Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TSS, TDS and TS of Effluents From Potassium Hydroxide and Calcium Hypochlorite Bleaching

Caricato da

Anonymous CwJeBCAXpTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TSS, TDS and TS of Effluents From Potassium Hydroxide and Calcium Hypochlorite Bleaching

Caricato da

Anonymous CwJeBCAXpCopyright:

Formati disponibili

Scholarly Research Journal for Interdisciplinary Studies,

Online ISSN 2278-8808, SJIF 2019 = 6.380, www.srjis.com

PEER REVIEWED & REFEREED JOURNAL, MAR-APR, 2020, VOL- 7/58

TSS, TDS AND TS OF EFFLUENTS FROM POTASSIUM HYDROXIDE AND

CALCIUM HYPOCHLORITE BLEACHING

Chukwudebelu, J.A.1 & Agunwamba, J.C.2

1

Chief Research Officer, Department of Chemical, Fibre& Environmental Technology,

Federal Institute of Industrial Research, Oshodi, Lagos- Nigeria

2

Professor, Department of Civil Engineering, University of Nigeria Nsukka, Enugu-Nigeria

Abstract

The use of different raw materials and chemicals by pulp and paper industries during pulp and paper

production has contributed immensely to the pollution load on the environment. This research used

TCF (KOH) and Hypochlorite (CaCIO)2 to bleach pulped agricultural residue (kenaf stem) to

determine one with better environmental parameters. The dewatered kenaf was pulped with different

concentrations of sodium hydroxide and formic acid at different time intervals. At the end, the pulp

from each cooking was bleached with 20%, 60% and 90% concentrations of potassium hydroxide and

calcium hypochlorite and the bleaching time were varied from 1hr, 2 hrs and 3 hrs at room

temperature and TSS, TDS and TS of the bleaching effluents were compare for environmental quality.

From physical pulp quality, 60% concentration and 2 hrs bleaching was selected and the effluent

from that gave TSS 507.5 mg/L, TDS 2341.5 mg/l and TS 2849 mg/L for KOH and TSS 4492.5 mg/L,

TDS 3707.5 mg/L and TS 8200 mg/L for Ca(CIO)2. This result showed that the effluent from KOH

bleaching has lower pollution load.

Keywords: Total dissolved solid, Calcium hypochlorite, Bleaching, Kenaf pulp, Environmental

quality.

Scholarly Research Journal's is licensed Based on a work at www.srjis.com

INTRODUCTION

Water is one of the essential requirements for life. Our water resources are depleting at an

alarming rate due to increasing population. Industries play a major role in water pollution,

Pulp and paper industry is considered as one of the most polluting industry due to the

compounds they release into the environment (Baharet al,. 2015). These compounds increase

the toxicity of effluent substances as well as Chemical Oxygen Demand (COD), Biological

Oxygen Demand (BOD) and Total Dissolved Solids (TDS) of the receiving aquatic

resources, which consequently imbalances the aquatic life (Singh and Chandra, 2019). The

most significant sources of pollution among various processing stages are wood preparation,

pulping, pulp washing, screening and bleaching (Akan,2008). Among various processes,

chemical pulping generates high amount of waste water.

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13764

Nowadays, bleaching of chemical pulps is achieved by two processes, i.e., the elemental

chlorine-free (ECF) process and/or the total chlorine-free (TCF) one, in which bleaching is

carried out essentially by using oxygen compounds (El-Sakhawy et al,. 1996). Which concept

is preferred depends mainly on the desired final brightness of the pulp to be bleached, its

properties, capital costs of bleaching chemicals, and concentration of chlorine-containing

components in the effluent (Otůček and Říhová, 2016).

In countries with limited forest resources, the use of agricultural residues for pulp

manufacturing offers a possibility to solve the lack of wood and also using totally chlorine-

free bleaching will be a win-win for the environment (El-Sakhawy et al,. 1996).

Bleaching is engaged on the brown pulp obtained after pulping in order to meet the desired

colour dictated by product standards(Parker et al,. 1990). Bleaching is a sequence of chemical

treatments and washes of the pulp. The bleaching of pulp generates wastes. A substantial part

of the waste is in liquid form. This effluent arises from the washing of pulp between some

bleaching stages. It contains spent bleaching chemicals, degraded lignin, and other substances

(Parker et al,. 1990). The particular sequence used mainly depends on the nature of the fibre

(for example, softwood, hardwood, or non-wood), the type of pulping process applied, and

the end use of the fibre. Regardless of the method of bleaching, the effluent may have certain

characteristics which can damage the environment, such as suspended and dissolved solids

and the capacity to deplete oxygen from the receiving waters (Parker et al,. 1990). Pulp and

paper mills can take measures to reduce the formation of organochlorines, organic materials,

heavy metals, suspended solids, and other potential pollutants in their bleaching wastes by

modifying bleaching processes as well as the use of total chlorine free chemicals (Parker et

al,. 1990.

Several bleaching agents, including chlorine, chlorine dioxide, hydrogen peroxide, oxygen,

ozone, etc. may be used either singly or in combination. It is in this step that lignin, phenols,

resin acids, etc. get chlorinated and transformed into highly toxic xenobiotics(Kaizar and

Norli,2015).

Bleaching of pulp using conventional methods releases a range of pollutants, including

organic products that have affected the water bodies and also the aquatic fauna as well as

livelihood of the surrounding communities.Up to 85% of the total effluent volume is

generated in the bleaching stage. The degree of delignification of the unbleached pulp, the

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13765

bleaching process, the washing loss, type of wood, final brightness desired, chemical and

water consumption and the degree of plant closure are important indicators of wastewater

characteristics (European Commission,2015 and Dalh,2008). The two main types of

bleaching methods in use are elemental chlorine free (ECF), when no molecular or gaseous

chlorine is dosed in the bleaching, and totally chlorine free (TCF) bleaching ( European

Commission. 2015). Owing to the differences between both the bleaching technologies and

chemical composition of the bleaching effluents, it is necessary to study in order to predict

and understand the environmental impact associated, and consequently to develop the most

suitable treatment that decreases effluent loads and toxicity(María,2017)

Effluent quality is commonly judged on the basis of such aggregate characteristics as

biochemical oxygen demand, chemical oxygen demand, total suspended solids (TSS), total

solids (TS), total dissolved solids (TDS) turbidity, pH, color e.t.c. Total suspended solid

(TSS) represents the solid particles mixed in water or effluent. Total dissolved solids (TDS)

are measured as the mass of residue remaining when a measured volume of filtered water is

evaporated. Total solids (TS) are the amount of solid present in dissolved and suspended

form.

A significant number of studies pertaining to the chemical composition of bleaching effluents

have been published. Several authors have worked inidentifying the chemical compounds in

filtrates. More than 500 organic compounds have beenidentified in bleaching effluents so far.

Most compounds identified in bleaching effluents are derived from lignin or other wood

components, such as extractives or carbohydrates (Kague and Carlberg, 1996).

Lignin is an organic material. The lignin that remains after chemical pulping is

oxidised in the case of chlorine bleaching process. The effluent from the process contains a

range of organochlorines. Some organochlorines break down quickly; and some, including

dioxins and furans, have long lives.Organochlorines may be largely removed by treatment of

effluent at the pulp mill, but it is not currently feasible to avoid discharging some into the

environment with the effluent. Some organochlorines can also remain embedded in the pulp

and, ultimately, in the paper products (Parker et al,. 1990). The effects of organochlorine

discharges on people and on natural ecological systems are not fully understood or quantified.

In this paper, soda and formic acid cooked pulps fromkenaf stemwere subjected to single

stage bleaching with potassium hydroxide and calcium hypochlorite under laboratory

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13766

conditions to check the effects of chemicals, concentrations and time on the effluent quality

with respect to solids.

MATERIALS AND METHODS

Kenaf stem was manually chopped into 1 to 4 cm long, washed with warm water to remove dirt and

dust. The washed kenaf was dewatered to a solid content of 40% to 45%. The dewatered

Kenaf was pulped with different concentrations of sodium hydroxide and formic acid at different time

intervals. At the end, the pulp from each cooking was bleached with 20%, 60% and

90% concentrations of potassium hydroxide and calcium hypochlorite and the bleaching time were

varied from 1hr, 2 hrs and 3 hrs at room temperature. At the end of each bleaching, the sample was

filtered with a fine mesh sieve of size 0.027 to get the effluent used in the analyses. The tests were

carried out in triplicate and each value is an average of three samples.

The effluent was analysed using the Standard Method for Examination of Water and Wastewater

(APHA, 2005). The parameters determined were TSS, TDS and TS.

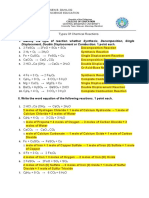

Kenaf stem Bleached pulp Bleaching effluent

Figure1. Samples of experimental materials

RESULTS AND DISCUSSION

Table 1: Effluent from-bleaching with 10g KOH-H2O2 and Ca (CIO)2 at 20%

Time(Hrs) Chemicals/Parameters TDS(mg/L) TSS(mg/L) TS(mg/L)

1 KOH 8726.5 367.5 9094

Ca(CIO)2 4170.2 3832 8002.2

2 KOH 7477 360 7837

Ca(CIO) 2 6770 1105 7875

3 KOH 4608 330 4938

Ca(CIO) 2 5564.5 473 6037.5

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13767

The pulps obtained from 1hr, 2hrs and 3hrs bleaching with 20%, 60% and 90%

concentrationswere examined physically and the pulp bleached with 60% concentration for 2

hrs gave the best. Table 1 showed the values of TSS, TDS and TS of the effluent when the

pulp was bleached with 20% concentration of potassium hydroxide and calcium hypochlorite

at 1, 2 and 3 h intervals. The result showed that with potassium hydroxide (KOH-H202), TSS

decreased from 367.5 mg/L to 330mg/L as the time of bleaching increased which was not so

significantly. This suggests that solid in the KOH solution was not degraded much with time

and concentration. With Hypochlorite (Ca(CIO)2), TSS values decreased significantly from

3832 g/L to 473 mg/L as the time of bleaching increased. From the study, TDS showed a

decrease in value with increase in bleaching time in KOH bleaching effluent while TDS

values increased with increase in bleaching time in Ca(CIO)2 bleached effluent. TS values

reflected the outcome of TSS and TDS for the two chemicals with results that showed

reduction in values as the bleaching time increased. This may be indicative that chemicals

and raw materials react differently.

Table 2: Effluent from bleaching with 10g KOH-H2O2 and Ca(CIO)2 at 60%

Time(Hrs) Chemicals/Parameters TDS(mg/L) TSS(mg/L) TS(mg/L)

1 KOH 2768 820 3588

Ca(CIO) 2 5275 5090 10365

2 KOH 2341.5 507.5 2849

Ca(CIO) 2 3707.5 4492.5 8200

3 KOH 1553 490 2043

Ca(CIO) 2 291.5 3037.5 3329

In table 2, values of TSS, TDS and TS of effluent obtained from bleaching of kenaf pulp at

1h, 2hrs and 3hrs time interval at 60% concentration of KOH and (Ca(CIO)2) was provided.

The result showed that the whole solids showed decrease in values as the time of bleaching

increased, this suggest that more organic matter was degraded with time. Most reduction was

observed in the values of TDS in Ca(CIO)2 bleaching that reduced from 5275 mg/L to 291.5

mg/L during the 3 hrs period. The highest values were obtained for TDS, TSS and TS from 1

hr bleaching with Ca(CIO)2 bleaching effluent having higher solid values than KOH effluent.

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13768

Table 3:Effluent from bleaching with 10g KOH-H2O2 and Ca(CIO)2 at 90%

Time(Hrs) Chemicals/Parameters TDS(mg/L) TSS(mg/L) TS(mg/L)

1 KOH 2602 1970 4572

Ca(CIO) 2 14522.5 4162.5 18685

2 KOH 2163.5 837.5 3001

Ca(CIO) 2 13446 3961 17407

3 KOH 998.5 537.5 1536

Ca(CIO) 2 13092.5 1887.5 14980

*Each value is an average of three samples.

From table 3 which recorded the values of 90% bleaching, the result showed reduction in

values of the solids as the bleaching time increased. This followed the same pattern with 20%

and 60% with the highest reduction being observed in the values of TSS that reduced from

1970 mg/L to 537.5 mg/L during the 3 hrtime of bleaching. This is similar with the result

reported by Nagdhi et al (2013) in which a value of 1800mg/L was obtained for TSS.

The TS of the three concentrations at the 3 hr periods followed the pattern of the TSS and

TDS and decreased as the bleaching time increased. The highest TS (18685 mg/L) was

reportedin the Ca(CIO)2 effluent after 1 hr bleaching with 90% concentration while KOH

effluent from 3 hr bleaching at 90% gave the lowest value (1536 mg/L). This may be due to

the reactions between the chemicals and the raw materials that determined the distribution of

the solids.Nagdhi et al (2013) and Kesalkar et al, (2012) reported 3000mg/L and between

1365 – 1798mg/L respectively for TS.

All the concentrations with the two chemicals have their maximum TSS, TDS and TS after 1

hr and minimum after 3 hr bleaching which suggest that more organic matter was degraded

with time.Higher values of TDS observed across the bleaching periods with different

concentrations may be due to the high concentration of sodium and potassium which can

cause increase in salinity of the wastewater (Chandra et al,. 2020). But generally, higher

values of solids were reported from Ca(CIO)2 bleaching effluentthan that of KOH effluent in

all the processes.

This study investigated TSS, TDS and TS in the KOH and Ca(CIO)2 bleaching effluentto

determine their environmental quality. Solids are contaminants in an effluent and their high

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13769

value poses danger of pollution to the environment. In Nigeria, the standard set by the

regulatory body (FEPA, 1991) put the maximum limit to be discharged to the environment

for total dissolved solid is 2000 mg/L, total suspended solid is 30 mg/L while total solid is

2030 mg/L.

Table 4: Mean and SE of TSS (mg/l) over the concentrations, time and chemicals for

Bleaching

Concentration Time Chemical Mean + SE

Ca(CIO)2 3832 + 3430.88a

1 Hour

KOH 7837 + 3430.88a

a

Ca(CIO)2 1105 + 3430.88a

20% 2 Hours

KOH 9094 + 3430.88b

Ca(CIO)2 473 + 3430.88a

3 Hours

KOH 936 + 3430.88a

Ca(CIO)2 14980 + 3430.88a

1 Hour

KOH 3588 + 3430.88b

b

Ca(CIO)2 17407 + 3430.88a

60% 2 Hours

KOH 2849 + 3430.88b

Ca(CIO)2 10365 + 3430.88a

3 Hours

KOH 2043 + 3430.88b

Ca(CIO)2 18685 + 3430.88a

1 Hour

KOH 1221 + 3430.88b

ab

Ca(CIO)2 8200 + 3430.88a

90% 2 Hours

KOH 536 + 3430.88b

Ca(CIO)2 3329 + 3430.88a

3 Hours

KOH 4572 + 3430.88b

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13770

Table 5: ANOVA Table

Source Sum of Squares df Mean Square F Sig.

Chemical 232054444.444 1 232054444.444 9.857 .006

Time 137025850.889 2 68512925.444 2.910 .080

Conc 130359500.222 2 65179750.111 2.769 .089

Chemical * Time 55919537.556 2 27959768.778 1.188 .328

Chemical * Conc 401358908.222 2 200679454.111 8.524 .002

Time * Conc 48529081.778 4 12132270.444 .515 .725

Chemical * Time * Conc 166987577.778 4 41746894.444 1.773 .178

Error 423753788.000 18 23541877.111

Corrected Total 1595988688.889 35

b. R Squared = .734 (Adjusted R Squared = .484)

The Anova table above shows that while all the factors are not significant, only chemical –

concentration interaction is significant (p < 0.05).

Table 6: Mean and SE of TS (mg/l) over the concentrations, time and chemicals for

bleaching

Concentration Time Chemical Mean + SE

Ca(CIO)2 360 + 2269.93a

1 Hour

KOH 12875 + 2269.93b

Ca(CIO)2 367.5 + 2269.93a

20%a 2 Hours

KOH 16252.5 + 2269.93b

Ca(CIO)2 330 + 2269.93a

3 Hours

KOH 6037.5 + 2269.93b

Ca(CIO)2 490 + 2269.93a

1 Hour

KOH 5090 + 2269.93b

Ca(CIO)2 820 + 2269.93a

60%b 2 Hours

KOH 4492.5 + 2269.93a

Ca(CIO)2 507.5 + 2269.93a

3 Hours

KOH 2037.5 + 2269.93a

Ca(CIO)2 537.5 + 2269.93a

1 Hour

KOH 572.5 + 2269.93a

Ca(CIO)2 837.5 + 2269.93a

90%b 2 Hours

KOH 562.5 + 2269.93a

Ca(CIO)2 1970 + 2269.93a

3 Hours

KOH 550 + 2269.93a

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13771

Table 7: ANOVA Table

Source Sum of Squares df Mean Square F Sig.

Chemical 198340277.778 1 198340277.778 19.247 .000

Time 25038179.167 2 12519089.583 1.215 .320

Conc 173646037.500 2 86823018.750 8.425 .003

Chemical * Time 34919926.389 2 17459963.194 1.694 .212

Chemical * Conc 222381776.389 2 111190888.194 10.790 .001

Time * Conc 36296145.833 4 9074036.458 .881 .495

Chemical * Time * Conc 24973431.944 4 6243357.986 .606 .663

Error 185493175.000 18 10305176.389

Corrected Total 901088950.000 35

R Squared = .794 (Adjusted R Squared = .600)

The table above shows that chemical, concentration and chemical – concentration interaction

were significant (p < 0.05) while the remainder were not.

Table 8: Mean ± Standard error of TDS(mg/L) of effluents from bleaching at different

percentage of chemicals/ parameters

Parameters 20 % 60% 90%

KOH 6937.17 ± 1219.16 2220.83 ± 355.89 1921.33 ± 478.47

Ca(CIO)2 5501.57 ± 751.16 3091.33 ± 1471.23 13687 ± 430.03

Table 9: Mean ± Standard error of TDS (mg/L) of effluents from bleaching at different time

of chemicals/ parameters

Parameters 1 hour 2 hours 3 hours

KOH 4698.83 ± 2014.4 3994 ± 1742.26 2386.5 ± 1122.22

Ca(CIO)2 7989.23 ± 3282.17 7974.5 ± 2875.05 6316.17 ± 3714.39

Table 10: ANOVA table

Type III Sum

Source of Squares df Mean Square F Sig.

Corrected Model 159682457.503a 5 31936491.501 2.335 0.106

Intercept 556419224.294 1 556419224.294 40.677 0.000

Concentration (%) 83422682.321 2 41711341.161 3.049 0.085

Time 13533428.354 2 6766714.177 0.495 0.622

Parameters 62726346.827 1 62726346.827 4.586 0.053

Error 164148467.493 12 13679038.958

Total 880250149.290 18

Corrected Total 323830924.996 17

a. R Squared = .493 (Adjusted R Squared = .282)

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13772

The ANOVA table showed no significant for the three factors but the interaction (intercept)

was significant (p < 0.05).

CONCLUSION

These two chemical bleaching processes (KOH and Ca(CIO) 2) were compared for

environmental quality with respect to solids. The method was bleaching with three different

concentrations for 1hr, 2hrs and 3 hrs intervals. The pulp bleached with 60% concentrations

of KOH and Ca(CIO)2 for 2 hrs gave better pulp on physical examination. The results of the

solids obtained from the analyses of the effluents from the 60% concentration for 2 hrs

bleaching showed that KOH process has fewer solids in its effluent. Though, the process did

not meet the effluent standard of Nigeria, but it is closer to it. From the statistical analysis,

mainly chemical-concentration interactions are significant (p > 0.05) while others are not.

There is need for further research into other effluent parameters for a robust conclusion.

Conflict of Interests

The authors have not declared any conflict of interests.

REFERENCES

Akan, J. (2008). Physicochemical determination of pollutants in waste water and vegetable

samples along the Jakara waste water channel in Kano Metropolis. European

Journal Scientific Research. pp 122-23.

Bahar, K.; Zeynep, C. and Etecioglu, O. (2015). Pollution prevention in the pulp and paper

industries. Institute of Environmental Science and Environmental Engineering,

Istanbul, Turkey.

Chandra, R.; Tripathi, S. and Sharma, P. (2020). Environmental Impacts of Pulp Paper Mill

Effluent: Potential Source of Chromosomal Aberration and Phytotoxicity.

International Journal of Applied Environmental Sciences ISSN 0973-6077 15(2) 77-

92.

Chukwudebelu, J.A. and Agunwamba, J.C. (2019).Characteristics of Effluent from

Potassium Hydroxide and Calcium Hypochlorite Bleaching of Pulp from Kenaf Stem.

SSRG International Journal of Agriculture & Environmental Science (SSRG-IJAES)

6, 6. ISSN: 2394 – 2568

Dahl, O. (2008). Process modifications to reduce effluent loads. In: Dahl O, editor.

Environmental management and control. 1st Ed. PaperijaPuuOy; Helsinki pp. 70–

84. ISBN: 978-952- 5216-30-1.

European Commission (2015). Joint Research Centre, Institute for Prospective

Technological Studies. Integrated Pollution and Prevention Control. Best Available

Techniques (BAT) reference document for the production of pulp, paper and board.

http://eippcb.jrc.ec.europa.eu/reference/BREF/PP_revised_BREF_2015.pdf.

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Chukwudebelu, J.A.& Agunwamba, J.C.

(Pg. 13763-13773) 13773

FEPA (1991). Guideline and Standard for Environmental Pollution Control in Federal

Environmental Protection Agency Act (Cap 131 LFN), National Environmental

Protection (Effluent Limitation) Regulation Official GazatteGovernment Publishing

Service Canberra.

Kague. M.; Carlberg, B. (1996). Effluent characteristics and composition. In: Dence C,

Reeve D, editors. Pulp bleaching-principles and practices. TAPPI Press; Atlanta-

GA; 1996, pp.751–65. ISBN:0-89852-063-0.

Kaizar, H. and Norli, I. (2015). Bioremediation and Detoxification of Pulp and Paper Mill

Effluent: A Review. Research Journal of Environmental Toxicology, 9: 113-134.

Kesalkar, V.; Khedikar, I.andSudame, A. (2012). Physico-chemical characteristics of

wastewater from Paper Industry. International Journal of Engineering Research and

Applications(IJERA).2(4)137-143.

M. El-Sakhawy, B. Lönnberg, Y. Fahmy and A. A. Ibrahim, Cellulose Chem. Technol., 30,

483 (1996).

María, N. (2017). Pulp Mill Wastewater: Characteristics and TreatmentUniversidad de la

República, Engineering School, Chemical Engineering Institute, Forest.

Naghdi, R. ;Karimi, A. ;Jahan, L.; Hamzeh. Y.; Mirshokraie. S andNadali, E. (2013).

Biological removal of chloro-organic compounds from bagasse soda pulp bleaching

effluent by Coriolusversicolor, Global NEST Journal, 15 (1) 29-36.

Parker, M.; Mauldon, R.and Chapman, D. (1990). Pulp and Paper: Bleaching and the

Environment. Overview and Findings Report No. 1 ISBN 0 644 12529 2 by

Australian.

Potůček, F. and Říhová, M. 2016 Elemental Chlorine-Free Bleaching of Soda Rapeseed

Pulp Cellulose Chemistry and Technology Journal.

Process Engineering, Montevideo, Uruguay.http://dx.doi.org/10.5772/67537.

Singh, A. and Chandra, R. (2019). Pollutants released from the pulp paper industry: Aquatic

toxicity and their health hazards. Aquatic Toxicology.pp.202-216.

Copyright © 2020, Scholarly Research Journal for Interdisciplinary Studies

Potrebbero piacerti anche

- Synthesis of Activated Carbon From Tree Sawdust and Its Usage For Diminution of Color and Cod of Paper-Mill EffluentsDocumento7 pagineSynthesis of Activated Carbon From Tree Sawdust and Its Usage For Diminution of Color and Cod of Paper-Mill EffluentsNagwa MansyNessuna valutazione finora

- Research Paper On Industrial Wastewater TreatmentDocumento8 pagineResearch Paper On Industrial Wastewater Treatmentm0d1p1fuwub2Nessuna valutazione finora

- COD ReductionDocumento12 pagineCOD ReductionS.Prabakaran S.PrabakaranNessuna valutazione finora

- Lawal 2017Documento26 pagineLawal 2017Yon tinyayaNessuna valutazione finora

- Ozone Pretreatment Optimization for Complex WastewaterDocumento9 pagineOzone Pretreatment Optimization for Complex WastewaterAnonymous aYmVPmdcLjNessuna valutazione finora

- Journal Paper-2013-Removal of Chlorophenolics From Pulp and PaperDocumento10 pagineJournal Paper-2013-Removal of Chlorophenolics From Pulp and PaperAlfi RohmanNessuna valutazione finora

- EffectofTCFand - JTropicalForestSci05Documento13 pagineEffectofTCFand - JTropicalForestSci05Kristian Yosef N. M.Nessuna valutazione finora

- 1 s2.0 S0301479719302312 MainDocumento7 pagine1 s2.0 S0301479719302312 MainmayaNessuna valutazione finora

- Comparison of Ozonation, Photolysis, Photocatalysis and Photoelectrocatalysis Methods For Wastewater DecolorizationDocumento8 pagineComparison of Ozonation, Photolysis, Photocatalysis and Photoelectrocatalysis Methods For Wastewater DecolorizationOllafNessuna valutazione finora

- Summary of ArticlesDocumento85 pagineSummary of ArticlesRay RayNessuna valutazione finora

- Electrooxidation and Subcritical Water Oxidation Hybrid Process For Pistachio Wastewater TreatmentDocumento23 pagineElectrooxidation and Subcritical Water Oxidation Hybrid Process For Pistachio Wastewater TreatmentFleur D'amitiéNessuna valutazione finora

- Journal of Environmental Management: Kanjana Chanworrawoot, Mali HunsomDocumento8 pagineJournal of Environmental Management: Kanjana Chanworrawoot, Mali Hunsomnavri_nalhadNessuna valutazione finora

- Pulp and PaperDocumento48 paginePulp and PaperDebaprakash NayakNessuna valutazione finora

- Photocatalytic Degradation of Congo Red Dye On Thermally Activated Zinc OxideDocumento13 paginePhotocatalytic Degradation of Congo Red Dye On Thermally Activated Zinc OxideAmin MojiriNessuna valutazione finora

- Archive of SID: Removal of Surfactant From Industrial Wastewaters by Coagulation Flocculation ProcessDocumento6 pagineArchive of SID: Removal of Surfactant From Industrial Wastewaters by Coagulation Flocculation ProcessrudymerchoNessuna valutazione finora

- Karamah 2019 J. Phys. Conf. Ser. 1198 062007Documento11 pagineKaramah 2019 J. Phys. Conf. Ser. 1198 062007Iqbal HalimNessuna valutazione finora

- 1 s2.0 S136403211830563X MainDocumento9 pagine1 s2.0 S136403211830563X MainNicole Forero SacristanNessuna valutazione finora

- Ultimate Biodegradability Potential of Trichloroethylene (TCE) Used As Degreaser in Marine, Brackish and Fresh WaterDocumento10 pagineUltimate Biodegradability Potential of Trichloroethylene (TCE) Used As Degreaser in Marine, Brackish and Fresh WaterIOSRjournalNessuna valutazione finora

- 10.1007@s11356 020 10613 6Documento12 pagine10.1007@s11356 020 10613 6Alexa RiveraNessuna valutazione finora

- Mam Report NewDocumento47 pagineMam Report NewAlps AnaNessuna valutazione finora

- Contribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Documento9 pagineContribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Van AlifNessuna valutazione finora

- COD Reduction in PTA Effluent with Coagulation, Oxidation & MembraneDocumento6 pagineCOD Reduction in PTA Effluent with Coagulation, Oxidation & MembraneBassam HameedNessuna valutazione finora

- Journal of Cleaner Production: Krit Sirirerkratana, Patiya Kemacheevakul, Surawut ChuangchoteDocumento8 pagineJournal of Cleaner Production: Krit Sirirerkratana, Patiya Kemacheevakul, Surawut ChuangchoteAngle JudieNessuna valutazione finora

- XRF Analysis of Heavy Metals in Oily Waste from Steel ProcessingDocumento9 pagineXRF Analysis of Heavy Metals in Oily Waste from Steel ProcessingUdrescu Andreea-IrinaNessuna valutazione finora

- Rang A Nathan 2007Documento10 pagineRang A Nathan 2007DerliantoDjanguNessuna valutazione finora

- GC/MS Analysis of Triclosan and Its Degradation By-Products in Wastewater and Sludge Samples From Different TreatmentsDocumento14 pagineGC/MS Analysis of Triclosan and Its Degradation By-Products in Wastewater and Sludge Samples From Different TreatmentsAjlaa RahimNessuna valutazione finora

- Treatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsDocumento8 pagineTreatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsIna ElenaNessuna valutazione finora

- Water: Treatment of Pulp and Paper Industrial E Physicochemical Process For RecyclingDocumento15 pagineWater: Treatment of Pulp and Paper Industrial E Physicochemical Process For RecyclingAchuNessuna valutazione finora

- 1 s2.0 S0045653519315206 MainDocumento7 pagine1 s2.0 S0045653519315206 MainMaría Fernanda Vallenas YrigoyenNessuna valutazione finora

- Best-Treatment of Highly Toxic Cardboard Plant Wastewater by A Combination of EC and EODocumento9 pagineBest-Treatment of Highly Toxic Cardboard Plant Wastewater by A Combination of EC and EOygNessuna valutazione finora

- T1PULP - Almira Jasmin - 03031381924095 - A - PLGDocumento19 pagineT1PULP - Almira Jasmin - 03031381924095 - A - PLGAlmira JasminNessuna valutazione finora

- Low 1996Documento15 pagineLow 1996Mark Le PetitNessuna valutazione finora

- Accepted ManuscriptDocumento32 pagineAccepted ManuscriptFarah El ShahawyNessuna valutazione finora

- Recent Developments of Textile Waste Water Treatment by Adsorption Process: A ReviewDocumento14 pagineRecent Developments of Textile Waste Water Treatment by Adsorption Process: A ReviewAmin MojiriNessuna valutazione finora

- 13 - Batch and Fixed-Bed Column Studies For The Biosorption of Cuii and Pbii by Raw and Treated Date Palm Leaves and Orange PeelDocumento15 pagine13 - Batch and Fixed-Bed Column Studies For The Biosorption of Cuii and Pbii by Raw and Treated Date Palm Leaves and Orange PeelArriane Faith EstoniloNessuna valutazione finora

- COD Reduction in Coffe Wastewater Through Flocculation An AOP PDFDocumento6 pagineCOD Reduction in Coffe Wastewater Through Flocculation An AOP PDFJesus SerranoNessuna valutazione finora

- Waste Management: Wei Zheng, Khamphe Phoungthong, Fan Lü, Li-Ming Shao, Pin-Jing HeDocumento9 pagineWaste Management: Wei Zheng, Khamphe Phoungthong, Fan Lü, Li-Ming Shao, Pin-Jing HeMir Hasib Ul LatifNessuna valutazione finora

- BambooDocumento8 pagineBambooCatastroNessuna valutazione finora

- Environmental Engineering Research PapersDocumento5 pagineEnvironmental Engineering Research Papersgvyztm2f100% (1)

- Aslim 12 PDFDocumento6 pagineAslim 12 PDFArif HidayatullahNessuna valutazione finora

- Organic Matter and Heavy Metals in Grey-Water Sludge: Rapid CommunicationDocumento4 pagineOrganic Matter and Heavy Metals in Grey-Water Sludge: Rapid CommunicationJuliansyah HarahapNessuna valutazione finora

- The Use of Activated Carbons For Removing OrganicDocumento10 pagineThe Use of Activated Carbons For Removing OrganicSiti HerlinaNessuna valutazione finora

- 2004 - Treatment-Of-Pulp-And-Paper-Mill-Wastewaterâ EURO - A-ReviewDocumento22 pagine2004 - Treatment-Of-Pulp-And-Paper-Mill-Wastewaterâ EURO - A-ReviewHoang Anh VuNessuna valutazione finora

- Brazilian Journal of Chemical Engineering study on decolorizing textile dye effluentDocumento7 pagineBrazilian Journal of Chemical Engineering study on decolorizing textile dye effluentJorge VecinoNessuna valutazione finora

- Niazmand Et Al. 2019Documento8 pagineNiazmand Et Al. 2019Tatiana Sainara Maia FernandesNessuna valutazione finora

- Ultrasonics Sonochemistry: Naresh N. Mahamuni, Yusuf G. AdewuyiDocumento14 pagineUltrasonics Sonochemistry: Naresh N. Mahamuni, Yusuf G. AdewuyiAnonymous 6tg80e6BqANessuna valutazione finora

- Review ArticleDocumento8 pagineReview ArticleAbida FarooqiNessuna valutazione finora

- Environmental Aspects ECF TCFDocumento3 pagineEnvironmental Aspects ECF TCFAgnes PardedeNessuna valutazione finora

- Bioremediatin YelypotrixDocumento5 pagineBioremediatin YelypotrixIrinaSalariNessuna valutazione finora

- Environmentally Benign Approaches for Pulp BleachingDa EverandEnvironmentally Benign Approaches for Pulp BleachingNessuna valutazione finora

- Alum Plus Ferric ZChlorideDocumento6 pagineAlum Plus Ferric ZChlorideFarhan TaseenNessuna valutazione finora

- Waste Management: Cátia Santos, João Fonseca, Alfredo Aires, João Coutinho, Henrique TrindadeDocumento11 pagineWaste Management: Cátia Santos, João Fonseca, Alfredo Aires, João Coutinho, Henrique TrindaderulyNessuna valutazione finora

- Ref-59 Preozonation and Prechlorination Effects On TOC Removal by Nanofiltration in Water TreatmentDocumento6 pagineRef-59 Preozonation and Prechlorination Effects On TOC Removal by Nanofiltration in Water TreatmentDanish JavedNessuna valutazione finora

- Textile Wastewater Treatment by Hybrid Advanced Oxidation ProcessesDocumento11 pagineTextile Wastewater Treatment by Hybrid Advanced Oxidation ProcessesCarolus OnikNessuna valutazione finora

- Printing Ink Wastewater Treatment Using ElectrocoagulationDocumento2 paginePrinting Ink Wastewater Treatment Using ElectrocoagulationBryan Alberto Cueva VásquezNessuna valutazione finora

- PeroxidoDocumento11 paginePeroxidoJorge VecinoNessuna valutazione finora

- Water Environment Research - 2018 - Deng - Textiles Wastewater TreatmentDocumento15 pagineWater Environment Research - 2018 - Deng - Textiles Wastewater TreatmentShirley ramosNessuna valutazione finora

- Comparative Account of Untreated and Treated Sago Effluent Analysis by Investigating Different Physical and Chemical ParametersDocumento4 pagineComparative Account of Untreated and Treated Sago Effluent Analysis by Investigating Different Physical and Chemical ParametersHadjer KermNessuna valutazione finora

- Enterobacter SP, Basic Red 9 PDFDocumento10 pagineEnterobacter SP, Basic Red 9 PDFANGELICA RAMOS RAMIREZNessuna valutazione finora

- A Comparative Treatment of Bleaching WasDocumento13 pagineA Comparative Treatment of Bleaching WasOscarNessuna valutazione finora

- 29.yuvraj SutarDocumento4 pagine29.yuvraj SutarAnonymous CwJeBCAXpNessuna valutazione finora

- 25.suresh ChenuDocumento9 pagine25.suresh ChenuAnonymous CwJeBCAXpNessuna valutazione finora

- Customers' Consciousness About Financial Cyber Frauds in Electronic Banking: An Indian Perspective With Special Reference To Mumbai CityDocumento13 pagineCustomers' Consciousness About Financial Cyber Frauds in Electronic Banking: An Indian Perspective With Special Reference To Mumbai CityAnonymous CwJeBCAXpNessuna valutazione finora

- Historical Development of Play Schools in IndiaDocumento11 pagineHistorical Development of Play Schools in IndiaAnonymous CwJeBCAXpNessuna valutazione finora

- 13.nasir RasheedDocumento9 pagine13.nasir RasheedAnonymous CwJeBCAXpNessuna valutazione finora

- Aggression Among Senior Secondary School Students in Relation To Their Residential BackgroundDocumento8 pagineAggression Among Senior Secondary School Students in Relation To Their Residential BackgroundAnonymous CwJeBCAXpNessuna valutazione finora

- 4.Dr Gagandeep KaurDocumento13 pagine4.Dr Gagandeep KaurAnonymous CwJeBCAXpNessuna valutazione finora

- Homesh RaniDocumento7 pagineHomesh RaniAnonymous CwJeBCAXpNessuna valutazione finora

- 19.Dr Ibrahim Aliyu ShehuDocumento29 pagine19.Dr Ibrahim Aliyu ShehuAnonymous CwJeBCAXpNessuna valutazione finora

- 1.prof. Ajay Kumar AttriDocumento8 pagine1.prof. Ajay Kumar AttriAnonymous CwJeBCAXpNessuna valutazione finora

- A Study of Effect of Age and Gender On Stress of AdolescentsDocumento5 pagineA Study of Effect of Age and Gender On Stress of AdolescentsAnonymous CwJeBCAXpNessuna valutazione finora

- Technostress, Computer Self-Efficacy and Perceived Organizational Support Among Secondary School Teachers: Difference in Type of School, Gender and AgeDocumento13 pagineTechnostress, Computer Self-Efficacy and Perceived Organizational Support Among Secondary School Teachers: Difference in Type of School, Gender and AgeAnonymous CwJeBCAXpNessuna valutazione finora

- A Lookout at Traditional Games Played by Tribes in IndiaDocumento4 pagineA Lookout at Traditional Games Played by Tribes in IndiaAnonymous CwJeBCAXpNessuna valutazione finora

- Effect of Life Skill Training On Mental Health Among B.ed. Interns in Relation To Their Impulsive BehaviourDocumento9 pagineEffect of Life Skill Training On Mental Health Among B.ed. Interns in Relation To Their Impulsive BehaviourAnonymous CwJeBCAXpNessuna valutazione finora

- Women Empowerment and Religion's Role in Gender Relations in KargilDocumento10 pagineWomen Empowerment and Religion's Role in Gender Relations in KargilAnonymous CwJeBCAXpNessuna valutazione finora

- The Use of English Language During PandemicDocumento7 pagineThe Use of English Language During PandemicAnonymous CwJeBCAXpNessuna valutazione finora

- 31 Dr. Suman Kumari, Prof. Sudarshana Rana & Ms. Anita VermaDocumento9 pagine31 Dr. Suman Kumari, Prof. Sudarshana Rana & Ms. Anita VermaAnonymous CwJeBCAXpNessuna valutazione finora

- The Need of Remote Voting Machine in Indian Voting SystemDocumento7 pagineThe Need of Remote Voting Machine in Indian Voting SystemAnonymous CwJeBCAXpNessuna valutazione finora

- 30 Trishala BhaskarDocumento7 pagine30 Trishala BhaskarAnonymous CwJeBCAXpNessuna valutazione finora

- 29 Balwinder SinghDocumento8 pagine29 Balwinder SinghAnonymous CwJeBCAXpNessuna valutazione finora

- 24 Adv Raj KumarDocumento5 pagine24 Adv Raj KumarAnonymous CwJeBCAXpNessuna valutazione finora

- 28 Shailaja KanwarDocumento12 pagine28 Shailaja KanwarAnonymous CwJeBCAXpNessuna valutazione finora

- 21 DR ReniDocumento6 pagine21 DR ReniAnonymous CwJeBCAXpNessuna valutazione finora

- 26 Dr. Reni Francis Mr. Rajendra DeshmukhDocumento5 pagine26 Dr. Reni Francis Mr. Rajendra DeshmukhAnonymous CwJeBCAXpNessuna valutazione finora

- 23 JayalakshmiDocumento9 pagine23 JayalakshmiAnonymous CwJeBCAXpNessuna valutazione finora

- Suyambukani VDocumento6 pagineSuyambukani VAnonymous CwJeBCAXpNessuna valutazione finora

- 25 AshaDocumento5 pagine25 AshaAnonymous CwJeBCAXpNessuna valutazione finora

- 22 Pavithra.g ArticleDocumento8 pagine22 Pavithra.g ArticleAnonymous CwJeBCAXpNessuna valutazione finora

- Deepa AnwarDocumento17 pagineDeepa AnwarAnonymous CwJeBCAXpNessuna valutazione finora

- Payal BhatiDocumento10 paginePayal BhatiAnonymous CwJeBCAXpNessuna valutazione finora

- AlloyDocumento100 pagineAlloywahyuNessuna valutazione finora

- 3 Alkyne Problem Set MOCDocumento13 pagine3 Alkyne Problem Set MOCMuhammad barakatNessuna valutazione finora

- Anju Ramakrishnan Thomas, Ajesh P. Suresh, Eringathodi Srinivasan, AlagarDocumento2 pagineAnju Ramakrishnan Thomas, Ajesh P. Suresh, Eringathodi Srinivasan, AlagarDavid OcampoNessuna valutazione finora

- Final Science 7 1ST Final ExamDocumento4 pagineFinal Science 7 1ST Final ExamrichardsamranoNessuna valutazione finora

- Metals and Alloys. Hume-Rothery RulesDocumento31 pagineMetals and Alloys. Hume-Rothery Rulesलेख् अर्याल्Nessuna valutazione finora

- Section 2: Structure and Written ExpressionDocumento6 pagineSection 2: Structure and Written ExpressionMalik RidwanNessuna valutazione finora

- Optimization of Natural Dye Extraction From Basella Alba Linn. (Alugbate) FRUITSDocumento35 pagineOptimization of Natural Dye Extraction From Basella Alba Linn. (Alugbate) FRUITSDante Jr. BitoonNessuna valutazione finora

- STP ChromatographyDocumento47 pagineSTP Chromatographymod002botNessuna valutazione finora

- DAHILOG Chemistry ACTIVITY by TAREDocumento2 pagineDAHILOG Chemistry ACTIVITY by TAREYbur Clieve Olsen DahilogNessuna valutazione finora

- Introduction and Scope of Anatomy and PhysiologyDocumento11 pagineIntroduction and Scope of Anatomy and PhysiologyPrathiNessuna valutazione finora

- Study On The Electro-Refining of Tin in Acid Solution From Electronic WasteDocumento4 pagineStudy On The Electro-Refining of Tin in Acid Solution From Electronic WasteadammplouhNessuna valutazione finora

- Test Bank For Microbiology A Systems Approach 6th Edition Marjorie Kelly Cowan Heidi SmithDocumento31 pagineTest Bank For Microbiology A Systems Approach 6th Edition Marjorie Kelly Cowan Heidi SmithAmandaReynoldsagfcy100% (23)

- Safety Assessment of Glycerin As Used in CosmeticsDocumento44 pagineSafety Assessment of Glycerin As Used in Cosmeticsanupamgupta112Nessuna valutazione finora

- Bioremediation of Heavy MetalsDocumento9 pagineBioremediation of Heavy MetalsshwetaNessuna valutazione finora

- Design of Storage Tanks for Lactic Acid ProductionDocumento30 pagineDesign of Storage Tanks for Lactic Acid ProductionPrabuddha GopeNessuna valutazione finora

- 2019 - Super Moisture-Absorbent Gels For All-Weather PDFDocumento7 pagine2019 - Super Moisture-Absorbent Gels For All-Weather PDFDanh TruongNessuna valutazione finora

- Periodni Sistem Elemenata-Crno BijeliDocumento1 paginaPeriodni Sistem Elemenata-Crno BijeliljubodragNessuna valutazione finora

- Chemical EquilibriaDocumento5 pagineChemical Equilibriaroku shinNessuna valutazione finora

- Properties and VOD of Common ExplosivesDocumento8 pagineProperties and VOD of Common ExplosivesbiaravankNessuna valutazione finora

- Lecture 3 Chemical ReactionsDocumento63 pagineLecture 3 Chemical ReactionsHiep NguyenNessuna valutazione finora

- Carbozinc 11 PDSDocumento2 pagineCarbozinc 11 PDSLim DongseopNessuna valutazione finora

- Carbohydrate and protein tests using lab proceduresDocumento13 pagineCarbohydrate and protein tests using lab proceduresCrist John Pastor0% (1)

- Economic Importance of AlgaeDocumento49 pagineEconomic Importance of Algaesantanu rana100% (1)

- Plant Nutrition and Soil Fertility Manual PDFDocumento296 paginePlant Nutrition and Soil Fertility Manual PDFDaniel Ion67% (3)

- Hydrometallurgy NotesDocumento96 pagineHydrometallurgy NotesTatenda SibandaNessuna valutazione finora

- A Modulated-TGA Approach To The Kinetics of Lignocellulosic BiomassDocumento10 pagineA Modulated-TGA Approach To The Kinetics of Lignocellulosic BiomassRicardoNessuna valutazione finora

- Liquid Phase Hydrogenation of Dimethyl Nitrobenzene Over Nickel CatalystsDocumento6 pagineLiquid Phase Hydrogenation of Dimethyl Nitrobenzene Over Nickel CatalystsIJARP PublicationsNessuna valutazione finora

- Bioethylene Production From Ethanol: A Review and Techno-Economical EvaluationDocumento18 pagineBioethylene Production From Ethanol: A Review and Techno-Economical EvaluationfadyahNessuna valutazione finora

- POC (Lab) - Activity 2 (Tests To Differentiate Organic From Inorganic)Documento2 paginePOC (Lab) - Activity 2 (Tests To Differentiate Organic From Inorganic)Sha ZaenudinNessuna valutazione finora

- Alcohol Oxidation NotesDocumento11 pagineAlcohol Oxidation Notesapi-281589298Nessuna valutazione finora