Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pile Foundation: Classification of Pile Foundations

Caricato da

Prabhakar SvTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pile Foundation: Classification of Pile Foundations

Caricato da

Prabhakar SvCopyright:

Formati disponibili

BUILDING WORLD CLASS CIVIL CAPABILITIES | 3rd July 2018 | Issue - 13

Pile Foundation Classification of Pile foundations:

Pile foundations are deep foundations used when the site The pile foundations are classified based on load carrying characteristic of piles, material of pile construction and type of soil.

has a weak shallow bearing stratum making it necessary to

transfer load to a deeper stratum either by friction or end

bearing principles. Foundations provide support for Based on Load Transmission Based on Material of Pile construction Based on effect of Soil

structures by transferring the load to the rock or layers of

soil that have sufficient bearing capacity and suitable 1. End bearing piles (Point 1. Timber piles 1. Driven piles

settlement characteristics. A wide range of foundation bearing) Timber can be used for shorter depth and manufacture of temporary In this process of driving of pile

types are available, which are suitable for different These transmit most of their loads to the load piles and for permanent ones in regions where timber is readily and into the ground, soil is moved

applications. Foundations are classified mainly as Shallow bearing layer (which can be dense sand or economically available. It is most suitable for long cohesion piling radially when the pile shaft

foundations and Deep foundations. rock). Most of the pile capacity is inferred from and piling under embankments. enters the ground. There may

the end bearing point. 2. Steel piles exist a component of

Steel can be used for marine works. They are suitable for handling movement of soil in the

and driving for piles with prolonged lengths. Their relatively small vertical direction. Hence

cross-sectional area along with the high strength makes penetration driven piles are considered as

easier in firm soil. If it is driven in to a soil with low Ph value, there displacement piles.

Pile foundation

may occur a risk of corrosion, which can be eliminated by tar coating 2. Bored piles

or cathodic protection. In this process, a void is formed

3. Concrete piles by boring or excavation before

Concrete is used to manufacture precast concrete piles, cast in place pile is introduced into the

and pre-stressed concrete piles. Pre-stressed concrete piles are ground. Piles can be produced

2. Friction piles: gaining more popularity than the ordinary pre-cast, as less by casting concrete in the void.

These transmit their load through the layers reinforcement is required and are commonly used in construction Boring piles are considered as

through which the piles pass, which is mostly industry. non-displacement piles.

Different cross sections used for steel piles

through the surface friction (skin friction) with 4. Composite piles

Shallow foundations are used where the load imposed by the surrounding soils. Here, the piles are driven When a pile consists of a combination of different materials in the

a structure is low, relative to bearing capacity of surface to such a depth that the frictional resistance, same pile, it is called as Composite pile. For example, part of timber

soils. Deep foundations are necessary where the which is developed at the side of the piles pile which is installed above ground water might get exposed to

bearing capacity of the surface soil is insufficient to equals the load coming on the piles. insect attack and decay. So, to avoid this, concrete or steel pile is

support load imposed on it and hence they are transferred used above ground water level, whilst timber is installed for under-

to deeper layers with high bearing capacity. ground water level.

Pile foundations are deep foundations, which are formed

by long slender columnar elements. They consist of two

components: Pile cap and single or group of piles. Pile

foundations are principally used to transfer the load from

super structure, through weak compressible strata or

water on to stronger, more compact, less compressible

and stiffer soil or rock. This type of foundation is used for

large structures and in situations where the soil is not

2. Steel Piles 4. Composite Piles

suitable to prevent excessive settlement.

Pile Installation Methods Pile Construction

Cast-in-place piles are made in the following steps:

Boring methods (non-displacement piles) 1. Hammer a thin-walled steel tube into the ground

Pile Installation Methods 2. Remove all earth left inside the tube

In pile foundations, Installation process and methods of installation are Continuous Flight Auger (CFA): If boring and pouring takes place

simultaneously during pile driving, then they are called CFA piles. Here 3. Lower a steel reinforcement cage into the tube

as important as the design process. During the design of piles, 4. Cast the pile by pouring wet concrete into the tube

the installation method and equipment should be carefully selected to the equipment comprises of a mobile base carrier fitted with a hollow

main flight auger, which is rotated and driven into the ground to get the The thin walled steel tube is called the casing, and only serves to

avoid the damages to the pile. form a secure mould for casting concrete that is free from earth

required depth of piling. This method is especially effective on soft

Pile driving methods (displacement piles) ground. and debris. It has no structural role to play after the casting is

Dropping weight: A hammer with approximately the weight of the complete.

Underreaming: This is a special type of auger bored piles, which is used

pile is raised to a suitable height and is released to strike the pile head. Some soils are highly cohesive, meaning that if one drills a hole into

to exploit the bearing capacity of respective strata by providing an

Vibration: The amplitude enlarged base. The soil can stand open unsupported to employ this the soil that is say 1 foot wide by 50 feet deep, then the soil holds

of vibration used here technique. the shape of the hole and does not collapse into the hole and block

should be sufficient to it. If such soil is present at the site, then one does not need to leave

break the skin friction on a casing in place: one can use the casing to drill the hole for the pile,

sides of pile. This is best remove it, and then cast the pile in place. This saves cost, as the

suited for sandy or same casing tube can be used to drill holes for all the piles.

gravelly soils. Precast Driven Piles are first cast at ground level and then

Jacking (only for micro hammered or driven into the ground using a pile driver. This is a

piles): To install jacking machine that holds the pile perfectly vertical, and then hammers it

piles, Hydraulic rams are into the ground blow by blow. Each blow is struck by lifting a heavy

used to push piles into the weight and dropping it on the top of the pile - the pile is

ground temporarily covered with a steel cap to prevent it from

Jetting: To aid the disintegrating. The pile driver thus performs two functions - first, it

penetration of piles in to acts as a crane, and lifts the pile from a horizontal position on the

sand or sand gravel, water Underreaming tool open Continuous Flight Auger process ground and rotates it into the correct vertical position, and second,

Pile driving using hammer jetting can be employed. position it hammers the pile down into the ground.

Potrebbero piacerti anche

- Final Folio Jacquelineo BrienDocumento62 pagineFinal Folio Jacquelineo BrienSimona David100% (1)

- Method Statement For Drywall PartitionDocumento5 pagineMethod Statement For Drywall PartitionAr John Ronald Ladaban100% (2)

- Pile vs Well Foundation ComparisonDocumento16 paginePile vs Well Foundation Comparisongvgbabu100% (4)

- FOUNDATIONS: Types, Design, and Failure CausesDocumento14 pagineFOUNDATIONS: Types, Design, and Failure CausesShiwangi NagoriNessuna valutazione finora

- Pile Foundation NotesDocumento11 paginePile Foundation Notesramya manirajanNessuna valutazione finora

- Chapter 1-Pile Foundations-Lecture NoteDocumento79 pagineChapter 1-Pile Foundations-Lecture NoteManal EsmaelNessuna valutazione finora

- Btech FoundationsDocumento17 pagineBtech Foundationsjohn100% (1)

- ITP-NMFOC - Type TestDocumento6 pagineITP-NMFOC - Type TestPrabhakar SvNessuna valutazione finora

- Project progress report with construction delaysDocumento29 pagineProject progress report with construction delaysHesham MohamedNessuna valutazione finora

- Classification of Pile FoundationDocumento1 paginaClassification of Pile FoundationSacademicusNessuna valutazione finora

- Deep Foundation: When Do We Use Deep Foundations?Documento7 pagineDeep Foundation: When Do We Use Deep Foundations?Cadfiles aasthaNessuna valutazione finora

- Types of Piles According To Method of InstallationDocumento13 pagineTypes of Piles According To Method of InstallationShara PalosNessuna valutazione finora

- I. Deep Foundation: A. PileDocumento7 pagineI. Deep Foundation: A. PileNikol CapulongNessuna valutazione finora

- Sheet Piles Walls: Name TitleDocumento4 pagineSheet Piles Walls: Name TitleKristin ArgosinoNessuna valutazione finora

- Everything You Need to Know About Pile FoundationsDocumento45 pagineEverything You Need to Know About Pile FoundationsGoutam NandiNessuna valutazione finora

- Deep Foundations: Kaidy DuarteDocumento22 pagineDeep Foundations: Kaidy DuarteCynthia XiuNessuna valutazione finora

- Factors Affecting Cast-In-situ Pile Foundation.Documento5 pagineFactors Affecting Cast-In-situ Pile Foundation.Gaurav DhangNessuna valutazione finora

- Shallow Foundation Deep FoundationDocumento39 pagineShallow Foundation Deep FoundationBmssa 2017BNessuna valutazione finora

- Piles DesignDocumento12 paginePiles Designn_sasanNessuna valutazione finora

- Design of A Pile GroupBy UsingSoil PropertiesDocumento12 pagineDesign of A Pile GroupBy UsingSoil PropertiesYogie Fian ZahriNessuna valutazione finora

- Introduction To Pile Foundations: Pile Foundation Design: A Student GuideDocumento12 pagineIntroduction To Pile Foundations: Pile Foundation Design: A Student GuideDeepak SaxenaNessuna valutazione finora

- Types of Piling - End Bearing, Friction, Bored, Driven, Screwed & MoreDocumento29 pagineTypes of Piling - End Bearing, Friction, Bored, Driven, Screwed & MoreMDanish AimanNessuna valutazione finora

- Pile Foundation TypesDocumento17 paginePile Foundation Typessad jam100% (6)

- Pile Foundation Tos Assignment - 2 Amey DeshmukhDocumento13 paginePile Foundation Tos Assignment - 2 Amey DeshmukhAmey Deshmukh100% (1)

- Construction Technology Bmcs I: G4 - Pile DrivingDocumento13 pagineConstruction Technology Bmcs I: G4 - Pile DrivingKasun ShideshNessuna valutazione finora

- Module 18, FounDocumento10 pagineModule 18, FounLeo DavifNessuna valutazione finora

- Mechanical Excavation MethodsDocumento16 pagineMechanical Excavation MethodsKashyap GoradiaNessuna valutazione finora

- Buildings-Types of FoundationsDocumento5 pagineBuildings-Types of FoundationsRonit ChariNessuna valutazione finora

- CEG 801 - Deep FoundationDocumento15 pagineCEG 801 - Deep FoundationAyanwale-cole pelumi AkeemNessuna valutazione finora

- Deep FoundationsDocumento23 pagineDeep FoundationsMushaid Ali SyedNessuna valutazione finora

- Pile Foundation DesignDocumento17 paginePile Foundation Designsunil khandelwalNessuna valutazione finora

- Assignment: Pile FoundationDocumento17 pagineAssignment: Pile Foundationsunil khandelwalNessuna valutazione finora

- Advanced Foundation TechniquesDocumento1 paginaAdvanced Foundation Techniquesapoorva jayaswalNessuna valutazione finora

- Form Two Foundation NotesDocumento6 pagineForm Two Foundation NotesTEMNessuna valutazione finora

- Pilefoundationgroup1 190430133745 PDFDocumento99 paginePilefoundationgroup1 190430133745 PDFNaveen Nagesh ChilakwadNessuna valutazione finora

- Lecture 09 - Design of Pile Foundation - Part 01 02Documento50 pagineLecture 09 - Design of Pile Foundation - Part 01 0221LE0079 Pasindu PrabashwaraNessuna valutazione finora

- Pile Foundation: Civil Engineering Practice (CE-203)Documento75 paginePile Foundation: Civil Engineering Practice (CE-203)Engr Ashfaq Nazir KharalNessuna valutazione finora

- Literature Review on Building FoundationsDocumento8 pagineLiterature Review on Building FoundationsLillian KobusingeNessuna valutazione finora

- Foundation:: Different Types of FoundationDocumento13 pagineFoundation:: Different Types of FoundationDwijendra ChanumoluNessuna valutazione finora

- Build Tech: Raft Foundations ExplainedDocumento6 pagineBuild Tech: Raft Foundations ExplainedBorel JasonNessuna valutazione finora

- ART306 Raft and Pile FoundationsDocumento19 pagineART306 Raft and Pile FoundationsAbhishek SoniNessuna valutazione finora

- Pile Foundations ExplainedDocumento57 paginePile Foundations ExplainedOromo Oromiya EtiophiaNessuna valutazione finora

- Topic 3: Foundation: CSE565 Construction Technology Ir DR Eddie LamDocumento11 pagineTopic 3: Foundation: CSE565 Construction Technology Ir DR Eddie Lamzhiliang yangNessuna valutazione finora

- Pile FoundationDocumento79 paginePile FoundationUsama UmarNessuna valutazione finora

- 149-Article Text-425-1-10-20181120 PDFDocumento6 pagine149-Article Text-425-1-10-20181120 PDFDavid HongNessuna valutazione finora

- Unit - VI: Pile FoundationDocumento14 pagineUnit - VI: Pile FoundationFaisal AbbasNessuna valutazione finora

- Ground EngineeringDocumento22 pagineGround EngineeringConstro FacilitatorNessuna valutazione finora

- Foundation ClassificationsDocumento6 pagineFoundation ClassificationsMarielle G. CastilloNessuna valutazione finora

- Deep Foundation Design ExplainedDocumento31 pagineDeep Foundation Design Explainedrose ann claveriaNessuna valutazione finora

- Pile Foundations ExplainedDocumento57 paginePile Foundations ExplainedOromo Oromiya EtiophiaNessuna valutazione finora

- BMC Shallow FoundationsDocumento6 pagineBMC Shallow Foundationsshenaz AfroseNessuna valutazione finora

- GBC FoundationDocumento20 pagineGBC Foundationsimonwanjiku598Nessuna valutazione finora

- Foundation Engineering Pile Capacity GuideDocumento39 pagineFoundation Engineering Pile Capacity GuideJelminda AlfaroNessuna valutazione finora

- Types of Pile FoundationsDocumento9 pagineTypes of Pile FoundationsAlex AnderNessuna valutazione finora

- PILE FOUNDATION DESIGN PRINCIPLESDocumento15 paginePILE FOUNDATION DESIGN PRINCIPLESanis farhanaNessuna valutazione finora

- Pile Foundation TGDocumento83 paginePile Foundation TGabhijitroy333Nessuna valutazione finora

- Chapter 7.PILEFOUNDDocumento42 pagineChapter 7.PILEFOUNDZsoloa adamNessuna valutazione finora

- Deep Foundations Types Piles Pier CaissonDocumento6 pagineDeep Foundations Types Piles Pier Caissonfarhan khanNessuna valutazione finora

- Pile FoundationsDocumento59 paginePile FoundationsSaiful Hoque Sohel100% (1)

- Application of Deep Foundation: (Yash Prabhat Priadarshi) (17-11-050)Documento45 pagineApplication of Deep Foundation: (Yash Prabhat Priadarshi) (17-11-050)Yash PrabhatNessuna valutazione finora

- Analysis of Pile Foundation of Thermal Power Plant at NelloreDocumento68 pagineAnalysis of Pile Foundation of Thermal Power Plant at NelloreAmanKediaNessuna valutazione finora

- Foundations: Silia Grover Assistant Professor, Deptt. of Architecture GNDU, AmritsarDocumento34 pagineFoundations: Silia Grover Assistant Professor, Deptt. of Architecture GNDU, AmritsarPalakNessuna valutazione finora

- ITP-Tubular Poles - Type Test PDFDocumento3 pagineITP-Tubular Poles - Type Test PDFPrabhakar SvNessuna valutazione finora

- ITP-Vibration Damper - Sample Test PDFDocumento3 pagineITP-Vibration Damper - Sample Test PDFPrabhakar SvNessuna valutazione finora

- ITP-Tubular Poles - Sample Test PDFDocumento4 pagineITP-Tubular Poles - Sample Test PDFPrabhakar SvNessuna valutazione finora

- Prequalified Testing Devices ListDocumento9 paginePrequalified Testing Devices ListPrabhakar SvNessuna valutazione finora

- Inspection Plan for Spacer DampersDocumento3 pagineInspection Plan for Spacer DampersPrabhakar SvNessuna valutazione finora

- ITP-OPGW - Type Test PDFDocumento4 pagineITP-OPGW - Type Test PDFPrabhakar SvNessuna valutazione finora

- Itp Opgw Fat PDFDocumento5 pagineItp Opgw Fat PDFPrabhakar Sv100% (1)

- Itp-Nmfoc - FatDocumento3 pagineItp-Nmfoc - FatPrabhakar SvNessuna valutazione finora

- Spacer Damper ITP TestsDocumento4 pagineSpacer Damper ITP TestsPrabhakar SvNessuna valutazione finora

- Inspection Plan for Optical Fiber RackDocumento3 pagineInspection Plan for Optical Fiber RackPrabhakar SvNessuna valutazione finora

- ITP-OFMR-Type Test PDFDocumento3 pagineITP-OFMR-Type Test PDFPrabhakar SvNessuna valutazione finora

- ITP-Line Hardware - Type TestDocumento3 pagineITP-Line Hardware - Type TestPrabhakar SvNessuna valutazione finora

- ITP-Joint Box-Type TestDocumento3 pagineITP-Joint Box-Type TestPrabhakar SvNessuna valutazione finora

- ITP-Composite Insulator - Type Test PDFDocumento4 pagineITP-Composite Insulator - Type Test PDFPrabhakar SvNessuna valutazione finora

- ITP-Line Hardware - Sample Test PDFDocumento3 pagineITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- QCS SummaryDocumento157 pagineQCS SummaryPrabhakar SvNessuna valutazione finora

- ITP-Joint Box - FAT PDFDocumento3 pagineITP-Joint Box - FAT PDFPrabhakar SvNessuna valutazione finora

- Lattice Steel Structure Inspection PlanDocumento4 pagineLattice Steel Structure Inspection PlanPrabhakar SvNessuna valutazione finora

- ITP-Joint Box - FATDocumento3 pagineITP-Joint Box - FATPrabhakar SvNessuna valutazione finora

- ITP-Composite Insulator - Sample TestDocumento3 pagineITP-Composite Insulator - Sample TestPrabhakar SvNessuna valutazione finora

- Material Label To ReleaseDocumento46 pagineMaterial Label To ReleasePrabhakar SvNessuna valutazione finora

- Hassa MSD Format Operational Spare For 4400003961Documento40 pagineHassa MSD Format Operational Spare For 4400003961Prabhakar SvNessuna valutazione finora

- Lattice Steel Structure Inspection and Test PlanDocumento3 pagineLattice Steel Structure Inspection and Test PlanPrabhakar SvNessuna valutazione finora

- CMCI Concrete Curing - KureNsealDocumento2 pagineCMCI Concrete Curing - KureNsealPrabhakar SvNessuna valutazione finora

- Construction Materials List With Manufacturer DetailsDocumento2 pagineConstruction Materials List With Manufacturer DetailsPrabhakar SvNessuna valutazione finora

- Concrete New Mix DesignsDocumento2 pagineConcrete New Mix DesignsPrabhakar Sv100% (1)

- Dismantling of 230kV & 380kV OHTL in Jubail & ShedgumDocumento3 pagineDismantling of 230kV & 380kV OHTL in Jubail & ShedgumPrabhakar SvNessuna valutazione finora

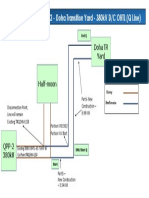

- M707-Block Diagram-Portion IVDocumento1 paginaM707-Block Diagram-Portion IVPrabhakar SvNessuna valutazione finora

- Concrete Pouring Records and Strength Test ResultsDocumento6 pagineConcrete Pouring Records and Strength Test ResultsPrabhakar SvNessuna valutazione finora

- CVL307 Instruction - Plan - BMC PDFDocumento2 pagineCVL307 Instruction - Plan - BMC PDFAkbar HamidNessuna valutazione finora

- Pemko - Bound Cat 08.27.10Documento184 paginePemko - Bound Cat 08.27.10Lucian Gunter IVNessuna valutazione finora

- Elsr QuantityDocumento106 pagineElsr Quantitykaridikonda Ramesh babuNessuna valutazione finora

- Bs Megaplast A Ready Mix PlasterDocumento1 paginaBs Megaplast A Ready Mix Plasterkavya singhalNessuna valutazione finora

- Le Corbusier and Mies Van Der Rohe Before World War IIDocumento196 pagineLe Corbusier and Mies Van Der Rohe Before World War IIjacqs2Nessuna valutazione finora

- Assignment IIDocumento2 pagineAssignment IIPrathyush ReddyNessuna valutazione finora

- Deltabeam Slim Floor Structure FinalDocumento5 pagineDeltabeam Slim Floor Structure FinalAnthony_I2CNessuna valutazione finora

- Prefabricated Truss AdvantagesDocumento2 paginePrefabricated Truss Advantageskhinwah88Nessuna valutazione finora

- Modular CoordinationDocumento107 pagineModular Coordinationchamil_dananjayaNessuna valutazione finora

- Structural Quantity Analysis of Tall BuildingsDocumento8 pagineStructural Quantity Analysis of Tall BuildingsAnkushNessuna valutazione finora

- Itemized Quotation Form For Construction of Citihardware Bancasi 10.7.19 v2Documento6 pagineItemized Quotation Form For Construction of Citihardware Bancasi 10.7.19 v2john philip OcapanNessuna valutazione finora

- Bar Bending Schedule OF Box CulvertDocumento1 paginaBar Bending Schedule OF Box Culvertahmed ktebahNessuna valutazione finora

- Advantages of Shell StructuresDocumento3 pagineAdvantages of Shell StructuresNeven Ahmed HassanNessuna valutazione finora

- Sample Take OffDocumento235 pagineSample Take OffNalyn EstacioNessuna valutazione finora

- PreCast Concrete ConstructionDocumento4 paginePreCast Concrete ConstructionKimo Keno100% (2)

- Building ContractDocumento7 pagineBuilding ContractJazelo CudillaNessuna valutazione finora

- Renaissance Vocabulary PDFDocumento4 pagineRenaissance Vocabulary PDFKenzcole 7Nessuna valutazione finora

- Assignment Constech - Sem 3Documento30 pagineAssignment Constech - Sem 3Venessa WahNessuna valutazione finora

- Boq - CivilDocumento25 pagineBoq - Civilbikash agarwalNessuna valutazione finora

- Packing List: Zhuhai Liri Tent Technology Co.,LtdDocumento3 paginePacking List: Zhuhai Liri Tent Technology Co.,LtdChristian Aguirre LópezNessuna valutazione finora

- Vastu For Staircase As Per StaircaseDocumento7 pagineVastu For Staircase As Per StaircaseHari Chanda PalNessuna valutazione finora

- Key site plan layout and emergency exitsDocumento1 paginaKey site plan layout and emergency exitsSLPlanner PlannerNessuna valutazione finora

- Scope of Works: TOTAL AMOUNT .Documento2 pagineScope of Works: TOTAL AMOUNT .alvin bautistaNessuna valutazione finora

- DCC - Day - 2023 - Adventure - Pack Pag 3Documento1 paginaDCC - Day - 2023 - Adventure - Pack Pag 3Jose Miguel Gallas OlmedoNessuna valutazione finora

- Siri Fort AudiDocumento38 pagineSiri Fort AudiĐhañushRaman KNessuna valutazione finora

- Project Mapping For Interior Design Related To CraftsDocumento30 pagineProject Mapping For Interior Design Related To CraftsShruti KohliNessuna valutazione finora

- Nfpa 220Documento17 pagineNfpa 220asdqwe3371Nessuna valutazione finora