Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AB8-ELE-74-HMO - Shale Shaker Motors Dismantling & Shifting To Main Deck

Caricato da

vikrant911Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AB8-ELE-74-HMO - Shale Shaker Motors Dismantling & Shifting To Main Deck

Caricato da

vikrant911Copyright:

Formati disponibili

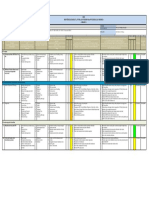

QHSET Documents Reviewed/Referred to How to use the form:

during the Pre-Task PAR Meeting 1. Crew performing task review ALL generic PAR considerations.

Policy No. Title ABAN 2. Review previous PARupdate(s) for useful information, which will help THIS task.

SAF 330.00 Process for Assessing Risk (Mandatory) 3. Create new PARupdate with generic form and ALL considerations for this task.

P.T.W. System-Pressure Vessels,

HAZARD MANAGEMENT

SAF 300.00

OUTLINE (HMO) 4. Include planned TOFS as a task step(s)before any crucial activity in the Task

Piping/valves

SAF 320.00 Lockout / Tag out (Form 2 of 2 for Assessing Risk) 5. Identify potential Dropped Objects as a specific hazard during discussion

SAF 310.00 Confined Space Entry 6. Carry out the task as per the plan. If any conditions change, STOP and RE-ASSESS!

TRM 105.20 P.P.E. 7. Keep the original copy of the two PAR formsfor auditing purposes.

L- LIKELIHOOD S - SEVERITY R - RATING RESULT

CATEGORY DEFINITION CATEGORY DEFINITIONS H 3 6 9 Unacceptable

SEVERITY

LOW (1) Remote LOW (1) No Injury No damage No Pollution M 2 4 6 Tolerable

MED (2) Possible MED (2) First Aid Injury Minor Damage Minor Pollution L 1 2 3 Acceptable

HIGH (3) Probable HIGH (3) Lost Time Injury Major Damage Major Pollution L M H PAR Policy Reference

IS THERE A SAFER WAY TO COMPLETE THE JOB? ARE THERE ALTERNATIVES WITH LESSER RISK? LIKELIHOOD SAF 330.00

Rig: Aban 8 Rig Job Risk Assessment Number ABAN8-ELE-74 Original Issue Date: 22nd May 2015

Task Date 22nd May 2015 Crew: Electrical Date Last Revised: 22nd May 2015

Dismantling of Shaker#2 Motors

Task Dept. Head Approval (Initials)Prior Last Revised by

for 5 yearly & Shaker Change Navodaya / Ch.ELec.

Activity to the Task starting: (Name/Position):

RISK REDUCTION MEASURE(S) Residual

(A Rescue Plan may be Risk

TASK(Include Planned TOFS as a HAZARD(Including Potential Acceptable?

STEP required e.g. Working at

specific Task Step) Dropped Object Hazards) Tolerable?

Height/Over Water/Confined L S R

L S R Space)

Review and update Risk Ensure that all participants are

Not all participants present while

1 Assessment & conduct a pre-task 2 3 6 present when conducting a risk 1 3 3 Tolerable

assessing risk.

meeting. assessment.

Obtain required initial Cold Ensure that issuing authorities

Work Permit and Isolation on all Permits and Certificates

Permits being signed without visual

2 2 3 6 visually inspect the work site as 1 3 3 Tolerable

permit inspection of work site.

specified on Permit and

certificate.

Wear the required PPE & Make sure proper PPE and area

assess ongoing job in Potential injury to body parts. to be physically inspected all

3 2 3 6 1 3 3 Tolerable

Condition leads to unidentified risk ongoing task in the surrounding

surrounding area.

area are assessed.

SAF-019, 11April 2012, Reference SAF 330.00 Page 1 of 2

Physically check and verify the Make sure effectiveness of

Proper LOTO has not been

4 effectiveness of isolation 2 3 6 LOTO is re-assessed by 1 3 3 Tolerable

implemented

physically checking it.

Inspection of tools for

Wrong tools may lead to physical

5 Use proper tools for doing job 2 3 6 suitability for the job and good 1 3 3 Tolerable

injuries

condition

PLANNED TIME OUT for

Belying the task steps and working Encourage personnel to call out

6 Safety 2 3 6 1 3 3 Tolerable

conditions are not assessed. TOFS

Take note of all the

Wrong connections may lead to Make sure all connections are

7 connections before opening 2 3 6 1 3 3 Tolerable

equipment damage. properly noted before opening

the connections

Remove connections from

junction box and remove both Figure injury while opening old Make sure proper PPE is used

8 2 3 6 1 3 3 Tolerable

the cable fixing cleats from bolts. Cable may damage and handle the cable properly.

cable tray.

Open both the motor Make sure proper PPE is used

Personnel injury and properly

9 mounting bolts 2 3 6 and secure the motor before 1 3 3 Tolerable

damage while opening.

opening with chain block

Shift both motors to main Personnel injury and properly Make sure proper PPE is used.

10 deck. damage while opening and shifting 2 3 6 Take help of barge / Drilling 1 3 3 Tolerable

the motor to main deck dept. to shift the motors

When finished ensure all tools Make sure work site is clean

& work material are removed Failure to re-instate work site on and all debris if any removed.

11 2 3 6 1 3 3 Tolerable

completion of job Return all working gears to

from work area

stores.

Close Cold Work Permit &

Ensure that issuing authorities

Isolation certificate or make Permits being signed without visual

12 2 3 6 on all Permits are cancel after 1 3 3 Tolerable

long term isolation if the job inspection of completed job.

Inspecting the completed job

continues by other dept.

Reinstate the circuit breaker Make sure the correct CB is

13 and do function test Reinstate of wrong CB 2 3 6 switched on by cross checking 1 3 3 Tolerable

the tag nos.

SAF-019, 11April 2012, Reference SAF 330.00 Page 2 of 2

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Risk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Documento2 pagineRisk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi89% (9)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Safety Questions and Answers PDFDocumento5 pagineSafety Questions and Answers PDFKokonok Tektek0% (1)

- Goal Zero: Zero Injuries, Zero FatalitiesDocumento3 pagineGoal Zero: Zero Injuries, Zero Fatalitiesvikrant911Nessuna valutazione finora

- Hatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic WasteDocumento1 paginaHatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic Wastevikrant911Nessuna valutazione finora

- Federal Decree-Law No. 32 of 2021Documento70 pagineFederal Decree-Law No. 32 of 2021vikrant911Nessuna valutazione finora

- 15 Working Hours and Places - CleanedDocumento6 pagine15 Working Hours and Places - Cleanedvikrant911Nessuna valutazione finora

- Worker Welfare in The UAE .CleanedDocumento5 pagineWorker Welfare in The UAE .Cleanedvikrant911Nessuna valutazione finora

- Hatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic WasteDocumento1 paginaHatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic Wastevikrant911Nessuna valutazione finora

- FR71ODSDocumento2 pagineFR71ODSvikrant911Nessuna valutazione finora

- OGUK Health and Safety Report 2021.cleanedDocumento40 pagineOGUK Health and Safety Report 2021.cleanedvikrant911Nessuna valutazione finora

- WhyIWorkSafe TemplateDocumento1 paginaWhyIWorkSafe Templatevikrant911Nessuna valutazione finora

- SafetyWeek ColoringPageDocumento1 paginaSafetyWeek ColoringPagevikrant911Nessuna valutazione finora

- IHS - Day 1 - Session 3 - Michel Theriault - Regulation From An Operators Perspective - CleanedDocumento15 pagineIHS - Day 1 - Session 3 - Michel Theriault - Regulation From An Operators Perspective - Cleanedvikrant911Nessuna valutazione finora

- DOS-AW-201645-SAS-1596185 Mining - Metal To Metal Contact Theme - Incident 3 March 2016Documento3 pagineDOS-AW-201645-SAS-1596185 Mining - Metal To Metal Contact Theme - Incident 3 March 2016vikrant911Nessuna valutazione finora

- GMSAnnualHSEReport2018 CleanedDocumento11 pagineGMSAnnualHSEReport2018 Cleanedvikrant911Nessuna valutazione finora

- AtHome ToolboxTalk SafetyWeek2022Documento3 pagineAtHome ToolboxTalk SafetyWeek2022vikrant911Nessuna valutazione finora

- OISD SA 2021 22 POL 11.cleanedDocumento2 pagineOISD SA 2021 22 POL 11.cleanedvikrant911Nessuna valutazione finora

- WhyIWorkSafe TemplateDocumento1 paginaWhyIWorkSafe Templatevikrant911Nessuna valutazione finora

- DOS-SAS-AW-201620 - 1613088 Turnaround - Worker Fell Asleep While Driving April 2016Documento2 pagineDOS-SAS-AW-201620 - 1613088 Turnaround - Worker Fell Asleep While Driving April 2016vikrant911Nessuna valutazione finora

- DIL AW 201601 Global FallsDocumento3 pagineDIL AW 201601 Global Fallsvikrant911100% (1)

- SafetyWeek ColoringPageDocumento1 paginaSafetyWeek ColoringPagevikrant911Nessuna valutazione finora

- OISD SA 2021 22 E&P 10.cleanedDocumento2 pagineOISD SA 2021 22 E&P 10.cleanedvikrant911Nessuna valutazione finora

- Dig LB 201604 q3 GC Lfi BulletinDocumento2 pagineDig LB 201604 q3 GC Lfi Bulletinvikrant911Nessuna valutazione finora

- DOS-AW-201644-SAS-1593571 Mining - Metal To Metal Contact Theme - Incident 2 March 2016Documento2 pagineDOS-AW-201644-SAS-1593571 Mining - Metal To Metal Contact Theme - Incident 2 March 2016vikrant911Nessuna valutazione finora

- Crane Hood Dropped ObjectDocumento4 pagineCrane Hood Dropped Objectvikrant911Nessuna valutazione finora

- Hand Injury - Restricted Work Case: DTS-AW-201627-EU-SA Trading & Supply Operations August 2016Documento2 pagineHand Injury - Restricted Work Case: DTS-AW-201627-EU-SA Trading & Supply Operations August 2016vikrant911Nessuna valutazione finora

- Dropped Object - Fatale AccidentDocumento9 pagineDropped Object - Fatale Accidentvikrant911Nessuna valutazione finora

- DOS-AW-201633-SAS-1617347 Turnaround - Fallen Object (Scaffold Tube) April 2016Documento2 pagineDOS-AW-201633-SAS-1617347 Turnaround - Fallen Object (Scaffold Tube) April 2016vikrant911Nessuna valutazione finora

- DOS-AW-201643-SAS-1576371 Mining - Metal To Metal Contact Theme - Incident 1 February 2016Documento2 pagineDOS-AW-201643-SAS-1576371 Mining - Metal To Metal Contact Theme - Incident 1 February 2016vikrant911Nessuna valutazione finora

- CFAG777Documento2 pagineCFAG777Sachzna LaparanNessuna valutazione finora

- Emergency Action Plan ChecklistDocumento2 pagineEmergency Action Plan Checklistsudeesh kumarNessuna valutazione finora

- Offshore Risk Management - Security Assessment For Offshore Oil PDFDocumento26 pagineOffshore Risk Management - Security Assessment For Offshore Oil PDFlightangeldavidNessuna valutazione finora

- Essence of Good HousekeepingDocumento26 pagineEssence of Good HousekeepingPritta VioletaNessuna valutazione finora

- Memo Fire AlarmDocumento2 pagineMemo Fire AlarmMiguel CuisiaNessuna valutazione finora

- Meeting Minutes Template-Activity 7, Q2Documento2 pagineMeeting Minutes Template-Activity 7, Q2Junita MagdalenaNessuna valutazione finora

- Hydro Static Test: Risk AssessmentDocumento10 pagineHydro Static Test: Risk Assessmentmohammed a hseNessuna valutazione finora

- Industrial Safety SyllabusDocumento2 pagineIndustrial Safety Syllabusrajeesh4meNessuna valutazione finora

- Deped K To 12 Technology and Livelihood Education - Household ServicesDocumento6 pagineDeped K To 12 Technology and Livelihood Education - Household Servicesyachiru12191% (11)

- Safety Data Sheet: Product Name: MOBIL SHC 627Documento13 pagineSafety Data Sheet: Product Name: MOBIL SHC 627Om Prakash RajNessuna valutazione finora

- Lab Report 1Documento9 pagineLab Report 1Muhammad SyuhailNessuna valutazione finora

- Process Hazard AnalysisDocumento103 pagineProcess Hazard AnalysisSabrinaQurrotaayun50% (2)

- HSE Identifikasi Bahaya, Penilaian Resiko Dan Pengendalian Resiko (Hiradc)Documento1 paginaHSE Identifikasi Bahaya, Penilaian Resiko Dan Pengendalian Resiko (Hiradc)Bambang IrawanNessuna valutazione finora

- Workplace Safety Emergency Action Plan Quiz QuestionDocumento2 pagineWorkplace Safety Emergency Action Plan Quiz QuestionHassan64041Nessuna valutazione finora

- Risk AssessmentDocumento22 pagineRisk AssessmentIhuhwa Marta TauNessuna valutazione finora

- Spray Nine Heavy DutyDocumento7 pagineSpray Nine Heavy DutyPubcrawlNessuna valutazione finora

- Liste de Vérification Du MagasinDocumento1.700 pagineListe de Vérification Du MagasinAnonymous a5KZQA100% (1)

- GRA - Civil Work - WWT HousekeepingDocumento17 pagineGRA - Civil Work - WWT HousekeepingMohamad Nazmi Mohamad RafianNessuna valutazione finora

- JSA For HDPE SLEEVING DEL 89Documento3 pagineJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- CIARA 62443 Risk AssessmentDocumento17 pagineCIARA 62443 Risk Assessmenthvananth100% (2)

- Hse Key Performance Indicator: Pt. Mastersystem Infotama 2018Documento6 pagineHse Key Performance Indicator: Pt. Mastersystem Infotama 2018Rizky RahmanNessuna valutazione finora

- Redcliffe Risk AssesssmentsDocumento2 pagineRedcliffe Risk Assesssmentsapi-270483993Nessuna valutazione finora

- Confined Space (Permit Required) Rescue and Emergency ServicesDocumento26 pagineConfined Space (Permit Required) Rescue and Emergency Servicesashok KumarNessuna valutazione finora

- AEL-IMS-WI-009 Rev-0 Emergency Response PlansDocumento8 pagineAEL-IMS-WI-009 Rev-0 Emergency Response PlansOscar IsingomaNessuna valutazione finora

- MCM Module 1 Risk Management PDFDocumento27 pagineMCM Module 1 Risk Management PDFFranciz Nicole RadanNessuna valutazione finora

- Analisis Implementasi Sistem Tanggap Darurat Berdasarkan Ohsas 18001:2007 Klausul 4.4.7 Di PT X Kalimantan SelatanDocumento8 pagineAnalisis Implementasi Sistem Tanggap Darurat Berdasarkan Ohsas 18001:2007 Klausul 4.4.7 Di PT X Kalimantan SelatanKhael DimasNessuna valutazione finora

- MSDS ThinnersDocumento2 pagineMSDS ThinnersBlouBul2Nessuna valutazione finora

- How To Complete A Job Hazard AnalysisDocumento4 pagineHow To Complete A Job Hazard AnalysisunniNessuna valutazione finora