Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maintenance of Absorption Column and Stripping Columns

Caricato da

Joseph OrjiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Maintenance of Absorption Column and Stripping Columns

Caricato da

Joseph OrjiCopyright:

Formati disponibili

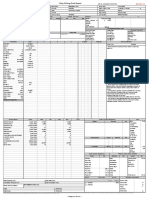

Maintenance of Absorption column and stripping columns

Daily maintenance Monthly Semi-Annual Maintenance Annual Inspection and

Maintenance Maintenance

(Turnaround)

Visual inspection Check valve Check shut down and Inspect and clean

of all instruments operations alarm systems internals. Check for

around the Check pipes Check for corrosion of contaminant build up

column for abrasion equipment Check control systems

Check corrosion and Carry out pressure Check instruments for

inhibitor levels corrosion testing to test for leaks rust and apply anti-rust

Check pH levels Check Dismantling of level where applicable

of amine sensors and regulators and Wash out old amine

Check for pipe alarm temperature probes for and introduce fresh

leaks systems for inspection amine

Check physical proper

condition of unit operation

for corrosion

Daily log should

be used to record

operating data log

Proper start up and shut down procedures are paramount in preventing corrosion and abrasion

in the absorption and stripping columns. Before startup, it is recommended to carry out a

complete internal inspection to ensure there are no operating problems. It is important not to

expose the absorption column to high temperature excursions during shutdown. The

following procedures should be adhered to strictly for start-up and planned shut down of the

columns.

Routine Start Up

1. Inspect and close all block valves of feed gas and liquid flow lines.

2. Ensure all controls and instruments are operational

3. Fill the amine tank to the appropriate level

4. Start the reboiler of the stripping column as well as the circulation pumps

5. Slowly open the feed gas valve to pressurize the contactor whiles the liquid line valve is

closed.

6. Check the amine solution concentration of the liquid.

7. Slowly open liquid line and allow circulation. Then adjust to proper flow.

8. Increase gas flow to the desired operating rate.

Routine Shut Down

1. Shut the feed gas line and open the bypass to ensure the absorption column is isolated

from any feed gas flow.

2. Continue pump operation until the absorption column is cooled down to prevent low pH

excursions after shutdown.

3. Switch off reboiler of the stripping column as well as circulation pumps.

4. Slowly close liquid line valve.

5. If an extended shutdown is anticipated, ensure all pipes are drained.

Potrebbero piacerti anche

- Titrimetric Determination of CO2 in EthanolaminesDocumento3 pagineTitrimetric Determination of CO2 in EthanolaminesDavinNessuna valutazione finora

- Boiler Operations - Soda BoilingDocumento3 pagineBoiler Operations - Soda BoilingBasty Tejano100% (1)

- ENCH607-ENPE625 Assignment-03 Fall 2020Documento3 pagineENCH607-ENPE625 Assignment-03 Fall 2020Ghost RiderNessuna valutazione finora

- Kohler K Series Owners ManualDocumento16 pagineKohler K Series Owners Manualapi-3721459100% (5)

- UFC-85 Plants For Urea Fertilizer Projects: Recommended DosageDocumento8 pagineUFC-85 Plants For Urea Fertilizer Projects: Recommended Dosagevaratharajan g rNessuna valutazione finora

- SOHAR Investors Guide PDFDocumento64 pagineSOHAR Investors Guide PDFShaikh Taufeeque AhmedNessuna valutazione finora

- Acetic Acid Recovery REPORT0Documento15 pagineAcetic Acid Recovery REPORT0Joseph OrjiNessuna valutazione finora

- ISO 13623, Petroleum and Gas Industries, Pipeline Transportation SystemsDocumento14 pagineISO 13623, Petroleum and Gas Industries, Pipeline Transportation Systemsoliver_34100% (2)

- API Piping PlansDocumento9 pagineAPI Piping PlansMohit MundraNessuna valutazione finora

- Flash Skim Vessel Descr.Documento5 pagineFlash Skim Vessel Descr.vanashley1Nessuna valutazione finora

- Soap Film TestingDocumento4 pagineSoap Film TestingyogacruiseNessuna valutazione finora

- LPG Leakage & DetectionDocumento3 pagineLPG Leakage & DetectionSravan GopuNessuna valutazione finora

- Fat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003Documento8 pagineFat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003kami safaviNessuna valutazione finora

- GT Tray Tower1 PDFDocumento12 pagineGT Tray Tower1 PDFJose Christian Viladegut GuzmanNessuna valutazione finora

- Pour Point of Crude Oils: Standard Test Method ForDocumento7 paginePour Point of Crude Oils: Standard Test Method ForSteven ErzhanNessuna valutazione finora

- Cat Load by Sock Method in Normal AtmosphereDocumento4 pagineCat Load by Sock Method in Normal Atmospherevishal bailurNessuna valutazione finora

- Topsoe Tk-575 BrimDocumento2 pagineTopsoe Tk-575 Brimcraigorio616Nessuna valutazione finora

- MCOT 017 Inter Tanks Transfer OperationsDocumento14 pagineMCOT 017 Inter Tanks Transfer OperationsLembang ApangNessuna valutazione finora

- Cat Loading by Sock Method in Inert AtmosphereDocumento5 pagineCat Loading by Sock Method in Inert Atmospherevishal bailurNessuna valutazione finora

- Process Op GAS PROCESSINGDocumento3 pagineProcess Op GAS PROCESSINGjohn MNessuna valutazione finora

- Molecular Sieve Type 5ADocumento2 pagineMolecular Sieve Type 5Akanu PatelNessuna valutazione finora

- Factors Contributing To Foarming Crude OilDocumento11 pagineFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- LPG SamplerDocumento2 pagineLPG SamplerAibiNessuna valutazione finora

- Microbial DesulfurizationDocumento34 pagineMicrobial DesulfurizationMiguel RazquinNessuna valutazione finora

- Astm D 4810 - 2006Documento3 pagineAstm D 4810 - 2006Nag RajNessuna valutazione finora

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesDocumento13 pagineNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianNessuna valutazione finora

- Case Histories of Amine Plant Equipment Corrosion Problems - Part 2Documento4 pagineCase Histories of Amine Plant Equipment Corrosion Problems - Part 2jdgh1986Nessuna valutazione finora

- Air Blowing Package (Sample)Documento3 pagineAir Blowing Package (Sample)YusufNessuna valutazione finora

- Air Separation Unit QRADocumento109 pagineAir Separation Unit QRALi QiNessuna valutazione finora

- Gassing Tendency of OilDocumento12 pagineGassing Tendency of OilY V JOSHI100% (3)

- Galuh Cakra Panigas - Yayuk Deviyanti - 2bd4 - PFD Pt. Samator Gas - Referensi PFDDocumento1 paginaGaluh Cakra Panigas - Yayuk Deviyanti - 2bd4 - PFD Pt. Samator Gas - Referensi PFDlebay cokNessuna valutazione finora

- Auto SDI ManualDocumento38 pagineAuto SDI ManualscribdkhatnNessuna valutazione finora

- Unit Conversion Data For NitrogenDocumento8 pagineUnit Conversion Data For NitrogenTrebor ZurcNessuna valutazione finora

- SG900 Specific GravityDocumento2 pagineSG900 Specific Gravitysaid_rahmansyah4750Nessuna valutazione finora

- 4.SOP Emergency Shut DownDocumento5 pagine4.SOP Emergency Shut DownDodik NugrohoNessuna valutazione finora

- NMi Productflyer EuroLoopDocumento2 pagineNMi Productflyer EuroLoopSarah ClarkNessuna valutazione finora

- Dynamic Modeling Using UniSim Design 2013engDocumento129 pagineDynamic Modeling Using UniSim Design 2013engHari PurwitoNessuna valutazione finora

- Settle Out Condition EstimationDocumento4 pagineSettle Out Condition Estimationnghiemta18Nessuna valutazione finora

- Project Standard and Specifications Electrical Induction Motors Rev01webDocumento4 pagineProject Standard and Specifications Electrical Induction Motors Rev01webhiyeonNessuna valutazione finora

- Sop SDV-R3Documento11 pagineSop SDV-R3Budbud YuaNessuna valutazione finora

- Water Content of High Pressure Natural GasDocumento43 pagineWater Content of High Pressure Natural Gasfarshidian100% (1)

- Biogas Processes For Sustainable DevelopmentDocumento246 pagineBiogas Processes For Sustainable DevelopmentQuarterbore100% (4)

- Proses Pengendalian ProsesDocumento2 pagineProses Pengendalian Prosesnisa methildaarNessuna valutazione finora

- Adiabtaic Vs Polytropic Head Compressor - ComparisonDocumento1 paginaAdiabtaic Vs Polytropic Head Compressor - Comparisonvijay_jvNessuna valutazione finora

- Integrated Amine Degreasing Schedule 30mar2018Documento1 paginaIntegrated Amine Degreasing Schedule 30mar2018KhairulNessuna valutazione finora

- Flow Metering Tutorial Part 4 Ultrasonic Flow MetersDocumento4 pagineFlow Metering Tutorial Part 4 Ultrasonic Flow MetersSenthil KumarNessuna valutazione finora

- The New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsDocumento3 pagineThe New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsvheshaghianNessuna valutazione finora

- Best Practices of Simulator TrainingDocumento26 pagineBest Practices of Simulator TrainingRudra Pratap Singh100% (1)

- Selecting: A Suitable ProcessDocumento6 pagineSelecting: A Suitable ProcesstermdoxaNessuna valutazione finora

- LPG Spec by EsdmDocumento73 pagineLPG Spec by EsdmronaldopasaribuNessuna valutazione finora

- HYSYS Simulation For Natural Gas Dehydration and SweeteningDocumento8 pagineHYSYS Simulation For Natural Gas Dehydration and SweeteningHaziq MirzaNessuna valutazione finora

- Materials Selection in Oil and Gas-An OverviewDocumento15 pagineMaterials Selection in Oil and Gas-An OverviewAli AliNessuna valutazione finora

- The Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChlorideDocumento2 pagineThe Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChloriderawadNessuna valutazione finora

- Dryer Selection and DesignDocumento43 pagineDryer Selection and DesignMuluken DeaNessuna valutazione finora

- Separator Problems: Dr. Abo ZaidDocumento5 pagineSeparator Problems: Dr. Abo ZaidMohamed A. EL-shafieNessuna valutazione finora

- NGL Extraction TechnologiesDocumento10 pagineNGL Extraction Technologieswylie010% (1)

- 2023 Artelia in IndonesiaDocumento1 pagina2023 Artelia in IndonesiaFardhan AdamyNessuna valutazione finora

- How Is Nitrogen Used in Oil and Gas FieldsDocumento4 pagineHow Is Nitrogen Used in Oil and Gas FieldsrajasekharboNessuna valutazione finora

- Skimming Job GeneralDocumento5 pagineSkimming Job Generalvishal bailurNessuna valutazione finora

- Shantanu DasDocumento10 pagineShantanu DasarunkdevassyNessuna valutazione finora

- Asma PVDocumento27 pagineAsma PVasma fatimaNessuna valutazione finora

- MANTENIMIENTODocumento5 pagineMANTENIMIENTOalextlv1996cvNessuna valutazione finora

- PM ProgramDocumento29 paginePM Programemad youssefNessuna valutazione finora

- How Many Gbosa You Want To Give JJ and JeylaniDocumento2 pagineHow Many Gbosa You Want To Give JJ and JeylaniJoseph OrjiNessuna valutazione finora

- Unit 1: Acetic Acid Scrubber: Johnson OlayiwolaDocumento12 pagineUnit 1: Acetic Acid Scrubber: Johnson OlayiwolaJoseph OrjiNessuna valutazione finora

- Scrap Generation AnalysisDocumento79 pagineScrap Generation AnalysisJoseph OrjiNessuna valutazione finora

- Jan RM RequirementDocumento62 pagineJan RM RequirementJoseph OrjiNessuna valutazione finora

- Plant Loss Tree DataDocumento1 paginaPlant Loss Tree DataJoseph OrjiNessuna valutazione finora

- Ophthalmic Standard S: A Presentation by Adiele Anita Ezinne and Ikenna-Ohia GraceDocumento32 pagineOphthalmic Standard S: A Presentation by Adiele Anita Ezinne and Ikenna-Ohia GraceJoseph OrjiNessuna valutazione finora

- C c c D F h h h h h h h H L L L M M M NC NT P T T T T U Vol V V x x y y z α τDocumento2 pagineC c c D F h h h h h h h H L L L M M M NC NT P T T T T U Vol V V x x y y z α τJoseph OrjiNessuna valutazione finora

- Biogas Market ResearchDocumento4 pagineBiogas Market ResearchJoseph OrjiNessuna valutazione finora

- John 4vs23 ExplainedDocumento1 paginaJohn 4vs23 ExplainedJoseph OrjiNessuna valutazione finora

- Am Board DesignDocumento1 paginaAm Board DesignJoseph OrjiNessuna valutazione finora

- Report 0Documento19 pagineReport 0Joseph OrjiNessuna valutazione finora

- Account Reconciliation: Date Name of Distributor Product Amount Unit PriceDocumento4 pagineAccount Reconciliation: Date Name of Distributor Product Amount Unit PriceJoseph OrjiNessuna valutazione finora

- TPM Pillar AssignmentsDocumento5 pagineTPM Pillar AssignmentsJoseph OrjiNessuna valutazione finora

- TPM Pillar AssignmentsDocumento5 pagineTPM Pillar AssignmentsJoseph OrjiNessuna valutazione finora

- Am Board DesignDocumento1 paginaAm Board DesignJoseph OrjiNessuna valutazione finora

- Principle of PDTDocumento9 paginePrinciple of PDTJoseph OrjiNessuna valutazione finora

- Mark Unit 4 Report FinalDocumento6 pagineMark Unit 4 Report FinalJoseph OrjiNessuna valutazione finora

- LT-3 LC-3: Recycled Solvent From Unit 4Documento4 pagineLT-3 LC-3: Recycled Solvent From Unit 4Joseph OrjiNessuna valutazione finora

- Controlled Variable Manipulated Variable Controlle R Type /scheme Gproms Model/Process NameDocumento5 pagineControlled Variable Manipulated Variable Controlle R Type /scheme Gproms Model/Process NameJoseph OrjiNessuna valutazione finora

- CENGM011 - Advanced Process Modelling & Design: Group 1: Report 1: Model and AssumptionsDocumento1 paginaCENGM011 - Advanced Process Modelling & Design: Group 1: Report 1: Model and AssumptionsJoseph OrjiNessuna valutazione finora

- Table X: Unit 4 Op Data Figure X: Unit 4 Process SchematicDocumento6 pagineTable X: Unit 4 Op Data Figure X: Unit 4 Process SchematicJoseph OrjiNessuna valutazione finora

- Chem 124 Worksheet 1Documento3 pagineChem 124 Worksheet 1ShatabdiDasNessuna valutazione finora

- KM 2820 Service ManualDocumento2 pagineKM 2820 Service ManualAriel BoisseauNessuna valutazione finora

- Project Definition Description Status SponsorDocumento3 pagineProject Definition Description Status SponsorRoynaldoo SimbolonNessuna valutazione finora

- Las Palmas: Canary Islands and MadeiraDocumento1 paginaLas Palmas: Canary Islands and MadeiraArun Kumar PancharajNessuna valutazione finora

- Construction Lifts: 2008 NISSAN Cabstar Aerial Platform in Vignolo, ItalyDocumento6 pagineConstruction Lifts: 2008 NISSAN Cabstar Aerial Platform in Vignolo, ItalySumati Vidya KendraNessuna valutazione finora

- Class XI Assignment States of MatterDocumento2 pagineClass XI Assignment States of MatterCheryl ChaudhariNessuna valutazione finora

- 11 Facts About Global WarmingDocumento1 pagina11 Facts About Global WarmingGabrielNessuna valutazione finora

- Single-Stage Centrifugal Compressor Modifications and ReratesDocumento2 pagineSingle-Stage Centrifugal Compressor Modifications and ReratesAli BarzegarNessuna valutazione finora

- Socony Oven Conveyer LubricantDocumento2 pagineSocony Oven Conveyer LubricantNoche de EstrellasNessuna valutazione finora

- Damper Datasheet: Stack Damper Multiple Stack ControlDocumento2 pagineDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNessuna valutazione finora

- Advantages and Disadvantages of Natural Gas Energy - Conserve EDocumento7 pagineAdvantages and Disadvantages of Natural Gas Energy - Conserve ETuba KhanNessuna valutazione finora

- Checklist For Unserviceable Equiptment: Vehicles / Heavy EquiptmentDocumento2 pagineChecklist For Unserviceable Equiptment: Vehicles / Heavy EquiptmentHavc B. Famor100% (1)

- Tartarini TM 7 TQ Ball ValvesDocumento3 pagineTartarini TM 7 TQ Ball ValvesadrianioantomaNessuna valutazione finora

- Engine Performance Data at 1500 RPM: QSK 1 Cummins IncDocumento4 pagineEngine Performance Data at 1500 RPM: QSK 1 Cummins Incmohsen_cumminsNessuna valutazione finora

- Waukesha Knock Index Power CurveDocumento1 paginaWaukesha Knock Index Power CurveparathasiNessuna valutazione finora

- Ratio: Golden Ratio Ratio in God's Creation Ratio in KoranDocumento22 pagineRatio: Golden Ratio Ratio in God's Creation Ratio in KoranKate RaileyNessuna valutazione finora

- Pertamina Patra Niaga Master List (Preliminary) - Rev.2A KHPT-DSGI PDFDocumento1 paginaPertamina Patra Niaga Master List (Preliminary) - Rev.2A KHPT-DSGI PDFWahyu Lailil FaisNessuna valutazione finora

- Chemistry of Fire, Triangle of Fire Etc.Documento48 pagineChemistry of Fire, Triangle of Fire Etc.HDF ltoncreastNessuna valutazione finora

- GE SPS Comp Brochure - 6-15 EnglishDocumento12 pagineGE SPS Comp Brochure - 6-15 EnglishEdinsonUribeTorres100% (1)

- Calculation of Equilibrium Flame Temperature and Composition For Gaseous Fuels CombustionDocumento12 pagineCalculation of Equilibrium Flame Temperature and Composition For Gaseous Fuels CombustionBahar MeschiNessuna valutazione finora

- Company ProfileDocumento24 pagineCompany ProfileMohamed RusfanNessuna valutazione finora

- Engine FormulasDocumento26 pagineEngine FormulasaaronNessuna valutazione finora

- Manzalai-07 Daily Mud Report (10!7!20)Documento1 paginaManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedNessuna valutazione finora

- DM900 - 9.00 kVA: ModelDocumento3 pagineDM900 - 9.00 kVA: ModelMohamed HusseinNessuna valutazione finora

- Utilev UT50P 4.0 - 7.0 Ton Forklift BrochureDocumento8 pagineUtilev UT50P 4.0 - 7.0 Ton Forklift BrochureОлег СкладремонтNessuna valutazione finora

- List LPG Wholesaler September 2020 1Documento1 paginaList LPG Wholesaler September 2020 1Yasharsha RdNessuna valutazione finora

- Significant Effluent Quality Parameters (SEQP) Per Sector PDFDocumento5 pagineSignificant Effluent Quality Parameters (SEQP) Per Sector PDFRenan RoqueNessuna valutazione finora