Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cysh12Af (Insb) Hall-Effect Element: 1. Maximum Ratings

Caricato da

babazadeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cysh12Af (Insb) Hall-Effect Element: 1. Maximum Ratings

Caricato da

babazadeCopyright:

Formati disponibili

Version 2

Released in May 2016

Dr.-Ing. habil. Jigou Liu Technologies GmbH & Co. KG

CYSH12AF (InSb) HALL-EFFECT ELEMENT

Hall-effect element CYSH12AF is made of compound semiconductor material indium stibnite (InSb), which

utilizes the Hall-effect principle. It can convert a magnetic flux density signal linearly into voltage output. It

is new generation of Hall Effect element CYTY101A.

Vi

RL

FEATURES TYPICAL APPLICATION

Magnetic Field Measurement

High Magnetic Sensitivity Current Sensor

H

Low Offset Voltage Detection of Speed

VH

Miniature Package DC Brushless Motor

Position Control

GND

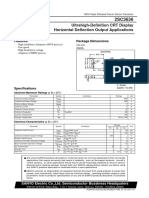

1. Maximum Ratings (Ta=25°C)

Parameter Symbol Rating Unit

Maximum Input Current Imax 20 (at 25°C) mA

Maximum Power Dissipation Pmax 150 (at 25°C) mW

Operating Temperature Range Top -40 ~ +110 °C

Storage Temperature Range Tst -40 ~ +150 °C

2. Electrical Characteristics (Measured at 25°C)

Parameter Symbol Measurement Conditions Min Max Unit

Output Hall Voltage VH Vin=1V, B=50mT 196 415 mV

Input Resistance Rin I=0.1mA 240 550

Output Resistance Rout I=0.1mA 240 550

Offset Voltage VO Vin=1V, B=0G -7 +7 mV

Temp. Coeff. of VH Ta=0 ~ +40°C AVG. - -1.8 % /°C

B=50mT, Ic=5mA

Temp. Coeff. of Rin, Rout Ta=0 ~ +40°C AVG. - -1.8 % /°C

B=0, Ic=0.1mA

VH=VHM-VO (VHM : The output voltage measured at 500G.)

3. Rank Classification and Mark on Output Hall Voltage

Output Hall Voltage,VH (mV) Rank Mark Measurement Conditions

196 ~ 236 D SSD

228 ~ 274 E** SSE

Vin=1V, B=50mT

266 ~ 320 F** SSF

(Constant Voltage)

310 ~ 370 G SSG

360 ~ 415 H SSH

** Als standard sensor we offer our customers the rank E and F

Markt Schwabener Str. 8 Tel.: +49 (0)8121 – 2574100

D-85464 Finsing Fax: +49 (0)8121– 2574101

Germany Email: info@cy-sensors.com

http://www.cy-sensors.com

Version 2

Released in May 2016

Dr.-Ing. habil. Jigou Liu Technologies GmbH & Co. KG

4. CHARACTERISTIC CURVES (only for references)

5. Method for Mounting

5-1. Soldering Conditions on PCB

1. No Rapid Heating and Cooling.

2. Recommended Preheating condition is at 130~150°C for 2~3minutes.

3. Recommended Reflowing condition is at 220~230°C for 10~15seconds.

Markt Schwabener Str. 8 Tel.: +49 (0)8121 – 2574100

D-85464 Finsing Fax: +49 (0)8121– 2574101

Germany Email: info@cy-sensors.com

http://www.cy-sensors.com

Version 2

Released in May 2016

Dr.-Ing. habil. Jigou Liu Technologies GmbH & Co. KG

5-2. Soldering Method and Temperature

Items Methods Temperature

Reflow Soldering by Passing the Heated Zone Max 250°C in 20sec

Solder Iron Soldering by Soldering Iron Max 300°C in 3sec

Temp

(℃)

20sec

250

Cooling in the

150 Air

30∼60sec

3min

time

Reflow Method

6. Packaging

6-1. Taping

1. CYSH12AF should be packed that marked side is viewed from cover tape andlong side is

put parallel with tape running direction. Making use of itafter 180o rotation has no problem

because of its symmetric mode.

2. The vacant parts more than 40mm are located at front and end side of the reel.

Tape Running Direction

Trailer Components Header Leader

Vacant Contained Vacant Part

Markt Schwabener Str. 8 Tel.: +49 (0)8121 – 2574100

D-85464 Finsing Fax: +49 (0)8121– 2574101

Germany Email: info@cy-sensors.com

http://www.cy-sensors.com

Version 2

Released in May 2016

Dr.-Ing. habil. Jigou Liu Technologies GmbH & Co. KG

6-2. Tape Specifications

1. Pull Strength(F) = 20~70g

F

165∼180°

COVER TAPE

CARRIER

TAPE

2. Devices should not be flipped out of a pocket when tape is bent down by 15mm curvature.

3. Devices should not be stuck to cover tape.

4. Devices should be kept below 40°C and below RH80% in the shade.

5. Tape has no joint.

6-3. Packing Unit

1. 3,000pcs of devices are packed in one reel.

2. Five reels are packed in one inner box.

3. Four inner boxes, 60,000pcs of devices, are packed in one outer box.

4. Dummy could be packed for safe dealing.

7. External Dimensions (Unit: mm)

Four leads of input and output terminals are designed in the diagonally symmetric mode and are

equal in dimensions. Regardless of 180°rotation of Hall sensor, CYSH12AF can be used.

Markt Schwabener Str. 8 Tel.: +49 (0)8121 – 2574100

D-85464 Finsing Fax: +49 (0)8121– 2574101

Germany Email: info@cy-sensors.com

http://www.cy-sensors.com

Version 2

Released in May 2016

Dr.-Ing. habil. Jigou Liu Technologies GmbH & Co. KG

Connection

Constant Voltage

source

Differential Amplifier

Circuit 1

2 1

+

CYSH12AF -

3 4

Constant Voltage

source (+)

Circuit 2

2 1

+

CYSH12AF -

3 4

Constant Voltage

source (-)

Application Notes

The Hall voltage VH can be positive and negative. But if one connects the sensor as follows (circuit1):

Pin 1: positive input voltage V+, for instance +5VDC.

Pin 3: GND

Pin 2: OUTPUT

Pin 4: GND

One can only measure the positive voltage at the pin 2. This means that the output voltage at zero magnetic

field is not zero. This voltage is called as offset voltage. The output voltage in this case is not equal to the Hall

voltage. The output voltage is equal to the sum of offset voltage and Hall voltage.

The offset voltage will be zero if you connect double power supplies V+ and V- to the sensor (circuit 2):

Pin 1: positive input voltage V+, for instance +5VDC.

Pin 3: negative input voltage V-, for instance -5VDC

Pin 2: OUTPUT

Pin 4: GND

In this case the output voltage is equal to the Hall Voltage.

Markt Schwabener Str. 8 Tel.: +49 (0)8121 – 2574100

D-85464 Finsing Fax: +49 (0)8121– 2574101

Germany Email: info@cy-sensors.com

http://www.cy-sensors.com

Version 2

Released in May 2016

Dr.-Ing. habil. Jigou Liu Technologies GmbH & Co. KG

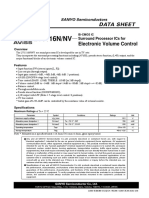

8. RELIABILITY

8. 1 TEST CONDITION

CONDITION

HIGH TEMP. STORAGE Ta=110°C,t=1000HR

LOW TEMP. STORAGE Ta=-40°C,t=1000HR

HIGH TEMP. OPERATION Ta=100°C,Iopr=6mA,t=1000HR

LOW TEMP. OPERATION Ta=-20°C,Iopr=6mA,t=1000HR

HIGH TEMP. HIGH UMIDITY Ta=60°C, HR=90%,Iopr=9mA,t=1000HR

OPERATION

HUMIDITY Ta=60°C,HR=90%, t=1000HR

PCT Ta=121°C,HR=100%, Pv=2atm, t=24HR

THERMAL SHOCK T(L)=-55°C,T(H)=150°C, t=(L,H)=30min,M=30CYCLE

SOLDERING HEAT solder temp=250±5°C, t=10sec,REFLOW

RESISTANCE

SOLDABILITY solder temp=230±5°C, t=5sec,dip

TERMINAL STRENGTH TENSION 300g/30sec

SURGE V=500V, C=200pF, R=0Ω (test method EIAJ EDX 8503)

8.2 CRITERION FOR JUDGING

After each reliability test, samples should be kept for at least 24 hrs at room temp. & humidity, and

then measured.

The change rates should be confined within the ranges as follows.

item OK SPEC NG/OK

ΔRin UNDER ±20%

ΔRout UNDER ±20% OK (SPEC SATISFYING)

ΔVH UNDER ±20%

ΔVo/VH UNDER ± 5%

Markt Schwabener Str. 8 Tel.: +49 (0)8121 – 2574100

D-85464 Finsing Fax: +49 (0)8121– 2574101

Germany Email: info@cy-sensors.com

http://www.cy-sensors.com

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Beginning Digital Electronics through ProjectsDa EverandBeginning Digital Electronics through ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Infrared Receiver Module: Module No.: PIC-2031SMB-M8D 1. Features: DimensionsDocumento3 pagineInfrared Receiver Module: Module No.: PIC-2031SMB-M8D 1. Features: DimensionsVictorManuelBernalBlancoNessuna valutazione finora

- 49E Hall Sensor SpecsDocumento4 pagine49E Hall Sensor Specsjoselito1juniorNessuna valutazione finora

- 49E Hall-Effect Linear Position Sensor: 1. Ge Neral DescriptionDocumento4 pagine49E Hall-Effect Linear Position Sensor: 1. Ge Neral DescriptionJorge MorochoNessuna valutazione finora

- Kmi 18Documento12 pagineKmi 18Andriy TokarchukNessuna valutazione finora

- CYD277Documento4 pagineCYD277TurkogluNessuna valutazione finora

- Stepper Motor Driver: Powerdip 12 + 2 + 2Documento8 pagineStepper Motor Driver: Powerdip 12 + 2 + 2Engin UzunNessuna valutazione finora

- MBRF1040CT VikingtechDocumento3 pagineMBRF1040CT VikingtechАлексей ГомоновNessuna valutazione finora

- Bas 28 R 2Documento3 pagineBas 28 R 2sergio ribeiroNessuna valutazione finora

- Everlight Electronics Co., LTD.: Device Number: DHI-092-003 Rev: 1.0 Model No: HI400 Ecn: 1/6Documento6 pagineEverlight Electronics Co., LTD.: Device Number: DHI-092-003 Rev: 1.0 Model No: HI400 Ecn: 1/6ihsanjuNessuna valutazione finora

- 2N3866 2N3866A NPN Silicon High Frequency Transistor DescriptionDocumento3 pagine2N3866 2N3866A NPN Silicon High Frequency Transistor Descriptionzbhp zNessuna valutazione finora

- 2n3866 Series PDFDocumento3 pagine2n3866 Series PDFzbhp zNessuna valutazione finora

- CYD505Documento5 pagineCYD505yasuluNessuna valutazione finora

- Ifm PK6520 Pressure Sensor Pressure Switch Compact Pressure Sensor - Spec SheetDocumento2 pagineIfm PK6520 Pressure Sensor Pressure Switch Compact Pressure Sensor - Spec SheetCleiton De oliveira limaNessuna valutazione finora

- LA3160Documento8 pagineLA3160astruc.claudeNessuna valutazione finora

- Ultrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsDocumento4 pagineUltrahigh-Definition CRT Display Horizontal Deflection Output Applicationsbugy costyNessuna valutazione finora

- Bas56r2 (WL5)Documento5 pagineBas56r2 (WL5)Gilvana Cristina FerreiraNessuna valutazione finora

- MMBTA06Documento5 pagineMMBTA06rodrigo2016.cdNessuna valutazione finora

- Luis Mota - V13700 - Datasheet PDFDocumento30 pagineLuis Mota - V13700 - Datasheet PDFAfonso OnoiaNessuna valutazione finora

- OH44E-svg44e Data SheetDocumento3 pagineOH44E-svg44e Data SheetharshaNessuna valutazione finora

- HLK-PM03 Ultra-Compact Module PowerDocumento4 pagineHLK-PM03 Ultra-Compact Module PowercarlosframirezbNessuna valutazione finora

- MA3810Documento7 pagineMA3810Ubaldo BritoNessuna valutazione finora

- Datasheet 2Documento3 pagineDatasheet 2Slimane SlimaneNessuna valutazione finora

- STC8050N: DescriptionsDocumento4 pagineSTC8050N: Descriptionsban4444Nessuna valutazione finora

- Datasheet 2Documento6 pagineDatasheet 2Danilo Concepción SánchezNessuna valutazione finora

- MA4820 Shindengen Elenota - PLDocumento9 pagineMA4820 Shindengen Elenota - PLNana Dwi WahanaNessuna valutazione finora

- PNP Silicon Transistor Specifications and SupportDocumento3 paginePNP Silicon Transistor Specifications and Supportsas999333Nessuna valutazione finora

- Temperature Sensing With NTC Circuit - Sboa323Documento5 pagineTemperature Sensing With NTC Circuit - Sboa323pippoNessuna valutazione finora

- Silicon PNP Power Darlington TransistorDocumento4 pagineSilicon PNP Power Darlington TransistorRomário CaribéNessuna valutazione finora

- 600KHz, 18V, 2.0A Synchronous Step-Down ConverterDocumento8 pagine600KHz, 18V, 2.0A Synchronous Step-Down ConverteralfredoNessuna valutazione finora

- LF-FMR020YSxxxxH: Flicker-Free LED DriverDocumento6 pagineLF-FMR020YSxxxxH: Flicker-Free LED Driveralex latronicoNessuna valutazione finora

- Sick Pbt-Rb250sg1ssnuma0zDocumento7 pagineSick Pbt-Rb250sg1ssnuma0zendangfarid hidayatNessuna valutazione finora

- 2N5179 Silicon NPN RF Transistor DescriptionDocumento4 pagine2N5179 Silicon NPN RF Transistor DescriptionCarlos ReisNessuna valutazione finora

- MOCD207M, MOCD208M Dual-Channel Phototransistor Small Outline Surface Mount OptocouplersDocumento9 pagineMOCD207M, MOCD208M Dual-Channel Phototransistor Small Outline Surface Mount OptocouplerscurzNessuna valutazione finora

- HLK-PM12 Ultra-Compact Module PowerDocumento4 pagineHLK-PM12 Ultra-Compact Module PowerMeenakshiNessuna valutazione finora

- Mo rx3400Documento4 pagineMo rx3400saurabhk291Nessuna valutazione finora

- 2N3866 2N3866A NPN Silicon High Frequency Transistor DescriptionDocumento3 pagine2N3866 2N3866A NPN Silicon High Frequency Transistor DescriptionandreasmonNessuna valutazione finora

- Bipolar Transistor: DescriptionDocumento2 pagineBipolar Transistor: Descriptiondok wahab siddikNessuna valutazione finora

- 2N3700 2N3701 Silicon NPN Transistors DescriptionDocumento4 pagine2N3700 2N3701 Silicon NPN Transistors DescriptionAndresVillaNessuna valutazione finora

- Datasheet DRST 160xx t3 Series 2182Documento2 pagineDatasheet DRST 160xx t3 Series 2182Juan GimenesNessuna valutazione finora

- 2N3866 2N3866A NPN Silicon High Frequency Transistor DescriptionDocumento3 pagine2N3866 2N3866A NPN Silicon High Frequency Transistor DescriptionRopota AdrianNessuna valutazione finora

- 2n3866 SeriesDocumento3 pagine2n3866 Seriessas999333Nessuna valutazione finora

- Datasheetarchive 2SA1740Documento4 pagineDatasheetarchive 2SA1740José AdelinoNessuna valutazione finora

- R33640G1 EngDocumento2 pagineR33640G1 Engihavenowingss fhNessuna valutazione finora

- Unisonic Technologies Co., LTD: NPN General Purpose AmplifierDocumento4 pagineUnisonic Technologies Co., LTD: NPN General Purpose AmplifierDavid Carrillo BarrosoNessuna valutazione finora

- Lb1836m (SMD H-Bridge)Documento5 pagineLb1836m (SMD H-Bridge)James JenNessuna valutazione finora

- BFR91A DatssheetDocumento8 pagineBFR91A DatssheetAriel BecerraNessuna valutazione finora

- BD9893F PDFDocumento5 pagineBD9893F PDFboled_2Nessuna valutazione finora

- LA6462M, 6462S: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocumento5 pagineLA6462M, 6462S: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersEdgard PiresNessuna valutazione finora

- Oscilador de Inverter BD9897FSDocumento5 pagineOscilador de Inverter BD9897FSAntonio ChavezNessuna valutazione finora

- 2N3494 2N3495 Silicon PNP Transistors DescriptionDocumento3 pagine2N3494 2N3495 Silicon PNP Transistors Descriptionsas999333Nessuna valutazione finora

- La 6581cl - SanyoDocumento5 pagineLa 6581cl - SanyoStevenNessuna valutazione finora

- La 78040Documento4 pagineLa 78040miloz58Nessuna valutazione finora

- Moc3072m DDocumento13 pagineMoc3072m DhiperdyniaNessuna valutazione finora

- LV1116N/NV: Electronic Volume ControlDocumento18 pagineLV1116N/NV: Electronic Volume Controlgun gun saepulNessuna valutazione finora

- Unisonic Technologies Co., LTD: NPN Bipolar Power Transistor For Switching Power Supply ApplicationsDocumento6 pagineUnisonic Technologies Co., LTD: NPN Bipolar Power Transistor For Switching Power Supply ApplicationssgianimNessuna valutazione finora

- 3W Monaural Power Amplifier: Audio Output For TV ApplicationDocumento3 pagine3W Monaural Power Amplifier: Audio Output For TV ApplicationRobertoNessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- OH44E-svg44e Data SheetDocumento3 pagineOH44E-svg44e Data SheetharshaNessuna valutazione finora

- OH44E-svg44e Data SheetDocumento3 pagineOH44E-svg44e Data SheetharshaNessuna valutazione finora

- AKM Magnetic Encoder IC, AK877x: AKM Magnetic Sensors Engineering and Development Kits Guide RohsDocumento1 paginaAKM Magnetic Encoder IC, AK877x: AKM Magnetic Sensors Engineering and Development Kits Guide RohsbabazadeNessuna valutazione finora

- AKM Magnetic Sensors: GMW AssociatesDocumento52 pagineAKM Magnetic Sensors: GMW AssociatesbabazadeNessuna valutazione finora

- Hall Sensors: Ordering Codes, Packaging, Handling: Edition Sept. 12, 2001 6200-249-2EDocumento24 pagineHall Sensors: Ordering Codes, Packaging, Handling: Edition Sept. 12, 2001 6200-249-2EbabazadeNessuna valutazione finora

- Legitimate Interests Assessment FormDocumento6 pagineLegitimate Interests Assessment FormRenataNessuna valutazione finora

- Given A List of Transaction Behaviors, Match Them With The Appropriate Transaction AttributesDocumento13 pagineGiven A List of Transaction Behaviors, Match Them With The Appropriate Transaction AttributesSandeep Tanugula SharmaNessuna valutazione finora

- AK 430 OM460LA - 01 - GB: ProjectDocumento55 pagineAK 430 OM460LA - 01 - GB: Projectpecirepi100% (1)

- Ece-Research Work 1Documento10 pagineEce-Research Work 1Peale ObiedoNessuna valutazione finora

- PP GF30 - Borealis Fibremod GB364WGDocumento3 paginePP GF30 - Borealis Fibremod GB364WGarmandoNessuna valutazione finora

- 1150 DVOR Overheads Selex Rev - TRDocumento125 pagine1150 DVOR Overheads Selex Rev - TRdulli fitriantoNessuna valutazione finora

- Bobcat 863 F Series Skid Steer Loader Parts Catalogue Manual (SN 5146 11001 - 39999) PDFDocumento28 pagineBobcat 863 F Series Skid Steer Loader Parts Catalogue Manual (SN 5146 11001 - 39999) PDFfjjsekfkskeme50% (6)

- Relay Controlled Lighting GuideDocumento130 pagineRelay Controlled Lighting GuideRM HaroonNessuna valutazione finora

- ENCS4320 Applied Cryptography SyllabusDocumento2 pagineENCS4320 Applied Cryptography Syllabusmarwa toameNessuna valutazione finora

- Rifai-R-RatheebDocumento181 pagineRifai-R-RatheebNiyas mkdNessuna valutazione finora

- Eub0002b Datasheet PDFDocumento1 paginaEub0002b Datasheet PDFMicheal0% (1)

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Documento12 pagine2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)SivaNessuna valutazione finora

- Falling From Grace by S L Naeole PDFDocumento2 pagineFalling From Grace by S L Naeole PDFDeniseNessuna valutazione finora

- 4.0 Drill Pipe W XT39 ConnectionsDocumento1 pagina4.0 Drill Pipe W XT39 ConnectionsDugas DeivyNessuna valutazione finora

- Solar Powered DC-DC ConverterDocumento25 pagineSolar Powered DC-DC ConverterKrishnashree KurupNessuna valutazione finora

- Form o - Quality AssuranceDocumento93 pagineForm o - Quality AssuranceonutocsNessuna valutazione finora

- CO2 SystemDocumento4 pagineCO2 SystemЕвгений БалцатуNessuna valutazione finora

- Empowerment Technology M3999Documento1 paginaEmpowerment Technology M3999Ericka Rivera SantosNessuna valutazione finora

- 20 09 25 Pristina Dose White Paper - JB73643XXDocumento10 pagine20 09 25 Pristina Dose White Paper - JB73643XXMerab KvintradzeNessuna valutazione finora

- Rcra Online: Howdoiuse Advanced Search?Documento2 pagineRcra Online: Howdoiuse Advanced Search?Franklin Crespo AmoresNessuna valutazione finora

- OIOUBL GUIDE ORDREBEKRAFT-enDocumento83 pagineOIOUBL GUIDE ORDREBEKRAFT-ensidath_pragnaratnaNessuna valutazione finora

- What's New or Changed in Dynamics 365 CommerceDocumento5 pagineWhat's New or Changed in Dynamics 365 CommerceWalter Carlin JrNessuna valutazione finora

- Suda Lexico - Suida Lexicon PDFDocumento1.316 pagineSuda Lexico - Suida Lexicon PDFde Damasco100% (1)

- System: Items Default Require D Setting DescriptionDocumento7 pagineSystem: Items Default Require D Setting DescriptionSubas Shrestha100% (2)

- Chapter 1 - Part 4 PDFDocumento27 pagineChapter 1 - Part 4 PDFأحمد الرقبNessuna valutazione finora

- Project Management Unit - 2Documento41 pagineProject Management Unit - 2Angelamary Maria SelvamNessuna valutazione finora

- Planmeca Promax: Technical ManualDocumento346 paginePlanmeca Promax: Technical ManualHaris BajrićNessuna valutazione finora

- Acoustic LensDocumento3 pagineAcoustic LensMorena SlpNessuna valutazione finora

- Interactive File Cabinets by SlidesgoDocumento58 pagineInteractive File Cabinets by Slidesgojakson bueberNessuna valutazione finora

- American Cinematographer 1923 Vol 4 No 3 PDFDocumento28 pagineAmerican Cinematographer 1923 Vol 4 No 3 PDFbrad_rushingNessuna valutazione finora