Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FSX 414 Weld Wire PDF

Caricato da

J. BangjakTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FSX 414 Weld Wire PDF

Caricato da

J. BangjakCopyright:

Formati disponibili

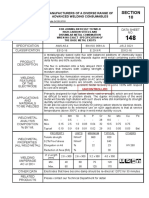

ISO 9001

®

USW ALLOY TURBALOY 414 LC AS 9100 DATA SHEET

DESIGNATION MC-GRADE

AND GTAW SOLID BARE WELDING WIRE Revision A

1745

DESCRIPTION COBALT BASE

CROSS-REFERENCE FSX 414LC 52Co 29.5Cr 10Ni 7W 0.70Mn

CONFORMANCE USW 1745V GE B50A823

SPECIFICATIONS

TURBALOY® 414 LC is produced by vacuum induction melting and re-melting techniques. The

final wire is manufactured by special lubricant-free, roller-die forming followed by surface abrasion and

cleaning processes.

METALLURGICAL These manufacturing processes ensure consistent metallurgical integrity of the alloy with regard to control

BACKGROUND of trace elements and physical purity of the welding wire surface.

INFORMATION

TURBALOY® 414 LC is a Co-Cr-Ni-W-C alloy with elevated temperature wear and oxidation resistance.

Similar composition to AMS 5789 but with greater resistance to crack propagation in service.

MATERIALS TO BE

Nozzle guide vane refurbishment. GE land based turbines.

WELDED

AND GE B50A823

APPLICATIONS

Casting repair.

Carbon 0.10 0.15 Zirconium - 0.01

Silicon 0.60 1.00 Copper - 0.15

WIRE CHEMISTRY Manganese 0.60 1.00 Boron - 0.003

WT% Sulfur - 0.008 Lanthanum 0.02 0.07

Phosphorus - 0.010 Oxygen - 0.005 (50ppm)

Chromium 28.5 30.5 Nitrogen - 0.0100 (100ppm)

Nickel 9.5 11.5 Hydrogen - 0.0010 (10ppm)

Tungsten 6.50 7.6 Cobalt Balance

Iron - 0.50

WELD

PROPERTIES

STRAIGHT LENGTHS SPOOLED WIRE

5 lb. (2.2kg) packs Precision layer wound, with controlled cast and helix

SIZES 36” (914mm) lengths 12” (300mm) diameter spools standard

AND Flag tagged for traceability. 8” (200mm), 4” (100mm) and proprietary spool sizes

(Double tagging and other lengths on request) on request.

FORMS AVAILABLE Wide range of diameters. Wide range of diameters and spool weights.

Sealed, air-evacuated, argon purged Vapor Barrier e nvelopes with desiccants ensure full protection from

PACKAGING atmospheric contamination and prolonged shelf-life.

DFARS Compliant www.usweldingcorp.com

Potrebbero piacerti anche

- Aerospace Material SpecificationDocumento6 pagineAerospace Material SpecificationAnonymous T6GllLl0Nessuna valutazione finora

- Refinery & CastingDocumento43 pagineRefinery & CastingMuhammad Sandi ArifNessuna valutazione finora

- Golden Age of China's Education Industry: Seize The MomentumDocumento42 pagineGolden Age of China's Education Industry: Seize The MomentumJ. BangjakNessuna valutazione finora

- IDC - China's Public Cloud Service Market Tops US$5.4 Billion in 1H 2019 As Competition IntensifiesDocumento7 pagineIDC - China's Public Cloud Service Market Tops US$5.4 Billion in 1H 2019 As Competition IntensifiesJ. BangjakNessuna valutazione finora

- ISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data SheetDocumento1 paginaISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data Sheetbunky bunkoNessuna valutazione finora

- Basics On Fatigue and Fracture MechanicsDocumento1 paginaBasics On Fatigue and Fracture Mechanicsdavood abbasiNessuna valutazione finora

- Turbaloy 310 (SS-310) Data SheetDocumento1 paginaTurbaloy 310 (SS-310) Data SheetcandraNessuna valutazione finora

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocumento1 paginaUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNessuna valutazione finora

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocumento1 paginaUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNessuna valutazione finora

- Afrox Subarc 904L: Welding Consumables Stainless SteelDocumento4 pagineAfrox Subarc 904L: Welding Consumables Stainless SteelBranko FerenčakNessuna valutazione finora

- 409 Stainless Steel PDFDocumento2 pagine409 Stainless Steel PDFDang Thanh TuanNessuna valutazione finora

- COPPER-110: Nearest StandardDocumento3 pagineCOPPER-110: Nearest StandardPS Pinturas pinturasNessuna valutazione finora

- 2594 TigDocumento1 pagina2594 TigAnonymous skBAwexNessuna valutazione finora

- Technical Data Sheet: Stainless Steel: SuperausteniticDocumento5 pagineTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicNessuna valutazione finora

- Material PC - CorrproDocumento61 pagineMaterial PC - CorrproHugo SuescunNessuna valutazione finora

- Slicklines SW-Data SheetDocumento3 pagineSlicklines SW-Data Sheethoss mosafaNessuna valutazione finora

- Brosure Kabel NA2XSYDocumento5 pagineBrosure Kabel NA2XSYcandra handarsenNessuna valutazione finora

- SAF 2507 Seamless Super Duplex Tubing: Fractional SizesDocumento2 pagineSAF 2507 Seamless Super Duplex Tubing: Fractional SizesAlexNessuna valutazione finora

- 254SMO 性能Documento8 pagine254SMO 性能yw_oulalaNessuna valutazione finora

- 254SMO 性能Documento8 pagine254SMO 性能yw_oulalaNessuna valutazione finora

- ARCAP - Grades and PropertiesDocumento7 pagineARCAP - Grades and PropertiesEminent RishNessuna valutazione finora

- Nickel Alloys Monel 400 N04400Documento4 pagineNickel Alloys Monel 400 N04400David Balboa VillenasNessuna valutazione finora

- Afrox Subarc 347: Back To Section 12Documento2 pagineAfrox Subarc 347: Back To Section 12Branko FerenčakNessuna valutazione finora

- Data MP35N Rev-2Documento2 pagineData MP35N Rev-2Nishant MehtaNessuna valutazione finora

- SilcoTek Coatings For High Purity ApplicationsDocumento30 pagineSilcoTek Coatings For High Purity ApplicationsKommu RohithNessuna valutazione finora

- Aerospace Material SpecificationDocumento6 pagineAerospace Material SpecificationAnonymous T6GllLl0Nessuna valutazione finora

- 36CrB4 Rod - Wire Rev4 PDFDocumento6 pagine36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNessuna valutazione finora

- Taihan. Introduction To Tfo Opgw Fiberoptics. August 11, 2014Documento25 pagineTaihan. Introduction To Tfo Opgw Fiberoptics. August 11, 2014jesus salazarNessuna valutazione finora

- SAW Content OnlyDocumento19 pagineSAW Content OnlyIslam SahafayatNessuna valutazione finora

- Al600 UNS N06600Documento4 pagineAl600 UNS N06600kart_rlNessuna valutazione finora

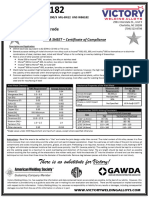

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocumento1 paginaNI-182 Victory ENICRFE-3 Electrode Data SheetgianNessuna valutazione finora

- TYIR ElectroplastDocumento3 pagineTYIR ElectroplastCiprian-Bogdan MihalacheNessuna valutazione finora

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocumento1 pagina3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNessuna valutazione finora

- Covered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelDocumento42 pagineCovered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelChainarong ArunchaiwatNessuna valutazione finora

- SAF 2507 Tubing (MS-02-151) R2Documento2 pagineSAF 2507 Tubing (MS-02-151) R2herysyam1980Nessuna valutazione finora

- Section 2.0 Alloy SteelsDocumento10 pagineSection 2.0 Alloy SteelsAloísio NascimentoNessuna valutazione finora

- Bronze Stock ListDocumento14 pagineBronze Stock ListFred Duarte Caldeira100% (1)

- Dual Shield 7100 LC PDFDocumento3 pagineDual Shield 7100 LC PDFNicolas MaximilianoNessuna valutazione finora

- sn995 Lowmaintenance Lowcost Pbfree Soldering Alloy 98572 r3Documento2 paginesn995 Lowmaintenance Lowcost Pbfree Soldering Alloy 98572 r3Pako DíazNessuna valutazione finora

- Carbo L Ag 40 SN eDocumento1 paginaCarbo L Ag 40 SN efadfadg2Nessuna valutazione finora

- Alloy 6moDocumento2 pagineAlloy 6moAndre SodaNessuna valutazione finora

- Short Course Anode Cu EW (Siegmund)Documento115 pagineShort Course Anode Cu EW (Siegmund)MaikPortnoy100% (1)

- AW - Datasheet - ALLOY 20 CB 3Documento2 pagineAW - Datasheet - ALLOY 20 CB 3.xNessuna valutazione finora

- Stainless Steel: Product FormsDocumento19 pagineStainless Steel: Product FormsDinalpinNessuna valutazione finora

- FabCO 811N1 PDFDocumento2 pagineFabCO 811N1 PDFAlejandroAcuñaMaureiraNessuna valutazione finora

- Covered Line Wire: Standards / Testing SpecificationsDocumento5 pagineCovered Line Wire: Standards / Testing Specificationsjorge_moralesmNessuna valutazione finora

- 904L PDFDocumento4 pagine904L PDFcarlos sotoNessuna valutazione finora

- Brass Properties PDFDocumento2 pagineBrass Properties PDFmaarten S.Nessuna valutazione finora

- Stainless SteelDocumento1 paginaStainless SteelSadashiva sahoo100% (1)

- Stainless Steel PlateDocumento19 pagineStainless Steel PlateHarsh AdvaniNessuna valutazione finora

- Spaulding Lighting Cambridge II Spec Sheet 1-87Documento2 pagineSpaulding Lighting Cambridge II Spec Sheet 1-87Alan MastersNessuna valutazione finora

- Shield Bright 309L-1Documento1 paginaShield Bright 309L-1adanmeneses1Nessuna valutazione finora

- Brass Cz108-Cw508L Sheet: SpecificationsDocumento1 paginaBrass Cz108-Cw508L Sheet: SpecificationsSuhas AnanthaNessuna valutazione finora

- CA6NMDocumento2 pagineCA6NMjoene3Nessuna valutazione finora

- 009 Stainless PDFDocumento34 pagine009 Stainless PDFKamil MarszałekNessuna valutazione finora

- Zeron 100hs Wirelines To Api9a Rev1Documento1 paginaZeron 100hs Wirelines To Api9a Rev1hesam abbaszadehNessuna valutazione finora

- T - Thermanit 25 - 09 CuT - de - en - 5Documento1 paginaT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINessuna valutazione finora

- 3 Slickline CapabilitiesDocumento14 pagine3 Slickline CapabilitiesHedi ChhidiNessuna valutazione finora

- Spoolarc 75: Elite SeriesDocumento2 pagineSpoolarc 75: Elite Seriesrajit kumarNessuna valutazione finora

- Ceramics and Ceramic Composites: Materialographic PreparationDa EverandCeramics and Ceramic Composites: Materialographic PreparationNessuna valutazione finora

- Announcement of Premium Income: (In RMB Ten Thousand) January-May 2020Documento2 pagineAnnouncement of Premium Income: (In RMB Ten Thousand) January-May 2020J. BangjakNessuna valutazione finora

- Telemedecine in ChinaDocumento9 pagineTelemedecine in ChinaJ. BangjakNessuna valutazione finora

- Overseas Regulatory AnnouncementDocumento42 pagineOverseas Regulatory AnnouncementJ. BangjakNessuna valutazione finora

- Boc Aviation Investor Update: November 2019Documento27 pagineBoc Aviation Investor Update: November 2019J. BangjakNessuna valutazione finora

- Announcement of Premium Income: (In RMB Ten Thousand) January-June 2020Documento2 pagineAnnouncement of Premium Income: (In RMB Ten Thousand) January-June 2020J. BangjakNessuna valutazione finora

- Announcement of Premium Income: (In RMB Ten Thousand) January-March 2020Documento2 pagineAnnouncement of Premium Income: (In RMB Ten Thousand) January-March 2020J. BangjakNessuna valutazione finora

- IDC - China's Public Cloud Service Market Tops US$5.4 Billion in 1H 2019 As Competition IntensifiesDocumento7 pagineIDC - China's Public Cloud Service Market Tops US$5.4 Billion in 1H 2019 As Competition IntensifiesJ. BangjakNessuna valutazione finora

- China Medical System (867.HK) : Drug Tender Leading To ASP Drop and New Acquisition To Enrich PipelineDocumento6 pagineChina Medical System (867.HK) : Drug Tender Leading To ASP Drop and New Acquisition To Enrich PipelineJ. BangjakNessuna valutazione finora

- Ping An Insurance - DBS 20200228Documento6 paginePing An Insurance - DBS 20200228J. BangjakNessuna valutazione finora

- Fu Shou Yuan International Group Limited 福 壽 園 國 際 集 團 有 限 公 司Documento1 paginaFu Shou Yuan International Group Limited 福 壽 園 國 際 集 團 有 限 公 司J. BangjakNessuna valutazione finora

- Special ShareDocumento8 pagineSpecial ShareJ. BangjakNessuna valutazione finora

- Alibaba Group Announces December Quarter 2018 ResultsDocumento30 pagineAlibaba Group Announces December Quarter 2018 ResultsJ. BangjakNessuna valutazione finora

- 2019FY Anual ResultDocumento48 pagine2019FY Anual ResultJ. BangjakNessuna valutazione finora

- AIA Group: China / Hong Kong Company GuideDocumento13 pagineAIA Group: China / Hong Kong Company GuideJ. BangjakNessuna valutazione finora

- March Quarter 2017 ResultsDocumento14 pagineMarch Quarter 2017 ResultsJ. BangjakNessuna valutazione finora

- Fu Shou Yuan IPODocumento3 pagineFu Shou Yuan IPOJ. BangjakNessuna valutazione finora

- p200522 PDFDocumento50 paginep200522 PDFJ. BangjakNessuna valutazione finora

- March Quarter 2019 and Full Fiscal Year 2019 Results: ConfidentialDocumento17 pagineMarch Quarter 2019 and Full Fiscal Year 2019 Results: ConfidentialJ. BangjakNessuna valutazione finora

- With ROE of Over 20% For A Decade While The Stock Price Falling - BloombergDocumento6 pagineWith ROE of Over 20% For A Decade While The Stock Price Falling - BloombergJ. BangjakNessuna valutazione finora

- Five Trends Shaping The Future of E-Commerce in China - World Economic ForumDocumento5 pagineFive Trends Shaping The Future of E-Commerce in China - World Economic ForumJ. BangjakNessuna valutazione finora

- en PDFDocumento49 pagineen PDFJ. BangjakNessuna valutazione finora

- Table 1: Tencent Service Offerings: Monetization User Base Communications and SocialDocumento11 pagineTable 1: Tencent Service Offerings: Monetization User Base Communications and SocialJ. BangjakNessuna valutazione finora

- Beijing Capital Intl Airport: China / Hong Kong Company GuideDocumento13 pagineBeijing Capital Intl Airport: China / Hong Kong Company GuideJ. BangjakNessuna valutazione finora

- Inside Information Announcement - COVID19 Impacts - enDocumento3 pagineInside Information Announcement - COVID19 Impacts - enJ. BangjakNessuna valutazione finora

- China Utilities Sector: China / Hong Kong Industry FocusDocumento7 pagineChina Utilities Sector: China / Hong Kong Industry FocusJ. BangjakNessuna valutazione finora

- China Everbright Water: China / Hong Kong Company GuideDocumento11 pagineChina Everbright Water: China / Hong Kong Company GuideJ. BangjakNessuna valutazione finora

- Effect of Minor and Trace Elements in Cast IronDocumento2 pagineEffect of Minor and Trace Elements in Cast IronsachinguptachdNessuna valutazione finora

- MME09MT 1403 PEMPrinciples of Metal Refining With ExamplesDocumento19 pagineMME09MT 1403 PEMPrinciples of Metal Refining With ExamplesGerald MahindaNessuna valutazione finora

- BMC TYPES OF CEMENTDocumento20 pagineBMC TYPES OF CEMENTBharath SrinivasanNessuna valutazione finora

- Comparative Study of Different Engineering Materials That Are-1Documento41 pagineComparative Study of Different Engineering Materials That Are-1Harish DekaNessuna valutazione finora

- Ballu Minor Project Report 2Documento30 pagineBallu Minor Project Report 2virendra behraNessuna valutazione finora

- Corrosion Guide Galvanic Chart SummaryDocumento1 paginaCorrosion Guide Galvanic Chart SummaryDan CosacNessuna valutazione finora

- 020.abrasive Blasting Rev.0 PDFDocumento12 pagine020.abrasive Blasting Rev.0 PDFYounis KhanNessuna valutazione finora

- PPRD ListDocumento3 paginePPRD ListtswNessuna valutazione finora

- ECS 3-12-9 - 3 - 800871dcDocumento8 pagineECS 3-12-9 - 3 - 800871dcFlorin Daniel AnghelNessuna valutazione finora

- BS en 10084-2008Documento40 pagineBS en 10084-2008Martijn Groot100% (1)

- Ste Conchem Q3M6 SinhsDocumento22 pagineSte Conchem Q3M6 SinhsJazmin Nicole AbanesNessuna valutazione finora

- Thermite PreparationDocumento8 pagineThermite PreparationNqobane MakhobaNessuna valutazione finora

- ASTM A1011 SpecificationDocumento7 pagineASTM A1011 SpecificationramorusoNessuna valutazione finora

- Handbook To Bc1 2023Documento59 pagineHandbook To Bc1 2023cklconNessuna valutazione finora

- Rolling DefectsDocumento4 pagineRolling DefectsSachith Praminda Rupasinghe100% (2)

- Welding RodsDocumento12 pagineWelding RodsDigital BusinessNessuna valutazione finora

- Asahiko SUGAKI and Arashi Kitakaze : MineralsDocumento17 pagineAsahiko SUGAKI and Arashi Kitakaze : MineralsOscar 2Nessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Astm A409 A409m 2001Documento6 pagineAstm A409 A409m 2001Roland CepedaNessuna valutazione finora

- Recovery of Nickel From PAL Disc LiquorsDocumento15 pagineRecovery of Nickel From PAL Disc LiquorsKtishna100% (1)

- SSP 214 Painting The Vehicle Pre TreatmentDocumento52 pagineSSP 214 Painting The Vehicle Pre TreatmentKarol GórskiNessuna valutazione finora

- Components of Railway Track 1Documento21 pagineComponents of Railway Track 1Mudasar HussainNessuna valutazione finora

- Cambridge O Level: CHEMISTRY 5070/21Documento20 pagineCambridge O Level: CHEMISTRY 5070/21Islamabad ALMA SchoolNessuna valutazione finora

- B951.927 - MG Alloy Naming and CompsDocumento7 pagineB951.927 - MG Alloy Naming and Compswanghongxuan66Nessuna valutazione finora

- Plastech 85P: Product DataDocumento2 paginePlastech 85P: Product DataFaisal YaniNessuna valutazione finora

- OREAS 256b CertificateDocumento23 pagineOREAS 256b CertificateRidouane RidNessuna valutazione finora

- Unit - Iii Gear Manufacturing Process: Sprx1008 - Production Technology - IiDocumento19 pagineUnit - Iii Gear Manufacturing Process: Sprx1008 - Production Technology - Iiramesh gondilNessuna valutazione finora

- Astm A102Documento2 pagineAstm A102kashif ehsanNessuna valutazione finora

- ESAB Welding Review RepairsDocumento28 pagineESAB Welding Review RepairsElias KapaNessuna valutazione finora