Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Desaireador PDF

Caricato da

SPGCTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Desaireador PDF

Caricato da

SPGCCopyright:

Formati disponibili

Smith MeterTM Air Eliminator

Model AR

Specifications

Issue/Rev. 0.4 (3/06) Bulletin SS03032

The Smith MeterTM Model AR Air Eliminator separates

and releases air or gas from petroleum or other liquids

before they are passed through the meter. Complete elimi-

nation of air or gas is essential for accurate metering.

Therefore, the Smith MeterTM Model AR Air Eliminator is a

necessary part of a metering system when there is a

possibility of air or gas being present in the flowstream.

Features

A wide selection of tanks and Air Eliminator Heads

for proper application - See selection guide on Page

3 of this bulletin.

Model AR Air Eliminators

Mechanical or Electrical Air Elimination Heads -

State-of-the-art electrical air elimination is now available.

Code Conformance - Tanks may be supplied in con- Applications

formance with the ASME Code Section VIII or other.

Air eliminators should always be installed as close to the

meter as possible. The air release head should be piped

Principle of Operation to a convenient and safe point of discharge. Never pipe to

the inside of a building. Provide the end of the air release

The air eliminators are horizontal pressure vessels with pipe with a suitable flame arrestor. The air release line

flanged end connections. The air eliminators perform by should have an open drip at the lowest point, discharging

reducing fluid line velocity, allowing vapor bubbles to rise into a condensate drum or suitable container at atmo-

to the top of the vessel where they are expelled through spheric pressure. A valve may be placed in the air re-

the air release head. lease line near the eliminator, provided the valve is al-

ways open except in emergency.

Pressure Drop (∆P)

The Most Trusted Name In Measurement

Specifications Materials of Construction

End Connections Inlet and Outlet Heads

Raised face flanges per ANSI B16.5. SA516 GR. 70

Maximum Working Pressure Shell

Class 150 RF: To 285 psig (1,965 kPa) at 100°F (38°C). SA516 GR. 70

Class 300 RF: To 300 psig (2,068 kPa) at 100°F (38°C).

Inlet and Outlet Pipes

Temperature Range SA53 or SA106 GR. B Type S

Standard: -20°F to 225°F (-29°C to 107°C) - Buna-N

elastomer. Wells

Optional: SA 53 or SA106 GR. B Type S

0°F to 400°F (-18°C to 205°C) - Viton elastomer. Drain

x°F to xxx°F (-xx°C to xxx°C) - Chemraz (UB Head

A105

only).

Other Temperatures and Pressures: Consult factory. Feet

A36

Hand-holes

SA516 GR. 70

Lifting Lugs

SA516 GR. 70

Modeling

AR — 4 — 2040 — 3 — R — C— S

Type Special Options

AR - Air Eliminator

Design Code

Flange Size Blank - Design per ASME VIII-1

C - ASME VIII-1 "U" Stamp

Tank Size

Air Release Head

R1 - RB-Head w/Buna-N

R2 - RB-Head w/ Viton

U1 - UB-Head w/ Viton

U2 - UB-Head w/ Chemraz

DE - Dual Electric DE-Head

PG - PetroGard

Connection/Pressure Rating*

3 - Class 150 RF/Class 285 (1,965 kPa)

5 - Class 300 RF/Class 300 (2,068 kPa)

*Flanges per ANSI B16.5.

Page 2 • SS03032 Issue/Rev. 0.4 (3/06)

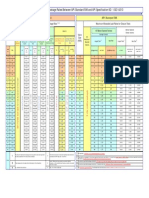

Dimensions

Inches (mm) H

P N M L 'RB'

Lifting Lug Head

Hand-hole

Flow K

G

R

D Drain

Opening Hand-hole

Anchor Bolt Holes

E

B C F

Note: Dimensions — Inches to the nearest tenth (millimetres to the nearest whole mm), each independently dimensioned from respective

engineering drawings.

Model

Dimen- 1030 1030 2040 3050 4565 45100 75200 75200 150300 150300 350700

sions 2" 3" 4" 6" 6" 8" 8" 10" 10" 12" 16"

34.0 34.0 46.0 56.0 66.0 84.0 90.0 92.0 96.0 96.0 132.0

A (864) (864) (1,168) (1,422) (1,676) (2,134) (2,286) (2,337) (2,438) (2,438) (3,353)

14.5 14.5 23.8 29.0 36.0 54.0 60.0 60.0 60.0 60.0 72.0

B (368) (368) (605) (737) (914) (1,372) (1,524) (1,524) (1,524) (1,524) (1,829)

9.8 9.8 11.1 13.5 15.0 15.0 15.0 16.0 18.0 18.0 30.0

C (249) (249) (282) (343) (381) (381) (381) (406) (457) (457) (762)

7.3 7.3 11.9 14.5 18.0 27.0 30.0 30.0 30.0 30.0 36.0

D (185) (185) (302) (368) (457) (686) (762) (762) (762) (762) (914)

6.0 6.0 8.5 9.5 12.5 12.5 21.0 21.0 28.0 28.0 30.0

E (152) (152) (216) (241) (318) (318) (533) (533) (711) (711) (762)

9.0 9.0 11.5 12.5 15.3 15.3 25.0 25.0 31.0 31.0 36.0

F (229) (229) (292) (318) (389) (389) (635) (635) (787) (787) (914)

20.8 20.8 24.0 23.5 29.3 29.0 40.1 40.5 45.0 45.0 47.4

G (528) (528) (610) (597) (744) (737) (1,019) (1,029) (1,143) (1,143) (1,204)

14.0 14.0 18.0 20.0 24.0 24.0 36.0 36.0 42.0 42.0 42.0

H (356) (356) (457) (508) (610) (610) (914) (914) (1,067) (1,067) (1,067)

9.5 9.5 11.0 11.0 11.0 11.0 13.0 13.0 14.0 14.0 18.5

J (241) (241) (279) (279) (279) (279) (330) (330) (356) (356) (470)

11.0 11.0 13.0 12.5 18.3 18.0 27.1 27.5 31.0 31.0 28.9

K (279) (279) (330) (318) (465) (457) (688) (699) (787) (787) (734)

14.3 14.3 15.8 16.4 17.8 17.3 21.1 22.1 24.0 24.0 25.0

L (363) (363) (401) (417) (452) (439) (536) (561) (610) (610) (635)

10.0 12.0 12.0 13.0 13.0 13.0

M — — — — — (254) (305) (305) (330) (330) (330)

13.0 13.0 13.0

N — — — — — — — — (330) (330) (330)

13.0

P — — — — — — — — — — (330)

1.5 3.5 3.5 7.0 7.0 7.8 7.8 5.5

R — — — (38) (89) (89) (179) (179) (197) (197) (140)

Drain Opening: 1-1/4" NPT on Models 1030 through 45100

2" NPT on Models 75200 through 150300

3" diameter opening on Model 350700.

Flanges: ANSI B16.5.

Anchor Bolt Holes: 4 (13/16") diameter on Models 1030 through 45100

4 (7/8") diameter on Models 75200 (8" and 10")

4 (7/8" and 1") diameter on Models 150300 (10" and 12")

4 (1-1/8") diameter on Model 350700 (16").

Lifting Lugs: On Models 2040 through 350700.

Hand-holes: On Models 150300 through 350700.

Issue/Rev. 0.4 (3/06) SS03032 • Page 3

Selection Guide Dry pipe at supply end not over 40 pipe diameters long with

length of at least 80 pipe diameters of liquid-filled pipe

The selection of the correct size deaerator is of utmost between the dry section and the air eliminator.

importance and will result in the highest possible effi- The Smith DE Air Release Head is recommended for this

ciency and metering accuracy. This selection must be service. See Bulletin SS03030.

based upon two factors: (1) the maximum flow rate, and

(2) air and gas conditions. Air and gas conditions are Condition C (Maximum)

divided into three categories as follows: Dry pipe directly before deaerator over 60 pipe diameters

long.

Condition A (Minimum) Dry pipe at supply end not over 40 pipe diameters long but

Long exposed lines where temperature rise could cause where wet pipe between dry section and air eliminator has

vaporization. Possible suction leaks causing air to be several elbows or other fittings which would cause turbu-

drawn into the system. lence in the line.

When valving from one tank to another introduces a Same condition as B but handling fluid more viscous than

section of dry pipe twenty pipe diameters or less in length gasoline. Any conditions where extreme air entrainment

provided there is at least seven times this length be- occurs, long dry lines, extreme turbulence, or where lines

tween the dry section and the air eliminator. are blown dry by compressed air.

Condition B (Average) The Smith DE Air Release Head is recommended for this

service. See Bulletin SS03030.

Where it is possible for a gravity or pump system to

run dry.

Dry pipe directly before deaerator not over 60 pipe di-

ameters long.

First determine the maximum expected rate of flow through the deaerator. Then by a careful survey of the proposed

installation, determine the category into which your particular problem falls and, by means of the chart below, select the

correct air eliminator.

C 1030 2040 3050 4565 45100 75200 150-300

Condition

B 1030 2040 3050 4565 45100 75200 150-300

A 1030 2040 3050 4565 45100 75200 150-300

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Rate of Flow - USGPM API Gravity 40.6 at 60°F

3/06 Editorial Change:

Page 2: Updated Specifications and Modeling Code.

The specifications contained herein are subject to change without notice and any user of said specifications should verify from the manufacturer that the specifications are

currently in effect. Otherwise, the manufacturer assumes no responsibility for the use of specifications which may have been changed and are no longer in effect.

Headquarters:

1803 Gears Road, Houston, TX 77067 USA, Phone: 281/260-2190, Fax: 281/260-2191

Gas Measurement Products: Liquid Measurement Products:

Houston, TX USA Phone 281/260-2190 Erie, PA USA Phone 814/898-5000 Beijing, China Phone (86) 10/6500-2251

Thetford, England Phone (44) 1842-82-2900 Los Angeles, CA USA Phone 661/702-8660 Singapore Phone (65) 6861-3011

Kongsberg, Norway Phone (47) 32/286-700 Slough, England Phone (44) 1753-57-1515 Chennai, India Phone (91) 44/450-4400

Buenos Aires, Argentina Phone 54 (11) 4312-4736 Ellerbek, Germany Phone (49) 4101-3040

Integrated Measurement Systems: Barcelona, Spain Phone (34) 93/201-0989

Corpus Christi, TX USA Phone 361/289-3400 Moscow, Russia Phone (7) 495/564-8705

Kongsberg, Norway Phone (47) 32/286-700 Melbourne, Australia Phone (61) 3/9807-2818

San Juan, Puerto Rico Phone 787/274-3760

United Arab Emirates, Dubai Phone 971 +4/331-3646

Visit our website at www.fmctechnologies.com

Printed in U.S.A. © 2/01 FMC Technologies Measurement Solutions, Inc. All rights reserved. SS03032 Issue/Rev. 0.4 (3/06)

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 451 110 - Falk Lifelign Gear Couplings - Catalog PDFDocumento60 pagine451 110 - Falk Lifelign Gear Couplings - Catalog PDFAnonymous f1Hp4F7Nessuna valutazione finora

- SS01014 - Measurement Solutions - FMC Technologies PDFDocumento6 pagineSS01014 - Measurement Solutions - FMC Technologies PDFSPGCNessuna valutazione finora

- ASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDocumento30 pagineASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDaniel Diaz PrietoNessuna valutazione finora

- AccuLoad III Preset Specifications Spanish SS06036SNDocumento12 pagineAccuLoad III Preset Specifications Spanish SS06036SNJohan ZuñigaNessuna valutazione finora

- OilRefineryWalk-Through CEP May2014 Hi-Res PDFDocumento8 pagineOilRefineryWalk-Through CEP May2014 Hi-Res PDFkhairul4008Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Iso 2604-2Documento15 pagineIso 2604-2Yusri WyeuserieyNessuna valutazione finora

- Herbert Metzendorff & Co. KGDocumento3 pagineHerbert Metzendorff & Co. KGbeu catalin0% (2)

- Vi. Fluid Friction in Steady One Dimensional FlowDocumento38 pagineVi. Fluid Friction in Steady One Dimensional FlowAlna LiviaNessuna valutazione finora

- Hydraulic Cylinder Side LoadDocumento8 pagineHydraulic Cylinder Side LoadsushilNessuna valutazione finora

- 3600 Marine Engine Application and Installation Guide: PipingDocumento10 pagine3600 Marine Engine Application and Installation Guide: PipingmikelinchpNessuna valutazione finora

- 11 Ok Comparison Leakage Rates API 598 & API 6dDocumento0 pagine11 Ok Comparison Leakage Rates API 598 & API 6dZoebair0% (1)

- Wre-Report-782 (WR&D) PRDocumento86 pagineWre-Report-782 (WR&D) PRjbfalcaoNessuna valutazione finora

- Spirax SarcoDocumento7 pagineSpirax SarcoWahluyo Budi UtomoNessuna valutazione finora

- Dgca & Easa Module 15: Part-16 Turbo-Prop, Turbo-Shaft Engine & Auxiliary Power Units (Apus)Documento5 pagineDgca & Easa Module 15: Part-16 Turbo-Prop, Turbo-Shaft Engine & Auxiliary Power Units (Apus)NS ChakravarthyNessuna valutazione finora

- High Pressure Gear Pump W300: Concentric ABDocumento8 pagineHigh Pressure Gear Pump W300: Concentric ABMarin GarazNessuna valutazione finora

- F5OHQ1 F5OHQ2: Code 61 Connector Code 61 / SAE-ORB Code 62 Connector Code 62 / SAE-ORBDocumento5 pagineF5OHQ1 F5OHQ2: Code 61 Connector Code 61 / SAE-ORB Code 62 Connector Code 62 / SAE-ORBHuy NguyễnNessuna valutazione finora

- Chem-Feed Diaphragm Metering Pump: FeaturesDocumento4 pagineChem-Feed Diaphragm Metering Pump: FeaturesAlejandro MoralesNessuna valutazione finora

- Hydraulic Machines Question BankDocumento11 pagineHydraulic Machines Question BankAdit Gaur100% (3)

- 1 Test Section 2 Thurst and Torque Dynamometer 3 Propeller Motor 4 Axial Flow Impeller 5 Impeller MotorDocumento2 pagine1 Test Section 2 Thurst and Torque Dynamometer 3 Propeller Motor 4 Axial Flow Impeller 5 Impeller MotorDavid AmayaNessuna valutazione finora

- Diffuser Versus Volute Casing - PumpsDocumento5 pagineDiffuser Versus Volute Casing - Pumpsjanamurali0% (1)

- RPL Dfo 1-1 2-2 3-3 Rev 14Documento32 pagineRPL Dfo 1-1 2-2 3-3 Rev 14Jesús Gabriel RodríguezNessuna valutazione finora

- LatihanDocumento5 pagineLatihanAyu Mustika100% (2)

- Commercial Unit Cooler:Cubic Type: E45HC 4922 E 9 N. Units: 1Documento1 paginaCommercial Unit Cooler:Cubic Type: E45HC 4922 E 9 N. Units: 1Mario UrsuNessuna valutazione finora

- Simple Vapour Compression Refrigeration System: Advantages of Air RefrigerationDocumento17 pagineSimple Vapour Compression Refrigeration System: Advantages of Air RefrigerationNikhil WaghalkarNessuna valutazione finora

- Boiler MtceDocumento3 pagineBoiler MtceJustin RajNessuna valutazione finora

- Valvula de Alivio 55LDocumento2 pagineValvula de Alivio 55LRobinzonJVilcchezzNessuna valutazione finora

- Chap 5. Design of Pressure VessedDocumento13 pagineChap 5. Design of Pressure VessedAli AhsanNessuna valutazione finora

- A319/A320/A321 Technical Training Manual General Familiarization Course 29 Hydraulic PowerDocumento38 pagineA319/A320/A321 Technical Training Manual General Familiarization Course 29 Hydraulic PowerAnas AbandehNessuna valutazione finora

- Tesco HCS 750 Troubleshooting Guide PDFDocumento86 pagineTesco HCS 750 Troubleshooting Guide PDFLuther MoletaNessuna valutazione finora

- GTDocumento33 pagineGTowais_36100% (4)

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) PneumaticDocumento32 pagineSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) PneumaticjuanNessuna valutazione finora

- Kartar Valves Price ListDocumento16 pagineKartar Valves Price ListPankaj105100% (1)

- 502 CAC-Unit IIIDocumento22 pagine502 CAC-Unit IIIGauri ShindeNessuna valutazione finora

- Sample Fire Water UFD For FloaterDocumento1 paginaSample Fire Water UFD For FloaterdoosraemailNessuna valutazione finora

- Control Panel STD DesignDocumento71 pagineControl Panel STD Designhardev100% (2)