Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Jsa Lifitng Gantry Fabrication

Caricato da

Osiobe EwomazinoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Jsa Lifitng Gantry Fabrication

Caricato da

Osiobe EwomazinoCopyright:

Formati disponibili

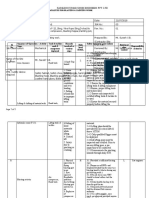

CLIENT/PROJECT LEKKI DEEP SEA PORT

HEALTH, SAFETY & ENVIRONMENTAL

PROGRAM JSA (JOB SAFETY ANALYSIS) DOCUMENT NO: LDSPP/CHELE/HSSE/JSA/028

ACTIVITY TITLE: LIFTING OF PILE PIPES CONTRACTOR: CHINA HARBOR ENGINEERING COMPANY DATE: SEPTEMBER 25, 2020

BRIEF DESCRIPTION OF THE ACTIVITY: Movement of pile sheets and movement of finished pile pipes with gantry crane at the fabrication workshop.

REVIEW AND APPROVAL RECORD OF THE PRESENT DOCUMENT

ACTION NAME DESIGNATION SIGNATURE DATE

PREPARED BY OSIOBE WEALTH HSSE OFFICER

REVIEWED BY CHEN JIAYU HSSE SUPERVISOR

APPROVED BY LIU JIANWEI HSSE MANAGER

REVISION STATUS

REV. DATE DESCRIPTION

HAZARD/RISK MANAGEMENT HAZARD/RISK IDENTIFICATION

Can all personnel in the group answer YES to the Does the work involve/require? WORK AREA: FABRICATION WORKSHOP

following questions:

• Is a separate lifting plan required? NO ACTIVITY: LIFTING OF HEAVY PILE PIPES

• Have all the significant hazards involved with the

• Working in a noisy area? YES

work been identified? YES

• Line breaching or potential Hydrocarbon release? NO SUPERVISOR: MR. CHEN

• Have control measures been identified for these

hazards? YES • Any Environmental impact? NO

• Have the people responsible for implementing these • Working near objects that may move? YES HSSE OFFICER: OSIOBE WEALTH

control measures been identified and are the controls • Working in an area with poor lighting or a tight/confined

in place? YES Space? NO PROJECT MANAGER: MR. TING MING GANG

• Has the method of communication been agreed and • Working at height? NO

tested? YES

• Working near areas that could cause personnel to slip, HSE MANAGER: LIU JIANWEI

• Is everyone aware what is being done at the work- trip or fall? YES

site? YES • Using portable electric equipment? YES

• Are we aware of what everyone else is doing at the • Working with dangerous goods and substances

work-site? YES hazardous to health? NO

• Does everyone know that any changes to the work • Personnel who are new to the location or each other? NO

plan have been communicated to everyone involved • Equipment which is potentially dangerous? YES

in the work? YES

If so the work may be hazardous and care should be

• Does everyone know that any new people joining taken to ensure the work is done safely

the work party must be given a full and thorough

update off what is going on? YES Remember, everyone is responsible for:

• Using the correct tools for the job

• Being aware of the hazards around them and

If the answer to any of these questions is remaining vigilant to change.

NO, then the safety of people is at risk. • Using/wearing the correct PPE for the task.

• Making themselves aware of, and working within the

requirements of the PTW system and construction

The tool box talk leader should confirm the procedures

understanding of the group by asking open

questions on the above points

JOB SAFETY ANALYSIS (JSA) FOR LIFTING WITH GANTRY CRANES

S/N0 Operation/Activity Possible Hazardous Situations Indicate Necessary Measure to be taken (how can the Responsible Control in

Stage (The Steps (What could go wrong and What hazards be prevented and /or eliminated) (Who is going to take place

involved in doing the would the effects be) action) YES þNO

job)

1 Movement of gantry Fall • PTW completed and obtained HSSE Supervisor

crane to workshop area Poor lifting accessories • Pre-job/Tool Box talk/JSA discussed and all hazards and Construction Manager

Collision controls explained and understood prior to all signing JSA. HSSE Officer

• PPE issued (Protective Footwear, hard hats, coveralls, hand

gloves and safety glasses,(clear glasses worn for night work, if

Type of Permit Required required to do night shift).

Additional PPE Requirements

(please indicate by ticking • Equipment and all tools inspected prior Special

to usetools or equipment required

and defective

(Please list)

box) items removed from use and replaced.

YES þ

General Permit to Work þ 1. Mandatory PPE •þ Sufficient

Drillinglighting

Rigs towers to illuminate the work areaShackles

if night

Hot Work 2. Face shield work should

Welding be carried out.

Machines Grease Pump

Lifting Permit þ 3. Fall arrestor • Jewelries,

Gantryrings, bracelets etc. removed priorþto starting

Cranes Excavator

work.

Excavation Certificate 4. High visibility vest þ Pay loader With Bucket Concrete Pump + Hoses

• trailer installed with stand-shore to prevent fall

Man basket Certificate 5. Dust Mask Pay loader With Fork Man Basket

Use of competent and licensed trailer drivers

MEWP Certificate 6. Breathing Apparatus Self-Loading Mixers/Washer Truck Shovels, Pile Head Mold, Hammers,

Other.__________________ Wire Ropes And Slings þ Surveyor Equipment’s

7. Other.______________

2 ___ Set up of work area Cuts • Trolleys

Area free from obstruction. CFA Cage Vibrator

Foreman Piping

JSA Review Process

Bruises Sufficient

Y N space available. Comments Permit Receiver

• Area barricaded and safety signs in place Safety Officer

Was the work crew involved in formulating the JSA? Y YES

• First aid box/first Aider available

Did the work crew review/discuss the JSA prior to starting task? • Y issued (Protective Footwear, hard hats, coveralls, hand

PPE

Was the JSA referred to during the task? Y gloves and safety glasses,(clear glasses worn for night work).

3 Were the job steps followed? Poor lifting accessories

Installation of gantry Y Pre-job Tool Box Talk/JSA discussed and all hazards and control Foreman

crane. falls explained and understood prior to all signing JSA Permit Receiver

Can you suggest improvements to the JSA? (Provide details)

Fatality Trained and certified crane operators deployed to install gantry HSSE Officer

Electrical hazards crane

Burns from welding Crane certified and inspected prior to installation

Welding spatters falling from The crane track conditions to be checked for obstruction

height Pre-use inspection of lifting accessories such as slings and belts

Barricade the area from unauthorized personnel

Install signage to indicate a critical lifting is being carried out

Ensure all cables are properly installed and earthed YES

Ensure fire extinguisher and first aid box are put in place

Ensure no work is being carried out under the gantry crane

during installation

Use of fall arrest protection such as full body harness while at

height

PPE issued (Protective Footwear, hard hats, coveralls, hand

gloves and safety glasses,(clear glasses worn for night work),

face shields and aprons for welders.

4 Preparation and Slips • PTW completed and obtained HSSE Supervisor

selection of proper lifting Trips • Pre-job/Tool Box talk/JSA discussed and all hazards and Construction Manager

belts and sling ropes and Falls controls explained and understood prior to all signing JSA. Foreman

other tools required to • PPE issued (Protective Footwear, hard hats, coveralls, hand HSSE Officer

Cuts

carry out the lifting gloves and safety glasses,(clear glasses worn for night work, if

bruises etc. required to do night shift).

Potrebbero piacerti anche

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocumento2 pagineNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNessuna valutazione finora

- Lifting Activity Permit To WorkDocumento1 paginaLifting Activity Permit To WorkBig ZaddyNessuna valutazione finora

- JSA Formet New Blasting & PaintingDocumento5 pagineJSA Formet New Blasting & Paintingsakthi venkatNessuna valutazione finora

- Jsa For The Installation of I EamDocumento5 pagineJsa For The Installation of I EamMohammed MinhajNessuna valutazione finora

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocumento2 pagineBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNessuna valutazione finora

- Excavaten Work PermitDocumento1 paginaExcavaten Work Permitasem sawalmehNessuna valutazione finora

- JHA Maintenance Tech HVACDocumento2 pagineJHA Maintenance Tech HVACMdavaNessuna valutazione finora

- SG-13 Safety Guideline For Material Handling (Manual and Mechanized) & StorageDocumento41 pagineSG-13 Safety Guideline For Material Handling (Manual and Mechanized) & StorageJames HoltNessuna valutazione finora

- Permit To Excavate: Section - I Contact DetailsDocumento1 paginaPermit To Excavate: Section - I Contact DetailsBig Zaddy0% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Documento3 pagineKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNessuna valutazione finora

- Petrochina International Jabung LTD.: Job Safety AnalysisDocumento4 paginePetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNessuna valutazione finora

- Confined Space Log SheetDocumento1 paginaConfined Space Log SheetRenatoNessuna valutazione finora

- JSA of Charging UnitDocumento3 pagineJSA of Charging UnitMuhammad AliNessuna valutazione finora

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocumento2 pagineJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNessuna valutazione finora

- JSA For Purging NitrogenDocumento1 paginaJSA For Purging Nitrogenlina ekawati100% (1)

- Job Safety AnalysisDocumento1 paginaJob Safety AnalysisWati KaNessuna valutazione finora

- JSA PRE-TEST UploadDocumento2 pagineJSA PRE-TEST UploadDenny Kurniawan PrawiraNessuna valutazione finora

- EHSWP004 - Hot Work Permit PDFDocumento2 pagineEHSWP004 - Hot Work Permit PDFRand raiNessuna valutazione finora

- JSA Working in Live AreasDocumento1 paginaJSA Working in Live Areasyc safetyNessuna valutazione finora

- Job Safety Analysis: JSA Basic DataDocumento5 pagineJob Safety Analysis: JSA Basic DataPrabhu DivakaranNessuna valutazione finora

- New Monthly SHE ReportsDocumento21 pagineNew Monthly SHE ReportsGIRI BISWAS100% (1)

- FORM-03-OHSE-08 General Work Permit (GWP)Documento2 pagineFORM-03-OHSE-08 General Work Permit (GWP)Fadil MuhammadNessuna valutazione finora

- Construction Site Inspection Check List ALMCDocumento2 pagineConstruction Site Inspection Check List ALMCAmeerHamzaWarraichNessuna valutazione finora

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Documento3 pagineZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNessuna valutazione finora

- JSA-Using A Type Ladder 2015Documento1 paginaJSA-Using A Type Ladder 2015nishanthNessuna valutazione finora

- Genie E Series Slab Scissor Lift Operation PDFDocumento11 pagineGenie E Series Slab Scissor Lift Operation PDFRajesh gpNessuna valutazione finora

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Documento3 pagineJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21Nessuna valutazione finora

- JSA Pipe Installation 2012Documento2 pagineJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- 14 JSA Excavation For Location Existing PipeDocumento5 pagine14 JSA Excavation For Location Existing PipeYosua SitumorangNessuna valutazione finora

- High Pressur Hydro Testing JSA 03Documento5 pagineHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNessuna valutazione finora

- Jha For CCB CommissioningDocumento6 pagineJha For CCB CommissioningChinedu AchilikeNessuna valutazione finora

- JSA FOR Moving and Handling MaterialsDocumento3 pagineJSA FOR Moving and Handling Materialswahyu nugrohoNessuna valutazione finora

- Mig Welding Work JSA HSE ProfessionalsDocumento2 pagineMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- JSA Steel Structure FabricationDocumento8 pagineJSA Steel Structure FabricationArib RahmanNessuna valutazione finora

- JSA-Hydraulic Press Testing For PilesDocumento6 pagineJSA-Hydraulic Press Testing For PilesUMUTNessuna valutazione finora

- JSA Formet New Structural Steel FabricationDocumento7 pagineJSA Formet New Structural Steel Fabricationsakthi venkatNessuna valutazione finora

- 0 JsaDocumento54 pagine0 JsaRavi AmarlapudiNessuna valutazione finora

- Permit To Work Shafts and Elevators: Compliance ChecklistDocumento1 paginaPermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorNessuna valutazione finora

- F-49 Full Body Harness Inspection ChecklistDocumento1 paginaF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- JHA For Installation 2 Inch Nozzle..Documento6 pagineJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- JSA TrainingDocumento28 pagineJSA Trainingkresna suryadiNessuna valutazione finora

- ENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous AreaDocumento4 pagineENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous Areamyn maliQue0% (1)

- Risk Assessment IIIDocumento1 paginaRisk Assessment IIIJosh Booth100% (2)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Documento6 pagineThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNessuna valutazione finora

- Jsa For Alignment of Vessel and DrumDocumento3 pagineJsa For Alignment of Vessel and DrumMohammed MinhajNessuna valutazione finora

- PVCMS-BMV-HSE-JSA-001 InsulationDocumento6 paginePVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNessuna valutazione finora

- SOP 4 - Coal Bed Leveling in PGPDocumento18 pagineSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNessuna valutazione finora

- Health and Safety Method Statement: SA Scaffolding LimitedDocumento8 pagineHealth and Safety Method Statement: SA Scaffolding LimitedAnonymous Wq35JtketnNessuna valutazione finora

- Job Safety Analysis Erection SiloDocumento3 pagineJob Safety Analysis Erection SiloDanangNessuna valutazione finora

- Risk Assessment (STL-STR)Documento15 pagineRisk Assessment (STL-STR)Abdullah Twfeeq100% (1)

- Construction Safety Audit PDFDocumento5 pagineConstruction Safety Audit PDFAnonymous Q1Y71rNessuna valutazione finora

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocumento2 pagineFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNessuna valutazione finora

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocumento2 pagineJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNessuna valutazione finora

- Working at HeightDocumento2 pagineWorking at HeightMohammed KadhimNessuna valutazione finora

- Hot Works: Risk Assesment Form For Rolling ShutterDocumento1 paginaHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30Nessuna valutazione finora

- JSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Documento3 pagineJSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Perwez21Nessuna valutazione finora

- Confine Space at Water TankDocumento7 pagineConfine Space at Water TanknaraNessuna valutazione finora

- Job Safety Analysis (JSA) : Description Hazard ControlDocumento3 pagineJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNessuna valutazione finora

- Jsa Loading and Unloading of Pile PipesDocumento4 pagineJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Documento5 pagineHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe EwomazinoNessuna valutazione finora

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Documento5 pagineHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe EwomazinoNessuna valutazione finora

- Jsa Loading and Unloading of Pile PipesDocumento4 pagineJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- (Your Business Name Here) - Safe Work Procedure Plasma CutterDocumento2 pagine(Your Business Name Here) - Safe Work Procedure Plasma CutterOsiobe EwomazinoNessuna valutazione finora

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Documento7 pagineHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Engineering Management 2 C Assignment QuestionsDocumento3 pagineEngineering Management 2 C Assignment Questionsabhinav kumarNessuna valutazione finora

- The Supply Chain of The FutureDocumento24 pagineThe Supply Chain of The FutureIrinaGabrielaEnescuNessuna valutazione finora

- Industrial RelationsDocumento20 pagineIndustrial RelationsankitakusNessuna valutazione finora

- Rahul Vs State of UP Moot COURT CASE PetitionerDocumento12 pagineRahul Vs State of UP Moot COURT CASE PetitionerRiddhi Furia100% (1)

- GEP 2021 2022 WorksheetDocumento2 pagineGEP 2021 2022 WorksheetYlaine NavaltaNessuna valutazione finora

- First Term Test-1-321Documento9 pagineFirst Term Test-1-321scribd1Nessuna valutazione finora

- Entrepreneurship and Small Business ManagementDocumento18 pagineEntrepreneurship and Small Business ManagementTanisha KhanamNessuna valutazione finora

- S6 Kohlberg The Child As A Moral PhilosopherDocumento9 pagineS6 Kohlberg The Child As A Moral PhilosopherValiNessuna valutazione finora

- Traffic Light ControllerDocumento24 pagineTraffic Light Controllerசெல்வம் முத்துராமன்100% (1)

- Regional Trading Blocs & Impact On Marketing: by - Prenitha BDocumento9 pagineRegional Trading Blocs & Impact On Marketing: by - Prenitha BPrenithaNessuna valutazione finora

- Problem 7Documento4 pagineProblem 7Ravidya ShripatNessuna valutazione finora

- Punjab 2016Documento4.298 paginePunjab 2016Yanamandra Radha Phani ShankarNessuna valutazione finora

- Action Plan Summer Journalism Camp 2019Documento1 paginaAction Plan Summer Journalism Camp 2019Darwin EstoqueNessuna valutazione finora

- Militairy Working Dog ManualADA332189Documento206 pagineMilitairy Working Dog ManualADA332189Lawrence R. San JuanNessuna valutazione finora

- What Is JCIDocumento15 pagineWhat Is JCIOdesa Aviles100% (2)

- Anatomy and Physiology (BPE)Documento8 pagineAnatomy and Physiology (BPE)Shiela MantillaNessuna valutazione finora

- Aviation History: Lecture 6: Flight InstrumentsDocumento43 pagineAviation History: Lecture 6: Flight Instrumentszuliana86% (7)

- Communication SkillsDocumento1 paginaCommunication SkillsSalmaBagulNessuna valutazione finora

- 2007 - KANNAIR - The Ethical Mind. Interview With Howard GardnerDocumento7 pagine2007 - KANNAIR - The Ethical Mind. Interview With Howard GardnerCarlos Arturo Hoyos VallejoNessuna valutazione finora

- December 2018 Issue PDFDocumento60 pagineDecember 2018 Issue PDFJichen LiuNessuna valutazione finora

- G.R. No. 207838 - Maula v. Ximex Delivery Express, IncDocumento17 pagineG.R. No. 207838 - Maula v. Ximex Delivery Express, IncMayumi RellitaNessuna valutazione finora

- Healthwire Proposal - CWPDocumento12 pagineHealthwire Proposal - CWPSyedArslanAttaNessuna valutazione finora

- ENGLISH (Code No. 301)Documento10 pagineENGLISH (Code No. 301)Ashmaaav SharmaNessuna valutazione finora

- Vageesha Padmananda: Cima Adv Dip MaDocumento2 pagineVageesha Padmananda: Cima Adv Dip Mavag eeNessuna valutazione finora

- Marketing Presentatio N: CadburyDocumento17 pagineMarketing Presentatio N: CadburyHARSH SHUKLANessuna valutazione finora

- DepositSlip 10068722031011441572339Documento1 paginaDepositSlip 10068722031011441572339Jehad Ur RahmanNessuna valutazione finora

- Strat MGT Book ReviewDocumento22 pagineStrat MGT Book ReviewLevirolfDeJesusNessuna valutazione finora

- Chapter Five Summary, Conclusion and Recommendations 5.1 Summary of FindingsDocumento22 pagineChapter Five Summary, Conclusion and Recommendations 5.1 Summary of Findingstt OoNessuna valutazione finora

- Course Manual Venice, Byzantium, Greek World - 2021-2022Documento3 pagineCourse Manual Venice, Byzantium, Greek World - 2021-2022SP CNessuna valutazione finora

- Rethinking Dubai's UrbanismDocumento14 pagineRethinking Dubai's UrbanismIbrahim AlsayedNessuna valutazione finora