Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Building Specification

Caricato da

Alemar Soriano MalintadTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Building Specification

Caricato da

Alemar Soriano MalintadCopyright:

Formati disponibili

SPECIFICATION

This set of Specifications shall govern the methods of construction and the kinds of materials to be

used for the proposed fence shown in the plans and detail drawings.

The plans, detail drawings and these Specifications shall be considered as complementing each,

other, so that what is mentioned or shown in one, although not mentioned or shown in the other, shall be

considered as appearing on both. In case of conflict between the two, the same should be referred to the

designing Architect/Engineer for resolution.

General Conditions-

All parts of the construction shall be finished with first class workmanship to the fullest talent and

meaning of the plans and these Specifications, and to the entire satisfaction of the Architect/ Engineer and

Owner.

The construction shall conform to all the requirements of the National Building Code, as well as the

local rules and regulations of the Municipality/ City of Mati, Davao Oriental, Philippines.

Clearing the Site-

The building site shall be leveled according to the plans and cleared of rubbish, roots and other

perishable and objectionable matters to a suitable sub grade.

All such unsuitable materials shall be removed from the building site and spread uniformly over the

areas adjacent to the proposed building, or otherwise disposed of as may be directed by the Architect or

Engineer in charge of the construction.

Staking out the Building Lines-

The building lines shall be staked out and all lines grades shown in the drawings established before

any excavation is started. Batter boards and reference marks shall be erected at such places where they will

not be disturbed during the excavation of the building.

Excavation-

All excavations shall be made to grade indicated in the drawings. Where the building site is covered with

any kind of fill, the excavation for footings should be made deeper until the stratum for safe bearing

capacity of the soil is reached.

Whenever water is encountered in the excavation process, it shall be removed by bailing or

pumping, care being taken that the surrounding soil particles are not disturbed or removed

Backfills-

After concrete for foundations is hard enough to withstand pressure resulting from fills, the

materials removed from excavation shall be used for backfill around them.

Backfills and fills shall be placed in layers not exceeding 150mm in thickness, and each layer shall be

thoroughly compacted by wetting, tamping and rolling.

Concrete Works-

All concrete shall be mixed thoroughly until there is a uniform distribution of the cement and

aggregates, and should be deposited as nearly as practicable in its final position, care being taken to avoid

segregation of the aggregates.

Water to be used for mixing concrete shall be clean and free from injurious amount of oil, acids,

alkalis, sails and other organic materials.

Proportioning of Concrete-

All concrete works shall be done in accordance with the standard specifications for plain and

reinforced concrete as adopted by the Government. Cement to be used shall be Union brand Portland

cement, or any other equivalent brands more readily available in the locality. Alternative cements so

selected must meet the requirements of Portland and pozzolan cements, and approved by the Architect or

Engineer in charge of constructions.

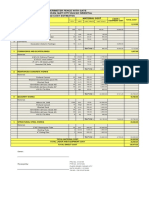

The following proportions of concrete mixtures shall be used for the various parts of the building:

Columns and footings - Class A (1 : 2 : : 4)

Conc. Holl. Blk. Footings - Class B (1 : 2 - ½ : 5)

Reinf. Conc. Beams and Slabs - Class A (1 : 2 : 4)

Concrete slab floor on fill - Class C (1 : 3 : 6)

Septic Vault cover - Class A (1 : 2 : 4)

1

The fine aggregate for concrete shall consist of natural sand, or of inert materials with similar

characteristics, having clean, hard and durable grains, free from organic matter or loam.

The coarse aggregate for concrete shall consist of crushed rock of durable and strong qualities, or

clean and hard gravel. Size of the coarse aggregate to be used shall vary from 20mm to 40mm (3/4” to 1 -

½).

Forms for Concrete Works-

All forms for concrete works shall be properly braced or tied together so as to maintain the correct

position and shapes of the concrete members. Forms shall be constructed sufficiently tight to prevent

bulging and seepage of water.

Forms shall not be removed until the concrete has attained sufficient strength to support its own

weight and any loads that may be placed on it. Side forms of beams and girders may be removed earlier

than the bottom forms but additional posts or shoring must be placed under the beams or girders until they

attained their strength.

Steel Reinforcing Bars-

All steel reinforcing bars to be used in this construction shall consist of round deformed bars with

lugs or projections on their sides to provide greater bond between the concrete and the steel.

All steel reinforcing bars shall be accurately placed and secured against displacement by tying them

together at each bar intersection with Gauge No. 16 GI Wire.

The steel reinforcing bars indicated for footings, columns and other concrete members shall all

conform to the number, size and spacing as indicated in the drawings or schedule of steel reinforcements.

No metal reinforcement shall be installed in placed unless it is free from rust, scale or other coatings

which will destroy or reduce the bond with concrete.

Concrete Hollow Blocks-

All exterior concrete hollow blocks to be used for first floor walls shall be at least 100mm thick, while

concrete hollow blocks for interior walls unless otherwise indicated, shall be 100mm thick. For interior CHB

walls where plumbing pipes and fittings shall be located, the thickness shall be at least 100mm.

The concrete hollow block walls shall be laid, and the cells filled with cement mortar consisting of 1

part Portland cement and 3 parts sand by volume. They shall be reinforce with round deformed bars, 10mm

diameter, space not more than 60m on centers, bothways.

The mixture of cement plaster for concrete hollow block wall finished indicated in the drawings shall

be 1 part cement, 1 part lime and 3 parts sand.

Conformed by:

Owner/Representative

Reviewed by:

Civil Engineer

PRC NO. : 0143159 PTR NO. : 3714732C

PLACE ISSUED: DAVAO CITY DATE ISSUED: 01/31/2020

TIN NO. : 702-013-579-000

Potrebbero piacerti anche

- Sample Construction SpecificationsDocumento9 pagineSample Construction SpecificationsMark Anjo Palero ErlanoNessuna valutazione finora

- Naga House Construction SpecificationsDocumento6 pagineNaga House Construction SpecificationsJason HallNessuna valutazione finora

- Specifications: Project Title: LocationDocumento5 pagineSpecifications: Project Title: LocationALZHAMMER MANUPACNessuna valutazione finora

- Marces Osmeña General SpecificationsDocumento5 pagineMarces Osmeña General SpecificationsAlexander Osmeña IINessuna valutazione finora

- SpecificationsDocumento20 pagineSpecificationsJohn Dominic Delos ReyesNessuna valutazione finora

- Specifications: Louie Jean Mabanag Ar - 3BDocumento8 pagineSpecifications: Louie Jean Mabanag Ar - 3BLouie Jean100% (1)

- Assignment 3 CEPM1 - SanchezRobertDocumento11 pagineAssignment 3 CEPM1 - SanchezRobertRjohn SanchezNessuna valutazione finora

- SPECIFICATIONS FOR PROPOSED BUILDING PROJECTDocumento9 pagineSPECIFICATIONS FOR PROPOSED BUILDING PROJECTShyra Dela CruzNessuna valutazione finora

- Sample Constrcution SpecificationsDocumento8 pagineSample Constrcution SpecificationsJino Martin100% (1)

- Specifications: Project: Proposed Two-Storey Residential BuildingDocumento9 pagineSpecifications: Project: Proposed Two-Storey Residential BuildingRey Gabriel Advincula Granada100% (1)

- SpecificationsDocumento8 pagineSpecificationsJosé Alvarez Betita67% (3)

- General SpecificationDocumento12 pagineGeneral Specificationmark100% (3)

- Reyes - BT4 - Specification Writing SeatworkDocumento11 pagineReyes - BT4 - Specification Writing SeatworkCameron ReyesNessuna valutazione finora

- BT4 SpecificationsDocumento8 pagineBT4 SpecificationsJet BlackNessuna valutazione finora

- Construction Specs GuideDocumento9 pagineConstruction Specs Guidejohn patrick75% (12)

- Outline of Specs2Documento10 pagineOutline of Specs2rmrv valdezNessuna valutazione finora

- Construction SpecificationsDocumento6 pagineConstruction SpecificationsRogerine Roy100% (2)

- General notes and specifications for one-storey residenceDocumento5 pagineGeneral notes and specifications for one-storey residenceJillian Flaire VillarNessuna valutazione finora

- Construction SpecificationsDocumento10 pagineConstruction SpecificationsDarwin AquinoNessuna valutazione finora

- Proposed Bungalow Technical SpecsDocumento17 pagineProposed Bungalow Technical Specslarry0lao0iiiNessuna valutazione finora

- General Construction SpecificationsDocumento6 pagineGeneral Construction SpecificationsCOMPASS LanguageAndskillsTrainingNessuna valutazione finora

- SpecificationsDocumento7 pagineSpecificationsCarlo Emozero Ibuyan100% (1)

- General construction and material specificationsDocumento13 pagineGeneral construction and material specificationsEquilibrium D.C.Nessuna valutazione finora

- General Specifications Allanalbano (2524)Documento7 pagineGeneral Specifications Allanalbano (2524)Allan AlbanoNessuna valutazione finora

- SpecificationsDocumento6 pagineSpecificationsRomeo Atienza100% (1)

- Specification For General Construction FroilanDocumento6 pagineSpecification For General Construction FroilanRafael Luis So100% (1)

- 4-Story Commercial and Residential Building SpecificationsDocumento5 pagine4-Story Commercial and Residential Building SpecificationsKURONessuna valutazione finora

- Two Storey General SpecificationsDocumento7 pagineTwo Storey General SpecificationsCarlos GozonNessuna valutazione finora

- Sample Building SpecificationsDocumento3 pagineSample Building SpecificationsSyrille alarcon100% (2)

- Residential BOM and SpecsDocumento4 pagineResidential BOM and SpecsMary Ann LictaoaNessuna valutazione finora

- Proposed Two-Storey Residential Project SpecsDocumento4 pagineProposed Two-Storey Residential Project SpecsJ.P.Almera ArDesignNessuna valutazione finora

- Building SpecificationsDocumento7 pagineBuilding SpecificationsElvin PrestoNessuna valutazione finora

- Sample Construction SpecificationsDocumento14 pagineSample Construction SpecificationsFrncesca MacalindongNessuna valutazione finora

- Proposed Residential Building SpecsDocumento6 pagineProposed Residential Building SpecsMaire Joy E. AzañaNessuna valutazione finora

- Part1 Outline SpecificationsDocumento16 paginePart1 Outline SpecificationsAdrienne Margaux DejorasNessuna valutazione finora

- Project:2 Bedroom Bungalow Residence: I. GeneralDocumento4 pagineProject:2 Bedroom Bungalow Residence: I. Generalpauly mari refuerzoNessuna valutazione finora

- Construction Specifications: General ConditionsDocumento2 pagineConstruction Specifications: General ConditionsKatrina GaygayNessuna valutazione finora

- Proposed Three-Storey Residence SpecsDocumento5 pagineProposed Three-Storey Residence SpecsCarlos Gozon100% (1)

- Specifications: Project: Owner:: LocationDocumento6 pagineSpecifications: Project: Owner:: LocationMaria Theresa AlarconNessuna valutazione finora

- Residential Specifications for 3-Storey ProjectDocumento4 pagineResidential Specifications for 3-Storey ProjectARJAY LERUMNessuna valutazione finora

- Residential Specs GuideDocumento3 pagineResidential Specs GuideBernie RomeroNessuna valutazione finora

- Arch 530 - BT4 Technical SpecificationsDocumento13 pagineArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNessuna valutazione finora

- Technical SpecificationsDocumento12 pagineTechnical SpecificationsDan Aragon RetotaNessuna valutazione finora

- General Specifications Musngi Residence - As Per SiteDocumento8 pagineGeneral Specifications Musngi Residence - As Per SiteJanine Palec100% (1)

- Architectural SpecificationDocumento5 pagineArchitectural SpecificationJustine Alexis IngresoNessuna valutazione finora

- SpecificationDocumento6 pagineSpecificationArnold VercelesNessuna valutazione finora

- RENOVATION SPECIFICATIONS FOR DUPLEX IN SUBICDocumento3 pagineRENOVATION SPECIFICATIONS FOR DUPLEX IN SUBICJan Alexis Monsalud85% (20)

- Two Storey General SpecificationsDocumento7 pagineTwo Storey General SpecificationsJoseph MalabananNessuna valutazione finora

- Specifications: (6 Storey Office-Commercial Building With Roof Deck & Basement)Documento14 pagineSpecifications: (6 Storey Office-Commercial Building With Roof Deck & Basement)Doroty Castro100% (2)

- Complete Outline SpecificationsDocumento16 pagineComplete Outline SpecificationsChoco MartiniNessuna valutazione finora

- Sample General SpecificationsDocumento4 pagineSample General SpecificationsRoshiel LargadoNessuna valutazione finora

- DIV 4 Masonry PDFDocumento12 pagineDIV 4 Masonry PDFMa Monica M. MuncadaNessuna valutazione finora

- Specification of Proposed Three Storey ApartmentDocumento7 pagineSpecification of Proposed Three Storey ApartmentJennifer AndalionNessuna valutazione finora

- Construction SpecificationDocumento9 pagineConstruction SpecificationYeth SantosNessuna valutazione finora

- Technical Specfications - Elsa AbenojaDocumento7 pagineTechnical Specfications - Elsa AbenojaCattleya PenalosaNessuna valutazione finora

- Construction Specifications LongDocumento7 pagineConstruction Specifications LongLimar SetatraNessuna valutazione finora

- Proposed Interior Fit-Out for Department of Tourism ShowroomDocumento4 pagineProposed Interior Fit-Out for Department of Tourism ShowroomJo BompatNessuna valutazione finora

- Specifications: Proposed Two-Storey Residential Building SpecificationDocumento5 pagineSpecifications: Proposed Two-Storey Residential Building SpecificationKarl Belleza100% (1)

- Construction ProcessDocumento8 pagineConstruction ProcessLa BeamNessuna valutazione finora

- Sample Construction SpecificationsDocumento12 pagineSample Construction SpecificationsCreativity is meNessuna valutazione finora

- AGUIMODDocumento1 paginaAGUIMODAlemar Soriano MalintadNessuna valutazione finora

- Building Specs (Jabilles)Documento3 pagineBuilding Specs (Jabilles)Alemar Soriano MalintadNessuna valutazione finora

- Brownies: Ingredient ChecklistDocumento3 pagineBrownies: Ingredient ChecklistAlemar Soriano MalintadNessuna valutazione finora

- Left and Right Side Views of Panel BoardDocumento1 paginaLeft and Right Side Views of Panel BoardAlemar Soriano MalintadNessuna valutazione finora

- FLOOR PLAN-Layout1 PDFDocumento1 paginaFLOOR PLAN-Layout1 PDFAlemar Soriano MalintadNessuna valutazione finora

- EstimateDocumento1 paginaEstimateAlemar Soriano MalintadNessuna valutazione finora

- Asm EstimateDocumento33 pagineAsm EstimateAlemar Soriano MalintadNessuna valutazione finora

- Building Specs (Jabilles)Documento3 pagineBuilding Specs (Jabilles)Alemar Soriano MalintadNessuna valutazione finora

- Cookies Description: Spoon & LeveledDocumento2 pagineCookies Description: Spoon & LeveledAlemar Soriano MalintadNessuna valutazione finora

- Fine CollectorDocumento1 paginaFine CollectorAlemar Soriano MalintadNessuna valutazione finora

- WPNEW Layout1Documento1 paginaWPNEW Layout1Alemar Soriano MalintadNessuna valutazione finora

- WPNEW Layout1 PDFDocumento1 paginaWPNEW Layout1 PDFAlemar Soriano MalintadNessuna valutazione finora

- The Effects of Korean Pop Culture among Education StudentsDocumento15 pagineThe Effects of Korean Pop Culture among Education StudentsAlemar Soriano MalintadNessuna valutazione finora

- Kilosang Kabataan Task FourceDocumento23 pagineKilosang Kabataan Task FourceAlemar Soriano MalintadNessuna valutazione finora

- @practical Guide To Electrical Grounding, 1st Edition, 1999Documento131 pagine@practical Guide To Electrical Grounding, 1st Edition, 1999cyong7788100% (15)

- Discoveries of early chemistsDocumento5 pagineDiscoveries of early chemistsAlemar Soriano MalintadNessuna valutazione finora

- Boracay's award-winning beaches and world-class relaxationDocumento8 pagineBoracay's award-winning beaches and world-class relaxationAlemar Soriano MalintadNessuna valutazione finora

- Problem 02Documento2 pagineProblem 02Mohammad Asgar Mangulamas GuialilNessuna valutazione finora

- NSPE Code of EthicsDocumento2 pagineNSPE Code of EthicsRizka WidyariniNessuna valutazione finora

- Presentation 1Documento9 paginePresentation 1Alemar Soriano MalintadNessuna valutazione finora

- DK Children Nature S Deadliest Creatures Visual Encyclopedia PDFDocumento210 pagineDK Children Nature S Deadliest Creatures Visual Encyclopedia PDFThu Hà100% (6)

- SOR 8th Ed 2013Documento467 pagineSOR 8th Ed 2013Durgesh Govil100% (3)

- Drugs Pharmacy BooksList2011 UBPStDocumento10 pagineDrugs Pharmacy BooksList2011 UBPStdepardieu1973Nessuna valutazione finora

- CANAL (T) Canal Soth FloridaDocumento115 pagineCANAL (T) Canal Soth FloridaMIKHA2014Nessuna valutazione finora

- Canon imageFORMULA DR-X10CDocumento208 pagineCanon imageFORMULA DR-X10CYury KobzarNessuna valutazione finora

- ProtectionDocumento160 pagineProtectionSuthep NgamlertleeNessuna valutazione finora

- BCP-8000 User's ManualDocumento36 pagineBCP-8000 User's ManualAsad PatelNessuna valutazione finora

- BMW Motronic CodesDocumento6 pagineBMW Motronic CodesxLibelle100% (3)

- Reiki BrochureDocumento2 pagineReiki BrochureShikha AgarwalNessuna valutazione finora

- Cs8791 Cloud Computing Unit2 NotesDocumento37 pagineCs8791 Cloud Computing Unit2 NotesTeju MelapattuNessuna valutazione finora

- Innovative Food Science and Emerging TechnologiesDocumento6 pagineInnovative Food Science and Emerging TechnologiesAnyelo MurilloNessuna valutazione finora

- IEQ CompleteDocumento19 pagineIEQ Completeharshal patilNessuna valutazione finora

- Material and Energy Balance: PN Husna Binti ZulkiflyDocumento108 pagineMaterial and Energy Balance: PN Husna Binti ZulkiflyFiras 01Nessuna valutazione finora

- A Study On Customer Satisfaction Towards Honda Bikes in CoimbatoreDocumento43 pagineA Study On Customer Satisfaction Towards Honda Bikes in Coimbatorenkputhoor62% (13)

- Answer Key p2 p1Documento95 pagineAnswer Key p2 p1Nafisa AliNessuna valutazione finora

- Motor GraderDocumento24 pagineMotor GraderRafael OtuboguatiaNessuna valutazione finora

- Pharmacokinetics and Drug EffectsDocumento11 paginePharmacokinetics and Drug Effectsmanilyn dacoNessuna valutazione finora

- An Online ECG QRS Detection TechniqueDocumento6 pagineAn Online ECG QRS Detection TechniqueIDESNessuna valutazione finora

- Maureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichDocumento20 pagineMaureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichAni LupascuNessuna valutazione finora

- Chap 2 Debussy - LifejacketsDocumento7 pagineChap 2 Debussy - LifejacketsMc LiviuNessuna valutazione finora

- Smart Note Taker Saves Time With Air WritingDocumento17 pagineSmart Note Taker Saves Time With Air WritingNagarjuna LokkuNessuna valutazione finora

- Naukri LalitaSharma (3y 4m)Documento2 pagineNaukri LalitaSharma (3y 4m)rashika asraniNessuna valutazione finora

- Handouts For TLG 3 1Documento5 pagineHandouts For TLG 3 1Daniela CapisnonNessuna valutazione finora

- Reflection 2: WHAT DOES It Mean To Be A Pacific Islander Today and in The Future To Me?Documento5 pagineReflection 2: WHAT DOES It Mean To Be A Pacific Islander Today and in The Future To Me?Trishika NamrataNessuna valutazione finora

- Smart Grid Standards GuideDocumento11 pagineSmart Grid Standards GuideKeyboardMan19600% (1)

- The Art of Now: Six Steps To Living in The MomentDocumento5 pagineThe Art of Now: Six Steps To Living in The MomentGiovanni AlloccaNessuna valutazione finora

- 1"a Study On Employee Retention in Amara Raja Power Systems LTDDocumento81 pagine1"a Study On Employee Retention in Amara Raja Power Systems LTDJerome Samuel100% (1)

- Swami Rama's demonstration of voluntary control over autonomic functionsDocumento17 pagineSwami Rama's demonstration of voluntary control over autonomic functionsyunjana100% (1)

- Advanced Ultrasonic Flaw Detectors With Phased Array ImagingDocumento16 pagineAdvanced Ultrasonic Flaw Detectors With Phased Array ImagingDebye101Nessuna valutazione finora

- WOOD Investor Presentation 3Q21Documento65 pagineWOOD Investor Presentation 3Q21Koko HadiwanaNessuna valutazione finora

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (241)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- Building Construction Technology: A Useful Guide - Part 2Da EverandBuilding Construction Technology: A Useful Guide - Part 2Valutazione: 5 su 5 stelle5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (137)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Summary of Neil Postman's Amusing Ourselves to DeathDa EverandSummary of Neil Postman's Amusing Ourselves to DeathValutazione: 4 su 5 stelle4/5 (2)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- An Architect's Guide to Construction: Tales from the Trenches Book 1Da EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Nessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDa EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsValutazione: 4.5 su 5 stelle4.5/5 (6)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- Civil Engineer's Handbook of Professional PracticeDa EverandCivil Engineer's Handbook of Professional PracticeValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Building Construction Technology: A Useful Guide - Part 1Da EverandBuilding Construction Technology: A Useful Guide - Part 1Valutazione: 4 su 5 stelle4/5 (3)

- Cable Supported Bridges: Concept and DesignDa EverandCable Supported Bridges: Concept and DesignValutazione: 5 su 5 stelle5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDa EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseValutazione: 5 su 5 stelle5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansValutazione: 4.5 su 5 stelle4.5/5 (21)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDa EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNessuna valutazione finora