Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IOZ Painting

Caricato da

Dhinesh ThanappanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

IOZ Painting

Caricato da

Dhinesh ThanappanCopyright:

Formati disponibili

Inorganic Zinc Silicate Primers 3.8.

What Are Inorganic Zinc Silicates?

Inorganic zinc silicates are coatings comprising metallic zinc held in a glassy silicate matrix. The zinc metal provides

galvanic corrosion protection to the mild steel substrate, whilst the porosity of the coating provides voids that contribute to

ongoing protection to the mild steel.

Compared with hot dip galvanising, inorganic zinc silicates provide superior galvanic corrosion protection to steelwork,

particularly in corrosive coastal environments. To understand how Inorganic Zinc silicates work and why they offer

superior corrosion protection, particularly in coastal environs, you need to understand some environmental corrosion

chemistry. Here’s how it works.

Environmental Corrosion Chemistry

Corrosion of metals, such as steel and zinc, requires the presence of water (H2O), oxygen (O2) and ions such as

chloride ions (Cl¯), all of which exist on the atmosphere. Atmospheric chloride ions are in greatest abundance anywhere

near the coastline.

In addition to these, the atmosphere also carries emissions from human activity, such as carbon dioxide (CO2), carbon

monoxide (CO), sulphur dioxide (SO2), nitrous oxide (NO2) and many other chemicals.

Mechanism:

CO2 acts as a weak acid thus:

H2O + CO2 → H2CO3 (Carbonic Acid)

The carbonic acid then reacts with the zinc metal

on the surface of the IOZ matrix:

H2CO3 (Carbonic Acid) + χZn + O2 →

(Zn)χ (OH) CO3

(zinc hydroxy carbonate - insoluble)

The insoluble and inert zinc hydroxy carbonate product then gets locked into the surface pores of the IOZ, creating

an effective barrier to further oxidation. The zinc hydroxy carbonate is symbolised as Zn+ in figure 2 below.

Inorganic Zinc Silicate Primers Jan-10 Page 1 of 3

Inorganic Zinc Silicate Primers 3.8.1

If the steelwork is coated, then the zinc hydroxy carbonate barrier greatly

prolongs the life of the coating system by providing stability in the substrate.

This longevity is not provided by the zinc metal, but by the pores and the stable

zinc hydroxy carbonate particles locked within.

HDG and electrolytically applied zinc do not have this porosity, and therefore

cannot produce a barrier with their initial zinc corrosion products. These corrosion

products simply delaminate from the surface, so zinc depletion continues at the

same rate. Subtle difference in behaviour – big difference in performance,

particularly in the case of coated steelwork, where the coating may be pushed off

by the increasing volume of zinc corrosion products on the surface of the zinc.

When Should You Use IOZ?

IOZ primers should be used for all steelwork that:

Is intended for use in moderate to severe coastal areas

Is intended for structures with very long service lives, such as buildings,

public spaces and infrastructure

Requires an extremely tough coating, particularly for friction-grip bolting

Is too large or long to fit in a hot dip galvanizing bath

Can be properly prepared by abrasive blast cleaning (Refer to Dulux

Protective Coatings Tech Note 1.1.2 – Mild Steel Surface Preparation)

Where long term corrosion performance is required in a single coat

Advantages of IOZ Primers

The advantages of IOZ primers over other forms of galvanic corrosion protection

are:

The cured film is harder and more damage-resistant than HDG steel.

Highly effective galvanic corrosion protection with more effective use of zinc

metal than HDG.

Waterborne/low VOC technology IOZ is available for projects governed by

“green” guidelines.

When Should You Not Use IOZ?

Good surface preparation of steelwork is absolutely essential for the IOZ primer to

perform as designed. IOZ is not appropriate for steel that:

Cannot be abrasive blast cleaned, such as thin-gauge steel or tubular steel, as the surface profile of the steel must

be sufficient to provide a good mechanical key for the coating to adhere to.

Cannot be prepared and coated in shop under controlled atmospheric conditions.

Is limited to brush or roller application, and therefore cannot be applied by spray.

Is to be exposed to acidic and certain chemical environments. (Consult Dulux Protective Coatings)

Inorganic Zinc Silicate Primers Jan-10 Page 2 of 3

Inorganic Zinc Silicate Primers 3.8.1

IOZ is not suitable for touch-up of damaged hot-dip galvanised steel, whereas an organic zinc-rich primer such as

Dulux® Metalshield® Cold Galv Primer is. (Tech Note 3.8.2 – Organic Zinc Rich Primers)

IOZ may be somewhat of an “over-specification” if the structure to be coated is only temporary (for example, constructed

for a special event), and may be adequately protected from corrosion by a fast cure, single-pack zinc phosphate primer.

Having said that, however, many such structures have in fact become permanent (such as the Eiffel Tower in France)!

Disadvantages of IOZ Primers

Certain coating types, such as alkyd enamels, cannot be applied directly over IOZ coatings (although this can easily

be rectified by changing the coating to another resin type).

Higher applicator skill is required to spray IOZ than some other types of anticorrosive primers.

Longer cure time and overcoat time compared with other types of anticorrosive primers. Typically IOZ’s take 24

hours to cure for recoat; other paint chemistries operate on faster recoat times.

Curing of IOZ’s typically rely on the weather conditions. Products like Zincanode® 304 and Zincgalv® 75 require

humidity to cure, while Aquagalv® will cure below 50% relative humidity.

Must be applied between the minimum and maximum recommended dry film builds; less and the dry film will not

fulfill AS2312 requirements and may compromise corrosion protection. Greater than the maximum recommended

dry film build may cause mud-cracking and/or delayed curing.

Current IOZ Products

Dulux Protective Coatings currently manufactures three inorganic zinc silicates:

ZINCANODE® 304 (as used at the Edith Cowan University WA)

ZINCGALV® 75

AQUAGALV®

AQUAGALV® is a second-generation water-borne inorganic zinc silicate,

and has a total VOC content less than 10 grams per litre.

Further Reading

For a comparison of the processes of applying HDG and applying IOZ, particularly from an ESD point of view, please

refer to Tech Note 2.3.4 - ESD and Corrosion Protection.

For more information, please contact the Dulux Protective Coatings Technical Consultant in your state.

Inorganic Zinc Silicate Primers Jan-10 Page 3 of 3

Potrebbero piacerti anche

- Corrosion: Corrosion ControlDa EverandCorrosion: Corrosion ControlL L ShreirValutazione: 5 su 5 stelle5/5 (1)

- Sefako Makgatho Health Sciences University: (Chemistry 1A)Documento6 pagineSefako Makgatho Health Sciences University: (Chemistry 1A)MotseilekgoaNessuna valutazione finora

- Inorganic Zinc Silicate Coatings Fallaci PDFDocumento9 pagineInorganic Zinc Silicate Coatings Fallaci PDFDhanush Kumar RamanNessuna valutazione finora

- 3.9.1 Organic Zinc Rich PrimersDocumento2 pagine3.9.1 Organic Zinc Rich PrimersKeith ChooNessuna valutazione finora

- Organic and Inorganic Zinc Rich CoatingsDocumento3 pagineOrganic and Inorganic Zinc Rich CoatingsEddy Norman Benites Delgado100% (6)

- FALLSEM2019-20 CHY1701 ETH VL2019201007055 Reference Material I 06-Sep-2019 Revised Module 4Documento73 pagineFALLSEM2019-20 CHY1701 ETH VL2019201007055 Reference Material I 06-Sep-2019 Revised Module 4yuvanNessuna valutazione finora

- DIsign Against CorrosionDocumento72 pagineDIsign Against CorrosionAMAL MATHEWNessuna valutazione finora

- Wet Storage Stain On Galvanized SteelDocumento8 pagineWet Storage Stain On Galvanized SteelDino PedutoNessuna valutazione finora

- Chemistry Project: Problems in Daily Life and Its SolutionDocumento32 pagineChemistry Project: Problems in Daily Life and Its Solutionanurag prernaNessuna valutazione finora

- Durability of Cement Based Building Materials: Silicate Silica GelDocumento7 pagineDurability of Cement Based Building Materials: Silicate Silica GelKerem SaygınNessuna valutazione finora

- ZincDocumento10 pagineZincHabibNessuna valutazione finora

- Surface FinishingDocumento7 pagineSurface Finishingcanveraza3122Nessuna valutazione finora

- RichBurgess FALLAS EN GALVANIZADO PDFDocumento9 pagineRichBurgess FALLAS EN GALVANIZADO PDFShenhua Kronen SohneNessuna valutazione finora

- Post Treatment of Hot Dip Galvanized Steel Sheet-Chromating, Phosphating and Other Alternative Passivation TechnologiesDocumento22 paginePost Treatment of Hot Dip Galvanized Steel Sheet-Chromating, Phosphating and Other Alternative Passivation TechnologiesAmirtharaaj VijayanNessuna valutazione finora

- Wet Storage Stain On Galvanized SteelDocumento5 pagineWet Storage Stain On Galvanized Steele.vicente.caballeroNessuna valutazione finora

- Spray Painting Unit 1.2Documento17 pagineSpray Painting Unit 1.2arun3kumar00_7691821Nessuna valutazione finora

- CorrosionDocumento51 pagineCorrosionshartendu100% (2)

- 1-Corrosion and Protection of Steel Reinforced ConcreteDocumento51 pagine1-Corrosion and Protection of Steel Reinforced ConcreteEmad Behdad100% (1)

- Corrosion Control MethodsDocumento14 pagineCorrosion Control MethodsYogesh D N YogeshNessuna valutazione finora

- 234 Esd and Galvanic Corrosion ProtectionDocumento9 pagine234 Esd and Galvanic Corrosion Protectionant1Nessuna valutazione finora

- Chapter 15 - Coatings-1Documento32 pagineChapter 15 - Coatings-1Sumit Ghosh KabboNessuna valutazione finora

- Corrosion InhibitorsDocumento38 pagineCorrosion Inhibitors20pcha122 20pcha122Nessuna valutazione finora

- What Is CorrosionDocumento4 pagineWhat Is CorrosionOsransyah Os100% (1)

- Corrosion Control PDFDocumento48 pagineCorrosion Control PDFAnkit SinghNessuna valutazione finora

- Module 4 - Corrosion ProtectionDocumento62 pagineModule 4 - Corrosion ProtectionPrashant RajNessuna valutazione finora

- Corrosion UpdatedDocumento28 pagineCorrosion UpdatedKiran ThunuguntlaNessuna valutazione finora

- Engineering Chemistry - Module 2Documento40 pagineEngineering Chemistry - Module 2Murthy Reddy100% (1)

- Lecturee 11Documento28 pagineLecturee 11عبد الرحمن قاسمNessuna valutazione finora

- BS-88R 2018 Literature On Corrosion Protection in Concrete StructuresDocumento48 pagineBS-88R 2018 Literature On Corrosion Protection in Concrete StructuresM PMNessuna valutazione finora

- Black PassivationDocumento12 pagineBlack PassivationZineb100% (1)

- CorrosionDocumento81 pagineCorrosionsureshs83Nessuna valutazione finora

- Corrosion and Protection of Steel Reinforced ConcreteDocumento51 pagineCorrosion and Protection of Steel Reinforced Concreteprojectcching8372Nessuna valutazione finora

- Corrosion in Oil and Gas IndustryDocumento25 pagineCorrosion in Oil and Gas IndustryAMINE0% (1)

- 1.2.4 HDG - Painting Issues PDFDocumento2 pagine1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0Nessuna valutazione finora

- Abuloc Significance of CorrosionDocumento12 pagineAbuloc Significance of CorrosionRed CrazyNessuna valutazione finora

- Durability Durability of of Steel Steel Structures StructuresDocumento21 pagineDurability Durability of of Steel Steel Structures StructuresKris d100% (1)

- Silicon Would Not Be TheDocumento10 pagineSilicon Would Not Be TheZhafrandy Eka SenidaNessuna valutazione finora

- What Is Corrosion?: Corrodere (Latin) - To Eat AwayDocumento21 pagineWhat Is Corrosion?: Corrodere (Latin) - To Eat Awayعبدالرحمن الفيفيNessuna valutazione finora

- Corrosion: IntroducingDocumento29 pagineCorrosion: Introducingkeval patelNessuna valutazione finora

- Corrosion 1Documento29 pagineCorrosion 1shaileshpathakNessuna valutazione finora

- CTB01 - General Introduction Sept 02Documento2 pagineCTB01 - General Introduction Sept 02Ravinesh SinghNessuna valutazione finora

- Corrosion of Steel Embedded in Concrete: Are Covered by A Thin Iron-Oxide FilmDocumento10 pagineCorrosion of Steel Embedded in Concrete: Are Covered by A Thin Iron-Oxide FilmSteven KuaNessuna valutazione finora

- CorrosionDocumento54 pagineCorrosionSorab Khosla100% (1)

- CorroisionDocumento21 pagineCorroisionIrtiza RasulNessuna valutazione finora

- Ronak Mehta ContentDocumento12 pagineRonak Mehta ContentDevashish JoshiNessuna valutazione finora

- Corrosion and Protective CoatingDocumento54 pagineCorrosion and Protective CoatingNeo MeltonNessuna valutazione finora

- The Composition of Clean, Dry Air As Being Approximately 78% Nitrogen, 21% Oxygen and The Remainder As Being A Mixture of Noble Gases and Carbon DioxideDocumento11 pagineThe Composition of Clean, Dry Air As Being Approximately 78% Nitrogen, 21% Oxygen and The Remainder As Being A Mixture of Noble Gases and Carbon DioxideShunzi YanNessuna valutazione finora

- What Is CorrosionDocumento17 pagineWhat Is CorrosionHaider AliNessuna valutazione finora

- CorisonDocumento10 pagineCorisonAryan GuptaNessuna valutazione finora

- Corrosion ControlDocumento24 pagineCorrosion ControlJane SmithNessuna valutazione finora

- Preparation of Galvanized Steel Before PaintingDocumento6 paginePreparation of Galvanized Steel Before PaintingjosephNessuna valutazione finora

- SchoolDocumento17 pagineSchoolEjaz ul Haq kakarNessuna valutazione finora

- Painting and Coating Inspector InterviewDocumento8 paginePainting and Coating Inspector Interviewkumar100% (2)

- Duplex SystemDocumento9 pagineDuplex Systemnightmanmx100% (1)

- Corrosion PDFDocumento73 pagineCorrosion PDFRajat VarshneyNessuna valutazione finora

- CorrosionDocumento40 pagineCorrosionPreetika Sastry100% (1)

- CFA Guidance - Fixings & CorrosionDocumento4 pagineCFA Guidance - Fixings & Corrosionmdavies20Nessuna valutazione finora

- Media File Sheehan Perf of HDG in Coastal Envs PDFDocumento18 pagineMedia File Sheehan Perf of HDG in Coastal Envs PDFFrankie ChanNessuna valutazione finora

- Utility of Thermal OxidationDocumento7 pagineUtility of Thermal OxidationRishi JhaNessuna valutazione finora

- Painting Inspection (Zinc Silicate)Documento17 paginePainting Inspection (Zinc Silicate)Rajesh Appu100% (1)

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksDa EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNessuna valutazione finora

- BiFr ListDocumento20 pagineBiFr Listnisarg_Nessuna valutazione finora

- 400 Important Chemistry Questions and Answer PDF For SSC @WWW - Letsstudytogether.coDocumento30 pagine400 Important Chemistry Questions and Answer PDF For SSC @WWW - Letsstudytogether.cobittal PoddarNessuna valutazione finora

- The Advanced Placement Examination in Chemistry: ElectrochemistryDocumento21 pagineThe Advanced Placement Examination in Chemistry: ElectrochemistrySreeyaNessuna valutazione finora

- Cambridge IGCSE: Co-Ordinated Sciences 0654/22Documento16 pagineCambridge IGCSE: Co-Ordinated Sciences 0654/22Gina ChenNessuna valutazione finora

- Kuettner Shaft-Furnace PDFDocumento6 pagineKuettner Shaft-Furnace PDFSamiran BanerjeeNessuna valutazione finora

- Stainless Steel Components Heat Treatment PDFDocumento45 pagineStainless Steel Components Heat Treatment PDFsmani170Nessuna valutazione finora

- NM FixDocumento37 pagineNM FixSherly EliisaNessuna valutazione finora

- Basics of Catalysts - Chemistry LibreTextsDocumento6 pagineBasics of Catalysts - Chemistry LibreTextsStatus loverNessuna valutazione finora

- Steel - WikipediaDocumento16 pagineSteel - WikipediaaravindNessuna valutazione finora

- Seminar Skor A+ StudentDocumento21 pagineSeminar Skor A+ StudentSora HikaruNessuna valutazione finora

- Corrosion: M285 Diagnosis of Engineering Failures Course Petronas, KL, May 2009 David KnowlesDocumento49 pagineCorrosion: M285 Diagnosis of Engineering Failures Course Petronas, KL, May 2009 David KnowlesWongChi LiekNessuna valutazione finora

- Hsslive Xi Chem Notes Anil CH 8. REDOX REACTIONSDocumento6 pagineHsslive Xi Chem Notes Anil CH 8. REDOX REACTIONSKrishnendu NairNessuna valutazione finora

- Stellite Alloys - Chemical Composition, Mechanical Properties and Common ApplicationsDocumento3 pagineStellite Alloys - Chemical Composition, Mechanical Properties and Common ApplicationsASHIL PRABHAKARNessuna valutazione finora

- Q3W3 GenChem1 Quipper Study Guide IsotopesDocumento11 pagineQ3W3 GenChem1 Quipper Study Guide IsotopesArjay NatividadNessuna valutazione finora

- KC and KP Exam Questions: Reigate Grammar School 1Documento4 pagineKC and KP Exam Questions: Reigate Grammar School 1megaordinarydayNessuna valutazione finora

- Exercise 1: MODUL 1: Formula KimiaDocumento5 pagineExercise 1: MODUL 1: Formula KimiaMiesya87Nessuna valutazione finora

- IJC H2 Paper 1 and 2 Answers (For Sharing)Documento9 pagineIJC H2 Paper 1 and 2 Answers (For Sharing)Sharon HowNessuna valutazione finora

- Factors Affecting Rate of ReactionDocumento20 pagineFactors Affecting Rate of ReactionMenaga A/P IlangkovanNessuna valutazione finora

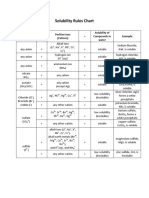

- Solubility Rules ChartDocumento2 pagineSolubility Rules ChartLumwanga MukadiNessuna valutazione finora

- Royal Queen MedlyedddddddDocumento6 pagineRoyal Queen MedlyedddddddAinah 16Nessuna valutazione finora

- HW#5Documento9 pagineHW#5AbdullahNessuna valutazione finora

- Percentage Composition of A Compound: What Is It?Documento7 paginePercentage Composition of A Compound: What Is It?Mira VeranoNessuna valutazione finora

- Phosphate 2004Documento3 paginePhosphate 2004Alexandra GarciaNessuna valutazione finora

- Exer 10Documento2 pagineExer 10Mariel TrinidadNessuna valutazione finora

- H Chem Grahams Law of Effusion 2017Documento14 pagineH Chem Grahams Law of Effusion 2017Mohan Ganjahally100% (1)

- The World of Mineral DepositsDocumento4 pagineThe World of Mineral DepositsDaniel TorresNessuna valutazione finora

- Lesson 3 - History of Periodic TableDocumento27 pagineLesson 3 - History of Periodic TableAileen SimNessuna valutazione finora

- ChlorinationDocumento13 pagineChlorinationVijaya LakshmiNessuna valutazione finora

- Radioactive Series and Successive GrowthDocumento19 pagineRadioactive Series and Successive GrowthAyushi AggarwalNessuna valutazione finora