Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Using a Mini Triple Point of Water System to Improve Temperature Calibration Reliability

Caricato da

Student ForeignDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Using a Mini Triple Point of Water System to Improve Temperature Calibration Reliability

Caricato da

Student ForeignCopyright:

Formati disponibili

Using a Mini Triple Point of Water System to Improve Reliability in a Tem-

perature Calibration Laboratory

Speaker: Mingjian Zhao

Authors: Mingjian Zhao and Rick Walker

Fluke Hart Scientific

799 East Utah Valley Drive, American Fork, Utah 84003-9775

E-mail: mingjian.zhao@hartscientific.com

Phone: (801) 763-1600; Fax: (801) 763-1010

Abstract

A mini TPW system was introduced as an excellent way to measure the errors in the calibration

system of a secondary level temperature laboratory. In this paper, the structure and operation of

this system is briefly introduced. Also, its performance is discussed. The mini TPW system was

directly compared to a traditional TPW cell. The difference between the mini TPW system and

the traditional TPW cell was found to be less than 0.3 mK using an SPRT. The expanded (k=2)

uncertainty of the mini TPW system is better than 0.5 mK. Several thermometers with different

structures were tested in the system. Errors seen with the different thermometers between the

mini TPW system and the traditional TPW system are reported.

1. Introduction

Temperature calibration laboratories not using fixed-point standards use some level of reference

or standard thermometer instead, such as a standard platinum resistance thermometer (SPRT) or

secondary platinum resistance thermometer (PRT), against which units under test (UUTs) are

calibrated. Reference thermometers are typically sent to primary or upper level calibration labo-

ratories for routine calibration. Often the calibration interval for a reference thermometer is one

year. However, it is difficult for many users to observe and track the drift of the reference ther-

mometer between calibrations. If the reference thermometer drifts beyond the acceptable limit

during the calibration interval, the process uncertainties may be compromised requiring recall of

calibration work.

Upon investigation of re-calibration results, it was found that the resistances at the triple point of

water (Rtpw) of some reference thermometers were significantly different between the two cali-

brations, and some reference thermometers had to be removed from service due to their inade-

quate stability. However, the “bad” reference thermometers had been in use as standards for cali-

bration work. No one knows when the thermometers drifted significantly.

Measurement instruments, including readouts and reference resistors, may also drift over some

time period, though their drifts are usually much smaller than that of reference thermometers. It

is suggested that the entire calibration system should be checked regularly.

An excellent way to measure the errors in a calibration system, including drift of the reference

thermometer, is to compare against an established fixed point, such as the triple point of water.

2005 NCSL International Workshop and Symposium

However the cost of a typical triple point of water cell and its maintenance apparatus (as well as

the time, effort, and training involved) can preclude its use in many laboratories. In order to

make fixed-point standards more accessible, a mini triple point of water (TPW) system was de-

veloped a few years ago [1] [2].

To ensure that the mini TPW system is usable as a watchdog for a calibration system with many

different types of reference thermometers, further research was completed. Several thermometers

with different structures were tested in the system. Errors seen with the different thermometers

between the mini TPW system and the traditional TPW system are reported in this paper.

2. Drifts of Reference Thermometers

Recently, we investigated a collection of SPRTs calibrated by Hart Scientific over at least four

one-year calibration intervals. These SPRTs were made by various manufacturers throughout the

world, and their structures vary. The investigation results are surprising—the R(tpw)s of many

SPRTs drifted over 10 mK in at least one calibration interval. The R(tpw) of a few SPRTs drifted

as much as 50 mK. As a sample, the drifts of the R(tpw)s of 11 metal-sheath SPRTs and eight

quartz-sheath SPRTs are shown in Fig.1 and Fig. 2 respectively.

60.00

Metal Sheath SPRT

40.00

SPRT 1

20.00

SPRT 2

SPRT 3

∆R(tpw)*(dt/dR), mK

0.00 SPRT 4

SPRT 5

-20.00 SPRT 6

SPRT 7

-40.00 SPRT 8

SPRT 9

-60.00 SPRT 10

SPRT 11

-80.00

-100.00

0 1 2 3 4 5 6 7

Routine Calibration, year

Fig. 1 The R(tpw) drifts of metal sheath SPRTs during routine calibration intervals

It was found that the R(tpw) might jump significantly in one interval, while the R(tpw) is quite

stable or at least acceptable in other intervals. The R(tpw) of SPRT 8 drifted almost 80 mK be-

tween the second year and third year. The R(tpw) of SPRTs 4 and 10 drifted significantly be-

tween the first year and second year, while the same problem happened on SPRT 5 between the

fourth year to fifth year. It is assumed that these SPRTs met unusual treatment during those years.

2005 NCSL International Workshop and Symposium

60

Quartz Sheath SPRT

50

40

SPRT 12

∆R(tpw)*(dt/dR), mK

30

SPRT 13

SPRT 14

20

SPRT 15

SPRT 16

10

SPRT 17

0 SPRT 18

SPRT 19

-10

-20

-30

0 2 4 6 8 10

Routine Calibration, year

Fig. 2 The R(tpw) drifts of quartz sheath SPRTs during routine calibration intervals

Comparing Fig. 1 and Fig. 2, the long-term stability of quartz-sheath SPRTs is better than that of

the metal-sheath SPRTs. The main reason, it is presumed, is that users treat the quartz-sheath

SPRTs more carefully because they are expected to be more fragile. Three among eight quartz-

sheath SPRTs exceeded the SPRT long-term stability limitation. The drift of the R(tpw) of a

good quartz sheath SPRT should be less than 3 mK per year, depending on the usage and han-

dling. An SPRT, whether quartz or metal sheath, should be handled very carefully to maintain its

excellent stability.

During our calibrations and services for customers, it was found that some reference thermome-

ters drifted significantly due to such various reasons as mechanical shock and overheating. Most

users had not noticed the drifts until the re-calibration was completed in the upper level tempera-

ture laboratories, or because the reference thermometer did not work anymore. If the “bad”

SPRT was used as reference thermometer in daily calibration, the process uncertainties may have

been compromised and recalls of calibrated work may be necessary.

The reference thermometer should be checked regularly between the calibration intervals to

guarantee the calibration reliability. An ideal and the easiest way to measure the errors in a cali-

bration system, including drift of the reference thermometer, is to compare against the triple

point of water.

Usually, the resistance ratio (W) of a reference platinum resistance thermometer is more stable

over time than the resistance at the triple point of water. Therefore, if the R(tpw) could be up-

dated regularly, the calibration uncertainty will improve significantly.

2005 NCSL International Workshop and Symposium

3. Mini TPW Cell and Realization System

The realization of the triple point of water (TPW) in traditional cells requires dry ice or liquid

nitrogen to create an ice mantle and a fluid bath or ice dewar to maintain the phase equilibrium

state within the cell. However, the cost of a typical triple point of water cell and its maintenance

apparatus (as well as the time, effort, and training involved) can preclude its use in many labora-

tories. In order to make fixed-point standards more accessible, a mini triple point of water (TPW)

automated system was developed a few years ago. In this paper, the system is briefly introduced

again. Detailed information and performance were presented in our previous paper [1] [2].

The triple point of water can be realized automatically using a miniature TPW cell and a portable

apparatus with thermo-electric cooling modules and temperature controller. The apparatus was

designed with built-in programming for fast and easy operation. Three pre-set temperatures are

built into the unit’s controller: 5°C (melt mode), near 0°C (maintain mode), and -4°C (freeze

mode). Operation is extremely simple. Enter the “freeze” mode through the front-panel buttons.

When the apparatus sounds an alerts (about ten to twenty minutes later), remove the mini cell

from the apparatus and give the cell a light shake. The water in the cell, supercooled at a tem-

perature of -4°C, immediately begins to freeze. Fine needle-crystals (dendrites) of ice appear uni-

formly throughout the cell and approximately 5% of the water freezes in a few seconds. Return

the cell into the apparatus and change the program mode to “maintain.”

4. Tests, results and discussions

Measurement Apparatus

In this study, all resistances were measured using a Guildline DC automatic bridge (Model

6675). The expanded uncertainty for the measurement of the ratio of two resistances was less

than 2×10−7. A Leeds & Northrup 10-ohm DC standard resistor was used. The triple point of wa-

ter, Hart Model 5901, with the maintenance bath, 7312, was used in the experiment.

Performance of the mini TPW system

Generally, the plateau will last from 14 to 20 hours. The temperature in a miniature TPW cell

newly frozen (within the first 30 minutes) in this manner is typically about 1 mK below the triple

point of water. This low initial temperature and the subsequent gradual rising in the cell’s tem-

perature are believed to be caused by structural strains in the cell’s suddenly frozen ice and the

subsequent relieving of this strain over time. Creating an “inner melt” around the central well (by

inserting a glass rod at room temperature) can expedite this settling. The equilibrium temperature

of a mini TPW cell in the above-described apparatus was compared with that of a traditional

TPW cell using an SPRT. The mini TPW cell was aged for ten hours after freezing the ice before

the comparison began. The average difference between the two cells was found to be within 0.1

mK. If an uncertainty less than 0.5 mK is required, it is suggested to freeze the mini TPW cell in

the late afternoon and use it the next day. If an uncertainty of 1 mK is satisfactory, the cell may

be used immediately after freezing the ice in the cell. Early research results were published in

our previous paper [1] [2]. Recent research show that the suggestions given were conservative.

2005 NCSL International Workshop and Symposium

Errors introduced by inadequate aging of ice mantel

To verify the errors introduced by inadequate aging of the ice mantel, more research was recently

conducted. A TPW plateau realized in the mini TPW system is shown in Fig. 3. The triple point

of water realized in the mini TPW system was compared to that of the traditional TPW cell. An

SPRT was measured in the traditional TPW cell before and after the SPRT was measured in the

mini TPW system. The average of the two measurement results is used as the triple point of wa-

ter value for the traditional TPW cell. When realizing the TPW in the mini system, the ice mantel

around the reentrant well was not inner melted. At the beginning of the plateau, the triple point

of water in mini system is 1 mK lower than that of traditional cell. The TPW increased from -1

mK to -0.5 mK within 2.7 hours. The difference was less than 0.3 mK after 10 hours. The pla-

teau lasted 18 hours with a temperature difference within 0.5 mK from the traditional cell. It is

suggested to allow three hours for stabilization for a desired uncertainty less than 0.5 mK with

the mini TPW system.

To reduce the stabilization time, a room temperature glass tube was inserted into the mini cell for

one minute as soon as the ice mantel was created. This is called the “inner melt” technique. A

plateau realized in the mini TPW system with “inner melt” is shown in Fig.4. It took 1.6 hours

for the TPW to stabilize within a temperature difference of 0.5 mK from the traditional TPW cell.

The difference was less than 0.3 mK after 4.5 hours. However, the plateau lasted only 12 hours.

2.552185

SPRT S/N 5681-1401

2.552180

Traditional TPW cell Value

0.5 mK

2.552175

R(tpw), ohm

TPW plateau realized in mini system

without inner melted

2.552170

0.5 mK

2.552165

2.7 hours

2.552160

0 2 4 6 8 10 12 14 16 18 20 22

Hours

Fig. 3 TPW Plateau realized in a mini TPW system (no inner melt at the beginning)

2005 NCSL International Workshop and Symposium

2.552185

SPRT S/N 5681-1401

2.552180

Traditional TPW cell Value

0.5 mK

2.552175

R(tpw), ohm

TPW Plateau Realized in Mini System

2.552170

0.5 mK

2.552165

1.6 hours

2.552160

0 2 4 6 8 10 12 14 16

Hours

Fig. 4 TPW Plateau realized in a mini TPW system (inner melt at the beginning)

Errors introduced by different thermometer structures

As a convenient check standard tool for the temperature laboratory, the mini TPW system should

be suitable for different types of reference thermometers. Since the immersion depth of the mini

TPW system is 117 mm, to verify the error due to the possible inadequate immersion, many ref-

erence thermometers with different structures were tested in both a regular TPW cell and a mini

TPW system. Details of the thermometers involved in the tests are listed in Table 1. The length

of the longest sensor is 60mm, while the length of the shortest sensor is 5 mm. The sheath mate-

rial types include Pyrex, fused silica, inconel, and alumina.

Table 1: Structure of thermometers involved in the tests

Thermometer sheath sheath sensor leads wire Leads insulation design

No. Type material diameter length material

A SPRT Pyrex 7.5 mm 40 mm Platinum Single-bore, glass

B SPRT Fused Silica 7.0 mm 40 mm Platinum Single-bore, fused silica

C SPRT Fused Silica 7.0 mm 40 mm Platinum Capillary

D SPRT Fused Silica 7.0 mm 55 mm Platinum Single-bore, fused silica

E SPRT Fused Silica 7.0 mm 60 mm Platinum Single-bore, fused silica

F SPRT Inconel 5.6 mm 5 mm Platinum Single-bore, Alumina

G SPRT Inconel 5.6 mm 35 mm Platinum Single-bore, Alumina

H SPRT Inconel 6.4 mm 45 mm Platinum Single-bore, Alumina

I SPRT Inconel 5.6 mm 45 mm Platinum Single-bore, Alumina

J PRT Inconel 6.4 mm 50 mm Platinum Single-bore, Alumina

K PRT Inconel 6.4 mm 40 mm nickel 4-bore alumina

L PRT Inconel 4.8 mm 35 mm nickel 4-bore alumina

M PRT Alumina 6.4 mm 30 mm Platinum Single-bore, Alumina

2005 NCSL International Workshop and Symposium

The temperature difference between the mini TPW system and the traditional TPW cell using

different thermometers are shown in Fig. 5. For the fused silica glass and inconel sheath ther-

mometers, as long as the sensor lengths are no more than 55mm, the temperature errors do not

exceed 0.3 mK. If the sensor length is 60 mm, the error is less than 0.5 mK. All the errors are

still within normal uncertainty. However, if the sheath material is alumina, even though the sen-

sor length is only 30 mm, the error could be 0.8 mK. Usually the sensor lengths of the commer-

cial reference thermometers are less than 50mm. Therefore, the mini TPW system is good

enough for all types of reference thermometers in secondary level temperature laboratories, in-

cluding quartz sheath and metal sheath SPRTs and PRTs.

1.00

0.80

∆t (Mini TPW system - Traditional TPW Cell), mK

0.60

0.40

0.20

0.00

-0.20

-0.40

-0.60

-0.80

-1.00

A B C D E F G H I J K L M

Thermometers

Fig. 5 Effects of thermometer structure

Check Standard of the Temperature Calibration System

Tracking the triple point of water resistance of the reference thermometer using the mini TPW

system not only helps to identify drift in the reference thermometer, but it also makes drift of

other components of the calibration system observable. Changes in the thermometer readout or

reference resistor can also produce apparent drift of the measured R(tpw) of the reference ther-

mometer. Other possible problems that might affect temperature measurements, such as due to

environmental conditions or electrical interference, might also be made known with this valuable

technique. When drift is observed, it is important to be able to identify which instrument or in-

struments are not stable. It can be helpful to also have reliable standard resistors for use in substi-

tution for the SPRT or PRT to test the electrical equipment.

2005 NCSL International Workshop and Symposium

5. Conclusion

Investigation results show that there are many reference thermometers outside tolerance limits

are still used as the standard in calibration work. Thus, the process uncertainties may have been

compromised which may lead to the need to recall calibration work. To guarantee the reliability

in a secondary level temperature calibration laboratory, the reference thermometer should be

checked regularly. The mini TPW system is an excellent and simple apparatus to assist the labo-

ratory in controlling their process. It allows a control chart to be maintained that indicates when a

reference thermometer should be sent to an upper level temperature laboratory for re-calibration.

The difference between the mini TPW system and the traditional TPW cell was found to be less

than 0.3 mK using an SPRT after the ice mantel is fully aged. The difference could be less than

0.5 mK after two or three hours of stabilizing after the ice mantel is created. The expanded (k=2)

uncertainty of the mini TPW system is better than 0.5 mK. The mini TPW system is good for

thermometers with sensor length no more than 60 mm.

The mini TPW system could be used as a verification and quality assurance device for a tem-

perature calibration system and can reduce uncertainty by allowing regular updating of the resis-

tance of the reference thermometer at the triple point of water.

Acknowledgments

The authors would like to acknowledge the assistance of Rose Heaton for her considerate advice,

Mike Coleman for his statistical data on thermometer calibration, and thank Wayne Newland for

his assistance with the illustrations and publishing of this paper. The authors would also like to

express their gratitude for the contributions made to this project by many other professionals at

Fluke Hart Scientific.

References

1. X. Li and M. Hirst. “Fixed-points for Secondary Level Calibration,” Proceedings of TEMP-

MEKO 99, The 7th International Symposium on Temperature and Thermal

2. Xumo Li, Deming Chen and Mingjian Zhao, NCSLI 2001

2005 NCSL International Workshop and Symposium

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Comparing Stability of Metal and Fused Silica SPRTsDocumento8 pagineComparing Stability of Metal and Fused Silica SPRTsAlexandraAndreeaNessuna valutazione finora

- BOR LOG BO1: Client Project Name Project NumberDocumento1 paginaBOR LOG BO1: Client Project Name Project NumberDileep K NambiarNessuna valutazione finora

- P03 coch bore logDocumento1 paginaP03 coch bore logDileep K NambiarNessuna valutazione finora

- Bor Log Bo3: Client Project Name Project NumberDocumento1 paginaBor Log Bo3: Client Project Name Project NumberDileep K NambiarNessuna valutazione finora

- Bor Log Bo2: Client Project Name Project NumberDocumento1 paginaBor Log Bo2: Client Project Name Project NumberDileep K NambiarNessuna valutazione finora

- P83 OPL FinalDocumento11 pagineP83 OPL FinalJorge León IllanesNessuna valutazione finora

- Power Levels RequiredDocumento4 paginePower Levels RequiredpankajengNessuna valutazione finora

- Time Table for Class XI from 29th July to 3rd August 2020Documento1 paginaTime Table for Class XI from 29th July to 3rd August 2020lakhuindiaNessuna valutazione finora

- AC to AC Converter ChaptersDocumento25 pagineAC to AC Converter ChaptersReeta DuttaNessuna valutazione finora

- Bagan BadmintonDocumento2 pagineBagan BadmintonBenny Putra WardanaNessuna valutazione finora

- Daily Progress Reports (Smondo Projects)Documento2 pagineDaily Progress Reports (Smondo Projects)Arif KhanNessuna valutazione finora

- AC to AC Converter GuideDocumento25 pagineAC to AC Converter GuidePrajay BhavsarNessuna valutazione finora

- Three-Phase Bridge Rectifiers (B6)Documento15 pagineThree-Phase Bridge Rectifiers (B6)Nuke-Comm LeakageNessuna valutazione finora

- F1 SMG 9mm Repair Parts ScaleDocumento36 pagineF1 SMG 9mm Repair Parts ScaleCaprikorn100% (4)

- A106 Pipe MTCDocumento2 pagineA106 Pipe MTCSocial FactsNessuna valutazione finora

- Parts Book BE1000 Full Scan OcrDocumento633 pagineParts Book BE1000 Full Scan OcrBhawani CopyNessuna valutazione finora

- Exp 11Documento10 pagineExp 11neha yarrapothuNessuna valutazione finora

- Roster Semester 2 - 2022.2023 Revisi 6Documento3 pagineRoster Semester 2 - 2022.2023 Revisi 6Dedi Jaya90Nessuna valutazione finora

- CA3081, CA3082: General Purpose High Current NPN Transistor Arrays FeaturesDocumento6 pagineCA3081, CA3082: General Purpose High Current NPN Transistor Arrays FeaturesaburizqiNessuna valutazione finora

- RX-K Rx-King TransmissionDocumento2 pagineRX-K Rx-King TransmissionDevii AryaNessuna valutazione finora

- Chapter 4 AC To AC Converters: OutlineDocumento25 pagineChapter 4 AC To AC Converters: OutlineKushaldinho DattaNessuna valutazione finora

- 8051 Addressing Modes + Interrupts + Pin DiagramDocumento18 pagine8051 Addressing Modes + Interrupts + Pin DiagramlalaNessuna valutazione finora

- TP Timetable Sheet1Documento2 pagineTP Timetable Sheet1Nicholas NgNessuna valutazione finora

- Es Lab ManualDocumento52 pagineEs Lab Manual19-L-0219 SainadhNessuna valutazione finora

- 4raspored Opreme Na STS-ModelDocumento1 pagina4raspored Opreme Na STS-ModelAnonymous hRePlgdOFrNessuna valutazione finora

- Vc34 Kompend Mds eDocumento4 pagineVc34 Kompend Mds eSafetyjoe2Nessuna valutazione finora

- Tower - A Daily Progress Repo (Somondo Projects)Documento2 pagineTower - A Daily Progress Repo (Somondo Projects)Arif KhanNessuna valutazione finora

- Al115c Mio Soul CarburetorDocumento2 pagineAl115c Mio Soul CarburetorJiwa TenangNessuna valutazione finora

- 1wbtrim Chartairport Alalisysfuelmelcdl.Documento10 pagine1wbtrim Chartairport Alalisysfuelmelcdl.Yicela Sanchez GilNessuna valutazione finora

- Product Improvement:: SP and TS Valves Now Feature 1,000-Hour Salt Spray ProtectionDocumento1 paginaProduct Improvement:: SP and TS Valves Now Feature 1,000-Hour Salt Spray ProtectionMiguel VlntìnNessuna valutazione finora

- t135hc Jupiter MX CarburetorDocumento2 paginet135hc Jupiter MX CarburetorPTCNessuna valutazione finora

- Tañamor-Plate8 Eu1Documento1 paginaTañamor-Plate8 Eu1Hector TañamorNessuna valutazione finora

- Al115c Mio Soul CarburetorDocumento2 pagineAl115c Mio Soul Carburetormic.sulivan99Nessuna valutazione finora

- ARL RESPAD TMPORT_EXPORT Commande BraebonDocumento1 paginaARL RESPAD TMPORT_EXPORT Commande BraebonAissa BenahmedNessuna valutazione finora

- 9304 CHUCK ASSEMBLY FIXTUREDocumento5 pagine9304 CHUCK ASSEMBLY FIXTUREomkarpatil795Nessuna valutazione finora

- Single-Shot Dynamics of Spin-Orbit Torque and Spin Transfer Torque Switching in Three-Terminal Magnetic Tunnel JunctionsDocumento17 pagineSingle-Shot Dynamics of Spin-Orbit Torque and Spin Transfer Torque Switching in Three-Terminal Magnetic Tunnel JunctionsMannojPaulSinghNessuna valutazione finora

- Hfe Teac v-480 Service enDocumento26 pagineHfe Teac v-480 Service enGuglielmoNessuna valutazione finora

- Modeliranje i analiza EES u EMTP-RVDocumento4 pagineModeliranje i analiza EES u EMTP-RVWorld TravelNessuna valutazione finora

- Vortex Redlion ParametersDocumento2 pagineVortex Redlion ParametersMahmoud Abdel MordyNessuna valutazione finora

- Bor Log Bo2: Client Project Name Project NumberDocumento1 paginaBor Log Bo2: Client Project Name Project NumberDileep K NambiarNessuna valutazione finora

- Renal Artery ProtocolDocumento11 pagineRenal Artery Protocolsneha ravichandranNessuna valutazione finora

- T110sec Jupiter Z CarburetorDocumento2 pagineT110sec Jupiter Z Carburetorandi.tasikNessuna valutazione finora

- P0 COCH 1 BOR LOG BO1 CLIENT MBITS PROJECT NAME p05 PROJECT NUMBER po5Documento1 paginaP0 COCH 1 BOR LOG BO1 CLIENT MBITS PROJECT NAME p05 PROJECT NUMBER po5Dileep K NambiarNessuna valutazione finora

- Summary of Instrumentation Installation and MonitoringDocumento3 pagineSummary of Instrumentation Installation and MonitoringJarugit PoonchaiNessuna valutazione finora

- AI ALL SpecificationDocumento18 pagineAI ALL SpecificationhtanhNessuna valutazione finora

- Global Technical Campus, Jaipur: Global Institute of Technology W.E.FDocumento1 paginaGlobal Technical Campus, Jaipur: Global Institute of Technology W.E.FGautam GunjanNessuna valutazione finora

- Data PDA & Kalendering ABT 1Documento16 pagineData PDA & Kalendering ABT 1fatmaNessuna valutazione finora

- 46 Capwap Jemb Kebun Durian Tahap 1Documento14 pagine46 Capwap Jemb Kebun Durian Tahap 1fatmaNessuna valutazione finora

- ADEDocumento10 pagineADEashwinishettytpNessuna valutazione finora

- E-CAPS-24 (CF&SS) - Physics (Final)Documento3 pagineE-CAPS-24 (CF&SS) - Physics (Final)Rajat BharadwajNessuna valutazione finora

- Mi21mtech11003 - BM5023 - 2021 - Lab 2Documento7 pagineMi21mtech11003 - BM5023 - 2021 - Lab 2Subhranil RoyNessuna valutazione finora

- Experiment-VIII: Characteristics of Directional Overcurrent RelayDocumento3 pagineExperiment-VIII: Characteristics of Directional Overcurrent Relayarjuna4306Nessuna valutazione finora

- Thermal Model Trip Times (SEL-710 Motor Relay)Documento1 paginaThermal Model Trip Times (SEL-710 Motor Relay)Suterm SeccionNessuna valutazione finora

- 3.4 Inspection CertificateDocumento1 pagina3.4 Inspection CertificateAlfian ImaduddinNessuna valutazione finora

- Schedule for Monday classesDocumento15 pagineSchedule for Monday classesheraasku7194Nessuna valutazione finora

- (TDB) VRF DVM S For India (R410a, 50 - 60hz, HP) - Ver.1.0Documento39 pagine(TDB) VRF DVM S For India (R410a, 50 - 60hz, HP) - Ver.1.0Mauro Cesar Remon ZavaletaNessuna valutazione finora

- SPE 125028 Hoiz Prod Logging With Multi Array ToolDocumento14 pagineSPE 125028 Hoiz Prod Logging With Multi Array ToolJose Gregorio FariñasNessuna valutazione finora

- Application Note AN-1121: Practical Layout For Current Sensing Circuit of IRMCF300 Series ICDocumento14 pagineApplication Note AN-1121: Practical Layout For Current Sensing Circuit of IRMCF300 Series ICHaris AmrullahNessuna valutazione finora

- 74HC HCT4060Documento19 pagine74HC HCT4060JorgeNessuna valutazione finora

- How To Calculate Conduit FillDocumento4 pagineHow To Calculate Conduit FillAliNessuna valutazione finora

- bms.0610 r0 Risk and Opportunities PDFDocumento5 paginebms.0610 r0 Risk and Opportunities PDFshadyalakhrasNessuna valutazione finora

- Install TTDM-128 PDFDocumento6 pagineInstall TTDM-128 PDFStudent ForeignNessuna valutazione finora

- Weighbridge indicator for explosive atmospheresDocumento2 pagineWeighbridge indicator for explosive atmospheresStudent ForeignNessuna valutazione finora

- Business Management System - BMS ManualDocumento11 pagineBusiness Management System - BMS ManualStudent ForeignNessuna valutazione finora

- TUV Austria ProfileDocumento56 pagineTUV Austria ProfileStudent ForeignNessuna valutazione finora

- Business Management System - Objectives and Programs: 1 PurposeDocumento2 pagineBusiness Management System - Objectives and Programs: 1 PurposeStudent ForeignNessuna valutazione finora

- Business Management System - Competence & Awareness: 1 PurposeDocumento3 pagineBusiness Management System - Competence & Awareness: 1 PurposeStudent ForeignNessuna valutazione finora

- bms.0630 r0 Management of Change PDFDocumento3 paginebms.0630 r0 Management of Change PDFLedo HoussienNessuna valutazione finora

- Vpflowmate User Manual: For Vpflowmate Probe, and Vpflowmate In-Line (With M12 8-Pole Connector)Documento40 pagineVpflowmate User Manual: For Vpflowmate Probe, and Vpflowmate In-Line (With M12 8-Pole Connector)Student ForeignNessuna valutazione finora

- 5000 Series Indicators Instruction Manual: T51P IndicatorDocumento64 pagine5000 Series Indicators Instruction Manual: T51P IndicatorStudent ForeignNessuna valutazione finora

- 04-52-05-1 MU - Precia Molen - ManualzzDocumento32 pagine04-52-05-1 MU - Precia Molen - ManualzzStudent ForeignNessuna valutazione finora

- Method of Statement - Transformer Maintenance - ScannedDocumento48 pagineMethod of Statement - Transformer Maintenance - ScannedStudent ForeignNessuna valutazione finora

- OHAUS Balance PDFDocumento4 pagineOHAUS Balance PDFninaNessuna valutazione finora

- Non-Budgeted Expenditure Request FormDocumento1 paginaNon-Budgeted Expenditure Request FormStudent ForeignNessuna valutazione finora

- Metrologia 2011 PRT in Dry-Block Calibration ProcessDocumento5 pagineMetrologia 2011 PRT in Dry-Block Calibration Processfernando diazNessuna valutazione finora

- COVID 19 Training Course For Doctors PDFDocumento2 pagineCOVID 19 Training Course For Doctors PDFStudent ForeignNessuna valutazione finora

- Ge Druck Dry TC 165 Dry Block Temperature Calibrator DatasheetDocumento8 pagineGe Druck Dry TC 165 Dry Block Temperature Calibrator DatasheetStudent ForeignNessuna valutazione finora

- 5.45 Inventory Management ProcedureDocumento4 pagine5.45 Inventory Management ProcedureRhozeiah LeiahNessuna valutazione finora

- Appendix-A EPM-SPD-PC-P-007 QC Dossier Index PDFDocumento14 pagineAppendix-A EPM-SPD-PC-P-007 QC Dossier Index PDFStudent Foreign100% (1)

- Calibration Datasheet Fro Multi Product Calibrator 3010 TransmilleDocumento4 pagineCalibration Datasheet Fro Multi Product Calibrator 3010 TransmilleStudent ForeignNessuna valutazione finora

- Specific Criteria Mechanical Testing 4 IANZDocumento29 pagineSpecific Criteria Mechanical Testing 4 IANZronargot100% (2)

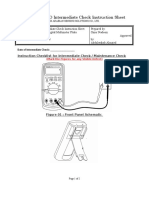

- SASSCO Intermediate Check Instruction SheetDocumento2 pagineSASSCO Intermediate Check Instruction SheetStudent ForeignNessuna valutazione finora

- Ventrack Control Valve TesterDocumento4 pagineVentrack Control Valve TesterStudent ForeignNessuna valutazione finora

- Icp SS 128Documento2 pagineIcp SS 128Student ForeignNessuna valutazione finora

- SASSCO Intermediate Check Instruction SheetDocumento2 pagineSASSCO Intermediate Check Instruction SheetStudent ForeignNessuna valutazione finora

- Field Communicator (Emerson 375)Documento1 paginaField Communicator (Emerson 375)Student ForeignNessuna valutazione finora

- SASSCO Intermediate Check Instruction SheetDocumento2 pagineSASSCO Intermediate Check Instruction SheetStudent ForeignNessuna valutazione finora

- SASSCO Intermediate Check InstructionDocumento4 pagineSASSCO Intermediate Check InstructionStudent ForeignNessuna valutazione finora

- MLX 90615Documento30 pagineMLX 90615Enrique GuerreroNessuna valutazione finora

- Liquid Expansion WorksheetDocumento2 pagineLiquid Expansion Worksheetjhanani.school2Nessuna valutazione finora

- NCERT Solutions for Mechanical Properties of FluidsDocumento288 pagineNCERT Solutions for Mechanical Properties of FluidsProcurement OfficerNessuna valutazione finora

- Research Paper 1Documento38 pagineResearch Paper 1Joshue Karlo AninoNessuna valutazione finora

- Grade 4 3rd SUMMATIVE EXAM 2Documento2 pagineGrade 4 3rd SUMMATIVE EXAM 2Mariel Gregore100% (5)

- Kinetic Theory of GasesDocumento8 pagineKinetic Theory of GasesAditya SallyNessuna valutazione finora

- Temperature MeasurementDocumento57 pagineTemperature MeasurementATUL ASWARNessuna valutazione finora

- Supco Refrigeration CatalogDocumento78 pagineSupco Refrigeration CatalogplasmapeteNessuna valutazione finora

- K194XX Dropping Point Apparatus ManualDocumento18 pagineK194XX Dropping Point Apparatus ManualManta SystemsNessuna valutazione finora

- Thermometers & Data LoggersDocumento2 pagineThermometers & Data LoggersMiguel EduardoNessuna valutazione finora

- (2004, Steinberg) Forces in Wingwalls of Skewed Semi-Integral BridgesDocumento9 pagine(2004, Steinberg) Forces in Wingwalls of Skewed Semi-Integral BridgesAnderson UrreaNessuna valutazione finora

- Chapter # 11 HeatDocumento6 pagineChapter # 11 HeatSIR USMAN KHAN50% (2)

- ASTM D445-21 Standard Test Method For Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Documento18 pagineASTM D445-21 Standard Test Method For Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)MahammadNessuna valutazione finora

- Ammonia-Syngas - Advanced Thermometry Solutions - DAILY THERMETRICSDocumento1 paginaAmmonia-Syngas - Advanced Thermometry Solutions - DAILY THERMETRICSHECTORNessuna valutazione finora

- Introduction To SensorsDocumento17 pagineIntroduction To SensorsssrgmanNessuna valutazione finora

- ASTM D445-19 - Viscosidad Cinematica CSTDocumento18 pagineASTM D445-19 - Viscosidad Cinematica CSTcarlosNessuna valutazione finora

- ASTM D36D36M Standart Test Method For Softening Point of Bitumen (Ring and Ball Apparatus)Documento5 pagineASTM D36D36M Standart Test Method For Softening Point of Bitumen (Ring and Ball Apparatus)Yeison GarciaNessuna valutazione finora

- Astm D86Documento29 pagineAstm D86amanda salgadoNessuna valutazione finora

- 2007 Bakery Whole CatalogDocumento13 pagine2007 Bakery Whole CatalogJorge MontanoNessuna valutazione finora

- Manual de Fabrcante - Ametek Pozo SecoDocumento8 pagineManual de Fabrcante - Ametek Pozo SecoMaricela EscamillaNessuna valutazione finora

- Temperature Sensor Tutorial! - 5 Steps (With Pictures)Documento16 pagineTemperature Sensor Tutorial! - 5 Steps (With Pictures)cesarinigillasNessuna valutazione finora

- Syringe ThermodynamicsDocumento8 pagineSyringe ThermodynamicsScrotumusTesticlesNessuna valutazione finora

- Heat Transfer: For SCIENCE Grade 7 Quarter 3 / Week 7Documento16 pagineHeat Transfer: For SCIENCE Grade 7 Quarter 3 / Week 7Tabada NickyNessuna valutazione finora

- Ds Electronic Measuring and Calibration Instruments PDFDocumento312 pagineDs Electronic Measuring and Calibration Instruments PDFfrankboteroNessuna valutazione finora

- Ika CatalogueDocumento91 pagineIka Cataloguekashif020Nessuna valutazione finora

- Distillation of Road Tars: Standard Test Method ForDocumento5 pagineDistillation of Road Tars: Standard Test Method ForPyone Ei ZinNessuna valutazione finora

- ME242 Mechanical Measurement Resource GuideDocumento88 pagineME242 Mechanical Measurement Resource Guidedynamics 123Nessuna valutazione finora

- BMS SpecificationsDocumento55 pagineBMS SpecificationseyadNessuna valutazione finora

- Green - Book - Chapter Cold Chain EnglandDocumento20 pagineGreen - Book - Chapter Cold Chain EnglandMario Vazquez BNessuna valutazione finora

- OFITE Cup Heater With Stainless Steel Cup 130-20Documento2 pagineOFITE Cup Heater With Stainless Steel Cup 130-20HenryNessuna valutazione finora