Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Past Project-FEED-DED PDF

Caricato da

finiteinjusticeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Past Project-FEED-DED PDF

Caricato da

finiteinjusticeCopyright:

Formati disponibili

DESIGN OF STORAGE TANK

Designed By Kingsley Eke +2348064382749

DESIGN OF STORAGE TANK

Designed By Kingsley Eke +2348064382749

DESIGN OF PRESSURE VESSEL – SURGE VESSEL

Designed By Kingsley Eke +2348064382749

DESIGN OF PRESSURE VESSEL – HORIZONTAL SEPARATOR

Designed By Kingsley Eke +2348064382749

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

Aspen Exchanger Design and Rating Shell & Tube V10

File: C:\Users\USER\Desktop\AEL-Heat Exchanger.EDR Printed: 9/3/2020 at 9:35:13 PM

TEMA Sheet

Heat Exchanger Specification Sheet

1 Company:

2 Location:

3 Service of Unit: Our Reference:

4 Item No.: Your Reference:

5 Date: Rev No.: Job No.:

6 Size : 1067 - 6096 mm Type: AEL Horizontal Connected in: 1 parallel 1 series

7 Surf/unit(eff.) 586.4 m² Shells/unit 1 Surf/shell(eff.) 586.4 m²

8 PERFORMANCE OF ONE UNIT

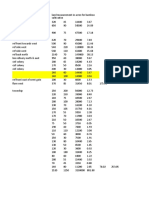

9 Fluid allocation Shell Side Tube Side

10 Fluid name Crude Inlet->Crude Outlet ColdWater Inlet->ColdWater Outlet

11 Fluid quantity, Total kg/s 50.8803 174.4194

12 Vapor (In/Out) kg/s 0 0 0 0

13 Liquid kg/s 50.8803 50.8803 174.4194 174.4194

14 Noncondensable kg/s 0 0 0 0

15

16 Temperature (In/Out) °C 95 40.38 25 32.65

17 Bubble / Dew point °C / / / /

18 Density Vapor/Liquid kg/m³ / 868.42 / 905.16 / 1007.46 / 1001.65

19 Viscosity mPa-s / 12.9359 / 61.7645 / 0.8904 / 0.7539

20 Molecular wt, Vap

21 Molecular wt, NC

22 Specific heat kJ/(kg-K) / 2.172 / 1.955 / 4.313 / 4.313

23 Thermal conductivity W/(m-K) / 0.1254 / 0.1329 / 0.611 / 0.6219

24 Latent heat kJ/kg

25 Pressure (abs) bar 5 4.36919 5 4.14806

26 Velocity (Mean/Max) m/s 0.36 / 0.4 1.23 / 1.23

27 Pressure drop, allow./calc. bar 1 0.63081 1 0.85193

28 Fouling resistance (min) m²-K/W 0.0001 0.0001 0.00013 Ao based

29 Heat exchanged 5741.4 kW MTD (corrected) 31.59 °C

30 Transfer rate, Service 309.9 Dirty 328.1 Clean 354.7 W/(m²-K)

31 CONSTRUCTION OF ONE SHELL Sketch

32 Shell Side Tube Side

33 Design/Vacuum/test pressure bar 5.51581 / / 5.51581 / /

34 Design temperature °C 132.22 71.11 T2 S1

35 Number passes per shell 1 2

36 Corrosion allowance mm 3.18 3.18 T1 S2

37 Connections In mm 1 152.4 / 150 ANSI 1 152.4 / 150 ANSI

38 Size/Rating Out 1 152.4 / 150 ANSI 1 152.4 / 150 ANSI

39 Nominal Intermediate / 150 ANSI / 150 ANSI

40 Tube #: 1638 OD: 19.05 Tks. Average 2.11 mm Length: 6096 mm Pitch: 23.81 mm Tube pattern:30

41 Tube type: Plain Insert:None Fin#: #/m Material:Carbon Steel

42 Shell Carbon Steel ID 1066.8 OD 1092.2 mm Shell cover -

43 Channel or bonnet Carbon Steel Channel cover Carbon Steel

44 Tubesheet-stationary Carbon Steel - Tubesheet-floating -

45 Floating head cover - Impingement protection None

46 Baffle-cross Carbon Steel Type Single segmental Cut(%d) 30.82 HorizSpacing: c/c 470 mm

47 Baffle-long - Seal Type Inlet 875.85 mm

48 Supports-tube U-bend 0 Type

49 Bypass seal Tube-tubesheet joint Expanded only (2 grooves)(App.A 'i')

50 Expansion joint - Type None

51 RhoV2-Inlet nozzle 8581 Bundle entrance 321 Bundle exit 308 kg/(m-s²)

52 Gaskets - Shell side - Tube side Flat Metal Jacket Fibe

53 Floating head -

54 Code requirements ASME Code Sec VIII Div 1 TEMA class R - refinery service

55 Weight/Shell 14101.1 Filled with water 19238.4 Bundle 9729.4 kg

56 Remarks

57

58

Views on arrow A

A 7369 Overall

5982

T2

287 350 216 5658

T2 S1

T1

S1

T1 S2

350 1219 3658

5540

Pulling Length

S2

76 76

152 152

2 Bolts 2 Bolts

Fixed Sliding

Nozzle Data Design Data Units Shell Channel Notes: Company:

Ref OD Wall Standard Notes Design Pressure bar 5.52 5.52 Location:

S1 168 mm 7.1 mm 150 ANSI Weld neck Design Temperature °C 132.22 71.11 Service of Unit: Our Reference:

S2 168 mm 7.1 mm 150 ANSI Weld neck Full Vacuum Item No.: Your Reference:

T1 168 mm 7.1 mm 150 ANSI Weld neck Corrosion Allowance mm 3.175 3.175 Date: Rev No.: Job No.:

T2 168 mm 7.1 mm 150 ANSI Weld neck Test Pressure bar

Number of Passes 1 2

Radiography

Company Name

City, State

PWHT

Internal Volume m³ 2.4847 2.7754 Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Section VIII Div. 1

Setting Plan

Weight Summary TEMA Type: AEL

Empty Flooded Bundle Size: 1067 - 6096 Dwg No.: Rev:

14101 kg 19238 kg 9729 kg TEMA Class: R AEL-Heat Exchanger 1

819

19.05

819

23.8125

Shell inside diameter mm 1066.8

Front head inside diameter mm 1066.8

Outer tube limit mm 1054.1

Tube number (calcs.) 1638

Tube number (layout) 1638

Tube length mm 6096

Tube O.D. mm 19.05

Tube pitch mm 23.8125

Tube pattern 30

Tube passes 2

Tie rod number 8

Tie rod diameter mm 12.7

Sealing strips (pairs) 4

Baffle type Single segmental

Centre to outer baffle cut mm 204.65

Centre to inner baffle cut

Impingement protection None

Shell Side Inlet Nozzle Inside Diameter mm 154.051

Shell Side Outlet Nozzle Inside Diameter mm 154.051

Notes: Company:

Location:

Service of Unit: Our Reference:

Item No.: Your Reference:

Date: Rev No.: Job No.:

Company Name

City, State

Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Code Sec VIII Div 1

TEMA Type: AEL

Tube Layout

Size: 1067 - 6096 Dwg No.: Rev:

TEMA Class: R - refinery service AEL-Heat Exchanger 2

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

DESIGN OF AEL-TYPE SHELL AND TUBE HEAT EXCHANGER

Designed By: Kingsley Eke ekemaraizu@gmail.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Chemistry - Periodic Table - Advanced PDFDocumento2 pagineChemistry - Periodic Table - Advanced PDFCA_Ken86% (7)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Lab 1 Food TestDocumento5 pagineLab 1 Food TestMichael Timson83% (6)

- Smart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganDocumento1 paginaSmart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganKathy Irene ReganNessuna valutazione finora

- Basics of Olymiad InequalitiesDocumento45 pagineBasics of Olymiad Inequalitiesmonivon83% (6)

- Historical Structural Steelwork HandbookDocumento76 pagineHistorical Structural Steelwork Handbookjimmyoftheworld100% (1)

- Base Plate DesignDocumento14 pagineBase Plate Designsoumi bhattacharyaNessuna valutazione finora

- 10 Handbook Standard For Portable Fire ExtinguishersDocumento205 pagine10 Handbook Standard For Portable Fire ExtinguishersJosesin SinsinNessuna valutazione finora

- Flexible Pavement Design SK RaoDocumento62 pagineFlexible Pavement Design SK Raokrishnarao krishnarao329100% (3)

- @eBookRoom. Minimalism PDFDocumento95 pagine@eBookRoom. Minimalism PDFfiniteinjusticeNessuna valutazione finora

- SIZE REDUCTION TECHNIQUES EXPLAINEDDocumento28 pagineSIZE REDUCTION TECHNIQUES EXPLAINEDveenaNessuna valutazione finora

- Chapter 20 PetrucciDocumento67 pagineChapter 20 PetrucciLoeyNessuna valutazione finora

- B 549 - 13 PDFDocumento8 pagineB 549 - 13 PDFTuanbk Nguyen0% (1)

- 2014-4800-0L-0008 Rev B Welding Procedures & Performance Qualification Spec - ApprovedDocumento19 pagine2014-4800-0L-0008 Rev B Welding Procedures & Performance Qualification Spec - ApprovedfiniteinjusticeNessuna valutazione finora

- 1 Finite Elements Analysis Short NotesDocumento12 pagine1 Finite Elements Analysis Short NotesfiniteinjusticeNessuna valutazione finora

- 2 Finite Elements Analysis Short Notes PDFDocumento10 pagine2 Finite Elements Analysis Short Notes PDFfiniteinjusticeNessuna valutazione finora

- @StandardSharing-EEMUA 237-2018Documento40 pagine@StandardSharing-EEMUA 237-2018Morteza ShakerienNessuna valutazione finora

- Spare Land CalculationDocumento1 paginaSpare Land CalculationfiniteinjusticeNessuna valutazione finora

- Paul Campbell Dinsmore, PMI Fellow: 1941-2020: One of The World's Leading Lights in Project Management Gone at 79Documento5 paginePaul Campbell Dinsmore, PMI Fellow: 1941-2020: One of The World's Leading Lights in Project Management Gone at 79finiteinjusticeNessuna valutazione finora

- Changes in The Scientific Output of RussDocumento32 pagineChanges in The Scientific Output of RussfiniteinjusticeNessuna valutazione finora

- Final Assessment On Past and Present Outstanding Issues Regarding Iran's Nuclear ProgrammeDocumento16 pagineFinal Assessment On Past and Present Outstanding Issues Regarding Iran's Nuclear ProgrammefiniteinjusticeNessuna valutazione finora

- James E. Fanell Hpsci Testimony - Final - 17may18Documento64 pagineJames E. Fanell Hpsci Testimony - Final - 17may18finiteinjusticeNessuna valutazione finora

- 2017 Technical Paper 6Documento46 pagine2017 Technical Paper 6finiteinjustice0% (1)

- Crs Defense j18Documento65 pagineCrs Defense j18finiteinjusticeNessuna valutazione finora

- 2 Private Companies Engage in Russias Non-Linear WarfareDocumento3 pagine2 Private Companies Engage in Russias Non-Linear WarfarefiniteinjusticeNessuna valutazione finora

- Principles of Process Plant layout-RIL PDFDocumento16 paginePrinciples of Process Plant layout-RIL PDFPedro DiazNessuna valutazione finora

- Richard Phillips Feynman-Meaning of It AllDocumento42 pagineRichard Phillips Feynman-Meaning of It AllfiniteinjusticeNessuna valutazione finora

- Math Book List EnglishDocumento2 pagineMath Book List EnglishahmedzaffNessuna valutazione finora

- BdMO Book List Under 40 CharactersDocumento5 pagineBdMO Book List Under 40 CharactersfiniteinjusticeNessuna valutazione finora

- Coker Heater Optimization and Heater Fouling KBC DCU Galveston 2013Documento22 pagineCoker Heater Optimization and Heater Fouling KBC DCU Galveston 2013finiteinjustice100% (1)

- mb2018 06 AsiaDocumento97 paginemb2018 06 AsiafiniteinjusticeNessuna valutazione finora

- C&S02a-0001 - B Civil & Structural SpecDocumento50 pagineC&S02a-0001 - B Civil & Structural SpecfiniteinjusticeNessuna valutazione finora

- 2017 03 20 Russia Arms Exporter Connolly SendstadDocumento32 pagine2017 03 20 Russia Arms Exporter Connolly SendstadfiniteinjusticeNessuna valutazione finora

- 76 204 16Documento7 pagine76 204 16finiteinjusticeNessuna valutazione finora

- Apx A PDFDocumento8 pagineApx A PDFfiniteinjusticeNessuna valutazione finora

- Cog 41 Chinas New Navy - A Short Guide For Australian Policy-MakersDocumento12 pagineCog 41 Chinas New Navy - A Short Guide For Australian Policy-Makersfiniteinjustice100% (1)

- IMO 2018 - EngDocumento2 pagineIMO 2018 - EngStella Seremetaki Pure MathematicianNessuna valutazione finora

- A Spreadsheet Approach To Business Quantitative MethodsDocumento16 pagineA Spreadsheet Approach To Business Quantitative MethodsJose Ramon VillatuyaNessuna valutazione finora

- UOP 344-87 Moisture in Hydrocarbon Streams Using An On-Line AnalysesDocumento5 pagineUOP 344-87 Moisture in Hydrocarbon Streams Using An On-Line AnalysesfiniteinjusticeNessuna valutazione finora

- Wrb-Air Barrier - Parex Usa Weatherseal Spray and Roll OnDocumento3 pagineWrb-Air Barrier - Parex Usa Weatherseal Spray and Roll Onsaffronbuilders9Nessuna valutazione finora

- 21.coordination Compound, D & F Block Transition ElementsDocumento21 pagine21.coordination Compound, D & F Block Transition ElementsQwerty100% (1)

- ABB NFLP IE3-Catalogue PDFDocumento12 pagineABB NFLP IE3-Catalogue PDFSabir NasimNessuna valutazione finora

- Assignment On Soil PollutionDocumento18 pagineAssignment On Soil PollutionImran Hussain100% (1)

- Pow Template Project 2020Documento7 paginePow Template Project 2020EdgarNessuna valutazione finora

- MouldsDocumento6 pagineMouldsAdnan AdamNessuna valutazione finora

- Magnetoplastic Effect in Nonmagnetic MaterialsDocumento8 pagineMagnetoplastic Effect in Nonmagnetic MaterialsSeindahNyaNessuna valutazione finora

- Nonlinear Analysis For Reactive Powder Concrete Beams Under Rapid Flexural LoadingsDocumento13 pagineNonlinear Analysis For Reactive Powder Concrete Beams Under Rapid Flexural Loadingspradeep kankeriNessuna valutazione finora

- JZ LSR Catalog AllDocumento27 pagineJZ LSR Catalog AllJZ HuangNessuna valutazione finora

- Life Estimation of Distribution Transformers Considering Axial Fatigue in Loose Winding ConductorsDocumento16 pagineLife Estimation of Distribution Transformers Considering Axial Fatigue in Loose Winding ConductorsVictor MartinNessuna valutazione finora

- R. L. Carlin Magnetochemistry 1986Documento337 pagineR. L. Carlin Magnetochemistry 1986Surender Malik100% (1)

- Rha GGBS 27 4Documento12 pagineRha GGBS 27 4KhaDeja MawraNessuna valutazione finora

- Angel CondensadaDocumento6 pagineAngel CondensadaAsnipah Dilaos MustapahNessuna valutazione finora

- Low-Bias Transport in Graphene:an IntroductionDocumento57 pagineLow-Bias Transport in Graphene:an IntroductionLIAKMANNessuna valutazione finora

- Synthesis and Characterization of Cadmium Sulphide NanoparticlesDocumento17 pagineSynthesis and Characterization of Cadmium Sulphide NanoparticlesHoneylyn IgnacioNessuna valutazione finora

- Environmental I AssDocumento15 pagineEnvironmental I AssAbel TayeNessuna valutazione finora

- Application of ACFM-1Documento5 pagineApplication of ACFM-1NILESHNessuna valutazione finora

- Effect of Mix Ratio and Curing Water On The Compressive Strength of Oil Palm Shell (Ops) Aggregate ConcreteDocumento88 pagineEffect of Mix Ratio and Curing Water On The Compressive Strength of Oil Palm Shell (Ops) Aggregate ConcreteSoma DeborahNessuna valutazione finora

- Simulation of torsion in a beamDocumento10 pagineSimulation of torsion in a beamToBi MorrisonNessuna valutazione finora

- Combat Rising Damp and Moisture IngressDocumento2 pagineCombat Rising Damp and Moisture IngressESwar KarthikNessuna valutazione finora

- Jinko Solar Photovoltaic Module Installation GuideDocumento22 pagineJinko Solar Photovoltaic Module Installation GuideFriedrichNessuna valutazione finora