaturesMitone DiazNessuna valutazione finora

- Chip Finish Icc TCLDocumento5 pagineChip Finish Icc TCLgenx142Nessuna valutazione finora

- SLS11Documento27 pagineSLS11maneeshNessuna valutazione finora

- Multistage Amplifier Lab ReportDocumento10 pagineMultistage Amplifier Lab ReportasifNessuna valutazione finora

- 1909 WFDocumento71 pagine1909 WFBob HazNessuna valutazione finora

- Week 9 - Ceramic Matrix CompositeDocumento31 pagineWeek 9 - Ceramic Matrix Compositewani75% (4)