Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1

Caricato da

Engr Ghulam SarwarDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1

Caricato da

Engr Ghulam SarwarCopyright:

Formati disponibili

World Journal of Microbiology and Biotechnology 7, 490493

High-yield ethanol production from

Jerusalem artichoke tubers

C. Barthomeuf, F. Regerat and H. Pourrat

Fermentation conditions were optimized for Current increases in oil prices have re-kindled interest in ethanol as an alternative

the production of ethanol from Jerusalem fuel. Its production by biotechnological means is now classical but, for the costs

artichoke with a strain of Sacc/taromyces

to be kept low, biomass materials must be cheap and fermentative processes

cerevlsiae able to use high-concentration

juice and undiluted pulp. Yields (95 to 125 g optimized. Among possible carbohydrate substrates for ethanol production,

ethanol/i = 85 to 98% of the theoretical Jerusalem artichokes have numerous advantages. The sugar content of the tubers

value) exceeded those obtained with strain represents 80% of the dry matter and is made up exclusively of inulin, a fructose

of Kbyveromyces used classically. polymer containing a terminal glucose. It is a raw material available in large

quantities at fairly low prices. The crop yield is on average 27 to 51 metric tonnes

The authors are with the Laboratoire de

Pharmacognosie et Biotechnoiogie, UFR of tubers/ha (Sachs et al. 1981; Duvnjac et al. 1982; Williams 1982). The plant

Pharmacie, 28 Place Henri-Dunant, 63001 grows well on poor-quality soils, requires minimal fertilizer additions, is able to

Clermont-Ferrand CtSdex, France. TBI: resist many common pests and diseases, and grows in cold climates. It is a hardy

73.60.80.00; Fax: 73.27.79.07. H. Pourrat is perennial crop able to grow on land unsuitable for other purposes.

the corresponding author.

The proper choice of micro-organism for bioconversion of Jerusalem artichoke

sugars to ethanol is vital. Important yeast characteristics include high ethanol

productivity, rapid growth and fermentation rates and relatively high ethanol

tolerance. Use of a micro-organism with inulinase activity, thus able directly to

metabolize inulin, is desirable because it would eliminate preliminary acidic or

enzymatic hydrolysis and thereby reduce processing costs. Two main types of

micro-organism are used; bacteria of the genus Zymomonas and, more often, yeasts

of the genus Kltiyveromyces, especially K. marxianus and K. fragilir. Traditional

brewing yeasts (Saccharomyces cerevisiue), used by distillers for their high ethanol

productivity, are for the most part unable directly to ferment inulin (Guiraud et

al. 1981; Ziobro & Williams 1983). This necessitated prior hyrolysis of the inulin

to simple sugars, either by acido-thermic or enzymatic processes. However,

previous work has shown that a strain from our laboratory collection, Saccbaromyces

cerevisiue Y-481, was able to ferment inulin directly (Pourrat et al. 1983). By

selection, we obtained this particularly productive strain, S. cerezjisiue Y-481. This

was tested in media containing high concentrations of inulin.

Materials and Methods

Jerusalem A rticbokes

Tubers of Jerusalem artichoke (Helianthw ttrberosq var. Mammoth French White)

@ 1991 Rapid Communications of Oxford Ltd. were washed, allowed to air dry and sealed in paper sacks for storage at 4 to 5°C.

490 World Journal of Microbiology and Biotechnology, Vol 7, 1991

Ethanol from Jerusalem artichokes

To prepare pulp, the tubers were sliced with a blade homogenizer and deep-frozen.

Juices (280 g/l total sugars) were prepared for inulin extraction by two successive

steepings of fresh pulp with water for 1 h at 70°C each followed by vacuum

filtration and storage of the extract at -20°C. Diluted juices were obtained by

dilution of the extract with de-ionized water.

Micro-organism and Growth

The strain of Saccharomyces cerevisiae Y-481 from sherry (‘Zerez’) from our

laboratory collection was used throughout. 40 mg of the lyophilized yeast was

incubated on dilute Jerusalem artichoke juice (100 g/l total sugars) containing

mineral salts [KH,PO, (1 g/l), (NH&SO, (1 g/l), MgS04 (0.3 g/l), NaCl (0.4 g/l),

FeCl, (0.004 g/l), MnSO, (0.007 g/l)] p reviously sterilized at 110°C for 30 min. It

was incubated with periodic agitation at 30°C for 24 h and then inoculated at

either 4% (v/v) for juice fermentation or at 10% (v/v) for pulp fermentation. For

all trials the inoculum contained 0.2 to 1.0 x IO’ cells/ml.

Fermentation

Juice fermentations were made in a Biolafitte 2 litre fermenter. The trials were

carried out at 30°C on 1.3 1 of Jerusalem artichoke juice containing mineral salts

(same composition/concentration as per inocula preparation). The pH was then

adjusted with 18 M HaSO,. For pulp fermentations, 1 kg artichoke pulp was placed

in 2 1 stainless steel containers for fermentation. As trials with or without addition

of mineral salts gave similar results, fermentations with pulp were made without

mineral salts. The pH of the pulp was adjusted to 3.2 to 3.3, and it was then

sterilized at 110°C for 30 min and incubated.

-4 nabtical Methods

Samples were measured for ethanol, total carbohydrates and yeast population.

Ethanol was measured by gas chromatography as described previously (Pourrat

et al. 1983), using a 1.2 m PORAPAK type QSO to 100 mesh column. Total sugars

were assayed by the anthrone method (Trevelyan & Harrison 1956). The yeast

cell population in juice samples was estimated by counting using a Malassez cell,

but in fermenting pulp samples was determined by the plate count method (Westby

& Gibbons 1982). Fermentation was also monitored by thin layer chromatography

on silica gel using chloroform/methanol/water (61: 32: 7, by vol.) as the elution

solvent. Sugars were revealed by spraying anisaldehyde solution.

Results and Discussion

The production of ethanol from Jerusalem artichoke was studied on juice prepared

by extraction or diffusion from tubers. These preliminary studies were to test the

potential of the strain but, for industrial use, the feedstock must be the tuber

itself. Accordingly, subsequent tests were carried out on pulp.

Fermentation oj Juice

Tests in liquid media were carried out on juice containing increasing concentra-

tions of inulin (84 to 280 g/l) after determining optimal operating conditions.

The most important parameters are aeration and stirring. Previous assays have

shown that aeration must be discontinuous. A systematic study was carried out

with aeration rates of 0.17, 0.3, 0.34, 0.5 and 0.85 vol/vol/min for 15 min to 2 h

at 15 min increments one, two or three times a day. The higher ethanol yields

and specific rate of production were obtained with aeration at flow rate of 0.34

vol/vol/min for 50 min every 8 h the first day, then once a day every 12 h, with

a stirring rate of about 160 rev/min. Any departure from this value either way

caused a large drop in yield.

World Journal of Microbiology and Biotechnology, Vol 7, 1991 491

C. Barthomeuf

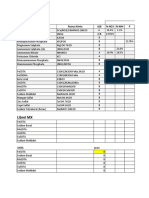

Table 1. Ethanol productlon by S. cerevislaeY-481 from Jerusalem artichoke We and pulp.

Total Fermentation Flnal ethanol Conversion Specific ethanol Specific substrate

sugars time concentration W) productlvlty uptake

(0) (h) [g/l (% v/v)] (ofW (g/kg wet fresh

(llnal tubers)

fermentation

time)

Juice fermentations

a4 72 42 (5.2) 99.1 0.583 70

120 72 60 (7.6) 98.4 0.833 101

220 72 110 (13.8) 98.3 1.527 a5

250 75 124 (15.5) 97.1 1.663 72

280 83 131 (16.4) 91.1 1.578 50

Pulp fermentations

120 80 49 (6.1) 80 0.612 89

200 a7 85 (10.6) 87 0.977 93

220 89 91 (11.3) 85 1.022 91

The optimal pH for ethanol production was 4.5 but since values between 3.2

and 4.5 give quite similar results, the starting pH was set at 3.4 to 3.5 without

regulation. Under these conditions, cell growth rate was maximal. Maximum cell

density (2.08 x 10’ cells/ml) was reached in 17 to 19 h. According to Gibbons

(1989), bacterial contamination was avoided and acidity stayed low enough to

reduce the risk of secondary contamination by other yeasts (De Miniac, 1989).

The inoculum for the fermentation had to be grown on artichoke juice; increasing

the size of inoculum from 4% (v/v) to 12% (v/v) did not significantly change the

specific ethanol productivity rate.

Under the optimal conditions thus established, all the sugars were consumed,

and the conversion was close to 98% of the theoretical yield for concentrations

less than, or equal to, 250 g/l (Table 1). This is markedly better than the yields

of 90% obtained with Kluyveromyces (Margaritis & Bajpai 1982; Rosa et al. 1987)

with practically identical specific ethanol productivity rates. According to Tour-

liere (1985), for a strain to be useful industrially, it has to produce ethanol to at

least 8.5 to 10% (v/v) and with a yield of at least 62 1 ethanol per 100 kg sugar.

S. cerevisiae Y-481 meets both criteria: with a juice containing 220 to 250 g total

sugars/l, it produces an ethanol concentration of 13.8 to 16% (v/v) with a yield

of 58 to 62 1 ethanol per 100 kg sugar. However, as the sugar concentration

increased, the specific substrate uptake, expressed as 1 of ethanol per tonne of

fresh raw material, decreased.

Fermentation of Pulp

Three types of trial were performed: with undiluted pulp, and pulp diluted with 10

and 30% (v/v) in water. According to Ziobro and Williams (Williams & Ziobro

1982; Williams 1982; Ziobro & Williams 1983), when the dilution of the pulp is

below 50%, it is not advisable to use a conventional system of stirring. The

high viscosity of the medium inhibits the normal circulating patterns in the tanks,

which then reduces heat dissipation and prevents adequate temperature control.

The lack of pulp homogeneity also causes a floating cap of solids to form in the

fermenter. Carbon dioxide compresses this cap and becomes trapped underneath

TIME (h)

it, eventually being released by ‘explosive disgorgement’. Vigorous mixing of the

Figure 1. Fermentation of Jerusalem arti-

medium is thus necessary to ensure gas exchange. We used a mechanical system

choke juice containing total sugars at 120 g/l

(V), 220 g/l (m), 250 g/l (e) and 280 g/l equipped with a bladed rotor of diameter 80% of that of the fermenter. To optimize

(A). yield, the operating parameters of the fermenter were systematically studied. Like

492 World Journa/ of Microbiology and Biotechnology, Vol 7, 19%

Ethanol from Jerusalem artichokes

Gibbons (1989), we found prior thermal treatment useful to facilitate diffusibility

of polyfructosans and, therefore, their assimilation by the yeast. The medium,

adjusted to pH 3.2 to 3.5, was sterilized for 30 min at 110°C. The best results

were obtained with undiluted or slightly diluted pulp with a stirring rate of 300

rev/min and an aeration rate of 0.34 vol/vol/min applied every 8 h during the first

24 h. The other parameters were the same as for the juice.

The fermentation profile of the Jerusalem artichoke juice and pulp are given

in Figures 1 and 2. The strain was not inhibited when ethanol was less than 95

to 110 g/l.

With pulp, the maximum cell density (3.2 to 3.0 x IO’ cells/g of fresh pulp)

was obtained in 25 to 27 h (instead of 17 to 19 h with the juice), resulting in a

lengthening of the duration of the fermentation (87 to 89 h instead of 72 to 75 h)

and hence a slowing of the conversion. However, the conversion was improved

(91 to 93 g instead of 72 to 85 g ethanol/kg fresh tubers), with 95 to 97% of the

sugars present being consumed with a 85 to 87% conversion into ethanol. The

ethanol yield was thus particularly high (85 to 91%).

These results are an improvement upon those of Gibbons (41 to 53%) (Gibbons

1989), Ziobro and Williams (50 to 75%) (Ziobro & Williams 1983) and Williams

and Ziobro (72 to 83%) (Williams & Ziobro 1982) with K. fTagi/is. They

correspond to an ethanol yield of 110 to 112 I/t, i.e. at the maximum feasible level

(100 to 110 l/t) according to the revised estimate of Gibbons and Westby (1984).

In summary, the fermentation of the inulin of Jerusalem artichokes by Xa‘acdar-

om_ycescereuisiae Y-481 gives good results indicating that its use for industrial-scale

production of ethanol deserves study.

References

24 72 96

DE MINIAC, M. 1989 Contamination de fermentations alcooliques industrielles par les

TIME (hl

levures du genre Brettanom_yces. Industries Alimentaires et .Agricoles (juillet-aolit) 559--

Figure 2. Fermentation of Jerusalem arti- 563.

choke pulp containing total sugars at 120 g/l DUVNJAC, Z., KOSARIC, N., KILZA, S. & HAYES, D. 1982 Production of alcohol from

(V), 200 g/l (0) and 220 g/l (W). Jerusalem artichokes by yeast. Biotechnology and Bioengineering 24, 2297-2308.

GIBBONS, W.R. & WESTBY, CA. 1984,-l bstracts of the *4 nnual Meeting of the -4 merican .SocieII

of MicrobioLogy 3, p. 189.

GIBBONS, W.R. 1989 Batch and continuous solid-phase fermentation of Jerusalem artichoke

tubers. Journal oy Fermentation and Bioengineering 67, 25S-265.

GLIIRAUD, J.P., DIX, T. & GAJ.ZY, I?. 1981 Selection of yeast strains for ethanol production

from inulin. Folia Microbiologica 24, 147-150.

MARGARJTIS, A. & BAJPAI, P. 1982 Ethanol production from Jerusalem artichoke tubers

using Kluyyljeromyces marxianus and J‘accbarom_yces rosei. Biotechnology and Bioengineering 24,

941-953.

POURRAT, H., BARTHOMEUF, C., REGERAT, F. & CARNAT, A.P. 1983 Production d’kthanol

i partir de topinambours par des souches de Saccharomyces cherensiensis et Sacrharon/yces

beticus. Industries ,4limentaires et Agricoles (mai) 181-190.

ROSA, M.F., CORREIA, I. Sr\ & NOVAJS, J.M. 1987 Production of ethanol at high

temperature in the fermentation of Jerusalem artichoke juice and a simple medium by

K/~veromyces marxianus. Biotechnology Letters 9, 441-444.

SACEIS,R.M., Low, C.B., VASAVADA, A., SUJ,L~, M.J., WJJ.LIAI\IS, L.A. & ZIOBRO, G.C.

1981 Fuel alcohol from Jerusalem artichokes. Calfornia Agricu/ture 35, 4-G.

TOURJ.JERE, R. 1985 L’kthanol de fermentation. Ses possibilitt?s, ses limitcs. Industries

Alimentaires et Agricoles (juillet-abut), 749753.

TREVEJ.YAN, W.E. & HARRISON, J.S. 1956 Studies on yeast metabolism. Biochemical Journal

63, 2S28.

WESTBY, C.A. & GIBBONS, W.R. 1982 Farm-scale production of fuel ethanol and wet

grain from corn in a batch process. Biotechnology and Bioengineering 24, 1681-1699.

WKLJA~~S, L.A. 1982 Proceedings of the Fifth International ~4lcohol Fuel Jjmposium 1, 55-61.

WILLIAMS, L.A. & ZIOBRO, G. 1982 Processing and fermentation of Jerusalem artichokes

for ethanol production. Biotechnology Letters, 4, 4550.

ZIOBRO, G.C. & WII.LIAIMS, L.A. 1983 Pilot scale fermentation of Jerusalem artichoke

tuber pulp mashes. Developments in Industrial hlicrobiology, 24, 22&229.

(Receiljed 12 November 1990; rezlisfd 20 February 1991; accepted 23 February 1991)

World Journal of Microbiology and Biotechnology, Vol 7, 1991 493

Potrebbero piacerti anche

- Ethanol Production From Various Feedstocks in Sugar Process - EthDocumento20 pagineEthanol Production From Various Feedstocks in Sugar Process - EthEngr Ghulam SarwarNessuna valutazione finora

- An Introduction: Factors Affecting Distillation Column OperationDocumento3 pagineAn Introduction: Factors Affecting Distillation Column OperationEngr Ghulam SarwarNessuna valutazione finora

- Wine Yeast Range Dep en LRDocumento8 pagineWine Yeast Range Dep en LREngr Ghulam SarwarNessuna valutazione finora

- 371 HW 03 SDocumento7 pagine371 HW 03 Sطريخم المشتاقNessuna valutazione finora

- Fuel Alcohol Production A Survey of Operating Systems 1981Documento51 pagineFuel Alcohol Production A Survey of Operating Systems 1981Engr Ghulam SarwarNessuna valutazione finora

- Adding Value To Bananas:: Progress Report To The Rockefeller FoundationDocumento55 pagineAdding Value To Bananas:: Progress Report To The Rockefeller FoundationJamshed TalpurNessuna valutazione finora

- Banana Peel: A Green and Economical Sorbent For CR (III) RemovalDocumento6 pagineBanana Peel: A Green and Economical Sorbent For CR (III) RemovalEngr Ghulam SarwarNessuna valutazione finora

- Alcohol Industry in IndiaDocumento9 pagineAlcohol Industry in IndiaashurebelNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- NV Pentosan Equine Injection SDS (Aug2016)Documento5 pagineNV Pentosan Equine Injection SDS (Aug2016)MathiNessuna valutazione finora

- General Characteristic of Crude OilDocumento20 pagineGeneral Characteristic of Crude Oildassi99Nessuna valutazione finora

- PresentationDocumento14 paginePresentationshu-sunanNessuna valutazione finora

- Clariant SDS AddWorks IBC 760 Australia EnglishDocumento10 pagineClariant SDS AddWorks IBC 760 Australia EnglishRafi UdeenNessuna valutazione finora

- Overview of The ProcessDocumento10 pagineOverview of The ProcessChaitanya PottiNessuna valutazione finora

- How Different Colors of Light Affect Plant GrowthDocumento5 pagineHow Different Colors of Light Affect Plant Growthmaybell pamaNessuna valutazione finora

- Conventional Manufacturing Process 20ME33: Class 05Documento5 pagineConventional Manufacturing Process 20ME33: Class 05Vinayaka G PNessuna valutazione finora

- Ecomax Front Loading DishwashersDocumento4 pagineEcomax Front Loading Dishwashersrichard9982Nessuna valutazione finora

- SZ-7510-P-DI - Cat (REV 2)Documento5 pagineSZ-7510-P-DI - Cat (REV 2)Richard BakerNessuna valutazione finora

- Chemical Raw Material PDFDocumento4 pagineChemical Raw Material PDFA MahmoodNessuna valutazione finora

- Pro Evolution MXE Panel User ManualDocumento20 paginePro Evolution MXE Panel User ManualcleoaminNessuna valutazione finora

- Catalogo Alu MarketDocumento40 pagineCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- Datasheet Altro-AquariusDocumento8 pagineDatasheet Altro-AquariusPaola Cares MoralesNessuna valutazione finora

- Advantages and Disadvantages of Hydraulic SystemsDocumento3 pagineAdvantages and Disadvantages of Hydraulic SystemsTina MilovanovićNessuna valutazione finora

- Project Work Chem1Documento15 pagineProject Work Chem1UMESH BIKRAM SHAHNessuna valutazione finora

- Gold RecoveryDocumento21 pagineGold RecoveryAnoop Chetia100% (2)

- Lamitex CE Tube Metric DataDocumento1 paginaLamitex CE Tube Metric Dataabdulloh_99Nessuna valutazione finora

- AC178 InterimCriteriaforInspectionandVerificationofConcreteandReinforcedandUnreinforcedMasonryusingFRPDocumento7 pagineAC178 InterimCriteriaforInspectionandVerificationofConcreteandReinforcedandUnreinforcedMasonryusingFRPBayram AygunNessuna valutazione finora

- Celulasas Usos IndustrialesDocumento16 pagineCelulasas Usos IndustrialesDanilo EcheverriNessuna valutazione finora

- Efficacy and Safety of Diabecon (D-400), A Herbal Formulation, in Diabetic PatientsDocumento5 pagineEfficacy and Safety of Diabecon (D-400), A Herbal Formulation, in Diabetic PatientsrawanNessuna valutazione finora

- Abiotic FactorsDocumento49 pagineAbiotic FactorsAlohNessuna valutazione finora

- Causes of Open ApicesDocumento2 pagineCauses of Open ApiceskowmudimaddineniNessuna valutazione finora

- Preparation of Reagents & Aseptic TechniquesDocumento21 paginePreparation of Reagents & Aseptic TechniquesReylen OracionNessuna valutazione finora

- 715 1Documento155 pagine715 1Aniculaesi MirceaNessuna valutazione finora

- Excel Meracik Nutrisi Bandung 11 Feb 2018Documento30 pagineExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNessuna valutazione finora

- Hardness Temperature in MetalsDocumento6 pagineHardness Temperature in MetalsStevenJacomeNessuna valutazione finora

- Unit 1, 2 and 8Documento71 pagineUnit 1, 2 and 8Noor SaleemNessuna valutazione finora

- Protein Structure Function and Uses WorksheetDocumento3 pagineProtein Structure Function and Uses WorksheetAngelon UdaniNessuna valutazione finora

- FORCE & PRESSURE NotesDocumento1 paginaFORCE & PRESSURE NotesPraveen KumarNessuna valutazione finora

- Final Report: Industrial Training (Construction of Flyover)Documento16 pagineFinal Report: Industrial Training (Construction of Flyover)Abhishek kumar100% (1)