Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ODN Construction Guidelines

Caricato da

Civ HerreraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ODN Construction Guidelines

Caricato da

Civ HerreraCopyright:

Formati disponibili

27 September 2016

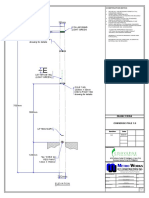

CONSTRUCTION METHOD: POLE-MOUNT LCP & NAP

Loop for Future NAP

w/ Cable Tie

Future NAP

Position

AML (Actual Measured Loss) of the Feeder lines from CO must be secured first prior to actual build

LCP and NAP pole-mount closure positions are fixed and installed facing road side

Provide 30m maintenance loop on feeder side, NO loop on succeeding LCPs and NAPs

Maintenance loop should be placed on PLDT poles only, NEVER on Meralco poles

For future or expansion NAPs, PROVIDE 5m loop at the identified locations where they will be installed

REMOVE messenger wire of expansion loop

PLACE expansion loop on the side of the future NAP facing the central office; same for future LCPs

SECURE the expansion loop with 3 cable ties and electrical tape, separated 120° apart

TECHNICAL STANDARDS DIVISION

LCP / NAP

Cable Tie

INSTALL LCP and NAP 1 to 2 feet below center bolt of C1 pole clamp; DO NOT install on

poles with transformer C1

MINIMUM clearance between LCP/NAP to ground is 12 ft

For NAPs:

INSTALL two (2) bridle rings on both sides and one (1) at the bottom 1’ - 2’ Guy Grip

PLACE the bottom bridle ring 5” to 6” directly under the drop cable ports

ROUTE the 24F Figure 8 FOC opposite the drop cable ports side of the NAP going

to the main cable ports. C2

DO NOT route on the same side where the drop cables are, so as not to

disturb the drops.

NO bridle rings required at LCP positions Bridle Ring

Drop

DO NOT route the 24F Figure 8 FOC through the bridle ring

Cable

Bridle rings are DEDICATED for drop cable use only

USE cable tie for added support

To 24F Figure 8 FOC on the guy grip

To secure the stub cable to the pole

Once cable ties are installed, cut any excess 24F Figure 8

5” - 6” FOC

TECHNICAL STANDARDS DIVISION

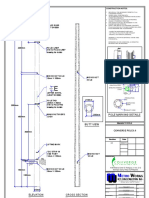

GUY GRIP

For Fig. 8 24F/48F/72F FOC, USE 1/7” Guy Grip

For Fig. 8 144F/216F, USE 3/16” Guy Grip

TECHNICAL STANDARDS DIVISION

GUY GRIP

TECHNICAL STANDARDS DIVISION

DOUBLE NAP (2-SPLITTERS / NAP)

For Greenfield Areas

NO double NAP allowed

With no RTA issue

If Eng’g design requires > 8 NAP ports, USE 2 NAPs (1 splitter /

NAP), INSTALLED side-by-side on the pole facing road side. ≥ 12ft

If with limited space or with constraints on the pole to

accommodate 2 NAPs, USE adjacent poles (1 NAP/pole).

≥ 12ft

With RTA issue

If Eng’g design requires > 8 NAP ports, USE 2 NAPs (1 splitter /

NAP), INSTALLED on adjacent poles (1 NAP / pole) facing road ≥ 12ft

side.

TECHNICAL STANDARDS DIVISION

DOUBLE NAP (2-SPLITTERS / NAP)

For Brownfield Areas

With no RTA issue and available space

If Eng’g design requires > 8 NAP ports, USE 2 NAPs (1 splitter /

NAP), INSTALLED side-by-side on the pole facing road side. ≥ 12ft

Double

With RTA issue, limited space and with constraints on the pole or NAP

adjacent poles

USE double NAP (2 splitters/NAP), INSTALLED facing road side.

≥ 12ft

TECHNICAL STANDARDS DIVISION

LCP CABLE STUB

PROVIDE 2 additional SS buckles on the SS Straps (1 buckle/strap) that secures the LCP on the pole

SECURE the LCP cable stub to the 2 additional SS buckles with yellow tie cable.

Yellow Tie

Additional Cable

SS Buckle

LCP Cable

Stub

TECHNICAL STANDARDS DIVISION

GROUNDING OF FIGURE 8 FOC

Ground messenger wire of Figure 8 FOC every end of aerial NAP and every LCP position

Route messenger wire for grounding on the side of the LCP facing the central office

KEEP insulation of messenger wire (DO NOT strip or remove cable sheath)

EXTEND and CONNECT messenger wire directly to ground (ground rod)

SECURE messenger wire to the pole with three (3) stainless steel strap

Messenger Yellow Tie

Wire Messenger

Cable

Wire

24F

FOC

SS

Strap Exposed Stainless

messenger Steel

wire Strap

To GRD

Ground

Rod

Clamp

Ground

Rod

TECHNICAL STANDARDS DIVISION

HOOKS WITH NUT ON POLE WITH NAP

INSTALL hooks with nut together with pole clamps on every pole where NAP is installed and

for future location of NAPs

INSTALL two (2) hooks, one (1) facing left and the other facing the right side of the street

For end poles with NAP, meaning poles installed at dead-ends or road-ends

INSTALL only one (1) hook and should be installed facing the open section of the

street

TECHNICAL STANDARDS DIVISION

24F FIGURE 8 FOC PROTECTION WHEN CROSSING ELECTRICAL CABLES

WRAP the 24F Figure 8 FOC with a ½ HDPE pipe, to protect and insulate it from electrical contacts

Length of HDPE pipe should be 16”

SECURE both ends of the HDPE pipe with electrical tape

18” x ½”

Power Line HDPE pipe

24F Fig 8

FOC

TECHNICAL STANDARDS DIVISION

ODN DESIGN

(for UG)

Traditional

Fiber Optic

Cable

24F Figure 8

Semi-Dry Fiber

Optic Cable

8 core x 3 buffer

Figure 8

Fiber Optic

Cable

(for Aerial)

Sub-feeder

If insertion point is underground, USE Traditional FOC

If insertion point is aerial, USE Figure 8 FOC

Distribution: LCP-to-NAP, USE Figure-8 FOC

TECHNICAL STANDARDS DIVISION

ODN DESIGN

(for UG)

Traditional

Fiber Optic

Cable

24F Figure 8

Semi-Dry Fiber

Optic Cable

8 core x 3 buffer

Figure 8

Fiber Optic

Cable

(for Aerial)

For all constructions, INSTALL Splice Closure before 1st LCP

Splice closure should be located at main road, or

Outside (before entry) the subdivision or village

TECHNICAL STANDARDS DIVISION

ODN DESIGN

TECHNICAL STANDARDS DIVISION

FIBER ASSIGNMENTS OF LCPS/NAPS USING 24-FIBER CABLE (8-CORE / 3-BUFFER)

TECHNICAL STANDARDS DIVISION

FIBER ASSIGNMENTS OF LCPS/NAPS USING 24-FIBER CABLE (8-CORE / 3-BUFFER)

TECHNICAL STANDARDS DIVISION

LCP DETAILS

TECHNICAL STANDARDS DIVISION

NAP DETAILS

TECHNICAL STANDARDS DIVISION

LCP / NAP NAMING CONVENTION

For stenciling to LCP and NAP

LCP NAP

MKT

MKT LP1

LP1 NP1

MKT - Town/Municipality/City Code

LP1 - LCP Number (Sequential Numbering per Town)

NP1 - NAP Number homing LP1 (Sequential Numbering)

TECHNICAL STANDARDS DIVISION

LCP / NAP / FDC STENCILING

USE Town/City/Municipality 3-letter code used by CSOZ

FONT: Bold Arial; FONT SIZE: 100 (equal to 1”)

Stencil shall be vertical and left-aligned

Spacing shall be 0.375 in. (equal to 0.95 cm.)

USE quick dry epoxy enamel spray paint

BLACK on light colored background

WHITE on dark colored background

FiberHome Fibercom Fujikura Tyco Fiberhome FDC

TECHNICAL STANDARDS DIVISION

ODN ACCEPTANCE

Acceptance Test Protocol

Checklist, End-to-End Test Forms, As-Built Plans, OLT PON Port Assignments,

LCP/NAP Keys

Acceptance Test Protocol should be complete and ready prior to start of any

acceptance activity

NO acceptance activities shall commence if above required documents are incomplete

PM, as head of the Acceptance Committee, shall make sure;

Completeness of the Acceptance Test Protocol

All necessary materials and equipment needed before start of actual activities

are available

Acceptance Committee shall compose of the following;

PM

End-user (Zone and FxATOp)

Contractor

WRITE all remarks and comments in the Acceptance Test Protocol.

After completion of the acceptance activities, the Acceptance Test Protocol shall be

signed-off by the members of the Acceptance Committee.

PM to furnish the Acceptance Committee with a copy of the signed ATP after

confirming completeness of the document.

TECHNICAL STANDARDS DIVISION

SECTIONALIZED ACCEPTANCE TESTING (PRE-TEST)

Bi-Directional Optical Insertion Loss & Optical Insertion Loss Measurement using Optical Loss Test Set (OLTS)

TECHNICAL STANDARDS DIVISION

SERVICE ACTIVATION TESTING (ACCEPTANCE TESTING)

Power Level Testing at Subscriber Side using Power Meter

Repair Margin = 1 dB

Keep records of all splicing and repair done on the link

TECHNICAL STANDARDS DIVISION

Potrebbero piacerti anche

- OSP Training For Local Designer of PLDTDocumento57 pagineOSP Training For Local Designer of PLDTChristine Ericka Manipol75% (4)

- FTTH Acceptance Template Final 12092015Documento12 pagineFTTH Acceptance Template Final 12092015Ronald AllanNessuna valutazione finora

- Mini-OLT Light ODN (MILO) Installation v.21Documento34 pagineMini-OLT Light ODN (MILO) Installation v.21Christian Earl Magpayo100% (9)

- FTTH (Fiber-To-The-Home) Technical StandardsDocumento21 pagineFTTH (Fiber-To-The-Home) Technical StandardsCiv Herrera100% (4)

- Globe FTTH Standard PDFDocumento213 pagineGlobe FTTH Standard PDFChristian Earl Magpayo100% (1)

- Tech Guide Ver21Documento45 pagineTech Guide Ver21Myka100% (3)

- BoQ OSP Backbone Phase-1Documento2 pagineBoQ OSP Backbone Phase-1adeng100% (1)

- Standards 001Documento23 pagineStandards 001Civ HerreraNessuna valutazione finora

- FiberHome Optical Network Overview Kntelecom IrDocumento49 pagineFiberHome Optical Network Overview Kntelecom IrRobert MorrisNessuna valutazione finora

- FTTH Aerial InstallationDocumento5 pagineFTTH Aerial InstallationMustafa KamalNessuna valutazione finora

- FOC Specs (Figure 8) - FTTHDocumento4 pagineFOC Specs (Figure 8) - FTTHLuis OdictaNessuna valutazione finora

- Huawei GPONDocumento30 pagineHuawei GPONmuneefrana100% (2)

- Standards 001Documento23 pagineStandards 001Civ HerreraNessuna valutazione finora

- Underground FOC GuidelinesDocumento70 pagineUnderground FOC GuidelinesCiv Herrera100% (1)

- Underground FOC GuidelinesDocumento70 pagineUnderground FOC GuidelinesCiv Herrera100% (1)

- Standards 001Documento23 pagineStandards 001Civ HerreraNessuna valutazione finora

- Health Promotion Throughout The Life Span 7th Edition Edelman Test BankDocumento35 pagineHealth Promotion Throughout The Life Span 7th Edition Edelman Test Bankcourtneyharrisbpfyrkateq100% (17)

- Tech Guide Ver21Documento34 pagineTech Guide Ver21Muhammad Furqon100% (1)

- Mini-OLT Light ODN (MILO) Installation v.20220429Documento38 pagineMini-OLT Light ODN (MILO) Installation v.20220429Angie BendijoNessuna valutazione finora

- v2.1 FTTX FiberGenDocumento39 paginev2.1 FTTX FiberGenCiv Herrera100% (1)

- Converge: Outside Plant DesignDocumento8 pagineConverge: Outside Plant DesignCiv HerreraNessuna valutazione finora

- Fhe NGG Training PP T 20181204Documento43 pagineFhe NGG Training PP T 20181204Bin LuNessuna valutazione finora

- FHEnggTrainingPPT20181204 PDFDocumento43 pagineFHEnggTrainingPPT20181204 PDFBin Lu100% (1)

- Cascade E2E - Aerial Inst Standards Deck 2018 For Sub - ConDocumento90 pagineCascade E2E - Aerial Inst Standards Deck 2018 For Sub - ConChristian Earl MagpayoNessuna valutazione finora

- Understanding OLT, ONU, ONT and ODN PDFDocumento3 pagineUnderstanding OLT, ONU, ONT and ODN PDFRajivparaj 李瑞杰100% (1)

- Aerial Installation GuidelinesDocumento57 pagineAerial Installation GuidelinesRonald AllanNessuna valutazione finora

- Detailed Design Drawings: PLDT Fibrization Via FTTH Project FALL17083152 MTI (0017) Davao City, Davao Del Sur Region XiDocumento23 pagineDetailed Design Drawings: PLDT Fibrization Via FTTH Project FALL17083152 MTI (0017) Davao City, Davao Del Sur Region XiFrancis Adrian Lañojan PernitesNessuna valutazione finora

- Comclark and Converge ICTDocumento10 pagineComclark and Converge ICTRhanda BernardoNessuna valutazione finora

- Stenciling Guidelines and Procedures For FTTH NAP LCP and FDC - v4Documento11 pagineStenciling Guidelines and Procedures For FTTH NAP LCP and FDC - v4Dacely RocaverteNessuna valutazione finora

- 3 FTTX Solutions PDFDocumento39 pagine3 FTTX Solutions PDFOscar MartinezNessuna valutazione finora

- FiberHome FTTX SoluciónDocumento54 pagineFiberHome FTTX Soluciónmacias_marlon100% (2)

- Huawei ODN Solution Introduction PDFDocumento28 pagineHuawei ODN Solution Introduction PDFJim Rey100% (2)

- OTDRDocumento22 pagineOTDRAurélio Adolfo NhancaleNessuna valutazione finora

- OSP Document New PDFDocumento82 pagineOSP Document New PDFjuminarNessuna valutazione finora

- Fiberhome Access Solution FTTHDocumento20 pagineFiberhome Access Solution FTTHPamela Sánchez Ramos100% (1)

- ODN Planning and Design Suggestions TLFDocumento52 pagineODN Planning and Design Suggestions TLFJairo Aguero MarotoNessuna valutazione finora

- 1 FTTH Features & FundamentalsDocumento40 pagine1 FTTH Features & FundamentalsgibogibogiboNessuna valutazione finora

- Huawei Future Oriented FTTxSolutionDocumento30 pagineHuawei Future Oriented FTTxSolutionokakaNessuna valutazione finora

- PLDT Detailed Design DrawingDocumento13 paginePLDT Detailed Design DrawingAba Trinidad LeopoldoNessuna valutazione finora

- Alphaland Makati Tower RectificationDocumento3 pagineAlphaland Makati Tower RectificationIan MauhayNessuna valutazione finora

- RTA RefresherDocumento47 pagineRTA RefresherLincoln HernandezNessuna valutazione finora

- AirScale Checklist FinalDocumento12 pagineAirScale Checklist FinalkrishkarnNessuna valutazione finora

- Huawei ODN Products Series Brochure PDFDocumento38 pagineHuawei ODN Products Series Brochure PDFEsmael Rodrigues PetitNessuna valutazione finora

- Design and Implementation of A Fiber To The Home FTTH Access Network Based On GPONDocumento14 pagineDesign and Implementation of A Fiber To The Home FTTH Access Network Based On GPONSarfrazNessuna valutazione finora

- FTTH Network Efficiency From Uneven 2.0 To QuickODN 3.0Documento20 pagineFTTH Network Efficiency From Uneven 2.0 To QuickODN 3.0Carlos PariseNessuna valutazione finora

- (Infographic) Outdoor Cabinet Portfolio V1.0Documento2 pagine(Infographic) Outdoor Cabinet Portfolio V1.0Andrey PerestykNessuna valutazione finora

- Gigabit Passive Optical Network: Ii. Theory A. FTTHDocumento4 pagineGigabit Passive Optical Network: Ii. Theory A. FTTHarif100% (1)

- Thomas Martin Fiber To The HomeDocumento56 pagineThomas Martin Fiber To The HomeBayu Bentar KumbaraNessuna valutazione finora

- 201mm Collar Band Light Green 76mm: ConvergeDocumento1 pagina201mm Collar Band Light Green 76mm: ConvergeCiv HerreraNessuna valutazione finora

- Backbone Planning & OSP Solution (Training Slide) V3.0Documento85 pagineBackbone Planning & OSP Solution (Training Slide) V3.0Gossan Anicet0% (1)

- Reference Guide FTTHDocumento116 pagineReference Guide FTTHturbozmejNessuna valutazione finora

- Cascade E2E - Aerial Inst Standards Deck 2018 For PSDocumento89 pagineCascade E2E - Aerial Inst Standards Deck 2018 For PSChristian Earl MagpayoNessuna valutazione finora

- Nap InstallationDocumento46 pagineNap InstallationDaniel BermodezNessuna valutazione finora

- Standard Instalasi Engineering JaringanDocumento23 pagineStandard Instalasi Engineering JaringanWaskito Widodo0% (1)

- Baofeng VarioDocumento6 pagineBaofeng VarioDiego García MedinaNessuna valutazione finora

- RPP V2 ManualDocumento6 pagineRPP V2 ManualArmyn RVNessuna valutazione finora

- QRP2004.0004Documento10 pagineQRP2004.0004Ian McNairNessuna valutazione finora

- Liebert Exs 10kva 60hz 208220v Quick Start GuideDocumento21 pagineLiebert Exs 10kva 60hz 208220v Quick Start GuidestuardobsaquicNessuna valutazione finora

- Project Subject DateDocumento68 pagineProject Subject DateMohammad SaquibNessuna valutazione finora

- ERbic Profibus eDocumento2 pagineERbic Profibus eOmar Alfredo Del Castillo QuispeNessuna valutazione finora

- Site Cabling & Antenna InstallationDocumento49 pagineSite Cabling & Antenna Installation0555668118Nessuna valutazione finora

- SA-GRSP11 (Access Floor Grounding Clamp) WEB 7-15-11Documento2 pagineSA-GRSP11 (Access Floor Grounding Clamp) WEB 7-15-11JUAN CARLOS LEAL LINERONessuna valutazione finora

- Cat 08b en Festoon Systems For Flatform Cable I ProfileDocumento40 pagineCat 08b en Festoon Systems For Flatform Cable I ProfilesonNessuna valutazione finora

- Opticom Fiber Optic Patch Panels and Trays: SpecificationsDocumento2 pagineOpticom Fiber Optic Patch Panels and Trays: SpecificationsBernie AguilarNessuna valutazione finora

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDa EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNessuna valutazione finora

- O Hesus, Hilumin MoDocumento3 pagineO Hesus, Hilumin MoCiv Herrera100% (1)

- Papuri Sayo Panginoong HesukristoDocumento1 paginaPapuri Sayo Panginoong HesukristoCiv HerreraNessuna valutazione finora

- Ent-Pm2 Feasibility Study Checklist: Pull Box/ Service Box/ Hand Hole Transition From OutsideDocumento1 paginaEnt-Pm2 Feasibility Study Checklist: Pull Box/ Service Box/ Hand Hole Transition From OutsideCiv HerreraNessuna valutazione finora

- Converge: Outside Plant DesignDocumento8 pagineConverge: Outside Plant DesignCiv HerreraNessuna valutazione finora

- 201mm Collar Band Light Green 76mm: ConvergeDocumento1 pagina201mm Collar Band Light Green 76mm: ConvergeCiv HerreraNessuna valutazione finora

- Pole 9.0Documento1 paginaPole 9.0Civ HerreraNessuna valutazione finora

- 201mm Collar Band Light Green 76mm: ConvergeDocumento1 pagina201mm Collar Band Light Green 76mm: ConvergeCiv HerreraNessuna valutazione finora

- StickerDocumento1 paginaStickerCiv HerreraNessuna valutazione finora

- Shree New Price List 2016-17Documento13 pagineShree New Price List 2016-17ontimeNessuna valutazione finora

- Goldhofer FTV 850 BrochureDocumento2 pagineGoldhofer FTV 850 BrochureMauroNessuna valutazione finora

- Flight Vehicle Design:: Example 2 (Uav)Documento43 pagineFlight Vehicle Design:: Example 2 (Uav)Anmol KumarNessuna valutazione finora

- Texto EBAU 1Documento2 pagineTexto EBAU 1haridianrm13Nessuna valutazione finora

- Stalthon Rib and InfillDocumento2 pagineStalthon Rib and InfillAndrea GibsonNessuna valutazione finora

- Digging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Documento2 pagineDigging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Рустам ХаджаевNessuna valutazione finora

- Cynosure Starlux 500 Palomar Technical Service ManualDocumento47 pagineCynosure Starlux 500 Palomar Technical Service ManualJF SilvaNessuna valutazione finora

- Process Costing Exercises Series 1Documento23 pagineProcess Costing Exercises Series 1sarahbeeNessuna valutazione finora

- Lesson 1 Chapter 9 ErosiondepositionDocumento1 paginaLesson 1 Chapter 9 Erosiondepositionapi-249320969Nessuna valutazione finora

- SCM (Subway Project Report)Documento13 pagineSCM (Subway Project Report)Beast aNessuna valutazione finora

- 9 5 - 358 362 PDFDocumento5 pagine9 5 - 358 362 PDFمالك مناصرةNessuna valutazione finora

- Better - Homes.and - Gardens.usa - TruePDF December.2018Documento136 pagineBetter - Homes.and - Gardens.usa - TruePDF December.2018MadaMadutsaNessuna valutazione finora

- Dawn of Solar PV CookingDocumento5 pagineDawn of Solar PV CookingAbhinav AgrawalNessuna valutazione finora

- Extract From The Painted Door' by Sinclair RossDocumento2 pagineExtract From The Painted Door' by Sinclair RosssajifisaNessuna valutazione finora

- Lab Report Marketing Mansi 4Documento39 pagineLab Report Marketing Mansi 4Mansi SharmaNessuna valutazione finora

- Guia de CondensadoresDocumento193 pagineGuia de CondensadoresPaola Segura CorreaNessuna valutazione finora

- Arduino Oscilloscope ProjectDocumento12 pagineArduino Oscilloscope ProjectSathya Narayan100% (1)

- TM-8000 HD Manual PDFDocumento37 pagineTM-8000 HD Manual PDFRoxana BirtumNessuna valutazione finora

- 41z S4hana2021 Set-Up en XXDocumento46 pagine41z S4hana2021 Set-Up en XXHussain MulthazimNessuna valutazione finora

- Biomedical Engineering Handbook Revised 5 2015Documento37 pagineBiomedical Engineering Handbook Revised 5 2015Teja GuttiNessuna valutazione finora

- Highway-And-Railroad-Engineering SummaryDocumento15 pagineHighway-And-Railroad-Engineering SummaryRodin James GabrilloNessuna valutazione finora

- Tuberculosis PowerpointDocumento69 pagineTuberculosis PowerpointCeline Villo100% (1)

- Douluo Dalu Volume 05 - Star Dou Forest PDFDocumento141 pagineDouluo Dalu Volume 05 - Star Dou Forest PDFRay Joseph LealNessuna valutazione finora

- GROSS Mystery of UFOs A PreludeDocumento309 pagineGROSS Mystery of UFOs A PreludeTommaso MonteleoneNessuna valutazione finora

- Dual Op Amp and Voltage Reference Ap4310/ADocumento12 pagineDual Op Amp and Voltage Reference Ap4310/AМихаил ЯненкоNessuna valutazione finora

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Documento31 pagineHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNessuna valutazione finora

- Nissan Copper LTDDocumento11 pagineNissan Copper LTDankit_shahNessuna valutazione finora

- Pediatric EmergenciesDocumento47 paginePediatric EmergenciesahmedNessuna valutazione finora

- Technical Information: Range-Free Controller FA-M3 System Upgrade GuideDocumento33 pagineTechnical Information: Range-Free Controller FA-M3 System Upgrade GuideAddaNessuna valutazione finora