Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ITW Product Catalog16 PDF

Caricato da

johnTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ITW Product Catalog16 PDF

Caricato da

johnCopyright:

Formati disponibili

Product Selector Guide

Preferred Approx. Approx. Gel Density Viscosity Peak

Mix Ratio Styrene

OEM ADHESIVES/SEALANTS

Product Description Red-Dye Gel Time to Peak Range Range

(cps) Exotherm

(%) Catalyst (%) (min) (min) (lbs/gal) (°F)

BARRIER COAT

1500-LS Fast cure time 1.50 MEKP HP-90, DHD-9 22 1-3 3-5 6.20-6.80 4,000-7,000 360-400o

MEKP-925 (HB #4 @ 20rpm)

1800-LS HP-90, DHD-9 4,000-7,000 360-400o

1800-LS Black Medium cure time 1.50 MEKP MEKP-925 22 3-5 3-7 6.20-6.80 (HB #4 @ 20rpm)

CORING/BULK PRINT BLOCKER

Ceramic compounded resin with a very 1.50 MEKP 4-8 5-8 10.00-10.50 3,000-5,000 250-325o

2045* fast gel and cure cycles; Adjustable high 2.00 MEKP/ HP-90 30 0.5-1.5 4-8 (~8.70-9.14) (RVF #4 @ 20rpm) 325-375o

and low densities 1.50 MR-100

Effectively blocks bulk print through in HP-90

2000-OS** minimum thickness of .090” and can be 1.75 -2.25 DHD-90 35 2.5 -3.5 7-9 5.60-6.00 13,000-15,000 285-345o

used to imbed plywood or other sheet MEKP MEKP-900 (HB #4 @ 20rpm)

core materials

Effectively blocks bulk print through in HP-90

2000-OS LS** minimum thickness of .090” and can be 1.75 -2.25 DHD-90 27 2.5 -3.5 6-9 5.60-6.00 13,000-15,000 285-345o

used to imbed plywood or other sheet MEKP MEKP-900 (HB #4 @ 20rpm)

core materials

6000 Economical solution for a variety of 1.50 MEKP HP-90, DHD-9 31 5-10 15-20 5.80-6.30 13,000-15,000 200-250o

applications MEKP-900 (RVF #5 @ 20rpm)

7315* 1.50 MEKP

Unique micro balloon ceramic resin with 2.00 MEKP/ HP-90 32 4-8 6-10 5.80-6.30 10,000-14,000 300-350o

adjustable low and high densities 0.5-1.5 4-8 (~4.29-4.67) (RVF #5 @ 20rpm)

1.50 MR-100

RADIUS COMPOUND

Longer gel time allows good working HP-90 20,000-25,000

900 1.50 MEKP DHD-9 25 21-26 21-26 10.80-11.30 250-300o

time with rollers MEKP-900 (RVF #6 @ 20rpm)

HP-90 15,000-20,000

1050 Can be sprayed and chopped while wet 1.50 MEKP DHD-9 27 25 -35 10-17 10.80-11.30 (RVF #6 @ 20rpm) 250-300o

MEKP-900

1060

HP-90 25,000-35,000

Can be brushed and chopped while wet 1.50 MEKP DHD-9 30 20-30 10-17 10.80-11.30 (RVF #6 @ 20rpm) 250-300o

MEKP-900

ADHESIVE PUTTIES

DDM-9 600,000-700,000

PDR 6000 Formulated for slow gel time 1.50 MEKP MEKP-9 25 75-105 15-30 6.10-6.60 (RVF T-E @ 5rpm)

200-250o

DDM-30

Ultrafast:

DDM-9 10-20 (Ultrafast) 5-15 650,000-750,000 180-250o

PDR 9000 Formulated for 1.50 MEKP MEKP-9 20 40-50 (Fast) 10-25 8.70-9.50 (RVF T-E @ 5rpm) 180-225o

3 different gel times DDM-30 80-105 (Slow) 25-50 Fast and Slow: 150-225o

750,000-850,000

(RVF T-E @ 5rpm)

AlphaFill 102,000-120,000

Lightweight Excellent adhesion and featheredge 2.00 BPO BPO 15-20 3-5 N/A 9.70 (SSA W/T-E Bar @ 5rpm)

N/A

PLUG BUILDING

Developed for easy routing HP-90 16,000-18,000

2000-HS 1.75-2.25 MEKP DHD-9 33 2.5-3.5 7-9 4.80-5.20 290-325o

with CNC equipment MEKP-900 (HB #4 @ 20rpm)

4500 High HDT 1.75-2.25 MEKP HP-90 26 8-13 14-20 5.30-6.00 9,000-15,000 280-320o

(HB #4 @ 20rpm)

MOLD BUILDING

Coring material w/ high heat HP-9 12,000-14,000

4000 HDT tolerance when used with MR-100 1.50-2.20 MEKP DHD-9 29 3-4 5-8 5.25-5.75 (HB #4 @ 20rpm) 300-350o

Blowing Agent**** MEKP 925

Can be applied at 20-30 mils directly 1.50 MEKP HP-9 8,000-11,000 270-305o

4055*** 2.00 MEKP/ DHD-9 26 8-13 7-13 9.70-10.70

onto the gelcoat 1.50 MR-100 MEKP 925 (RVF #5 @ 20rpm) 325-375o

Rapidly wets out and cures uniformly HP-9 450-650

VELR 4000 with a low exotherm 1.50 MEKP DHD-9 32 15-25 4-10 8.80-9.20 (RVF #2 @ 20rpm) 325-375o

MEKP-925

Vinylester blended premium mold MEKP-925 7,000-11,000

4600 HTT building resin 1.50 MEKP HP-90 20-24 12-20 20-30 10.40-11.10 (RVT #5 @ 2.5/20rpm)

210-255o

DHD-9

High performance shrink controlled filled MEKP-900 3,000-4,500

4700 Tooling Resin 1.50 MEKP MEKP-925 23 13-30 5-12 12.3-12.8 280-330°

MEKP-925H (LVT #3 @ 30rpm)

SPRAYABLE FILLER

AlphaCoat MEKP-9H 60-90 1,200-1,400

1700 Extremely fast cure time 2.00 MEKP DDM-9 20 3-6 (Dry to sand) 9.20-9.70 (LVT #3 @ 30rpm) N/A

AlphaCoat MEKP-9H 60-90 1,600-1,850

1710 Extremely fast cure time 2.00 MEKP DDM-9 20 3-6 (Dry to sand) 11.75-12.25 (LVT #3 @ 30rpm) N/A

SPECIALTY PRODUCTS

Developed specifically for compression DHD-9, DDM-9 18,000-22,000

2000-CM molding. Makes a product stiffer without 1.75-2.25 MEKP MEKP-900 28 20-30 20-30 4.80-5.20 (HB #4 @ 20rpm) >220o

adding more fiberglass laminates HP-90

5000 Pourable or injectable syntactic transom 1.00 MEKP MEKP-9H 17 20-30 20-30 8.25-8.75 25,000-35,000 125-160o

coring material DDM-9 (HB #4 @ 20rpm)

*Can be used with or without the MR-100 Blowing Agent for density weight reduction. **Does not use MR 100 Blowing Agent however, can be used to bed other materials.

***Can be used with MR-100 Blowing Agent for added stiffness. ****Addition of MR-100 Blowing Agent is optional.

16 www.itwadhesives.com

Potrebbero piacerti anche

- Excelam-: Q1400COLD/RS Q1400COLD/RSER Q1600COLD/RS Q1600COLD/RSER Q1600COMBI/RSERDocumento2 pagineExcelam-: Q1400COLD/RS Q1400COLD/RSER Q1600COLD/RS Q1600COLD/RSER Q1600COMBI/RSEROdien SalehNessuna valutazione finora

- CPCC, CPCF High Volume: Vishay DaleDocumento3 pagineCPCC, CPCF High Volume: Vishay DaleSukrisdianto DiantoNessuna valutazione finora

- Restek Rt2560columnDocumento1 paginaRestek Rt2560columnCarlos CavalheiroNessuna valutazione finora

- Metco105TechnicalBulletin PDFDocumento8 pagineMetco105TechnicalBulletin PDF張政雄100% (1)

- HIRENOL BrochureDocumento1 paginaHIRENOL BrochureTasos PapadopoulosNessuna valutazione finora

- TDS - Vinyl 907-1 (En)Documento2 pagineTDS - Vinyl 907-1 (En)OXY Composite TechNessuna valutazione finora

- BASF Products Guide PDFDocumento22 pagineBASF Products Guide PDFAtiq uRehman100% (1)

- Abelmarle Referencia KF-868 PDFDocumento24 pagineAbelmarle Referencia KF-868 PDFEdgar Hector GarciaNessuna valutazione finora

- RO4400 PrepregDocumento2 pagineRO4400 Prepreggcohen03Nessuna valutazione finora

- Couplant Feature Comparison Chart: N/A N/ADocumento1 paginaCouplant Feature Comparison Chart: N/A N/AdantegimenezNessuna valutazione finora

- Molins: Technical Data SheetDocumento2 pagineMolins: Technical Data SheetsasidharkanthetiNessuna valutazione finora

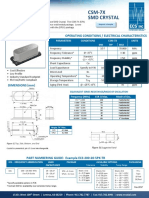

- Csm-7Xdu SMD Crystal: Operating Conditions / Electrical CharacteristicsDocumento2 pagineCsm-7Xdu SMD Crystal: Operating Conditions / Electrical CharacteristicsMae MegumiNessuna valutazione finora

- WOKA 3652 - JP5000 - KeroseneDocumento1 paginaWOKA 3652 - JP5000 - KeroseneRavi ViswanadhaNessuna valutazione finora

- WHOC 2019, H, Salimi, EOR Strategy For A Heavy-Oil Field Development in South America, A Case Study, ID 747Documento13 pagineWHOC 2019, H, Salimi, EOR Strategy For A Heavy-Oil Field Development in South America, A Case Study, ID 747Amelia Van KallenNessuna valutazione finora

- Tecnical R 802Documento16 pagineTecnical R 802Dyah Ayu100% (1)

- GCColumnsDocumento4 pagineGCColumnsasel ppNessuna valutazione finora

- LGHB 2Documento2 pagineLGHB 2sergio.sanchezcmiNessuna valutazione finora

- CSM 12r PDFDocumento1 paginaCSM 12r PDFYashodeep KambleNessuna valutazione finora

- Dowex Monosphere 650C (H)Documento2 pagineDowex Monosphere 650C (H)agnarindra01_8550147Nessuna valutazione finora

- New Brochure Dec 2023Documento24 pagineNew Brochure Dec 2023ror ketanNessuna valutazione finora

- Secondary Coating Line: Processing DataDocumento2 pagineSecondary Coating Line: Processing DataAS TorrealbaNessuna valutazione finora

- SIPOMER Resin Modi ErsDocumento7 pagineSIPOMER Resin Modi ErsVictor LopezNessuna valutazione finora

- Merkel Omegat OMK-MR 01Documento13 pagineMerkel Omegat OMK-MR 01Ana Tereza Holzhausen GrönerNessuna valutazione finora

- Engineering Data Sheet: PART NUMBER: 812EGF9015-FDocumento2 pagineEngineering Data Sheet: PART NUMBER: 812EGF9015-FLydia Eva HariniNessuna valutazione finora

- 4300 lf4300 TFDocumento2 pagine4300 lf4300 TFArguetaManuelNessuna valutazione finora

- Structural Design Criteria: Load Type Type of OccupancyDocumento4 pagineStructural Design Criteria: Load Type Type of OccupancyOtep TimusNessuna valutazione finora

- Rma 223Documento2 pagineRma 223Sergio ChicNessuna valutazione finora

- Phenicon HS EN-đã Chuyển ĐổiDocumento6 paginePhenicon HS EN-đã Chuyển Đổichuongphan3004Nessuna valutazione finora

- Axeon XE1 Membrane Spec SheetDocumento1 paginaAxeon XE1 Membrane Spec Sheetamanuel waleluNessuna valutazione finora

- Dowex Monosphere 650CDocumento2 pagineDowex Monosphere 650CBrianNessuna valutazione finora

- 419 - Composites Catalogue-AtulDocumento12 pagine419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- TeflexDocumento1 paginaTeflexArstNessuna valutazione finora

- N4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyDocumento2 pagineN4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyRafael CastroNessuna valutazione finora

- Mud Engineer TrainingDocumento8 pagineMud Engineer Trainingsanjeet giri100% (1)

- 820 Series TDSDocumento2 pagine820 Series TDSajaldaco100% (1)

- Metco®73F-NS-1 (-2) 10-058 PDFDocumento7 pagineMetco®73F-NS-1 (-2) 10-058 PDF張政雄Nessuna valutazione finora

- Croda Eseminar Coatings Polymers Mar 312010Documento32 pagineCroda Eseminar Coatings Polymers Mar 312010Giovanna Guerrero100% (1)

- Diesel Loco Shed Bandra: Standard Testing of Crank Case Lubricating Oil (Rdso/Mp/Guide No. 6 Rev Ii May - 2007)Documento5 pagineDiesel Loco Shed Bandra: Standard Testing of Crank Case Lubricating Oil (Rdso/Mp/Guide No. 6 Rev Ii May - 2007)Rahul Rajpal SinghNessuna valutazione finora

- RCA-HP E3: Vishay DraloricDocumento10 pagineRCA-HP E3: Vishay DraloricMohendra PatiNessuna valutazione finora

- Membranes: Treatment of Electroplating Wastewater Using NF pH-Stable Membranes: Characterization and ApplicationDocumento27 pagineMembranes: Treatment of Electroplating Wastewater Using NF pH-Stable Membranes: Characterization and Applicationabdo kasebNessuna valutazione finora

- Resistencia Planar VishayDocumento4 pagineResistencia Planar Vishayfelipe a chica acevedoNessuna valutazione finora

- Rogers - Unknown - RO4400 Series BondplyDocumento4 pagineRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNessuna valutazione finora

- The Evolving Problem of Corrosive Sulfur in Transformer Oil: IEEE/PES Transformers CommitteeDocumento89 pagineThe Evolving Problem of Corrosive Sulfur in Transformer Oil: IEEE/PES Transformers CommitteemahsaNessuna valutazione finora

- Nelco N4000-11: Nelco Advanced Circuitry MaterialsDocumento2 pagineNelco N4000-11: Nelco Advanced Circuitry MaterialsMandeep ChaudharyNessuna valutazione finora

- Irmair ElzeDocumento2 pagineIrmair ElzeRoman ChubaNessuna valutazione finora

- Ipi TrivediDocumento55 pagineIpi TrivediROHAN KULKARNINessuna valutazione finora

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Documento2 pagineAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNessuna valutazione finora

- Spe 151770 MS PDocumento20 pagineSpe 151770 MS PjbetancourtNessuna valutazione finora

- Softening Cation Exchange Resins: Go To MenuDocumento4 pagineSoftening Cation Exchange Resins: Go To Menuedal_108Nessuna valutazione finora

- Polylon 1900 (3853091)Documento4 paginePolylon 1900 (3853091)JOCELYN MEDINANessuna valutazione finora

- Paper 9.5 - H DingDocumento22 paginePaper 9.5 - H Dingmarg1972Nessuna valutazione finora

- Dow Water & Process SolutionsDocumento11 pagineDow Water & Process SolutionsZulfikri ZulkifliNessuna valutazione finora

- Everlube 9002 TDSDocumento2 pagineEverlube 9002 TDSValentinNessuna valutazione finora

- CSM-7X SMD Crystal: Operating Conditions / Electrical CharacteristicsDocumento3 pagineCSM-7X SMD Crystal: Operating Conditions / Electrical CharacteristicsMilo VanvanNessuna valutazione finora

- Flexitallic SF5000 DATA CURRENTDocumento2 pagineFlexitallic SF5000 DATA CURRENTGlobal VillageNessuna valutazione finora

- CSM-7X SMD Crystal: Operating Conditions / Electrical CharacteristicsDocumento2 pagineCSM-7X SMD Crystal: Operating Conditions / Electrical CharacteristicsRamon Alberto BriceñoNessuna valutazione finora

- En Wima Application Guide 2012Documento12 pagineEn Wima Application Guide 2012maciejNessuna valutazione finora

- CSM 7x PDFDocumento2 pagineCSM 7x PDFprasadNessuna valutazione finora

- Dowex Marathon C 10 LDocumento2 pagineDowex Marathon C 10 LahmedNessuna valutazione finora

- ITW Product Catalog40 PDFDocumento1 paginaITW Product Catalog40 PDFjohnNessuna valutazione finora

- ITW Product Catalog29 PDFDocumento1 paginaITW Product Catalog29 PDFjohnNessuna valutazione finora

- ITW Product Catalog39 PDFDocumento1 paginaITW Product Catalog39 PDFjohnNessuna valutazione finora

- ITW Product Catalog29 PDFDocumento1 paginaITW Product Catalog29 PDFjohnNessuna valutazione finora

- ITW Product Catalog33 PDFDocumento1 paginaITW Product Catalog33 PDFjohnNessuna valutazione finora

- ITW Product Catalog23Documento1 paginaITW Product Catalog23johnNessuna valutazione finora

- ITW Product Catalog30 PDFDocumento1 paginaITW Product Catalog30 PDFjohnNessuna valutazione finora

- Epoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250Documento1 paginaEpoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250johnNessuna valutazione finora

- ITW Product Catalog17Documento1 paginaITW Product Catalog17johnNessuna valutazione finora

- ITW Product Catalog21 PDFDocumento1 paginaITW Product Catalog21 PDFjohnNessuna valutazione finora

- ITW Product Catalog12Documento1 paginaITW Product Catalog12johnNessuna valutazione finora

- Sprayable Syntactic Materials: Radius Compound Coring/Bulk Print BlockerDocumento1 paginaSprayable Syntactic Materials: Radius Compound Coring/Bulk Print BlockerjohnNessuna valutazione finora

- Methacrylate Structural Adhesives: Plexus MA422 Plexus MA832Documento1 paginaMethacrylate Structural Adhesives: Plexus MA422 Plexus MA832johnNessuna valutazione finora

- Methacrylate Structural Adhesives: Dispensing Equipment (10:1)Documento1 paginaMethacrylate Structural Adhesives: Dispensing Equipment (10:1)johnNessuna valutazione finora

- ITW Product Catalog13Documento1 paginaITW Product Catalog13johnNessuna valutazione finora

- The ABCs of Geothermal SystemsDocumento3 pagineThe ABCs of Geothermal SystemsRon MacKinnonNessuna valutazione finora

- Quotation-Municiple Waterproofing WorkDocumento3 pagineQuotation-Municiple Waterproofing WorkAnkita Baban GavadeNessuna valutazione finora

- 400 KPH Boiler IBR Design Calculations - R1-6-2-13Documento8 pagine400 KPH Boiler IBR Design Calculations - R1-6-2-13Vishal KandNessuna valutazione finora

- Thermostatic Expansion Valve: Series RFGBDocumento10 pagineThermostatic Expansion Valve: Series RFGBRajat JunejaNessuna valutazione finora

- M2 NDT Liquid Penetrant TestingDocumento41 pagineM2 NDT Liquid Penetrant TestingAravind SANessuna valutazione finora

- Carrier - Company ProfileDocumento1 paginaCarrier - Company Profiledeboline mitraNessuna valutazione finora

- Electrical and Equipment SafetyDocumento82 pagineElectrical and Equipment SafetybkannurbsNessuna valutazione finora

- TDS Hipersite W7000Documento1 paginaTDS Hipersite W7000It WittayaNessuna valutazione finora

- Selectarc ElektrodyDocumento149 pagineSelectarc ElektrodymalyczopekNessuna valutazione finora

- 09 - TDS - Masterflow 928T PDFDocumento5 pagine09 - TDS - Masterflow 928T PDFGibbs PerNessuna valutazione finora

- Thermocouples Mineral InsulatedDocumento10 pagineThermocouples Mineral InsulatedEliasNessuna valutazione finora

- 2 Literature ReviewDocumento11 pagine2 Literature Reviewsantkabir100% (1)

- Specification - Civil WorkDocumento61 pagineSpecification - Civil WorkdhanabalNessuna valutazione finora

- Understanding NPSH in Centrifugal PumpsDocumento16 pagineUnderstanding NPSH in Centrifugal Pumpssocrates19582405100% (2)

- Supply, Spread and Compact: C:roadpDocumento5 pagineSupply, Spread and Compact: C:roadpntah84Nessuna valutazione finora

- Dasco Linear Bargrilles&RegistersDocumento28 pagineDasco Linear Bargrilles&Registersblue airNessuna valutazione finora

- Iso 9974-2 - Metric - Stud Ends With Elastomeric Sealing (Type E)Documento14 pagineIso 9974-2 - Metric - Stud Ends With Elastomeric Sealing (Type E)Gowtham KbNessuna valutazione finora

- Glo Sikacontrol Aer 200 PDocumento4 pagineGlo Sikacontrol Aer 200 PKing MKNessuna valutazione finora

- Vitogas 050-Ecd IsDocumento28 pagineVitogas 050-Ecd IsIñaki GonzalezNessuna valutazione finora

- History of Architecture-V: Lecture - X Chicago Style ArchitectureDocumento46 pagineHistory of Architecture-V: Lecture - X Chicago Style ArchitectureItika AtriNessuna valutazione finora

- 2 - 10.00 PMA Fire Barrier Solutions EN45545-3Documento45 pagine2 - 10.00 PMA Fire Barrier Solutions EN45545-3Ronald LopezNessuna valutazione finora

- CE 48-Timber Design SyllabusDocumento3 pagineCE 48-Timber Design Syllabuspicefeati75% (4)

- Anti Fouling Paints ComparedDocumento6 pagineAnti Fouling Paints ComparedDean Foote100% (1)

- Shaft Calculation BaseDocumento40 pagineShaft Calculation BaseObaciuIonel100% (1)

- Stress Analysis and Design of Bolted Flange Connections UnderDocumento11 pagineStress Analysis and Design of Bolted Flange Connections UndervijaygalaxyNessuna valutazione finora

- 4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFDocumento5 pagine4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFSatria PurwantoNessuna valutazione finora

- Cascade Refrigeration System (Report)Documento8 pagineCascade Refrigeration System (Report)THE PUBGTV100% (1)

- Structural Report of Proposed Fencing and ExtensionDocumento21 pagineStructural Report of Proposed Fencing and ExtensionLester LazoNessuna valutazione finora

- Final Year Project Report: Micro RefrigeratorDocumento40 pagineFinal Year Project Report: Micro RefrigeratorWaseem Aulakh100% (1)