Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

(GeoScience Engineering) Development of Software To Evaluate Roof Fall Risk in Bord and Pillar Method - Depillaring Phase

Caricato da

katta_sridharDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

(GeoScience Engineering) Development of Software To Evaluate Roof Fall Risk in Bord and Pillar Method - Depillaring Phase

Caricato da

katta_sridharCopyright:

Formati disponibili

DOI: 10.

1515/gse-2015-0014 14

DEVELOPMENT OF SOFTWARE TO EVALUATE ROOF FALL

RISK IN BORD AND PILLAR METHOD - DEPILLARING PHASE

Devidas S. NIMAJE 1, Shiva SAI 2

1

Department of Mining Engineering, National Institute of Technology

Rourkela 769008, Odisha, India, tel. +919 437 943 121

e-mail: dsnimaje@nitrkl.ac.in

2

e-mail: shiva222sai@gmail.com

Abstract

Roof fall is one of the major problems of the bord and pillar coal mines during the depillaring phase. Roof

fall not only causes considerable damage to the mining equipment but also to the miners. To keep in view,

development of software is essential for the calculation of roof fall risk to reduce the accidents to a certain

extent. In this paper, the software has been developed and tested on seam-2, the main panel of RK-5

underground coal mine, Singareni Collieries Company Limited, India and corresponding roof fall risk was

calculated. The best combination of the parameters causing roof fall risk was evaluated to reduce the risk.

Keywords: Roof fall risk, parameters, software, probability, risk factor.

1 INTRODUCTION

Roof falls in underground mines are one of the most significant hazards for miners. Roof fall can threaten

miners, damage equipment, disrupt ventilation and block critical emergency escape routes. The hazardous nature

of roof fall risk can be illustrated from statistics of accidents in Indian mines.

A total no. of 278 fatal accidents took place due to roof fall from 1998 to 2010 in different coal mines of

India and is listed in Table 1 year wise [2]. Accidents due to fall of roof occurred in the same proportion in bord

and pillar development as well as depillaring methods. In underground coal mines, bord and pillar is one of the

oldest method used for extraction of flat and tabular coal seams. Pillars are left behind to support the roof and

preventing it from collapse. To increase the utilization of coal, the pillars are extracted after development known

as depillaring method. Depillaring mining is one of the most hazardous activities because it creates an inherently

unstable situation. The process of depillaring method removes the main support after extraction of the pillars to

an extreme extent and allows the roof and overlying rocks to cave. As a result, pillar line was extremely dynamic

and highly stressed. The software was developed based on the equation designed to calculate the risk of roof fall

during retreat mining in room and pillar coal mines [1].

Table 1: Trend of fatal accidents in coal mines due to roof falls in India [2]

Sl. No. Year No. of roof falls

1 1998 35

2 1999 33

3 2000 27

4 2001 30

5 2002 23

6 2003 18

7 2004 26

8 2005 18

9 2006 13

10 2007 13

11 2008 14

12 2009 17

13 2010 11

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 15

2 PARAMETERS CONTRIBUTING TO THE ROOF FALL DURING DEPILLARING

METHOD

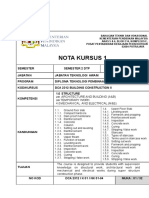

Figure 1: Flow chart of major parameters contributing for roof failure in depillaring phase

The parameters contributing to the roof fall during depillaring phase can be divided into three categories,

and they are

a) Geological parameters

b) Design parameters

c) Operational parameters

2.1 Geological Parameters:

DEPTH OF COVER

Increasing the depth leads to increase of virgin stress levels in rock mass, both vertically and horizontally.

So, achieving sufficient stability is harder at greater depths, and special precautions are required to ensure

ground stability [1].

ROOF ROCK QUALITY

The quality of roof fall rock has a significant role in the occurrence of roof fall. Various methods have

been presented for classification and evaluation of roof in coal mines, but most applicable is coal mine roof

rating (CMRR). When CMRR approaches ‘0’, the roof is weaker and when it approaches ‘100’, the roof is

stronger. Based on CMRR value, the probability of roof fall risk [1, 5] can be classified into five categories.

Extreme 0-45

High 45-55

Moderate 55-65

Low 65-85

Negligible 85-100

FLOOR ROCK QUALITY

Floor, pillar and roof treat as a system in bord and pillar mines. It plays an important role. When the floor

rock doesn’t have suitable quality, pillars penetrate into the floor, which leads to roof convergence and

ultimately its failure. If the floor heave is found to a greater extent, then it can be considered as a weak floor. If

no heave is observed, then the floor is considered as strong. In other cases, it is considered as moderate [1, 4].

GROUND WATER

The presence of groundwater resource and strata containing water above the extracting panel is one of the

effective parameters of roof instability. If the roof is dry, the roof fall is not probable, if the roof is wet, the

probability of roof fall is low, if dripping occurs, the probability is high, and if flow of water is steady, then the

probability is extreme [1].

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 16

OVERLYING MASSIVE STRATA

One of the most important influencing parameters on roof cavability is the existence of massive strata

such as sill over the panel. Massive strata can cause intense roof fall during retreat mining because these strata

tend to be hang up in large spans, but after achieving a critical span, they break violently. Based on research, the

nature of immediate roof strata (up to 20 m over the coal seam) has a significant role in cavability and creation of

gob. Therefore, if the massive strata are in this range, the probability of roof fall is high. In these situations,

partial pillar extraction with proper cut sequence is effective to prevent violent roof fall [1].

MULTIPLE-SEAM INTERACTION

In many coalfields, coal seams are formed close to each other and as series separated by rock strata

(interburden). The mining of two adjacent seams is called multiple-seam mining and the ground control

problems caused by this mining method are called multiple-seam interaction. Ground instability is greatest

hazard due to multiple seam interaction [1].

If thickness of extracting coal seam is ‘h’ and interburden thickness is ‘T’ then

T < 4h interaction is extreme

4h < T < 10h interaction is high

10h < T < 24h interaction is moderate

24h < T < 60h interaction is low

T> 60h interaction is negligible

2.2 Design Parameters:

PANEL WIDTH

Panel width affects abutment loads distribution and over- burden caving mechanism during retreat

mining. Moreover, with increase of panel width, the height of tensile zone developed in the overburden

increases, which can cause violent failure and eventually full caving of overburden. Width to depth ratio panels

[1] is divided into three categories:

sub critical (P/H<2tan b)

Critical (P/H=2tan b)

Super-critical (P/H>2tan b)

Where, P is the panel width, H is the panel depth and b is the abutment angle. Super-critical panels have

more width in comparison with two other categories.

PANEL UNIFORMITY

Panel shape and panel’s pillars shape and size are important in panel uniformity. Because irregular panel

shapes make pillar lines uneven during retreat mining and this causes unpredictable an uncontrollable roof falls.

Moreover, panel development consisting uniformly sized pillars is recommended strongly, because non-uniform

and unequal sized pillars cause non-uniform stress distribution and therefore decrease the roof stability [4].

ENTRY WIDTH

One of the most important methods of decreasing the roof instability at intersections is that entries

creating an intersection should be mined to the minimum possible width, in order to make the operation of

extraction safe and the haulage equipment possible [1]. Regarding the equipment which are used in room and

pillar mines now a-days (continuous miner, shuttle car and LHD), the proper width of entries is about 4.5 to 5m

and also at width more than 7m, roof fall and support problems are probable based on researches done by Jeffrey

[7].

PILLAR DESIGN

Proper pillar design has a significant role in roof stability. Analysis of retreat mining pillar stability

(ARMPS) program is an effective means for pillar design and prediction of pillar stability during retreat mining

[1]. ARMPS was developed by Mark and Chase in 1997[8]. Stability factor depends on depth of cover, and roof

quality (Coal Mine Roof rating - CMRR). If H is the depth and S is the safety factor of pillar then design is said

to be suitable if it follows Table 2, else it is considered as unsuitable.

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 17

Table 2: Suitable safety factor for stability of the pillars during retreat mining[3]

Weak and intermediate roof

Depth of cover (H) Strong roof (CMRR > 65)

(CMRR < 65)

H ≤ 200 m ≥ 1.5 ≥ 1.4

200 < H ≤ 400 m 0.9 < S < 1.5 0.8 < S < 1.4

400 < H ≤ 600 m 0.9 0.8

ROOF BOLTING

Experimentally, installation of one roof bolt in one square meters of roof (bolt density = 1) in coal mine

entries seems to be safe but this value is not adequate at intersection because intersections are subjected to

abutment loads during retreat mining, and therefore require extra roof bolting. Based on bolt density, the

probability of roof fall risk at intersections [1] is divided into three categories:

High, when bolt density is less than 1

Moderate, when bolt density is between 1 and 1.5

Low, when bolt density is more than 1.5

2.3 Operational parameters:

PANEL AGE

As time passes, the roof of mine becomes weaker. Supplemental bolting is often required, particularly in

intersections, to prepare old panels for retreat mining. If the panel age is less than one year, no additional support

is needed and the probability of roof fall is low. But in older panels, the probability of roof fall increases [1].

SUPPLEMENTAL SUPPORT

Supplemental roof support is necessary in depillaring phase to increase the safety and minimize the risk

of injury from roof falls. Timber posts and mobile roof supports (MRSs) provide supplemental support for retreat

mining. Nowadays, using MRS is recommended strongly because using timber posts as pillar line supports has

many disadvantages and the most important is that timber posts are passive supports and roof convergence

would be small [1] .

CUT SEQUENCE

Mines employ a wide variety of cut sequences to recover pillars and most of them can be divided into

three categories

Left– right (also called Christmas tree or twinning) in which cuts are taken on both sides of the entry

and it does not require place changes and bolting

Outside lift in which cuts are taken on just one side and similar to left–right, it does not place changes

and bolting

Cut sequences that require cuts to be bolted

These methods are usually used when the pillars are so large that they must be split before they are fully

recovered. Split-and-fender and pocket-and-wing are two common types of these methods [1].

3 CALCULATION OF ROOF FALL RISK

Risk is defined as the chance of occurrence of unwanted events that will have adverse effects on

purposes. It is measured in terms of probability (P) and consequence (C). Roof falls during retreat mining

continue to be one of the greatest geotechnical risks faced by underground coal miners and cause a lot of loss,

injury or fatalities. Therefore, the roof fall risk [1] can be defined as:

Rrf = P * C (1)

3.1 Probability

In order to make the roof fall probability quantitative, two measures have been considered. The first one

is to assign the probability factor (PF) for each sub-category. The second one is to give a weight to each

parameter. The probability factor is an index which represents the probability of roof fall for each sub-category

and was obtained from Table 6 based on proposed method by Joy [1]. Based on this table, the probability factor

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 18

can be a number between 0 and 4; 0 shows that the roof fall probability is negligible and 4 shows that the roof

fall probability is extreme. Since the effects of different parameters on roof fall are not the same, it is necessary

to give a weight to each parameters based on its importance on roof fall occurrence. In this study, a weight

between 1 and 10 was assigned to each parameter based on judgments of mining engineers and ground control

experts (Tables 3–5). 1 indicates the least effective parameter and 10 shows the most effective parameter on roof

fall [1].

Table 3: Geological parameters influencing roof fall risk [1]

Sl. No. Parameters Probability factor Weight

Depth of cover (m)

Less than 40 4

Between 40 and 200 1

1

Between 200 and 400 2 9

Between 400 and 600 3

More than 600 4

Roof rock quality (CMRR)

Less than 45 4

Between 45 and 55 3

2

Between 55 and 65 2 10

Between 65 and 85 1

More than 85 0

Floor rock quality

Weak 3

3

Intermediate 2 4

Strong 1

Groundwater

Dry roof 0

4 Wet roof 1

2

Dripping 3

Steady flow 4

Overlying massive strata/D

Do Not present 0

5

Present/Less than 20 m 3 5

Present/ More than 20 m 1

Multiple-seam interaction/ Interburden thickness

Not present

0

present/Less than 10 h

6 4

Present/Between 10 h and 24 h 7

3

Present/Between 24 h and 60 h

2

Present/More than 60 h

1

Where, D- Distance from the coal seam, h – Thickness of the coal seam

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 19

Table 4: Design parameters influencing roof fall risk [1]

Sl. No. Parameters Probability factor Weight

Panel width

Sub-critical 1

1

Critical 2 3

Super-critical 3

Panel uniformity

Uniform 1

2

Partly uniform 2 1

Non-uniform 3

Entry width (m)

Less than 5 1

3

Between 5 and 7 2 8

More than 7 3

Pillar design

4 Suitable 1

6

Unsuitable 4

Roof bolting

Bolt density less than 1 3

5

Bolt density between 1 and 1.5 2 7

Bolt density more than 1.5 1

Table 5: Operational parameters influencing roof fall risk [1]

Sl. No. Parameters Probability factor Weight

Panel age (year)

Less than 1 1

1

Between 1 and 2 2 2

More than 2 3

Supplemental support

2 Mobile roof support 1

7

Timber post 4

Cut sequence

Outside lift 1

3

Left–right 2 6

Other sequence 3

Final stump

4 Proper 1

8

Improper 4

The probability of roof fall during retreat mining [1] is calculated as:

n n

P = [(∑ PFi ∗ Wi ) / (∑ MPFi ∗ Wi )] ∗ 100 (2)

i=1 i=1

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 20

Where, PFi, MPFi and Wi are probability factor, maximum probability factor and weight of i-th

parameter, respectively. The MPF for nine parameters is 3 and for the other parameters is 4 (Tables 3–5).

Therefore, the above equation can be summarized as follows:

n

P = 0.33 ∗ [(∑ PFi ∗ Wi )] (3)

i=1

Table 6: Probability of an event in mining industry [6]

Sl. Probability

Probability Description

No. Factor (PF)

Common or frequent occurrence,

1 Extreme 4

‘‘happens all the time’’

Is known to occur,

2 High 3

‘‘it has happened or it probably will happen’’

Could occur,

3 Moderate 2

‘‘I have heard of it happening’’

Not likely to occur,

4 Low 1

‘‘highly unlikely to happen”

Practically impossible,

5 Negligible 0

‘‘doubt it could ever happen”

3.2 Consequence

The roof fall during retreat mining can cause injury, disability and fatality of miners, damage to

equipment, disruption and delay in mining operation simultaneously [1]. Furthermore, most of the roof falls

caused burial of continuous miner and mobile roof support (MRS). The necessity to recover this equipment

because of their high initial costs has caused several days of delay in mine production. Therefore, consequence

of roof fall during retreat mining is catastrophic, which is the highest rank of consequence, and the number 1

(highest rank) can be allocated to it [6], which cause elimination of consequence term from derived equation 1.

3.3 Evaluation of roof fall risk

Considering what was mentioned in two previous sections, derived equation can be presented as:

n

R rf = 0.33 ∗ [(∑ PFi ∗ Wi )] (4)

i=1

Based on equation (4), the roof fall risk during retreat mining (Rrf) is between 0 and 100. When the Rrf is

approaching to 0, the roof fall risk during retreat mining is low and when R rf is approaching to 100, the roof fall

risk is very high [1]. In this study, the roof fall risk during retreat mining based on R rf values is divided into four

categories: low, medium, high, and very high (Table 7).

Table 7: Classification of roof fall risk during retreat mining [1]

Risk category Rrf value Roof fall probability Level of roof fall risk

Low 0-28 Improbable Acceptable

Acceptable with management review,

Moderate 28-48 Possible

monitoring and auditing

Undesirable and requires control

High 48-70 Probable

measures widely

Very high 70-100 Very probable Unacceptable

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 21

4 DEVELOPMENT OF SOFTWARE

Software was developed using asp.net to calculate the roof fall risk in bord and pillar mining-depillaring

phase and tested on seam-2, the main panel of RK-5 underground coal mine, Singareni Collieries Company

Limited (SCCL), Godavarikhani district, Telangana state, India. Data collected from the above said mine has

been summarized in Table 8.

Table 8: Data collected from RK-5 mine

Sl. No. Parameters Data

1. Depth of cover (m) 180

2. Roof rock quality 56

3. Floor rock quality Intermediate

4. Ground water Wet roof

5. Overlying massive strata Present < 20m

6. Multiple seam interaction Present/ less than 10H

7. Panel width Sub critical

8. Panel uniformity Uniform

9. Entry width (m) 4.5

10. Pillar design Suitable

11. Roof bolting density 1.75

12. Panel age (Years) 1.5

13. Supplemental support Timber post

14. Cut sequence Left right

15. Final stump Proper

5 5. RESULT

All the above data (Table 8) are entered into the software and found that roof fall risk was ~ 52.47 in

RK-5 mine which represents high risk category, as the roof fall risk was between 48 and 70. By changing the

supplemental support from timber post to mobile roof support, the roof fall risk for RK-5 mine was reduced to

45.54 which interprets moderate category i.e. between 28 and 48. Since, this software provides the roof fall risk

in advance so that preventive measures should be taken to avoid the accidents. The pictorial view of calculation

of roof fall risk with different roof supports of RK-5 mine have been represented in Figures 2 – 3.

Figure 2: Pictorial view of software of RK-5 mine when supplemental support is timber post

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

DOI: 10.1515/gse-2015-0014 22

Figure 3: Pictorial view of software of RK-5 mine when supplemental support is mobile roof support

6 CONCLUSIONS

Depillaring method is mostly associated with high amount of risk and most of the accidents causes due to

roof failure. By development of software for the prediction of roof failure, we can reduce the number of

accidents to a certain extent. Use of software eases the calculation of roof fall risk with different combinations of

parameters causing roof failure and finds the suitable risk factor. The combination with the least risk factor can

be adopted in the mine and hence accidents due to roof failure can be reduced. When changing the support from

timber to mobile roof support, the roof fall risk of RK-5 underground coal mines was changing from high risk

category to moderate risk category, so, we can take preventive measures in advance with the proposed software

to reduce the roof fall risk to a certain extent with feasible constraint.

REFERENCES

[1] Ghasemi, E., Ataei, M. et al. 2012. Assessment of roof fall risk during retreat mining in room and pillar

coal mines. In International Journal of Rock Mechanics and Mining Sciences, 2012, vol. 54, pp. 2-9.

[2] DGMS STRATEGIC PLAN. 2011. Trend of fatal accidents in coal mines. [online] Published 1.07.2011.

[cited 31.05.2015]. Accessible from <http://www.scribd.com/doc/59115207/Dgms-Strategic-Plan-

2011#scribd >.

[3] CHASE, F.E., MARK, C. et al. 2002. Deep cover pillar extraction in the US coalfields. In Proc. of the

21st international conf. on Ground Control in Mining. Morgantown, West Virginia University, USA,

2002, p. 69–80.

[4] GHASEMI, E., SHAHRIAR, K. et al. 2010. A new method for risk assessment of pillar recovery

operation. In Safety Science, 2010, vol. 48, pp. 1304–1312.

[5] MARK, C., CHASE, F.E. et al. 2003. Reducing the risk of ground falls during pillar recovery. In Trans.

Soc. Min. Engg., 2013, vol. 314, pp. 153–160.

[6] JOY, J. 2000. System safety in Australian coal mining. In Proc. of the 12th Turkish coal congress.

Turkey, 2000, p. 11–20.

[7] JEFFREY, L.S. 2002. The impact of geotechnical factors on the secondary extraction of coal in the

Witbank and Northern Highveld Coalfields, specifically related to safety. Safety in Mines Research

Advisory committee (SIMRAC), final project report, 2002, No. COL810.

[8] MARK, C., CHASE, F.E. 1997. Analysis of Retreat Mining Pillar Stability (ARMPS). In Proc. of the

new technology for ground control in retreat mining. US Department of Health and Human Services,

Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 1997,

NIOSH Publication No. 9446, p. 17–37.

GeoScience Engineering Volume LXI (2015), No.2

http://gse.vsb.cz p. 14-22, ISSN 1802-5420

Unauthenticated

Download Date | 7/1/19 1:55 PM

Potrebbero piacerti anche

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceDa EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNessuna valutazione finora

- Final Project Report Final Ko FinalDocumento16 pagineFinal Project Report Final Ko FinalRaja SabapathyNessuna valutazione finora

- Use of Rigid Foundation System On Expansive Soils: and Ali, H.EDocumento10 pagineUse of Rigid Foundation System On Expansive Soils: and Ali, H.Eمنير أحمدNessuna valutazione finora

- Ppr12 227clrDocumento19 paginePpr12 227clrah maNessuna valutazione finora

- PAPER1 Minetech11Documento10 paginePAPER1 Minetech11SushantNessuna valutazione finora

- A Study On The Rigid Pavement Construction Joint and Crack FormationDocumento6 pagineA Study On The Rigid Pavement Construction Joint and Crack FormationAjit P. SinghNessuna valutazione finora

- Silt Factor For Scour Calculation AroundDocumento7 pagineSilt Factor For Scour Calculation AroundPrem Dheep100% (1)

- Design and Planning of Instrumentation WorksDocumento46 pagineDesign and Planning of Instrumentation WorksMin Min SoeNessuna valutazione finora

- Investigation On Causes of Pavement Failure and Its Remedial MeasuresDocumento5 pagineInvestigation On Causes of Pavement Failure and Its Remedial MeasuresIJRASETPublicationsNessuna valutazione finora

- Causal Factors of Malaysian Landslides: A Narrative StudyDocumento7 pagineCausal Factors of Malaysian Landslides: A Narrative StudyMOGANESWARY A/P RENGANATHANNessuna valutazione finora

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDocumento4 pagineStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127Nessuna valutazione finora

- MAINTENANCE & REPAIR Micro ProjectDocumento13 pagineMAINTENANCE & REPAIR Micro ProjectIchigoNessuna valutazione finora

- Wind and SeismicDocumento6 pagineWind and Seismiclance lancelottiNessuna valutazione finora

- Slope Stability and Seepage Analysis of Earth Dams Using Numerical Models: A Case Study, EgyptDocumento12 pagineSlope Stability and Seepage Analysis of Earth Dams Using Numerical Models: A Case Study, Egyptijetrm journalNessuna valutazione finora

- 9251-Article Text-34502-1-10-20220630Documento10 pagine9251-Article Text-34502-1-10-20220630rullyirwandiNessuna valutazione finora

- Use of Industrial Wastes in The Construction of Flexible PavementsDocumento6 pagineUse of Industrial Wastes in The Construction of Flexible Pavementssai venkateshNessuna valutazione finora

- Landslide of Highland Towers 1993 A Case Study of MalaysiaDocumento10 pagineLandslide of Highland Towers 1993 A Case Study of MalaysiaWan Ahmad At-Tirmidzi100% (1)

- Study On Characteristic of Overburden Movement in Unsymmetrical Isolated Longwall Mining Using Microseismic TechniqueDocumento10 pagineStudy On Characteristic of Overburden Movement in Unsymmetrical Isolated Longwall Mining Using Microseismic Techniquekatta_sridharNessuna valutazione finora

- Compressive Strength of Blocks Made of Hollow Sandcrete Using Portland Limestone Cement and RabbishDocumento6 pagineCompressive Strength of Blocks Made of Hollow Sandcrete Using Portland Limestone Cement and RabbishIJRASETPublicationsNessuna valutazione finora

- Highland TowerDocumento10 pagineHighland Towermuhammad iqbalNessuna valutazione finora

- Konstantis 2017Documento11 pagineKonstantis 2017Paloma CortizoNessuna valutazione finora

- Drilling Fluids For DeepwaterDocumento28 pagineDrilling Fluids For Deepwateripali4christ_5308248Nessuna valutazione finora

- Soil NailingDocumento24 pagineSoil NailingVivekNessuna valutazione finora

- IJCRT2207264Documento17 pagineIJCRT2207264Ali Asghar LangahNessuna valutazione finora

- Keruntuhan Galian DalamDocumento16 pagineKeruntuhan Galian Dalamlimara65Nessuna valutazione finora

- Deterioration of PavementsDocumento7 pagineDeterioration of PavementsMohammad Irshad AlamNessuna valutazione finora

- Numurical Mom.' MIR Si Twl-S Tii ITY.: / / Ys IsDocumento15 pagineNumurical Mom.' MIR Si Twl-S Tii ITY.: / / Ys IsSachin NaikNessuna valutazione finora

- Group 26 PlublishedReserch PaperDocumento7 pagineGroup 26 PlublishedReserch PaperDaily FunNessuna valutazione finora

- D Cracking of Concrete PavementDocumento2 pagineD Cracking of Concrete PavementObulareddy ChemikalaNessuna valutazione finora

- 60 PDFDocumento7 pagine60 PDFYogiIndraPrayogaNessuna valutazione finora

- (2020) Calculation of Residual Surface Subsidence AboveDocumento12 pagine(2020) Calculation of Residual Surface Subsidence AboveRizto SaliaNessuna valutazione finora

- Landslide of Highland Towers 1993: A Case Study of Malaysia: December 2017Documento10 pagineLandslide of Highland Towers 1993: A Case Study of Malaysia: December 2017syazmirrNessuna valutazione finora

- Case 1Documento10 pagineCase 1Jahid HasanNessuna valutazione finora

- SL - 03an Overview of Professional Practice of Geotechnical Engineering inDocumento0 pagineSL - 03an Overview of Professional Practice of Geotechnical Engineering inTu Tu DarNessuna valutazione finora

- International Journal of Mining Science and TechnologyDocumento7 pagineInternational Journal of Mining Science and Technologyrico andreanNessuna valutazione finora

- Geotechical KaseseDocumento9 pagineGeotechical KaseseDaphine UweeraNessuna valutazione finora

- CrackDocumento15 pagineCrackLucky XeroxNessuna valutazione finora

- Subgrade Hydraulic Characteristics SeepaDocumento17 pagineSubgrade Hydraulic Characteristics SeepaOLUWASEUN QUADRINessuna valutazione finora

- 1-2 Scope and Importance of Rock Excavation With CasesDocumento13 pagine1-2 Scope and Importance of Rock Excavation With CasesLipsa MahapatraNessuna valutazione finora

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Documento10 pagineInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)suhail ahmadNessuna valutazione finora

- Building Construction Ii - StrukturDocumento33 pagineBuilding Construction Ii - StrukturMie Ai Sya100% (2)

- 115mn0544 Project Report - Ardhagram 8th Sem MidDocumento25 pagine115mn0544 Project Report - Ardhagram 8th Sem MidPrabhupad PandaNessuna valutazione finora

- Optimum Design and Performance of Porous Concrete For Heavy-Load Traffic Pavement in Cold and Heavy Rainfall Region of NE ChinaDocumento16 pagineOptimum Design and Performance of Porous Concrete For Heavy-Load Traffic Pavement in Cold and Heavy Rainfall Region of NE ChinaRizal RifdoNessuna valutazione finora

- Logistic Regression Model For Prediction of Roof Fall Risks in Bord and Pillar Workings in Coal Mines - An ApproachDocumento9 pagineLogistic Regression Model For Prediction of Roof Fall Risks in Bord and Pillar Workings in Coal Mines - An ApproachDURGAM HIMALAYNessuna valutazione finora

- Bituminous Pavement Failures: Surajo Abubakar WadaDocumento7 pagineBituminous Pavement Failures: Surajo Abubakar WadaAyebaifiemiemi DienaghaNessuna valutazione finora

- HGF 312Documento18 pagineHGF 312Muhamad Kamarulzaman OmarNessuna valutazione finora

- Stability Analysis MizoramDocumento9 pagineStability Analysis Mizoramdimas.pratamaNessuna valutazione finora

- Fs Falla de Fondo Kohsaka & IshizukaDocumento15 pagineFs Falla de Fondo Kohsaka & IshizukaJosé Francisco Martínez GutiérrezNessuna valutazione finora

- Study of Deformations That Occur On Road Surfaces and Develop Measures To Prevent ThemDocumento5 pagineStudy of Deformations That Occur On Road Surfaces and Develop Measures To Prevent ThemResearch ParkNessuna valutazione finora

- Construction On Soft GroundDocumento9 pagineConstruction On Soft GroundyantieschumiNessuna valutazione finora

- Landslides in The Hillside Development in The Hulu Klang, Klang ValleyDocumento15 pagineLandslides in The Hillside Development in The Hulu Klang, Klang ValleyMiza MijaNessuna valutazione finora

- Zaw Final Isuet2006Documento19 pagineZaw Final Isuet2006zaw69Nessuna valutazione finora

- Micropiles Prospects & ChallengesDocumento28 pagineMicropiles Prospects & Challengesbarad1Nessuna valutazione finora

- Keynote - Prof. Purnanand - Landslides - Stability and Control MeasuresDocumento8 pagineKeynote - Prof. Purnanand - Landslides - Stability and Control Measuresdigvijay singhNessuna valutazione finora

- Study of Sustainable Techniques For Effective Risk Management and Control A ReviewDocumento11 pagineStudy of Sustainable Techniques For Effective Risk Management and Control A ReviewIJRASETPublicationsNessuna valutazione finora

- Analisis Stabilitas Lereng Dengan Perkuatan Soil NailingDocumento8 pagineAnalisis Stabilitas Lereng Dengan Perkuatan Soil NailingrullyirwandiNessuna valutazione finora

- Site Safety Handbook for the Petroleum IndustryDa EverandSite Safety Handbook for the Petroleum IndustryValutazione: 5 su 5 stelle5/5 (1)

- NUMERICAL MODELLING OF SURFACE SUBSIDENCE Due To LWDocumento12 pagineNUMERICAL MODELLING OF SURFACE SUBSIDENCE Due To LWkatta_sridharNessuna valutazione finora

- Design of Rib Pillars in LW MiningDocumento16 pagineDesign of Rib Pillars in LW Miningkatta_sridharNessuna valutazione finora

- Pressure Arch Theory (Longwall) : Prepared by P. Vinay CharyDocumento23 paginePressure Arch Theory (Longwall) : Prepared by P. Vinay Charykatta_sridharNessuna valutazione finora

- Experience in Longwall Mining at Coalbrook CollieriesDocumento15 pagineExperience in Longwall Mining at Coalbrook Collierieskatta_sridharNessuna valutazione finora

- Thick Seam Longwall MiningDocumento10 pagineThick Seam Longwall Miningkatta_sridharNessuna valutazione finora

- The Ground Control Management Plan of A Mine Ovacık Gold MineDocumento8 pagineThe Ground Control Management Plan of A Mine Ovacık Gold Minekatta_sridharNessuna valutazione finora

- WATER PROBLEMS ASSOCIATED With Undersea LWDocumento20 pagineWATER PROBLEMS ASSOCIATED With Undersea LWkatta_sridharNessuna valutazione finora

- Deformation Failure and Permeability of Coal Bearing Strata During Longwall Mining 2016 Engineering GeologyDocumento12 pagineDeformation Failure and Permeability of Coal Bearing Strata During Longwall Mining 2016 Engineering Geologykatta_sridharNessuna valutazione finora

- Stress Evolution and Induced Accidents Mechanism in Shallow Coal Seam in Proximity Underlying The Room Mining Residual PillarsDocumento7 pagineStress Evolution and Induced Accidents Mechanism in Shallow Coal Seam in Proximity Underlying The Room Mining Residual Pillarskatta_sridharNessuna valutazione finora

- 15.production and Productivity Improvement Measures at MOIL-MOILDocumento8 pagine15.production and Productivity Improvement Measures at MOIL-MOILkatta_sridharNessuna valutazione finora

- 16.shortwall Mining-D M Gokhale, WCLDocumento6 pagine16.shortwall Mining-D M Gokhale, WCLkatta_sridharNessuna valutazione finora

- 14.an Overview of Ug Coal mining-WCL HQDocumento30 pagine14.an Overview of Ug Coal mining-WCL HQkatta_sridharNessuna valutazione finora

- 19 Ratnesh Mine ClosureDocumento12 pagine19 Ratnesh Mine Closurekatta_sridharNessuna valutazione finora

- Caving Mechanisms of Loose Top Coal in Longwall Top Coal Caving Mining Method 2014 International Journal of Rock Mechanics and Mining SciencesDocumento11 pagineCaving Mechanisms of Loose Top Coal in Longwall Top Coal Caving Mining Method 2014 International Journal of Rock Mechanics and Mining Scienceskatta_sridharNessuna valutazione finora

- Behaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical EngineeringDocumento10 pagineBehaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical Engineeringkatta_sridharNessuna valutazione finora

- Computers and Geotechnics: G.S.P. Singh, U.K. SinghDocumento15 pagineComputers and Geotechnics: G.S.P. Singh, U.K. Singhkatta_sridharNessuna valutazione finora

- Grid Pattern PortraitDocumento8 pagineGrid Pattern PortraitEmma FravigarNessuna valutazione finora

- How To Convert Files To Binary FormatDocumento1 paginaHow To Convert Files To Binary FormatAhmed Riyadh100% (1)

- EVOM ManualDocumento2 pagineEVOM ManualHouston WhiteNessuna valutazione finora

- Morfologi Dan Citra Kota Kawasan Kauman, Kecamatan Juwana, Kabupaten Pati The Morphology and Image of Kauman Town, Juwana Sub District, Pati RegencyDocumento16 pagineMorfologi Dan Citra Kota Kawasan Kauman, Kecamatan Juwana, Kabupaten Pati The Morphology and Image of Kauman Town, Juwana Sub District, Pati RegencyRABIAH ARDIANTI TUM TOMAGOLANessuna valutazione finora

- 3 Diversion&CareDocumento2 pagine3 Diversion&CareRyan EncomiendaNessuna valutazione finora

- Formula:: High Low Method (High - Low) Break-Even PointDocumento24 pagineFormula:: High Low Method (High - Low) Break-Even PointRedgie Mark UrsalNessuna valutazione finora

- BMGT 200 Assignment 2 Answer KeysDocumento3 pagineBMGT 200 Assignment 2 Answer Keysharout keshishianNessuna valutazione finora

- Case Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityDocumento5 pagineCase Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityluxoftNessuna valutazione finora

- CLG418 (Dcec) PM 201409022-EnDocumento1.143 pagineCLG418 (Dcec) PM 201409022-EnMauricio WijayaNessuna valutazione finora

- 385C Waw1-Up PDFDocumento4 pagine385C Waw1-Up PDFJUNA RUSANDI SNessuna valutazione finora

- Mosharaf HossainDocumento2 pagineMosharaf HossainRuhul RajNessuna valutazione finora

- Implications of A Distributed Environment Part 2Documento38 pagineImplications of A Distributed Environment Part 2Joel wakhunguNessuna valutazione finora

- Prospekt Puk U5 en Mail 1185Documento8 pagineProspekt Puk U5 en Mail 1185sakthivelNessuna valutazione finora

- EKC 202ABC ManualDocumento16 pagineEKC 202ABC ManualJose CencičNessuna valutazione finora

- Network Fundamentas ITEC90Documento5 pagineNetwork Fundamentas ITEC90Psychopomp PomppompNessuna valutazione finora

- Importance of Communications 05sept2023Documento14 pagineImportance of Communications 05sept2023Sajib BhattacharyaNessuna valutazione finora

- Product NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Documento14 pagineProduct NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Paras ShardaNessuna valutazione finora

- BIAN How To Guide Developing Content V7.0 Final V1.0 PDFDocumento72 pagineBIAN How To Guide Developing Content V7.0 Final V1.0 PDFميلاد نوروزي رهبرNessuna valutazione finora

- Ring and Johnson CounterDocumento5 pagineRing and Johnson CounterkrsekarNessuna valutazione finora

- Hazardous Locations: C.E.C. ClassificationsDocumento4 pagineHazardous Locations: C.E.C. ClassificationsThananuwat SuksaroNessuna valutazione finora

- Alternative Network Letter Vol 7 No.1-Apr 1991-EQUATIONSDocumento16 pagineAlternative Network Letter Vol 7 No.1-Apr 1991-EQUATIONSEquitable Tourism Options (EQUATIONS)Nessuna valutazione finora

- Native VLAN and Default VLANDocumento6 pagineNative VLAN and Default VLANAaliyah WinkyNessuna valutazione finora

- BS 7974 2019Documento68 pagineBS 7974 2019bcyt00Nessuna valutazione finora

- Google Tools: Reggie Luther Tracsoft, Inc. 706-568-4133Documento23 pagineGoogle Tools: Reggie Luther Tracsoft, Inc. 706-568-4133nbaghrechaNessuna valutazione finora

- Focus Edition From GC: Phosphate Bonded Investments For C&B TechniquesDocumento35 pagineFocus Edition From GC: Phosphate Bonded Investments For C&B TechniquesAlexis De Jesus FernandezNessuna valutazione finora

- Vemu Institute of Technology: Department of Computer Science & EngineeringDocumento79 pagineVemu Institute of Technology: Department of Computer Science & EngineeringSiva SankarNessuna valutazione finora

- Participants ListDocumento13 pagineParticipants Listmailway002Nessuna valutazione finora

- Surgery - 2020 With CorrectionDocumento70 pagineSurgery - 2020 With CorrectionBaraa KassisNessuna valutazione finora

- Understanding and Teaching Fractions: Sybilla BeckmannDocumento26 pagineUnderstanding and Teaching Fractions: Sybilla Beckmannjhicks_mathNessuna valutazione finora

- Stentofon Pulse: IP Based Intercom SystemDocumento22 pagineStentofon Pulse: IP Based Intercom SystemCraigNessuna valutazione finora