Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Optimize Chillers in Parallel: Central Plant Water Chiller Optimization 263

Caricato da

Rohit Shrestha0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni2 pagineThis document discusses optimizing multiple chillers that are piped in parallel by installing dedicated pumps for each chiller and valves to isolate offline chillers. This allows the online chillers and pumps to operate more efficiently at lighter cooling loads instead of circulating water through all chillers. Variable speed pumps can also be used to further optimize flow to match varying loads. Diagrams show how a variable flow system with chillers in parallel and a bypass loop allows the dedicated chiller pumps to turn off at lighter loads while variable speed system pumps supply flow through the online chillers and bypass loop.

Descrizione originale:

Titolo originale

1 (4)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses optimizing multiple chillers that are piped in parallel by installing dedicated pumps for each chiller and valves to isolate offline chillers. This allows the online chillers and pumps to operate more efficiently at lighter cooling loads instead of circulating water through all chillers. Variable speed pumps can also be used to further optimize flow to match varying loads. Diagrams show how a variable flow system with chillers in parallel and a bypass loop allows the dedicated chiller pumps to turn off at lighter loads while variable speed system pumps supply flow through the online chillers and bypass loop.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni2 pagineOptimize Chillers in Parallel: Central Plant Water Chiller Optimization 263

Caricato da

Rohit ShresthaThis document discusses optimizing multiple chillers that are piped in parallel by installing dedicated pumps for each chiller and valves to isolate offline chillers. This allows the online chillers and pumps to operate more efficiently at lighter cooling loads instead of circulating water through all chillers. Variable speed pumps can also be used to further optimize flow to match varying loads. Diagrams show how a variable flow system with chillers in parallel and a bypass loop allows the dedicated chiller pumps to turn off at lighter loads while variable speed system pumps supply flow through the online chillers and bypass loop.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Central Plant Water Chiller Optimization 263

Increasing chiller and coil temperature differential will re-

duce the flow rate or gpm required.

Optimize Chillers in Parallel

In some multiple-chiller operations, with chillers piped in

parallel, chilled water is always circulated through all the chillers

even when only one chiller is operating to meet a light cooling

load demand. The result of this process results in wasted pump

energy. The situation requires that the on-line chiller operate at a

low evaporator temperature to produce chilled water at tempera-

tures to meet the desired supply water temperature and offset the

mixing effect of the water being circulated through the off-line

chillers. COP is reduced and horsepower rises.

Optimizing a parallel-piped system requires the installation

of multiple pumps, one for each chiller. Each pump is selected

and balanced for the gpm required and interlocked with its asso-

ciated chiller. Isolating valves that close when a chiller goes off-

line are installed on each chiller. Then, under lighter loads off-line

chillers will be isolated. Only on-line chillers and pumps will be

operating, thus reducing pumping horsepower. The on-line chill-

ers will operate at evaporator and water temperatures to meet the

load. Pumping horsepower will drop by the cube [HP2 = HPl ×

(gpm2/gpml)3] if the chilled water volume through the chiller can

be reduced and the pump impeller trimmed. Another solution,

instead of multiple chilled water pumps, is the installation of a

multi-speed or variable drive on the present pump to make it

multi- or variable volume.

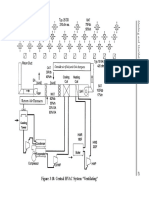

When greater water volume is required in the system than

can be supplied by on-line chillers consider installing variable

volume system pumps sized for the critical load and a bypass

(uncoupler or common loop) around the chillers. Each chiller

has a dedicated constant volume pump. At lighter loads the

chillers and the dedicated pumps go off-line and the system

pumps draw through the bypass (common or uncoupler loop)

and from the on-line chillers to satisfy the load (Figure 16-1,

operations 1-5).

264 HVAC Fundamentals

Figure 16-1. Variable flow chilled water system, chillers in parallel.

Figure 16-1 Operation 1—Maximum Flow (2000 gpm)

1. Both chillers and their associated pumps are operating. The

pumps are constant speed and volume. Each pump, when

on, moves 1000 gpm, a total of 2000 gpm.

2. The thermostats in the system are calling for full flow (full

cooling), 2000 gpm.

3. Both system pumps are operating. The pumps are variable

speed and volume. At maximum flow each pump is moving

1000 gpm, a total of 2000 gpm.

4. Water leaves the chillers at 45°F, goes through the coils where

it picks up heat, and returns to the chillers at 55°F.

Figure 16-1 Operation 2—Reduced Flow (1500 gpm)

1. Both chillers and their associated pumps are operating. The

Potrebbero piacerti anche

- Standard Operating Procedure - HVAC - V01 - 29082010Documento10 pagineStandard Operating Procedure - HVAC - V01 - 29082010Karthik MandyaNessuna valutazione finora

- CoolingDocumento26 pagineCoolingShahrukh AnsariNessuna valutazione finora

- Heat Pumps - ArticleDocumento6 pagineHeat Pumps - Articlearnol_fo2Nessuna valutazione finora

- Variation In Refrigeration Coefficient Of PerformanceDocumento17 pagineVariation In Refrigeration Coefficient Of PerformanceSyahirzabidiNessuna valutazione finora

- Design and Implementation of Computerized Child Care Information SystemDocumento40 pagineDesign and Implementation of Computerized Child Care Information Systemchukwu solomon33% (3)

- HVAC Primary and Secondary Pumps 8Documento33 pagineHVAC Primary and Secondary Pumps 8Anonymous qxOHkF100% (2)

- Optimize Central Plant Water Chiller SystemDocumento2 pagineOptimize Central Plant Water Chiller SystemRohit ShresthaNessuna valutazione finora

- Basecase Water Side As Per ASHRAE 90.1 (05!12!22)Documento10 pagineBasecase Water Side As Per ASHRAE 90.1 (05!12!22)chakka nagendra subrahmanyamNessuna valutazione finora

- Avery 112Documento5 pagineAvery 112Leed ENNessuna valutazione finora

- Central Plant Water Chiller Optimization 265: Figure 16-1 Operation 3-Reduced Flow (1200 GPM)Documento2 pagineCentral Plant Water Chiller Optimization 265: Figure 16-1 Operation 3-Reduced Flow (1200 GPM)rohitNessuna valutazione finora

- HVAC ControlsDocumento24 pagineHVAC ControlsKunal DeshmukhNessuna valutazione finora

- Ishrae Variable Volume Pumping SystemDocumento14 pagineIshrae Variable Volume Pumping SystemAidrus AliNessuna valutazione finora

- Parallel ChillerDocumento2 pagineParallel ChillerSharon LambertNessuna valutazione finora

- Water Cooled Chiller GuideDocumento5 pagineWater Cooled Chiller GuideMUHAMMAD TAHANessuna valutazione finora

- HVAC Chilled Water Distribution SchemesDocumento56 pagineHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Leading in the World of BIMDocumento35 pagineLeading in the World of BIMRobby Renz100% (1)

- Constant Volume - Constant Speed. Chilled Water Systems. Chillers Pumps & PiDocumento3 pagineConstant Volume - Constant Speed. Chilled Water Systems. Chillers Pumps & PiMohamed AdelNessuna valutazione finora

- Chiller Loading StrategyDocumento4 pagineChiller Loading StrategyRafael Echano AcederaNessuna valutazione finora

- Optimize Central Plant Water ChillersDocumento2 pagineOptimize Central Plant Water ChillersRohit ShresthaNessuna valutazione finora

- Heat Pumps Water WaterDocumento105 pagineHeat Pumps Water Wateratisz333Nessuna valutazione finora

- RAC Refrigeration System ExplainedDocumento7 pagineRAC Refrigeration System ExplainedMuhammad AkhtarNessuna valutazione finora

- Simplifying Contemporary HVAC Piping: by James B. (Burt) Rishel, P.E., Fellow/Life Member ASHRAEDocumento7 pagineSimplifying Contemporary HVAC Piping: by James B. (Burt) Rishel, P.E., Fellow/Life Member ASHRAEbradalbicomcastNessuna valutazione finora

- 3 Dk2831 - ch35 EvaporadoresDocumento10 pagine3 Dk2831 - ch35 EvaporadoresHarold Valle ReyesNessuna valutazione finora

- Chiller Plant LectureDocumento10 pagineChiller Plant LectureGrano PrabumuktiNessuna valutazione finora

- NPTI (SR) Scheme Tracing Report TSIIDocumento62 pagineNPTI (SR) Scheme Tracing Report TSIIiwantinthatve75% (4)

- Engine cooling system componentsDocumento5 pagineEngine cooling system componentsAdnan ParkerNessuna valutazione finora

- Free Cooling Types and ControlsDocumento2 pagineFree Cooling Types and ControlsHnin PwintNessuna valutazione finora

- Chapter 4 HRSGDocumento39 pagineChapter 4 HRSGGloria Del Carmen Muñoz100% (1)

- Refrigeration and LiquefactionDocumento51 pagineRefrigeration and LiquefactionAlbert ShesmanNessuna valutazione finora

- Chapter Two Literature Review 2.1 Technical Feasibility StudyDocumento20 pagineChapter Two Literature Review 2.1 Technical Feasibility StudymutencoNessuna valutazione finora

- Efficient Chilled Water Piping Systems ExplainedDocumento48 pagineEfficient Chilled Water Piping Systems Explainedryxor-mrbl100% (1)

- Chiller MCQDocumento3 pagineChiller MCQHibaNessuna valutazione finora

- Chilled Water SystemsDocumento10 pagineChilled Water SystemsLavanya...100% (5)

- Energy Efficient Buildings Energy Efficient Cooling Plants: Chiller Plant ControlDocumento10 pagineEnergy Efficient Buildings Energy Efficient Cooling Plants: Chiller Plant ControlAnonymous 7CnrWpzZf1Nessuna valutazione finora

- HRSGDocumento24 pagineHRSGsathishsggsNessuna valutazione finora

- Report Technical Vol41 - 3Documento8 pagineReport Technical Vol41 - 3rojanmathewNessuna valutazione finora

- Vapor Jet RefrigeratorDocumento11 pagineVapor Jet RefrigeratorAlyan YousafNessuna valutazione finora

- Chiller BasicsDocumento38 pagineChiller BasicsGiftson ImmanuelNessuna valutazione finora

- Lecture 6 RefrigerationDocumento65 pagineLecture 6 RefrigerationRamon Gerald AsiloNessuna valutazione finora

- Chilled Water Systems GuideDocumento31 pagineChilled Water Systems Guide123john123100% (1)

- Operation and Maintenance of HVAC Water SystemDocumento8 pagineOperation and Maintenance of HVAC Water SystemHenry SuarezNessuna valutazione finora

- Vapor Compression Cycle (History) : (Schmidt Et Al., 2002)Documento8 pagineVapor Compression Cycle (History) : (Schmidt Et Al., 2002)jess calderonNessuna valutazione finora

- Performance Analysis of Regenerative Feed Water Heating System in 270 MW Thermal Power PlantDocumento7 paginePerformance Analysis of Regenerative Feed Water Heating System in 270 MW Thermal Power PlantFirman Adi SusetyoNessuna valutazione finora

- Water Side As Per Ashrae 90-05-12-2022Documento17 pagineWater Side As Per Ashrae 90-05-12-2022chakka nagendra subrahmanyamNessuna valutazione finora

- Water Distribution: Cross Connection Control Water ConservationDocumento10 pagineWater Distribution: Cross Connection Control Water ConservationOwolabi RuthNessuna valutazione finora

- WP024 PDFDocumento6 pagineWP024 PDFRizki LarasatiNessuna valutazione finora

- How Heat Pumps Reverse Natural Heat Transfer Using RefrigerantsDocumento2 pagineHow Heat Pumps Reverse Natural Heat Transfer Using RefrigerantsanandanNessuna valutazione finora

- Module 3 - Chiller SystemDocumento45 pagineModule 3 - Chiller Systemmadan karkiNessuna valutazione finora

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDa EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- Air Conditioning Condenser GuideDocumento2 pagineAir Conditioning Condenser GuideRohit ShresthaNessuna valutazione finora

- Figure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Documento2 pagineFigure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Rohit ShresthaNessuna valutazione finora

- Air Conditioning Systems 51Documento2 pagineAir Conditioning Systems 51rohitNessuna valutazione finora

- Figure 4-1. Central HVAC System "Air Conditioning"Documento2 pagineFigure 4-1. Central HVAC System "Air Conditioning"rohitNessuna valutazione finora

- Air Conditioning Systems 69: Heat Pump (Air-Air)Documento2 pagineAir Conditioning Systems 69: Heat Pump (Air-Air)Rohit ShresthaNessuna valutazione finora

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocumento2 pagineAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNessuna valutazione finora

- 1 PDFDocumento2 pagine1 PDFRohit ShresthaNessuna valutazione finora

- 1 PDFDocumento2 pagine1 PDFRohit ShresthaNessuna valutazione finora

- Compressors: Chapter FiveDocumento2 pagineCompressors: Chapter FiveRohit ShresthaNessuna valutazione finora

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Documento2 pagineAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNessuna valutazione finora

- Air Conditioning Systems 57Documento2 pagineAir Conditioning Systems 57rohitNessuna valutazione finora

- Figure 4-.2 Air Conditioning System ExampleDocumento2 pagineFigure 4-.2 Air Conditioning System ExamplerohitNessuna valutazione finora

- Heating and Ventilating Systems 43: MAT (%OA ×Documento2 pagineHeating and Ventilating Systems 43: MAT (%OA ×rohitNessuna valutazione finora

- Air Conditioning Systems 55Documento2 pagineAir Conditioning Systems 55rohitNessuna valutazione finora

- Figure 3-10. Central HVAC System "Ventilating"Documento2 pagineFigure 3-10. Central HVAC System "Ventilating"rohitNessuna valutazione finora

- 1 PDFDocumento2 pagine1 PDFRohit ShresthaNessuna valutazione finora

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocumento2 pagineHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNessuna valutazione finora

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocumento2 pagineHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNessuna valutazione finora

- 1 PDFDocumento2 pagine1 PDFrohitNessuna valutazione finora

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocumento2 pagineFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNessuna valutazione finora

- Heating and Ventilating Systems 33Documento2 pagineHeating and Ventilating Systems 33rohitNessuna valutazione finora

- Heating and Ventilating Systems 25Documento2 pagineHeating and Ventilating Systems 25rohitNessuna valutazione finora

- Heat Flow 17: ConductionDocumento2 pagineHeat Flow 17: ConductionrohitNessuna valutazione finora

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocumento2 pagineHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNessuna valutazione finora

- Heating and Ventilating Systems 27Documento2 pagineHeating and Ventilating Systems 27rohitNessuna valutazione finora

- HVAC Systems 13: VentilatingDocumento2 pagineHVAC Systems 13: VentilatingrohitNessuna valutazione finora

- Heating and Ventilating Systems 35Documento2 pagineHeating and Ventilating Systems 35rohitNessuna valutazione finora

- Heat Flow 15Documento2 pagineHeat Flow 15rohitNessuna valutazione finora

- Air Volume: HVAC Systems 11Documento2 pagineAir Volume: HVAC Systems 11rohitNessuna valutazione finora

- Latent HeatDocumento2 pagineLatent HeatrohitNessuna valutazione finora

- A40-10-112 06a FAADocumento3 pagineA40-10-112 06a FAAPolkaboy2Nessuna valutazione finora

- CimatronDocumento20 pagineCimatronsagarbolisettiNessuna valutazione finora

- ERPnext System FeaturesDocumento4 pagineERPnext System FeaturesMohammed Abdulsalam Esmail AbdullahNessuna valutazione finora

- Pcs 7Documento34 paginePcs 7Josh JoshNessuna valutazione finora

- Kelebihan Heat PumpDocumento1 paginaKelebihan Heat PumpAgungNessuna valutazione finora

- Section-1 MiddlewareDocumento4 pagineSection-1 MiddlewareIberisNessuna valutazione finora

- Global Business Management of Clever Tap: Report SubmissionDocumento25 pagineGlobal Business Management of Clever Tap: Report SubmissionkaranNessuna valutazione finora

- 30HXCDocumento2 pagine30HXCvbharath21100% (1)

- Automation in Manufacturing Unit-1Documento58 pagineAutomation in Manufacturing Unit-1Krishna MurthyNessuna valutazione finora

- The Future of HR in Oil & Gas: Managing Talent in a Disrupted IndustryDocumento8 pagineThe Future of HR in Oil & Gas: Managing Talent in a Disrupted IndustryRubens Correa Sarafim JuniorNessuna valutazione finora

- Gantt Chart of Scada Project 2020 Pt. Petrosea, TBKDocumento1 paginaGantt Chart of Scada Project 2020 Pt. Petrosea, TBKTyas UtamiNessuna valutazione finora

- Mustafa Cem Aldag Bulent Eker: What Is Quality 4.0 in The Era of Industry 4.0?Documento4 pagineMustafa Cem Aldag Bulent Eker: What Is Quality 4.0 in The Era of Industry 4.0?Tieu Yen TuNessuna valutazione finora

- 0105DB0305 PDFDocumento9 pagine0105DB0305 PDFtintucinbNessuna valutazione finora

- Color Sorting System Using Arduino NanoDocumento7 pagineColor Sorting System Using Arduino NanoIJRASETPublicationsNessuna valutazione finora

- Fabricator201911 DL PDFDocumento144 pagineFabricator201911 DL PDFluis bolmoNessuna valutazione finora

- Cops PDFDocumento8 pagineCops PDFnairam2003Nessuna valutazione finora

- AcuBeam v2 - XX Laser Galvo Control Software User's GuideDocumento158 pagineAcuBeam v2 - XX Laser Galvo Control Software User's GuidemmtrybaNessuna valutazione finora

- Voltas Profile in Process RefrigerationDocumento1 paginaVoltas Profile in Process Refrigerationkamal_muralikumarNessuna valutazione finora

- TPS and Its Functional AspectsDocumento24 pagineTPS and Its Functional Aspectsanahad VaidyaNessuna valutazione finora

- BN RPL96 2Documento56 pagineBN RPL96 2chrsolvegNessuna valutazione finora

- An Introduction of Aimil Ltd. World of Instrumentation and TechnologyDocumento28 pagineAn Introduction of Aimil Ltd. World of Instrumentation and TechnologyAimilNessuna valutazione finora

- Dokumen - Tips 168336354 Automation Studio 6 0 Crack DownloadDocumento3 pagineDokumen - Tips 168336354 Automation Studio 6 0 Crack Downloadmesbah mNessuna valutazione finora

- General Brochure - Johnson ControlsDocumento4 pagineGeneral Brochure - Johnson Controlst_i_f_anoNessuna valutazione finora

- Communication and Wireless Sensor Topics ListDocumento3 pagineCommunication and Wireless Sensor Topics ListSabari NathanNessuna valutazione finora

- PLC To Deltav Systems MigrationDocumento14 paginePLC To Deltav Systems MigrationzacriasNessuna valutazione finora

- NJ NX P089-E1 3 3 csm1042739 PDFDocumento35 pagineNJ NX P089-E1 3 3 csm1042739 PDFDaniel DumitruNessuna valutazione finora

- 1 s2.0 S0968090X19300270 MainDocumento18 pagine1 s2.0 S0968090X19300270 MainDavid PadialNessuna valutazione finora

- Honeywell - Pro1000 User ManualDocumento48 pagineHoneywell - Pro1000 User ManualRubens KunNessuna valutazione finora

- Shaangu Group Brochure 2017Documento22 pagineShaangu Group Brochure 2017zzgiadinhzz0% (1)