Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Procedure Vs Instruction

Caricato da

kendall06090 valutazioniIl 0% ha trovato utile questo documento (0 voti)

111 visualizzazioni2 pagineComparison between a written procedure and an instruction

Titolo originale

procedure vs instruction

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoComparison between a written procedure and an instruction

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

111 visualizzazioni2 pagineProcedure Vs Instruction

Caricato da

kendall0609Comparison between a written procedure and an instruction

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

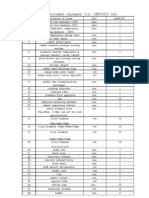

Quality Procedure and Instruction Writing December, 2010

Written Procedure Breakdown: Written Instruction Breakdown:

• Introduction: Executive summary (is a • Foreword: Should include: Document

summary of the highlights of your inspection reference and status; Purpose of the test;

plan), method(s) to be used, does not Originator's details; Authorising person's

contain the details of the procedure. Type of details; safety requirements

discontinuities sought and method

• Personnel: The minimum requirements for

limitations.

training (including job-specific training if

• Scope: description part(s) to be inspected, necessary), certification and authorization

part dimensions, material. Usually includes of NDT operators.

a sketch of the part.

• Apparatus to be used: Equipment to be

• References and standards: Source of the used, together with settings

documents, title, document identifier

• Product: (description or drawing, including

number, date and revision.

area of interest and the purpose of the test)

• Personnel qualifications: Education and component identification.

qualification requirements, responsibilities.

Verification, review and evaluation. • Test conditions, including preparation for

testing, post test cleaning and

• Safety requirements: Reference general preservation of test object

material (e.g. Company safety

indoctrination). Specific personal protective • Detailed instructions: Step by step

equipment. Special considerations re- instructions in the application of the NDT

technique, with reference to sketches if

inspection equipment, part handling etc.

Discarding of chemical products. appropriate; a statement instructing the

operator on actions to be taken in the event

• Preparation of part and site area: that the instruction cannot be applied.

Housekeeping requirement. Ventilation,

lighting, cleanliness, part identification and • Recording and classifying the results of

reference location(s). Statement of part test, action to be taken when defects are

surface condition required, e.g. cleanliness detected

and finish and the extent of area to be • Reporting the results: Essential data for the

prepared. What do you do if surface cannot report, e.g.: procedure reference,

be made suitable, who is responsible. component, equipment data ,

• Equipment required: List of all the settings/sensitivity, location of defects,

equipment that is necessary to perform the status of defects, e.g. accept, reject or

simply record, against agreed standard

inspection including ancillary equipment.

code or specification, operator name and

• Equipment calibration: Calibration qualification, date of test, operator’s and

intervals, performance checks, control /or supervisor’s signature.

method(s), e.g. log book.

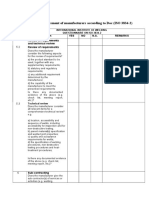

Written Procedure Breakdown cont’d:

• Part examination: Part must have its own

technique Include each stage describing the

processes (how). Specify inspection area and

refer to a sketch. Non-relevant indications,

what and how do you deal with them?

• Recording criteria: What is to be recorded

about each part? Inspection parameters, serial

number. If discontinuities to be recorded,

manner of recording. Sketches photos,

dimensions and orientation.

• Acceptance criteria: Type, size, orientation and

position of discontinuities, refer to

specification.

• Disposition instruction: General statement to

contact supervisor or customer if unable to

comply with procedure. Identification of the

part. Quarantining instructions and post

cleaning.

• Reporting criteria: Final reporting instruction.

Details to be included in report.

Potrebbero piacerti anche

- WPQR Sample FormDocumento1 paginaWPQR Sample FormshwayeNessuna valutazione finora

- Welding Machine ChecklistDocumento34 pagineWelding Machine ChecklistShahid BhattiNessuna valutazione finora

- Elcometer 345 Coating Thickness Gauge - Datasheet PDFDocumento1 paginaElcometer 345 Coating Thickness Gauge - Datasheet PDFVallik TadNessuna valutazione finora

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Documento5 pagineStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNessuna valutazione finora

- Gate & Globe PDFDocumento0 pagineGate & Globe PDFZoebairNessuna valutazione finora

- In-House Calibration SheetDocumento4 pagineIn-House Calibration SheetKannan MurugesanNessuna valutazione finora

- Outsourced Processes 9001 2015Documento2 pagineOutsourced Processes 9001 2015Navnath Tamhane0% (1)

- 1.1 Welding Procedure Specification (WPS)Documento35 pagine1.1 Welding Procedure Specification (WPS)Mohamed WahidNessuna valutazione finora

- Pickling Work InstructionDocumento1 paginaPickling Work InstructionmanesarkarNessuna valutazione finora

- Bar Bending MachineDocumento8 pagineBar Bending MachineVirendra ChavdaNessuna valutazione finora

- TS 0071Documento1 paginaTS 0071Seleccion Tecnico IndustrialNessuna valutazione finora

- Quality Procedure Procedure For Weld RepairDocumento1 paginaQuality Procedure Procedure For Weld Repairbalakumar rajaramNessuna valutazione finora

- Process Validation 1Documento1 paginaProcess Validation 1tayyab100% (1)

- RNS - NDT - MT - 001 Rev.0Documento10 pagineRNS - NDT - MT - 001 Rev.0Goutam Kumar DebNessuna valutazione finora

- Heat Treatment - Furnace TreatmentDocumento19 pagineHeat Treatment - Furnace Treatmentkumar QANessuna valutazione finora

- CTS 49 CTS 59 Operation ManualDocumento83 pagineCTS 49 CTS 59 Operation ManualKrista Maldonado100% (3)

- ISO 9001 2015 Cluases PDFDocumento1 paginaISO 9001 2015 Cluases PDFA MNessuna valutazione finora

- Visual Inspection Checklist PipingDocumento2 pagineVisual Inspection Checklist PipingshifaNessuna valutazione finora

- Checklist - ISO 9001-2015Documento6 pagineChecklist - ISO 9001-2015pratomo E TNessuna valutazione finora

- API Q1 Supplier Audit Check List-MarketingDocumento8 pagineAPI Q1 Supplier Audit Check List-MarketingSandra SandersNessuna valutazione finora

- Work Instructions For Arc Welding Machine: ReferenceDocumento1 paginaWork Instructions For Arc Welding Machine: Referencevivek sureshNessuna valutazione finora

- Master List of Forms FormatsDocumento1 paginaMaster List of Forms Formatschahi100% (1)

- Ins-P-021, Long Seam Set UpDocumento4 pagineIns-P-021, Long Seam Set UpDeepak100% (1)

- Test Instrument Equipment List (Sepcoiii Lab)Documento2 pagineTest Instrument Equipment List (Sepcoiii Lab)Kuldeep ChakerwartiNessuna valutazione finora

- Work Instructions - Gas CuttingDocumento2 pagineWork Instructions - Gas Cuttingvivek sureshNessuna valutazione finora

- Kerosene Leak TestDocumento3 pagineKerosene Leak TestsapkotamonishNessuna valutazione finora

- Visit Report - 312Documento4 pagineVisit Report - 312Vinay YadavNessuna valutazione finora

- SOP For DrawingDocumento2 pagineSOP For DrawingShashank DwivediNessuna valutazione finora

- Manufacturing Quality Plan (MQP)Documento2 pagineManufacturing Quality Plan (MQP)Ranjit Singh100% (3)

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocumento1 paginaMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan Raja100% (1)

- Random Mtrasonic Examination of Butt Welds: Prepared Pipe Fabrication Institute Engineering CommitteeDocumento9 pagineRandom Mtrasonic Examination of Butt Welds: Prepared Pipe Fabrication Institute Engineering CommitteeДенис ПекшуевNessuna valutazione finora

- Master List of InstrumentsDocumento35 pagineMaster List of Instrumentskrichenaraj6931100% (1)

- MT ProcedureDocumento13 pagineMT Procedureاباذر الدراجي100% (1)

- ISO 9001 2015 Quality Management System RequirementDocumento4 pagineISO 9001 2015 Quality Management System RequirementVincent S RyanNessuna valutazione finora

- Audit Checklist TemplateDocumento12 pagineAudit Checklist TemplateMurugeswari Rajaselvam100% (1)

- PreheatDocumento2 paginePreheatScott TrainorNessuna valutazione finora

- JD KRA LAB TeamDocumento27 pagineJD KRA LAB TeamANILNessuna valutazione finora

- Required Procedures and Records For 2015Documento1 paginaRequired Procedures and Records For 2015Jeff DrewNessuna valutazione finora

- Qhi Classroom Training List PDFDocumento2 pagineQhi Classroom Training List PDFPrakash kumarTripathiNessuna valutazione finora

- QA-R-05 - Weld Traceability RecordDocumento1 paginaQA-R-05 - Weld Traceability RecordvinothNessuna valutazione finora

- Coatings Audit Handbook Nov 2011Documento19 pagineCoatings Audit Handbook Nov 2011Neil PiersonNessuna valutazione finora

- 17.work Instruction For CNC-CLGDocumento1 pagina17.work Instruction For CNC-CLGSAKTHIVEL ANessuna valutazione finora

- Cs f11 Non Conformity ReportDocumento1 paginaCs f11 Non Conformity ReportIdrus IsmailNessuna valutazione finora

- DFT Measurement Worksheet: Paint InspectionDocumento1 paginaDFT Measurement Worksheet: Paint Inspectionjay nathNessuna valutazione finora

- Welding Process: Work InstructionDocumento6 pagineWelding Process: Work Instructionmkcsekar100% (1)

- Procedure Progress ISO 3834 2 PDFDocumento3 pagineProcedure Progress ISO 3834 2 PDFKumar DNessuna valutazione finora

- 2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFDocumento59 pagine2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFGeorge JhonsonNessuna valutazione finora

- Check List For Assessment of Manufacturers According To Doc (ISO 3834-2)Documento5 pagineCheck List For Assessment of Manufacturers According To Doc (ISO 3834-2)Brijesh KumarNessuna valutazione finora

- Quality Manual1111Documento35 pagineQuality Manual1111Nizar KhalidNessuna valutazione finora

- Visual Inspection ReportDocumento5 pagineVisual Inspection ReportOmar WardehNessuna valutazione finora

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Documento12 pagineChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalNessuna valutazione finora

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocumento3 pagineSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNessuna valutazione finora

- Quality Alert / Flash Note: Photo / Sketch:-Ng Part Photo / Sketch: - Ok PartDocumento1 paginaQuality Alert / Flash Note: Photo / Sketch:-Ng Part Photo / Sketch: - Ok PartMohit SinghNessuna valutazione finora

- PGS-JOBN-190582-P05-LS4-01-Plan de Contrôle QualitéDocumento15 paginePGS-JOBN-190582-P05-LS4-01-Plan de Contrôle QualitéHoussem Ettwil100% (1)

- Astm A 986 - 2016 PDFDocumento3 pagineAstm A 986 - 2016 PDFEmmanuel BoquetNessuna valutazione finora

- Updated Layered Welding Audit ChecklistDocumento1 paginaUpdated Layered Welding Audit Checklistcarey stewart100% (1)

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocumento5 pagineWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNessuna valutazione finora

- Asnt 8Documento8 pagineAsnt 8amin.adineh97Nessuna valutazione finora

- NDT - Visual Inspection Checklist Page 1 of 4Documento4 pagineNDT - Visual Inspection Checklist Page 1 of 4thindmanmohanNessuna valutazione finora

- Goldhofer FTV 850 BrochureDocumento2 pagineGoldhofer FTV 850 BrochureMauroNessuna valutazione finora

- Kindergarten Math Problem of The Day December ActivityDocumento5 pagineKindergarten Math Problem of The Day December ActivityiammikemillsNessuna valutazione finora

- SDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaDocumento13 pagineSDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaAleksandar PetkovicNessuna valutazione finora

- Ficha Tecnica-Skyjack SJ3219 8mtDocumento2 pagineFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALNessuna valutazione finora

- Mean Variance Portfolio TheoryDocumento85 pagineMean Variance Portfolio TheoryEbenezerNessuna valutazione finora

- Sika - Bitumen: Bitumen Emulsion Waterproof & Protective CoatingDocumento3 pagineSika - Bitumen: Bitumen Emulsion Waterproof & Protective Coatingdinu69inNessuna valutazione finora

- WPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFDocumento88 pagineWPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFbabuzducNessuna valutazione finora

- Sat Vocabulary Lesson and Practice Lesson 5Documento3 pagineSat Vocabulary Lesson and Practice Lesson 5api-430952728Nessuna valutazione finora

- 2022 Audi e Tron 22Documento318 pagine2022 Audi e Tron 22Alejandro Alberto Robalino MendezNessuna valutazione finora

- PEH Q3 Long QuizDocumento1 paginaPEH Q3 Long QuizBenedict LumagueNessuna valutazione finora

- G.S 5Documento2 pagineG.S 5Jamsher BalochNessuna valutazione finora

- Hopeless PlacesDocumento1.304 pagineHopeless Placesmoreblessingmarvellous659Nessuna valutazione finora

- Dusta ManaDocumento16 pagineDusta ManamahaphalaNessuna valutazione finora

- Fighting Techniques of The Early Modern World AD 1500-AD 1763 - Equipment Combat Skills Amp Amp TacticsDocumento258 pagineFighting Techniques of The Early Modern World AD 1500-AD 1763 - Equipment Combat Skills Amp Amp Tacticslupoeva100% (3)

- HCPL 316J 000eDocumento34 pagineHCPL 316J 000eElyes MbarekNessuna valutazione finora

- Gamak MotorDocumento34 pagineGamak MotorCengiz Sezer100% (1)

- Ad149 Manual RDocumento69 pagineAd149 Manual RCharityNessuna valutazione finora

- 3200AMMe - Part 4Documento207 pagine3200AMMe - Part 4Tanja Kesic100% (1)

- Curriculum Vitae - RadikaDocumento3 pagineCurriculum Vitae - RadikaradikahendryNessuna valutazione finora

- Save Water SpeechDocumento4 pagineSave Water SpeechHari Prakash Shukla0% (1)

- Updated Factory Profile of Aleya Apparels LTDDocumento25 pagineUpdated Factory Profile of Aleya Apparels LTDJahangir Hosen0% (1)

- Middle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryDocumento22 pagineMiddle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryMerlinNessuna valutazione finora

- Emw 2007 FP 02093Documento390 pagineEmw 2007 FP 02093boj87Nessuna valutazione finora

- GROSS Mystery of UFOs A PreludeDocumento309 pagineGROSS Mystery of UFOs A PreludeTommaso MonteleoneNessuna valutazione finora

- Ali Erdemir: Professional ExperienceDocumento3 pagineAli Erdemir: Professional ExperienceDunkMeNessuna valutazione finora

- Passenger Lift Alert - Health and Safety AuthorityDocumento4 paginePassenger Lift Alert - Health and Safety AuthorityReginald MaswanganyiNessuna valutazione finora

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDocumento10 pagineThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaNessuna valutazione finora

- Semi Finals in Tle 2015Documento3 pagineSemi Finals in Tle 2015LoraineTenorioNessuna valutazione finora

- CapstoneDocumento23 pagineCapstoneA - CAYAGA, Kirby, C 12 - HermonNessuna valutazione finora

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesDocumento8 pagineElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadNessuna valutazione finora