Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Corrective Action Request (CAR) - Rev 0: Stop Here. Submit CAR To N.A.Tuan

Caricato da

Nguyen Anh Tuan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

65 visualizzazioni1 paginaCAR FORM

Titolo originale

CAR Form

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCAR FORM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

65 visualizzazioni1 paginaCorrective Action Request (CAR) - Rev 0: Stop Here. Submit CAR To N.A.Tuan

Caricato da

Nguyen Anh TuanCAR FORM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

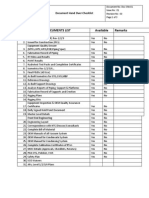

CAR #

Corrective Action Request (CAR) - Rev 0

001

Type Corrective Action (existing issue) Preventive Action (potential issue) Name: N.A.Tuan

Check one

Opportunity for Improvement / Suggestion Date: 20 Aug. 2020

Employee Feedback Customer Feedback Supplier / Subcontractor Feedback

Source External Audit Finding Internal Audit Finding Management Review Action Item

Check one

Other:

Welding Painting Inspection

Process DESIGN Packing FABRICATION

Check one PM

Other:

Priority Low Medium High Urgent / Critical

Check One

Describe the issue or problem in detail.

During pressure testing of Module at modularization yard site 17 leaks were observed on the USDM nozzle shop welds due to defects

present at welds intersection

Stop here. Submit CAR to N.A.Tuan

CAR Assigned to: Fabrication Group Date Assigned: 28 Aug. 2020 Respond by:

Nguyen Minh Thanh

To be completed by the Assignee.

Root Cause of Problem: (Required for all corrective and preventive issues; optional for suggestions for improvement.)

1. Improper Welding Sequence of reinforcement Stiffeners and Nozzle Flange

2. -Nozzle to Flange Internal Weld present defect somewhere along the length.

3. -Faulty Welding Technique

4. -NDT not performed on Flange to Nozzle, internal weld.

5. -Lack of coping in stiffeners

Action Plan: (Actions taken to eliminate root cause, resolve issue and prevent recurrence.)

1 Establish an instruction to fabrication the nozzle.

2. In the instruction will describe the welding sequence and NDT method

3. The instruction will be submitted to Evapco for review and applied to all team who fabrication the USDM

Date Action Completed: 15-Sep-2020 Name: Nguyen Minh Thanh

Stop here. Return CAR to N.A.Tuan

CAR Effectiveness verified by: Date:

Result: PASS FAIL: Returned for Further Processing

Notes and

justification:

Potrebbero piacerti anche

- 4-Welding Painting Repair-PDocumento8 pagine4-Welding Painting Repair-PNguyen Anh TuanNessuna valutazione finora

- 10mm THKDocumento1 pagina10mm THKtarun3fauzdarNessuna valutazione finora

- Mau ReportDocumento30 pagineMau ReportNguyễn Hoàng DũngNessuna valutazione finora

- Package 2s E0001 - Jupiter DCR 30-10-2021Documento96 paginePackage 2s E0001 - Jupiter DCR 30-10-2021senthilNessuna valutazione finora

- Quy Trình Ks Chất LượngDocumento18 pagineQuy Trình Ks Chất LượngNguyễn Hoàng DũngNessuna valutazione finora

- Welding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXDocumento62 pagineWelding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXkingstonNessuna valutazione finora

- Document Hndover ChecklistDocumento3 pagineDocument Hndover ChecklistM Uzair ShaikhNessuna valutazione finora

- 20190612-DTNB- Bill of Quotation ELEC (Khảnh)Documento17 pagine20190612-DTNB- Bill of Quotation ELEC (Khảnh)nguyenvanmyk410kxNessuna valutazione finora

- Master List of InstrumentsDocumento35 pagineMaster List of Instrumentskrichenaraj6931100% (1)

- Welding Insection ReportDocumento4 pagineWelding Insection ReportRanjeet MouryaNessuna valutazione finora

- F-05 Corrective Action FormDocumento1 paginaF-05 Corrective Action Formsuhara hussainNessuna valutazione finora

- BDL Ed QM 1Documento162 pagineBDL Ed QM 1Sai DhruvNessuna valutazione finora

- 30 - Painting ProcedureDocumento12 pagine30 - Painting ProcedureNguyen Anh TuanNessuna valutazione finora

- ICAT SOP AIS - 137 - 2-Wheeler PDFDocumento325 pagineICAT SOP AIS - 137 - 2-Wheeler PDFTushar Ballabh BMLNessuna valutazione finora

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocumento3 pagineVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNessuna valutazione finora

- Inspection and Test PlanDocumento3 pagineInspection and Test PlanGCRIADHNessuna valutazione finora

- Quality Tools and Techniques-Cause - and - Effect - Diagram - Fall20Documento12 pagineQuality Tools and Techniques-Cause - and - Effect - Diagram - Fall20Ashik ShariarNessuna valutazione finora

- Tub Mill Fist Piece & Inprocess Inspection ReportDocumento1 paginaTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNessuna valutazione finora

- ATE-ODC-QCP-M-005 Rev 02 Surface Preparation CoatingDocumento21 pagineATE-ODC-QCP-M-005 Rev 02 Surface Preparation CoatingDevam RajNessuna valutazione finora

- PGB - RnA - GS5R - Daily Report - Preshutdown - DAY1Documento1 paginaPGB - RnA - GS5R - Daily Report - Preshutdown - DAY1azrul100% (1)

- Inspection Plan NDTDocumento7 pagineInspection Plan NDTEdison WalitNessuna valutazione finora

- AIAG CQI-15 Special Process: Welding System Assessment Mabuchi Motor Mexico, S.A.De C.VDocumento30 pagineAIAG CQI-15 Special Process: Welding System Assessment Mabuchi Motor Mexico, S.A.De C.VLuis AldanaNessuna valutazione finora

- Mahabal Metals Pvt. LTD.: Induction TrainingDocumento3 pagineMahabal Metals Pvt. LTD.: Induction TrainingNitin KambleNessuna valutazione finora

- Welding Coordinator WeldMap Weld Data Sheet PDFDocumento1 paginaWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNessuna valutazione finora

- Appendix - 9 - APQP - Timing - PlanDocumento1 paginaAppendix - 9 - APQP - Timing - PlanChandru JattiNessuna valutazione finora

- ITP Fuel Fillter (J-1001) Rev10+Documento9 pagineITP Fuel Fillter (J-1001) Rev10+DjokoNessuna valutazione finora

- Baofeng Uv-5r Ce Certificate 18-211428Documento3 pagineBaofeng Uv-5r Ce Certificate 18-211428anshadNessuna valutazione finora

- Verite Corrective Action Report Rosita KnitwearsDocumento15 pagineVerite Corrective Action Report Rosita Knitwearstaleb_ctgNessuna valutazione finora

- Incoming Equipment For Factory Inspection/Testing (FAT) : StepsDocumento1 paginaIncoming Equipment For Factory Inspection/Testing (FAT) : StepsGoyal SanjaiNessuna valutazione finora

- TS 0071Documento1 paginaTS 0071Seleccion Tecnico IndustrialNessuna valutazione finora

- Control Flow Diagram For Gacc'S New and Trained Welders: JCC IssuedDocumento1 paginaControl Flow Diagram For Gacc'S New and Trained Welders: JCC IssuedSiddiqui Abdul KhaliqNessuna valutazione finora

- Ajts QCP Fab Format Rev 01Documento4 pagineAjts QCP Fab Format Rev 01Pradip DabhiNessuna valutazione finora

- 8.fixture Inspection ReportDocumento1 pagina8.fixture Inspection ReportBASAVA ENGINEERINGNessuna valutazione finora

- CT476-BPP-001 Rev 0 20180409Documento27 pagineCT476-BPP-001 Rev 0 20180409Nasrul HumairahNessuna valutazione finora

- List of Abbreviations Used by Flextronics Romania: Abbreviation Meaning Current NumberDocumento11 pagineList of Abbreviations Used by Flextronics Romania: Abbreviation Meaning Current NumberAna Iulia StaiculescuNessuna valutazione finora

- Procedure For New DevelopmentsDocumento2 pagineProcedure For New DevelopmentsspdhimanNessuna valutazione finora

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Documento7 paginePBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNessuna valutazione finora

- Break Down SlipDocumento7 pagineBreak Down SlipUmangtarangNessuna valutazione finora

- Engineering Process FlowDocumento2 pagineEngineering Process FlowNavneesh bansal100% (1)

- Inprocess Inspection ReportDocumento1 paginaInprocess Inspection ReportSanjay KumarNessuna valutazione finora

- Annex-1-Process Flow ChartDocumento1 paginaAnnex-1-Process Flow ChartDeepak DasNessuna valutazione finora

- RFI & ITR Workflow - 20200116Documento1 paginaRFI & ITR Workflow - 20200116nickoNessuna valutazione finora

- Audit ComplianceDocumento1 paginaAudit ComplianceNitin SharmaNessuna valutazione finora

- MOM - Control PlanDocumento17 pagineMOM - Control PlanraghulramasamyNessuna valutazione finora

- Scope Location 1 CC-2319 P TEJ CALIBRATION CENTREDocumento64 pagineScope Location 1 CC-2319 P TEJ CALIBRATION CENTREkumarNessuna valutazione finora

- 18558-1002 A Quality ITP PDFDocumento8 pagine18558-1002 A Quality ITP PDFBRENNessuna valutazione finora

- 04 HTD-F-04-P2 - HT Process Log SheetDocumento2 pagine04 HTD-F-04-P2 - HT Process Log SheetDeepak kumarNessuna valutazione finora

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocumento5 pagineWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNessuna valutazione finora

- Approved ITP 06012023 For WT6Documento1 paginaApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Internal Audit Observation ReportDocumento2 pagineInternal Audit Observation Reportsenk197100% (1)

- In-House Calibration SheetDocumento4 pagineIn-House Calibration SheetKannan MurugesanNessuna valutazione finora

- Heat Treatment - Furnace TreatmentDocumento19 pagineHeat Treatment - Furnace Treatmentkumar QANessuna valutazione finora

- WIC-WPS-01 Rev. 00 - FCAW - 1.2Documento2 pagineWIC-WPS-01 Rev. 00 - FCAW - 1.2murshid badshahNessuna valutazione finora

- TDC 004 CS Fittings r0Documento1 paginaTDC 004 CS Fittings r0samkarthik47Nessuna valutazione finora

- Procurement Services: Industry & Facilities DivisionDocumento6 pagineProcurement Services: Industry & Facilities DivisionVikas Mani TripathiNessuna valutazione finora

- Potential Failure Modes and Effects AnalysisDocumento15 paginePotential Failure Modes and Effects AnalysisPrakash RanjanNessuna valutazione finora

- PQCS Tube Flange Rough - ForgingDocumento1 paginaPQCS Tube Flange Rough - ForgingBalram JiNessuna valutazione finora

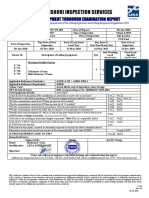

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento1 paginaAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNessuna valutazione finora

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento1 paginaAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNessuna valutazione finora

- CQI-12 Coating System 3-29-16Documento71 pagineCQI-12 Coating System 3-29-16Georgeta ComanNessuna valutazione finora

- 12414-00-1765 - Rev.0 - VT ProcedureDocumento12 pagine12414-00-1765 - Rev.0 - VT ProcedureNguyen Anh TuanNessuna valutazione finora

- Refractory Lining & Repair ProcedureDocumento11 pagineRefractory Lining & Repair ProcedureNguyen Anh TuanNessuna valutazione finora

- Quality Control Plan For Ducting: Project Name: TokushimaDocumento4 pagineQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanNessuna valutazione finora

- 12414-00-1762 - Rev.0 - MT ProcedureDocumento14 pagine12414-00-1762 - Rev.0 - MT ProcedureNguyen Anh TuanNessuna valutazione finora

- 12414-00-1761 - Rev.0 - RT ProcedureDocumento39 pagine12414-00-1761 - Rev.0 - RT ProcedureNguyen Anh TuanNessuna valutazione finora

- 12414-00-1763 - Rev.0 - PT ProcedureDocumento13 pagine12414-00-1763 - Rev.0 - PT ProcedureNguyen Anh TuanNessuna valutazione finora

- 12414-00-1760 - Rev.0 - Ut ProcedureDocumento22 pagine12414-00-1760 - Rev.0 - Ut ProcedureNguyen Anh TuanNessuna valutazione finora

- Regulation of Wood Packaging Material in International Trade ISPM 15Documento22 pagineRegulation of Wood Packaging Material in International Trade ISPM 15erharsinghNessuna valutazione finora

- Paint Application Record: Condition of Surface PreperationDocumento2 paginePaint Application Record: Condition of Surface PreperationNguyen Anh TuanNessuna valutazione finora

- Fb40rev1 Audit-Checkliste EN15085 ENGDocumento14 pagineFb40rev1 Audit-Checkliste EN15085 ENGNguyen Anh TuanNessuna valutazione finora

- Quality Assurance CourseDocumento63 pagineQuality Assurance CourseNguyen Anh Tuan100% (1)

- Corrosion Management Issue119 LowresDocumento36 pagineCorrosion Management Issue119 LowresNguyen Anh Tuan100% (1)

- SC C06 Cag HBK PRC STDocumento26 pagineSC C06 Cag HBK PRC STNguyen Anh Tuan100% (2)

- 2010v01 Inspection Is Not QaDocumento2 pagine2010v01 Inspection Is Not QaNguyen Anh TuanNessuna valutazione finora

- E401 1000 Air Cooled CondensersDocumento4 pagineE401 1000 Air Cooled CondensersNguyen Anh TuanNessuna valutazione finora

- (Env Safety) 1 - Global Safety Management - ENDocumento49 pagine(Env Safety) 1 - Global Safety Management - ENNguyen Anh TuanNessuna valutazione finora

- Stemming The TideDocumento48 pagineStemming The TideDevika Hemalatha DeviNessuna valutazione finora

- MGT Sys Track - 1 - M Boudreaux - Risk MGTDocumento33 pagineMGT Sys Track - 1 - M Boudreaux - Risk MGTVenkatesan KattappanNessuna valutazione finora

- Standard & Specification Status - 170709Documento2 pagineStandard & Specification Status - 170709Nguyen Anh TuanNessuna valutazione finora

- A Training Presentation On The N7Documento69 pagineA Training Presentation On The N7Nguyen Anh TuanNessuna valutazione finora

- 01 Outokumpu Portfolio Wallchart May 2015 PDFDocumento4 pagine01 Outokumpu Portfolio Wallchart May 2015 PDFNguyen Anh TuanNessuna valutazione finora

- Standard & Specification Status - 170709Documento2 pagineStandard & Specification Status - 170709Nguyen Anh TuanNessuna valutazione finora

- Documented InformationDocumento5 pagineDocumented InformationbkssdgNessuna valutazione finora

- ElectricDocumento42 pagineElectricAbd ZouhierNessuna valutazione finora

- AWS - CMWS-2005 - Certified Welding Supervisor Manual For Quality and Productivity ImprovementDocumento449 pagineAWS - CMWS-2005 - Certified Welding Supervisor Manual For Quality and Productivity ImprovementNguyen Anh Tuan94% (16)

- H2FC-Materials-WS Hydrogen Embrittlement of Steels JorcinDocumento40 pagineH2FC-Materials-WS Hydrogen Embrittlement of Steels JorcinNguyen Anh TuanNessuna valutazione finora

- Iso9001 2015 Process ApprDocumento7 pagineIso9001 2015 Process ApprHaitham NegmNessuna valutazione finora

- Documents - Tips TCVN Iso 90042011 Iso 90042009Documento64 pagineDocuments - Tips TCVN Iso 90042011 Iso 90042009Nguyen Anh TuanNessuna valutazione finora

- Quality Manual SampleDocumento16 pagineQuality Manual SampleDrManoj Kumar Sharma100% (1)

- FMEADocumento23 pagineFMEAtbmariNessuna valutazione finora

- ISO 14001:2015 - 03rd Edition Environmental Management Systems RequirementsDocumento79 pagineISO 14001:2015 - 03rd Edition Environmental Management Systems RequirementsSilajit Rony DasguptaNessuna valutazione finora

- Procedure For Management Review MeetingDocumento3 pagineProcedure For Management Review MeetingQuality Unit 1 Ajay PandeyNessuna valutazione finora

- The ISM Code Development Implementation and Legal AspectsDocumento47 pagineThe ISM Code Development Implementation and Legal AspectsOdumoduChigozieUzoma100% (1)

- r7 Ems Internal Audit Report - Fy14 15Documento13 paginer7 Ems Internal Audit Report - Fy14 15tanaNessuna valutazione finora

- BRCGS Issue 9 Templates Toolkit IndexDocumento14 pagineBRCGS Issue 9 Templates Toolkit IndexJayashri chitte0% (1)

- Adm 06 02Documento6 pagineAdm 06 02Mikhail GalatinovNessuna valutazione finora

- Haccp CateringDocumento12 pagineHaccp CateringDeparted MoonNessuna valutazione finora

- Basic Induction of ISO 9001 - 2008 - QMS Standards and Documenta - 2Documento78 pagineBasic Induction of ISO 9001 - 2008 - QMS Standards and Documenta - 2qazi12Nessuna valutazione finora

- Ifs GMP Checklist Pac enDocumento9 pagineIfs GMP Checklist Pac enCevdet BEŞENNessuna valutazione finora

- Quality, Health, Safety AND Environment Management SystemsDocumento50 pagineQuality, Health, Safety AND Environment Management SystemsJay JaniNessuna valutazione finora

- ISO 9001 DocumentationDocumento3 pagineISO 9001 DocumentationBogdan BătrânuNessuna valutazione finora

- Internal AuditsDocumento9 pagineInternal Audits李哲祥100% (1)

- Introduction To QualityDocumento28 pagineIntroduction To QualitySuraj ParmarNessuna valutazione finora

- ISO 9001:2015 Internal Audit Checklist For Manufacturing CompaniesDocumento4 pagineISO 9001:2015 Internal Audit Checklist For Manufacturing Companiesjapv_pas100% (4)

- Aqap 2310 2017 Eng en DataDocumento34 pagineAqap 2310 2017 Eng en Data신동득Nessuna valutazione finora

- TQA-HACCP Manual For Clam Production and ProcessingDocumento49 pagineTQA-HACCP Manual For Clam Production and ProcessingcysautsNessuna valutazione finora

- Fleet Section 3 - AdministrationDocumento27 pagineFleet Section 3 - Administrationmajdirossross100% (1)

- PI - Standard - Feed Mill Standard - Issue 3.0 - 15-June-2020 PDFDocumento28 paginePI - Standard - Feed Mill Standard - Issue 3.0 - 15-June-2020 PDFHelmut AlemánNessuna valutazione finora

- Turtle DiagramDocumento22 pagineTurtle DiagramVikas0% (1)

- Workplace Hazard Inspection Program - ProcedureDocumento4 pagineWorkplace Hazard Inspection Program - ProcedureLoveNessuna valutazione finora

- Sanitation Presentation 2.0Documento40 pagineSanitation Presentation 2.0rajvie2000Nessuna valutazione finora

- GSPL Manual Revision 00Documento110 pagineGSPL Manual Revision 00Dwitikrushna RoutNessuna valutazione finora

- Safety - Sirim Product Certification PDFDocumento14 pagineSafety - Sirim Product Certification PDFSyafiq MazlanNessuna valutazione finora

- Comparision ISO 9001 2018 & 2015Documento8 pagineComparision ISO 9001 2018 & 2015manish100% (1)

- RM QAFA Training DocumentDocumento27 pagineRM QAFA Training Documentស្រី ស្រស់Nessuna valutazione finora

- Top Drive VARCO Drilling Systems Pages From Service Bulletins To 300 396Documento97 pagineTop Drive VARCO Drilling Systems Pages From Service Bulletins To 300 396Álvaro SandovalNessuna valutazione finora

- Hazard Identification PlanDocumento36 pagineHazard Identification PlanLawrenceNessuna valutazione finora

- PMP Exam Preparation CourseDocumento132 paginePMP Exam Preparation Courserasputin0780803494100% (5)