Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

STR PDF

Caricato da

Luis Alfonso Ortiz ESpinosaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

STR PDF

Caricato da

Luis Alfonso Ortiz ESpinosaCopyright:

Formati disponibili

ENGINE

SECTION

STARTING SYSTEM

STR STR

E

CONTENTS

QR25DE Special Service Tool ................................................24 F

Commercial Service Tool ........................................24

BASIC INSPECTION .................................... 3

ON-VEHICLE REPAIR ................................. 25 G

DIAGNOSIS AND REPAIR WORKFLOW .......... 3

Work Flow ................................................................. 3 STARTER MOTOR ........................................... 25

Removal and Installation .........................................25

FUNCTION DIAGNOSIS ............................... 6 Removal and Installation .........................................25 H

STARTING SYSTEM ........................................... 6 SERVICE DATA AND SPECIFICATIONS

System Diagram ........................................................ 6 (SDS) ............................................................ 26 I

System Description ................................................... 6

Component Description ............................................ 7 STARTER MOTOR ........................................... 26

Starter ......................................................................26

COMPONENT DIAGNOSIS .......................... 8 VQ35DE J

B TERMINAL CIRCUIT ....................................... 8 BASIC INSPECTION ................................... 27

Description ................................................................ 8

K

Diagnosis Procedure ................................................. 8 DIAGNOSIS AND REPAIR WORKFLOW ........ 27

Work Flow ................................................................27

S CONNECTOR CIRCUIT ................................... 9

Description ................................................................ 9 FUNCTION DIAGNOSIS .............................. 30 L

Diagnosis Procedure ................................................. 9

STARTING SYSTEM ......................................... 30

STARTING SYSTEM ..........................................10 System Diagram ......................................................30

Wiring Diagram - Coupe .......................................... 10 M

System Description ..................................................30

Wiring Diagram - Sedan .......................................... 16 Component Description ..........................................31

SYMPTOM DIAGNOSIS .............................. 22 COMPONENT DIAGNOSIS ......................... 32 N

STARTING SYSTEM ..........................................22 B TERMINAL CIRCUIT ..................................... 32

Symptom Table ....................................................... 22 Description ...............................................................32

O

Diagnosis Procedure ...............................................32

PRECAUTION .............................................. 23

S CONNECTOR CIRCUIT ................................. 33

PRECAUTIONS ..................................................23 Description ...............................................................33 P

Precaution for Supplemental Restraint System Diagnosis Procedure ...............................................33

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................. 23 STARTING SYSTEM ......................................... 34

Wiring Diagram - Coupe ..........................................34

PREPARATION ........................................... 24 Wiring Diagram - Sedan ..........................................40

PREPARATION ..................................................24 SYMPTOM DIAGNOSIS .............................. 46

Revision: July 2007 STR-1 2008 Altima

STARTING SYSTEM ......................................... 46 Commercial Service Tool ........................................ 48

Symptom Table ...................................................... 46

ON-VEHICLE REPAIR ............................... 49

PRECAUTION ............................................. 47

STARTER MOTOR ............................................ 49

PRECAUTIONS ................................................. 47 Removal and Installation ......................................... 49

Precaution for Supplemental Restraint System Removal and Installation ......................................... 49

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................. 47 SERVICE DATA AND SPECIFICATIONS

(SDS) .......................................................... 51

PREPARATION ........................................... 48

STARTER MOTOR ............................................ 51

PREPARATION ................................................. 48 Starter ..................................................................... 51

Special Service Tool ............................................... 48

Revision: July 2007 STR-2 2008 Altima

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [QR25DE]

BASIC INSPECTION A

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow INFOID:0000000001346369

STR

OVERALL SEQUENCE

C

JSBIA0001GB

DETAILED FLOW

Revision: July 2007 STR-3 2008 Altima

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [QR25DE]

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and alternator test segments must be

done as a set from start to finish.

1.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the starting system test with Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Test result

CRANKING VOLTAGE NORMAL>>GO TO 2

CRANKING VOLTAGE LOW>>GO TO 5

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12

hours.) Perform battery test again. Refer to Technical Service Bulletin.

REPLACE BATTERY>>Before replacing battery, clean the battery cable clamps and battery posts. Perform

battery test again. Refer to Technical Service Bulletin. If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

2.CRANKING CHECK

Check that the starter motor operates properly.

Does the engine crank normally?

YES >> GO TO 3

NO >> GO TO 4

3.ENGINE START CHECK

Check that the engine starts.

Does the engine start?

YES >> Starter motor is OK. Inspection end.

NO >> Perform further diagnosis of engine mechanical or engine control system. Refer to EM and EC

sections. Once resolved, perform battery test again.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

Does the starter motor turn?

YES >> Check ring gear and starter motor drive pinion. Once resolved, perform battery test again.

NO >> GO TO 7

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and verify the cranking voltage is within specification.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

Engine coolant temperature [°C (°F)] Voltage [V]

−30 to −20 (−22 to −4) 8.6

−19 to −10 (−2 to 14) 9.1

−9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Is the voltage less than the specified value?

YES >> GO TO 7

NO >> GO TO 6

6.STARTER OPERATION

Check the starter operation.

Does the starter motor turn smoothly?

YES >> Starter motor is OK. Inspection end.

NO >> GO TO 7

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to STR-8, "Diagnosis Procedure".

Is “B” terminal circuit normal?

Revision: July 2007 STR-4 2008 Altima

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [QR25DE]

YES >> GO TO 8

NO >> Repair as needed. A

8.“S” CONNECTOR CIRCUIT INSPECTION

Check “S” connector circuit. Refer to STR-9, "Diagnosis Procedure".

STR

Is “S” connector circuit normal?

YES >> GO TO 9

NO >> Repair as needed.

C

9.ENGINE ROTATION STATUS

Check that the engine can be rotated by hand.

Does the engine turn freely by hand? D

YES >> Replace starter motor.

NO >> Perform further diagnosis of engine mechanical or powertrain mechanism. Refer to EM, TM or CL

sections. Once resolved, perform battery test again. Refer to Technical Service Bulletin. E

Revision: July 2007 STR-5 2008 Altima

STARTING SYSTEM

< FUNCTION DIAGNOSIS > [QR25DE]

FUNCTION DIAGNOSIS

STARTING SYSTEM

System Diagram INFOID:0000000001346370

ALBIA0499GB

System Description INFOID:0000000001346371

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Revision: July 2007 STR-6 2008 Altima

STARTING SYSTEM

< FUNCTION DIAGNOSIS > [QR25DE]

Component Description INFOID:0000000001346372

Component part Description

PNP switch supplies power to the starter relay and starter control STR

PNP switch (CVT models) relay inside IPDM E/R when the selector lever is shifted to the P

or N position.

The switch turns ON and electric power is supplied to the starter C

Clutch interlock switch (M/T models) relay and starter control relay inside IPDM E/R when the clutch

pedal is depressed.

BCM BCM controls the starter relay inside IPDM E/R.

D

IPDM E/R CPU inside IPDM E/R controls the starter control relay.

The starter motor plunger closes and the motor is supplied with

Starter motor battery power, which in turn cranks the engine, when the “S” ter- E

minal is supplied with electric power.

Revision: July 2007 STR-7 2008 Altima

B TERMINAL CIRCUIT

< COMPONENT DIAGNOSIS > [QR25DE]

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

Description INFOID:0000000001346373

The “B” terminal is constantly supplied with battery power.

Diagnosis Procedure INFOID:0000000001346374

CAUTION:

Perform diagnosis under the condition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL B POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal B connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal B

and ground.

B - ground Battery voltage

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for

open circuit.

WKIA0137E

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift CVT selector lever to “P” or “N” position. (CVT models)

Press and hold the clutch pedal fully with the control lever in neutral. (M/T models)

2. Check voltage between battery positive terminal and starter

motor connector F27 terminal B while cranking the engine.

While cranking the engine

Terminal B - B+ terminal Less than 0.5V

Is the voltage drop less than 0.5V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter

motor for high resistance.

WKIA0138E

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift CVT selector lever to “P” or “N” position. (CVT models)

Press and hold the clutch pedal fully with the control lever in neutral. (M/T models)

2. Check voltage between starter motor case and battery negative

terminal while cranking the engine.

While cranking the engine

Starter case - B- terminal Less than 0.2V

Is the voltage drop less than 0.2V?

YES >> Terminal B circuit is OK. Further inspection necessary.

Refer to STR-3, "Work Flow".

NO >> Check the starter motor case to engine mounting for

high resistance. WKIA0139E

Revision: July 2007 STR-8 2008 Altima

S CONNECTOR CIRCUIT

< COMPONENT DIAGNOSIS > [QR25DE]

S CONNECTOR CIRCUIT

A

Description INFOID:0000000001346375

The starter motor magnetic switch is supplied with power when the ignition switch is turned to the START posi- STR

tion while the selector lever is in the P or N position (CVT models) or the clutch pedal is fully depressed (M/T

models).

Diagnosis Procedure INFOID:0000000001346376 C

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse. D

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT E

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift CVT selector lever to “P” or “N” position. (CVT models)

F

Press and hold the clutch pedal fully with the control lever in

neutral. (M/T models)

4. Check voltage between starter motor harness connector F28

terminal S and ground with the ignition in START. G

With ignition switch in START

S - ground Battery voltage H

ALBIA0501GB

Is battery voltage present?

YES >> “S” circuit is OK. Further inspection necessary. Refer to STR-3, "Work Flow".

NO >> GO TO 2 I

2.CHECK CONNECTOR

1. Turn ignition switch OFF. J

2. Check the following terminals and connectors for damage, bent pins and loose connections.

- IPDM E/R harness connector F10

- Starter motor harness connector F28

K

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector. L

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

- IPDM E/R connector F10 M

- Starter motor connector F28

2. Check continuity between starter motor harness connector F28

terminal S and IPDM E/R harness connector F10 terminal 80. N

S - 80 Continuity exists

Is there proper continuity between the two pins? O

YES >> Further inspection necessary. Refer to STR-3, "Work

Flow".

ALBIA0502GB

NO >> Repair the harness. P

Revision: July 2007 STR-9 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STARTING SYSTEM

Wiring Diagram - Coupe INFOID:0000000001346377

AWBWA0023GB

Revision: July 2007 STR-10 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STR

AWBWA0024GB

Revision: July 2007 STR-11 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

ALBIA0268GB

Revision: July 2007 STR-12 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STR

AWBIA0181GB

Revision: July 2007 STR-13 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

ALBIA0270GB

Revision: July 2007 STR-14 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STR

ALBIA0271GB

Revision: July 2007 STR-15 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

Wiring Diagram - Sedan INFOID:0000000003221742

AWBWA0117GB

Revision: July 2007 STR-16 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STR

AWBWA0118GB

Revision: July 2007 STR-17 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

AWBIA0423GB

Revision: July 2007 STR-18 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STR

ALBIA0269GB

Revision: July 2007 STR-19 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

AWBIA0424GB

Revision: July 2007 STR-20 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [QR25DE]

STR

AWBIA0425GB

Revision: July 2007 STR-21 2008 Altima

STARTING SYSTEM

< SYMPTOM DIAGNOSIS > [QR25DE]

SYMPTOM DIAGNOSIS

STARTING SYSTEM

Symptom Table INFOID:0000000001346378

Symptom Reference

No normal cranking

Refer to STR-3, "Work Flow".

Starter motor does not rotate

Revision: July 2007 STR-22 2008 Altima

PRECAUTIONS

< PRECAUTION > [QR25DE]

PRECAUTION A

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT STR

PRE-TENSIONER" INFOID:0000000001346379

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along C

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted. D

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING: E

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

F

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this G

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

H

Revision: July 2007 STR-23 2008 Altima

PREPARATION

< PREPARATION > [QR25DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000001346380

Tool number (Kent Moore No.)

Description

Tool name

(J-48087) Tests Battery.

Battery Service Center For operating instructions, refer to Technical

Service Bulletin and Battery Service Center

User Guide.

WKIA5280E

(J-44373) Model 620 Tests starting and charging systems.

Starting/Charging system tester For operating instructions, refer to Technical

Service Bulletin.

SEL403X

Commercial Service Tool INFOID:0000000001346381

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: July 2007 STR-24 2008 Altima

STARTER MOTOR

< ON-VEHICLE REPAIR > [QR25DE]

ON-VEHICLE REPAIR A

STARTER MOTOR

Removal and Installation INFOID:0000000001346382

STR

M/T MODELS

Removal C

1. Disconnect the negative battery terminal.

2. Disconnect the starter motor harness connectors.

D

3. Remove the two starter motor bolts, using power tools.

4. Remove the starter motor.

Installation E

Installation is in the reverse order of removal.

H

AWBIA0042GB

Removal and Installation INFOID:0000000001346383

I

CVT Models

REMOVAL J

1. Disconnect the negative and positive battery terminal.

2. Remove the air duct (front).

3. Remove the battery and battery tray bracket. K

4. Disconnect the starter harness connectors.

5. Remove the two starter bolts, using power tools.

L

6. Remove the starter.

INSTALLATION

Installation is in the reverse order of removal. M

AWBIA0043GB

P

Revision: July 2007 STR-25 2008 Altima

STARTER MOTOR

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

STARTER MOTOR

Starter INFOID:0000000001346384

Application QR25DE

M/T model CVT model

Manufacturer Mitsubishi M001T87181ZC Mitsubishi M001T68781ZC

Type Reduction gear type

System voltage 12V

Terminal voltage 11V

No-load Current 90A Max.

Revolution 2,750 rpm Min.

Minimum diameter of commutator 28.8 mm

Minimum length of brush 5.5mm 7.0 mm

15.0-20.4 N (1.53-2.08 kg, 18.3-24.8 N (1.87-2.53 kg,

Brush spring tension

3.37-4.59 lb) 4.11-5.58 lb)

Clearance between pinion front edge and pinion stopper 0.5-2.0 mm

Revision: July 2007 STR-26 2008 Altima

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [VQ35DE]

BASIC INSPECTION A

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow INFOID:0000000001346385

STR

OVERALL SEQUENCE

C

JSBIA0001GB

DETAILED FLOW

Revision: July 2007 STR-27 2008 Altima

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [VQ35DE]

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and alternator test segments must be

done as a set from start to finish.

1.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the starting system test with Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Test result

CRANKING VOLTAGE NORMAL>>GO TO 2

CRANKING VOLTAGE LOW>>GO TO 5

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12

hours.) Perform battery test again. Refer to Technical Service Bulletin.

REPLACE BATTERY>>Before replacing battery, clean the battery cable clamps and battery posts. Perform

battery test again. Refer to Technical Service Bulletin. If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

2.CRANKING CHECK

Check that the starter motor operates properly.

Does the engine crank normally?

YES >> GO TO 3

NO >> GO TO 4

3.ENGINE START CHECK

Check that the engine starts.

Does the engine start?

YES >> Starter motor is OK. Inspection end.

NO >> Perform further diagnosis of engine mechanical or engine control system. Refer to EM and EC

sections. Once resolved, perform battery test again.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

Does the starter motor turn?

YES >> Check ring gear and starter motor drive pinion. Once resolved, perform battery test again.

NO >> GO TO 7

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and verify the cranking voltage is within specification.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

Engine coolant temperature [°C (°F)] Voltage [V]

−30 to −20 (−22 to −4) 8.6

−19 to −10 (−2 to 14) 9.1

−9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Is the voltage less than the specified value?

YES >> GO TO 7

NO >> GO TO 6

6.STARTER OPERATION

Check the starter operation.

Does the starter motor turn smoothly?

YES >> Starter motor is OK. Inspection end.

NO >> GO TO 7

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to STR-32, "Diagnosis Procedure".

Is “B” terminal circuit normal?

Revision: July 2007 STR-28 2008 Altima

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [VQ35DE]

YES >> GO TO 8

NO >> Repair as needed. A

8.“S” CONNECTOR CIRCUIT INSPECTION

Check “S” connector circuit. Refer to STR-33, "Diagnosis Procedure".

STR

Is “S” connector circuit normal?

YES >> GO TO 9

NO >> Repair as needed.

C

9.ENGINE ROTATION STATUS

Check that the engine can be rotated by hand.

Does the engine turn freely by hand? D

YES >> Replace starter motor.

NO >> Perform further diagnosis of engine mechanical or powertrain mechanism. Refer to EM, TM or CL

sections. Once resolved, perform battery test again. Refer to Technical Service Bulletin. E

Revision: July 2007 STR-29 2008 Altima

STARTING SYSTEM

< FUNCTION DIAGNOSIS > [VQ35DE]

FUNCTION DIAGNOSIS

STARTING SYSTEM

System Diagram INFOID:0000000001346386

ALBIA0500GB

System Description INFOID:0000000001346387

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Revision: July 2007 STR-30 2008 Altima

STARTING SYSTEM

< FUNCTION DIAGNOSIS > [VQ35DE]

Component Description INFOID:0000000001346388

Component part Description

TCM supplies power to the starter relay and starter control relay STR

TCM (CVT models) inside IPDM E/R when the selector lever is shifted to the P or N

position.

The switch turns ON and electric power is supplied to the starter C

Clutch interlock switch (M/T models) relay and starter control relay inside IPDM E/R when the clutch

pedal is depressed.

BCM BCM controls the starter relay inside IPDM E/R.

D

IPDM E/R CPU inside IPDM E/R controls the starter control relay.

The starter motor plunger closes and the motor is supplied with

Starter motor battery power, which in turn cranks the engine, when the “S” ter- E

minal is supplied with electric power.

Revision: July 2007 STR-31 2008 Altima

B TERMINAL CIRCUIT

< COMPONENT DIAGNOSIS > [VQ35DE]

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

Description INFOID:0000000001346389

The “B” terminal is constantly supplied with battery power.

Diagnosis Procedure INFOID:0000000001346390

CAUTION:

Perform diagnosis under the condition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL B POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal B connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal B

and ground.

B - ground Battery voltage

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for

open circuit.

WKIA0137E

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift CVT selector lever to “P” or “N” position. (CVT models)

Press and hold the clutch pedal fully with the control lever in neutral. (M/T models)

2. Check voltage between battery positive terminal and starter

motor connector F27 terminal B while cranking the engine.

While cranking the engine

Terminal B - B+ terminal Less than 0.5V

Is the voltage drop less than 0.5V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter

motor for high resistance.

WKIA0138E

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift CVT selector lever to “P” or “N” position. (CVT models)

Press and hold the clutch pedal fully with the control lever in neutral. (M/T models)

2. Check voltage between starter motor case and battery negative

terminal while cranking the engine.

While cranking the engine

Starter case - B- terminal Less than 0.2V

Is the voltage drop less than 0.2V?

YES >> Terminal B circuit is OK. Further inspection necessary.

Refer to STR-27, "Work Flow".

NO >> Check the starter motor case to engine mounting for

high resistance. WKIA0139E

Revision: July 2007 STR-32 2008 Altima

S CONNECTOR CIRCUIT

< COMPONENT DIAGNOSIS > [VQ35DE]

S CONNECTOR CIRCUIT

A

Description INFOID:0000000001346391

The starter motor magnetic switch is supplied with power when the ignition switch is turned to the START posi- STR

tion while the selector lever is in the P or N position (CVT models) or the clutch pedal is fully depressed (M/T

models).

Diagnosis Procedure INFOID:0000000001346392 C

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse. D

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT E

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift CVT selector lever to “P” or “N” position. (CVT models)

F

Press and hold the clutch pedal fully with the control lever in

neutral. (M/T models)

4. Check voltage between starter motor harness connector F28

terminal S and ground with the ignition in START. G

With ignition switch in START

S - ground Battery voltage H

ALBIA0503GB

Is battery voltage present?

YES >> “S” circuit is OK. Further inspection necessary. Refer to STR-27, "Work Flow".

NO >> GO TO 2 I

2.CHECK CONNECTOR

1. Turn ignition switch OFF. J

2. Check the following terminals and connectors for damage, bent pins and loose connections.

- IPDM E/R harness connector F10

- Starter motor harness connector F28

K

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector. L

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

- IPDM E/R connector F10 M

- Starter motor connector F28

2. Check continuity between starter motor harness connector F28

terminal S and IPDM E/R harness connector F10 terminal 80. N

S - 80 Continuity exists

Is there proper continuity between the two pins? O

YES >> Further inspection necessary. Refer to STR-27, "Work

Flow".

ALBIA0504GB

NO >> Repair the harness. P

Revision: July 2007 STR-33 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STARTING SYSTEM

Wiring Diagram - Coupe INFOID:0000000001346393

AWBWA0023GB

Revision: July 2007 STR-34 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STR

AWBWA0024GB

Revision: July 2007 STR-35 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

ALBIA0268GB

Revision: July 2007 STR-36 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STR

AWBIA0181GB

Revision: July 2007 STR-37 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

ALBIA0270GB

Revision: July 2007 STR-38 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STR

ALBIA0271GB

Revision: July 2007 STR-39 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

Wiring Diagram - Sedan INFOID:0000000003221760

AWBWA0115GB

Revision: July 2007 STR-40 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STR

AWBWA0116GB

Revision: July 2007 STR-41 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

AWBIA0420GB

Revision: July 2007 STR-42 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STR

ALBIA0269GB

Revision: July 2007 STR-43 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

AWBIA0421GB

Revision: July 2007 STR-44 2008 Altima

STARTING SYSTEM

< COMPONENT DIAGNOSIS > [VQ35DE]

STR

AWBIA0422GB

Revision: July 2007 STR-45 2008 Altima

STARTING SYSTEM

< SYMPTOM DIAGNOSIS > [VQ35DE]

SYMPTOM DIAGNOSIS

STARTING SYSTEM

Symptom Table INFOID:0000000001346394

Symptom Reference

No normal cranking

Refer to STR-27, "Work Flow".

Starter motor does not rotate

Revision: July 2007 STR-46 2008 Altima

PRECAUTIONS

< PRECAUTION > [VQ35DE]

PRECAUTION A

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT STR

PRE-TENSIONER" INFOID:0000000001346395

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along C

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted. D

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING: E

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

F

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this G

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

H

Revision: July 2007 STR-47 2008 Altima

PREPARATION

< PREPARATION > [VQ35DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000001346396

Tool number (Kent Moore No.)

Description

Tool name

(J-48087) Tests Battery.

Battery Service Center For operating instructions, refer to Technical

Service Bulletin and Battery Service Center

User Guide.

WKIA5280E

(J-44373) Model 620 Tests starting and charging systems.

Starting/Charging system tester For operating instructions, refer to Technical

Service Bulletin.

SEL403X

Commercial Service Tool INFOID:0000000001346397

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: July 2007 STR-48 2008 Altima

STARTER MOTOR

< ON-VEHICLE REPAIR > [VQ35DE]

ON-VEHICLE REPAIR A

STARTER MOTOR

Removal and Installation INFOID:0000000001346398

STR

M/T Models

REMOVAL C

1. Disconnect the negative battery terminal.

2. Disconnect the starter motor harness connectors.

D

3. Remove the two starter motor bolts, using power tools.

4. Remove the starter motor.

E

F

WKWA0065E

INSTALLATION G

Installation is in the reverse order of removal.

J

WKIA0394E

Removal and Installation INFOID:0000000001346399

K

CVT Models

REMOVAL

L

1. Disconnect the negative and positive battery terminal.

2. Remove the air cleaner assembly and air ducts.

3. Disconnect the following: M

• ECM

• CVT control unit (if equipped)

• IPDM/ER

N

4. Remove the battery tray. Refer to PG-132, "Removal and Installation".

5. Disconnect the starter harness connectors.

6. Remove the two starter bolts, using power tools. O

7. Remove the starter.

INSTALLATION

P

Revision: July 2007 STR-49 2008 Altima

STARTER MOTOR

< ON-VEHICLE REPAIR > [VQ35DE]

Installation is in the reverse order of removal.

WKIA0394E

Revision: July 2007 STR-50 2008 Altima

STARTER MOTOR

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS) A

STARTER MOTOR

Starter INFOID:0000000001346400

STR

Application VQ35DE

C

M/T model CVT model

Manufacturer Mitsubishi M000T87281ZC Mitsubishi M000T87181ZC

Type Reduction gear type D

System voltage 12V

Terminal voltage 11V

E

No-load Current 90A Max.

Revolution 2,800 rpm Min.

Minimum diameter of commutator 28.8 mm F

Minimum length of brush 7.0 mm

Brush spring tension 18.3-24.8 N (1.87-2.53 kg, 4.11-5.58 lb)

Clearance between pinion front edge and pinion stopper 0.5-2.0 mm G

Revision: July 2007 STR-51 2008 Altima

Potrebbero piacerti anche

- Nissan VG33E PDFDocumento100 pagineNissan VG33E PDFGabriel Balcazar88% (17)

- 22 Manual Nissan Sentra 2013Documento53 pagine22 Manual Nissan Sentra 2013David100% (1)

- State Farm Teen Driving A Handbook For Parents EnglDocumento15 pagineState Farm Teen Driving A Handbook For Parents EnglNarcisa RudnicNessuna valutazione finora

- Updated List of SBFZ Traffic Violations & PenaltiesDocumento3 pagineUpdated List of SBFZ Traffic Violations & Penaltiesmysubicbay50% (2)

- QR25DE Starting System GuideDocumento56 pagineQR25DE Starting System GuideDiego496Nessuna valutazione finora

- Starting System: SectionDocumento42 pagineStarting System: SectionLíder DieselNessuna valutazione finora

- Section: Body Exterior, Doors, Roof & Vehicle SecurityDocumento64 pagineSection: Body Exterior, Doors, Roof & Vehicle SecurityАндрей НадточийNessuna valutazione finora

- Road Wheels & Tires: SectionDocumento66 pagineRoad Wheels & Tires: SectionАндрей НадточийNessuna valutazione finora

- ENGINE STARTING SYSTEM GUIDEDocumento42 pagineENGINE STARTING SYSTEM GUIDEАндрей НадточийNessuna valutazione finora

- Road Wheels & Tires: SectionDocumento74 pagineRoad Wheels & Tires: SectionA_triniNessuna valutazione finora

- Road Wheels & Tires: SectionDocumento66 pagineRoad Wheels & Tires: SectionALexis IbacetaNessuna valutazione finora

- Engine Cooling System: SectionDocumento47 pagineEngine Cooling System: SectionOscar VillaseñorNessuna valutazione finora

- Brake System: SectionDocumento88 pagineBrake System: SectionA_triniNessuna valutazione finora

- WT PDFDocumento50 pagineWT PDFMisha KulibaevNessuna valutazione finora

- Electrical & Power Control GuideDocumento48 pagineElectrical & Power Control GuideАндрей Надточий100% (2)

- Charging System: SectionDocumento29 pagineCharging System: SectionMax SamNessuna valutazione finora

- Brake Control System Diagnosis and RepairDocumento277 pagineBrake Control System Diagnosis and RepairalvarodvNessuna valutazione finora

- Charging System: SectionDocumento55 pagineCharging System: Sectionjair Hernandez100% (1)

- WW PDFDocumento61 pagineWW PDFMisha KulibaevNessuna valutazione finora

- Cruise Control ModesDocumento34 pagineCruise Control Modesciro_svNessuna valutazione finora

- Starting System Diagnosis and RepairDocumento35 pagineStarting System Diagnosis and RepairGustavo Portilla MartinezNessuna valutazione finora

- Wiper & Washer: SectionDocumento64 pagineWiper & Washer: SectionbatozNessuna valutazione finora

- Brake Control System: SectionDocumento298 pagineBrake Control System: SectionLuis BarriosNessuna valutazione finora

- CHG PDFDocumento30 pagineCHG PDFSebastián PeñaNessuna valutazione finora

- Starting System Diagnosis and Repair WorkflowDocumento43 pagineStarting System Diagnosis and Repair WorkflowJuan Miguel Ossa OspinaNessuna valutazione finora

- Brake Control System: SectionDocumento317 pagineBrake Control System: SectionnyanhtunlimNessuna valutazione finora

- Wiper & Washer: SectionDocumento71 pagineWiper & Washer: SectionRonald Yucra CadenaNessuna valutazione finora

- Engine Cooling System: SectionDocumento87 pagineEngine Cooling System: SectionLuis BarriosNessuna valutazione finora

- Drive Mode System: SectionDocumento36 pagineDrive Mode System: SectionPlatinumNessuna valutazione finora

- Wiper & Washer: SectionDocumento81 pagineWiper & Washer: SectionGustavo Portilla MartinezNessuna valutazione finora

- Wiper & Washer: SectionDocumento115 pagineWiper & Washer: SectionSlava SlickNessuna valutazione finora

- PB PDFDocumento95 paginePB PDFMisha KulibaevNessuna valutazione finora

- CHG Altima L32Documento30 pagineCHG Altima L32Henry SilvaNessuna valutazione finora

- Nissan-Versa 2015 EN US Manual de Taller Ecu Modulo Carroceria Relay-Of-Ventilador Radiador Etc A21c4b9aaa.Documento72 pagineNissan-Versa 2015 EN US Manual de Taller Ecu Modulo Carroceria Relay-Of-Ventilador Radiador Etc A21c4b9aaa.victor borjaNessuna valutazione finora

- Brake Control System: SectionDocumento120 pagineBrake Control System: SectionsalusfrankNessuna valutazione finora

- Wiper & Washer: SectionDocumento284 pagineWiper & Washer: SectionTESA MOTORS100% (1)

- Engine Cooling System: SectionDocumento60 pagineEngine Cooling System: SectionsggtanleyNessuna valutazione finora

- 2012 Nissan Leaf 27Documento95 pagine2012 Nissan Leaf 27Eva Hoytema van KonijnenburgNessuna valutazione finora

- Wiper & Washer: SectionDocumento97 pagineWiper & Washer: SectionjapaxploseNessuna valutazione finora

- PcsDocumento71 paginePcsgsmsbyNessuna valutazione finora

- Nissan-Versa 2015 en US Manual de Taller Sapito Limpia Parabrisas Bomba Limpiaparabrisas A51af0976eDocumento57 pagineNissan-Versa 2015 en US Manual de Taller Sapito Limpia Parabrisas Bomba Limpiaparabrisas A51af0976eBetth GaytanNessuna valutazione finora

- SNDocumento35 pagineSNluis CebergNessuna valutazione finora

- Engine Cooling System: SectionDocumento31 pagineEngine Cooling System: SectionAgustin Borge GarciaNessuna valutazione finora

- BRC PDFDocumento115 pagineBRC PDFWilderReyesSilvaNessuna valutazione finora

- Brakes ControlDocumento277 pagineBrakes ControlGabriel BalcazarNessuna valutazione finora

- WW PDFDocumento86 pagineWW PDFalexNessuna valutazione finora

- Starting System: SectionDocumento37 pagineStarting System: SectioncesarNessuna valutazione finora

- BRAKE CONTROL SYSTEM DIAGNOSISDocumento92 pagineBRAKE CONTROL SYSTEM DIAGNOSISPauloNessuna valutazione finora

- Murano 2009Documento138 pagineMurano 2009alexNessuna valutazione finora

- Driver controls guide to wiper and washer diagnosisDocumento138 pagineDriver controls guide to wiper and washer diagnosisalexNessuna valutazione finora

- Section: Body InteriorDocumento39 pagineSection: Body Interiorjair HernandezNessuna valutazione finora

- Charging System: SectionDocumento31 pagineCharging System: Sectionratatrampa25Nessuna valutazione finora

- Engine Cooling System: SectionDocumento48 pagineEngine Cooling System: SectionAsghar AnjumNessuna valutazione finora

- Road Wheels & Tires: SectionDocumento60 pagineRoad Wheels & Tires: Sectiondmitry esaulkovNessuna valutazione finora

- Steering Control System: SectionDocumento50 pagineSteering Control System: SectionАндрей НадточийNessuna valutazione finora

- 21. WT - КОЛЁСА И ШИНЫDocumento71 pagine21. WT - КОЛЁСА И ШИНЫНаталья Ч.Nessuna valutazione finora

- Road Wheels & Tires: SectionDocumento75 pagineRoad Wheels & Tires: Sectionjair HernandezNessuna valutazione finora

- Power Control System: SectionDocumento74 paginePower Control System: SectionErick Gonzalo ChincheNessuna valutazione finora

- Cruise & Driver Assist GuideDocumento76 pagineCruise & Driver Assist GuideJuan Carlos Velasquez100% (1)

- Body, Lock & Security System: SectionDocumento182 pagineBody, Lock & Security System: SectionDorusNessuna valutazione finora

- Nissan Sentra 2012 DIDocumento77 pagineNissan Sentra 2012 DIDagoberto MoralesNessuna valutazione finora

- Av PDFDocumento180 pagineAv PDFRuben E. Aguilar LazarteNessuna valutazione finora

- Teardowns: Learn How Electronics Work by Taking Them ApartDa EverandTeardowns: Learn How Electronics Work by Taking Them ApartNessuna valutazione finora

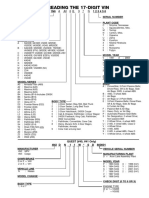

- Reading The 17-Digit Vin: 1N6 A A0 6 B 9 7 N 1 2 3 4 5 6Documento1 paginaReading The 17-Digit Vin: 1N6 A A0 6 B 9 7 N 1 2 3 4 5 6Luis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Revised TPS Adjustment ProcedureDocumento4 pagineRevised TPS Adjustment ProcedureEdith SanchezNessuna valutazione finora

- Pathfinder 1997 Quick Reference Engine: Tune UpDocumento18 paginePathfinder 1997 Quick Reference Engine: Tune UpJoel DelgadoNessuna valutazione finora

- BRM PDFDocumento102 pagineBRM PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Diagrama Seguros Switch 3 Patas - PNGDocumento1 paginaDiagrama Seguros Switch 3 Patas - PNGLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Charging System: SectionDocumento28 pagineCharging System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- 1996 - 1999 Nissan Pathfinder (R50) Automatic To Manual Transmission Conversion ManualDocumento24 pagine1996 - 1999 Nissan Pathfinder (R50) Automatic To Manual Transmission Conversion ManualLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Diagrama Seguros Alarma - PNGDocumento1 paginaDiagrama Seguros Alarma - PNGLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Pathfinder 1994 Quick Reference Engine: Tune UpDocumento20 paginePathfinder 1994 Quick Reference Engine: Tune UpLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- ST PDFDocumento32 pagineST PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Pathfinder 1994 Quick Reference Engine: Tune UpDocumento20 paginePathfinder 1994 Quick Reference Engine: Tune UpLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- ST PDFDocumento32 pagineST PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Steering Control System Diagnosis GuideDocumento23 pagineSteering Control System Diagnosis GuideLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- CL PDFDocumento16 pagineCL PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Engine Cooling System: SectionDocumento48 pagineEngine Cooling System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Charging System: SectionDocumento28 pagineCharging System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- SRC PDFDocumento87 pagineSRC PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Cruise Control System: SectionDocumento4 pagineCruise Control System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- BRM PDFDocumento102 pagineBRM PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Av PDFDocumento447 pagineAv PDFAdrian VilleNessuna valutazione finora

- BRC PDFDocumento241 pagineBRC PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- AutomovelDocumento5 pagineAutomovelCarlos BraiaNessuna valutazione finora

- Brake System: SectionDocumento42 pagineBrake System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- AutomovelDocumento5 pagineAutomovelCarlos BraiaNessuna valutazione finora

- ISUZU - Manual Common Rail Motor Isuzu 6DE1-1 PDFDocumento35 pagineISUZU - Manual Common Rail Motor Isuzu 6DE1-1 PDFAngelNessuna valutazione finora

- Body Control System: SectionDocumento88 pagineBody Control System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Body Control System: SectionDocumento88 pagineBody Control System: SectionLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- BRC PDFDocumento241 pagineBRC PDFLuis Alfonso Ortiz ESpinosaNessuna valutazione finora

- Electrical SystemDocumento576 pagineElectrical SystemAilan KnightsNessuna valutazione finora

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocumento1 paginaNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comNessuna valutazione finora

- Mvss206 Door LockDocumento51 pagineMvss206 Door LockPratik_rush2905Nessuna valutazione finora

- Perodua Nautica BrochureDocumento12 paginePerodua Nautica BrochureMeor Amri100% (1)

- Rexton II 2006 User ManualsDocumento322 pagineRexton II 2006 User ManualsPablo Villagran100% (1)

- 2011 Jetta Specifications SheetDocumento13 pagine2011 Jetta Specifications SheetVolkswagen of AmericaNessuna valutazione finora

- Bus SpecificationDocumento22 pagineBus Specificationmouds22Nessuna valutazione finora

- Electricalor SystemDocumento5 pagineElectricalor SystemyonasNessuna valutazione finora

- Fit For Every Fam.: The All-New Toyota AvanzaDocumento2 pagineFit For Every Fam.: The All-New Toyota AvanzaAllyson BautistaNessuna valutazione finora

- Ssangyong Rexton BrochureDocumento32 pagineSsangyong Rexton BrochureJuan de las heras calvoNessuna valutazione finora

- Cessna 152A Information ManualDocumento12 pagineCessna 152A Information ManualtanmayNessuna valutazione finora

- Manual For Alfa Romeo 156Documento358 pagineManual For Alfa Romeo 156Jean Machuca100% (2)

- Polo Brochure 10 2008Documento28 paginePolo Brochure 10 2008Mare Care100% (1)

- Peugeot Expert Prices and SpecificationsDocumento12 paginePeugeot Expert Prices and SpecificationsBrandon WilliamsNessuna valutazione finora

- 2014 Ford Escape 2.5L - E104 E214 E224 E404 E414Documento1 pagina2014 Ford Escape 2.5L - E104 E214 E224 E404 E414Ankit ChawlaNessuna valutazione finora

- Restraint System Diagnostics and DTC ReferenceDocumento88 pagineRestraint System Diagnostics and DTC ReferencechrideerNessuna valutazione finora

- Automobile Safety NotesDocumento40 pagineAutomobile Safety Notesgkarthikeyan100% (1)

- Peugeot 408 Press Info EnglishDocumento19 paginePeugeot 408 Press Info Englishanthonykylim100% (1)

- Electric Forklift Stability and Control FeaturesDocumento2 pagineElectric Forklift Stability and Control FeaturesTRM100% (1)

- Mitsubishi ASXDocumento15 pagineMitsubishi ASXreadalotbutnowisdomyetNessuna valutazione finora

- 2 AS No Man Is An IslandDocumento3 pagine2 AS No Man Is An Islandmaian sajaNessuna valutazione finora

- Defensive DrivingDocumento48 pagineDefensive DrivingWyn Kennedy JimenezNessuna valutazione finora

- Korando SUV Style and PracticalityDocumento10 pagineKorando SUV Style and PracticalitydotorelNessuna valutazione finora

- Mazda Bt-50 AncapDocumento2 pagineMazda Bt-50 AncapcarbasemyNessuna valutazione finora

- Owner S Manual: It Contains Important Safety InformationDocumento55 pagineOwner S Manual: It Contains Important Safety InformationwhyspeedflyNessuna valutazione finora

- Cube Harnesssystem Cargo Bike Manual de enDocumento5 pagineCube Harnesssystem Cargo Bike Manual de enapi-652055634Nessuna valutazione finora

- Transmission Diagnostics and RepairDocumento257 pagineTransmission Diagnostics and Repairjulio797100% (1)