Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Crane Operations and Safety: Section 12

Caricato da

Khalid ZaeemTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Crane Operations and Safety: Section 12

Caricato da

Khalid ZaeemCopyright:

Formati disponibili

Section 12

Crane Operations and Safety

Table of Contents

Introduction ........................................................................................................................................12-3

Requirements......................................................................................................................................12-3

Post Job – Cems Maintenance Checklist .............................................................................................12-7

Truck:..........................................................................................................................................12-7

Crane:..........................................................................................................................................12-7

Test Your Knowledge .........................................................................................................................12-8

Halliburton 12 • 1 Coiled Tubing Essentials

© 2000, Halliburton

Crane Operators and Safety

Halliburton 12 • 2 Coiled Tubing Essentials

© 2000, Halliburton

Crane Operators and Safety

4. The relief valve installed on the crane control

Introduction console shall not be readjusted to a higher

setting.

Cranes are used to rig up and rig down coiled tubing 5. The control console shall have each control

units and they are often used to provide structural function identified and the direction of actuation

support for the unit. The crane is usually mounted to must be indicated (Refer to Halliburton

a trailer or truck frame. Stability of the crane is Equipment Design Verification SE-DV39 or

important to safe rig-up and operation of the unit. SE-DV-40).

Proper use of standardized hand signals between a 6. Before operating the crane, visually inspect the

signalman and the crane operator is important for entire crane for obvious defects. The inspection

safe operations. criteria are defined in SE-IM-39 and SE-IM-40.

The condition of the wire rope at the

Each land-based coiled tubing unit is equipped with a terminations, hooks, and shackles are especially

crane. The crane is used to place the equipment and critical.

to support the injector. The trailer or truck is

equipped with outriggers to provide stability when 7. Before moving the crane boom from the stowed

hoisting heavy loads. position, deploy the outriggers. Visually inspect

the outriggers for cracks and visible damage. The

All cranes are subject to certain regulatory outrigger jacks should be set on a mat or pad

requirements concerning operation, inspection, (timbers) to provide enhanced ground support.

repair, and maintenance. Halliburton SE-DV-39, SE- The outriggers should be adjusted to level the

DV-40, SE-IM-39, and SE-IM-40 outline inspection crane base.

and maintenance criteria for all hydraulic cranes.

Note: If the crane is not level, the accuracy of the

load chart is affected.

Requirements 8. After deploying the outriggers, test the crane for

leakdown by suspending a load (less than the

load chart rating) with the boom at an angle of

1. All cranes shall be maintained, repaired, and 30°. With all valves in the neutral position,

periodically inspect in accordance with verify that the suspended weight does not creep

Halliburton SE-DV-39, SE-DV-40, SE-IM-39, more than I in. over a period of 15 minutes.

and SE-DM-40. Weld repairs on major structural

Note: Ambient temperature changes may affect

components are prohibited unless performed by a

performance of the crane during the test.

qualified crane repair facility. The original crane

manufacturer and the Vessel Support Group are 9. When moving loads near the load chart limits,

qualified repair facilities. first make a trial lift at the desired distance

before hoisting the load over 2 ft high. This is to

2. The crane operator acting as signalman shall be

verify stability and avoid tipping over.

properly trained and licensed. Crew members

acting as signalmen must know universal hand 10. Before hoisting any load, verify that the proper

signals, crane operation, rigging procedures, hooks, lift bars, and slings are used (refer to the

crane maintenance, and other safety procedures. crane operating manuals).

3. The crane shall be equipped with an operable 11. Before using a crane to lift or move any object,

boom-angle indicator and a load chart showing the crane operator should appoint one person as

the maximum load rating as a function of the signalman.

distance from the crane centerline. Do not

operate the crane with load and distance 12. The signalman will communicate with the

operator by hand signals unless another means of

combinations that exceed the load chart.

communication is available, such as two-way

Note: The reach is the horizontal distance from the radio headsets or equivalent.

centerline of rotation of the bearing to the suspended

wire rope hook (not the near edge of the pedestal or 13. Should the crane operator lose contact with the

signalman, he will immediately stop any

suspended weight).

function in progress until contact is regained.

14. Other personnel should not signal the crane

operator except in an emergency. An emergency

Halliburton 12 • 3 Coiled Tubing Essentials

© 2000, Halliburton

Crane Operators and Safety

situation can be described as any time a Note: Do not stand or work under the crane boom or

movement of the load can result in foreseen the suspended load. Cranes are rated at the

personal injury or equipment damage. completely retracted and fully boomed up position.

When scoping out and/or booming down, the useable

15. Before leaving the job site, the crane boom lift capacity decreases (refer to angle/reach charts for

should be stored and secured in the transport lift capacity).

cradle. If the crane is equipped with road/bypass

valve(s), open the valve(s) so that the boom

cannot rise while being transported.

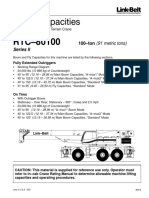

Fig 1: Standard service crane trailer

Halliburton 12 • 4 Coiled Tubing Essentials

© 2000, Halliburton

Crane Operations and Safety

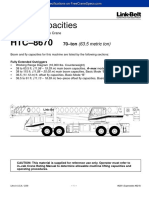

Fig 2: API - RP 2D- Standard hand signals.

12 • 5 Coiled Tubing Essentials

Halliburton

Crane Operations and Safety

Fig. 3: API - RP 2D- Standard hand signals continued.

12 • 6 Coiled Tubing Essentials

Halliburton

Crane Operations and Safety

Post Job – Cems Maintenance Checklist

(To be performed before every job)

Truck:

( ) Perform post job inspection and maintenance as per Halliburton document 223R4 and attach copy to checklist.

Crane:

( ) Check outriggers for secure installation and road trip.

( ) Check pedestal for secure installation for road trip.

( ) Check control valves to ensure levers operate freely and return to neutral.

( ) Verify load chart is correct and intended operator is familiar with load chart

( ) Verify Boom angle indicator is working properly

( ) Check hydraulic cylinders and winch motors for leaks

( ) Verify winch cable is not damaged and reeved correctly.

( ) Check load block for secure installation for road trip

12 • 7 Coiled Tubing Essentials

Halliburton

Crane Operations and Safety

Test Your Knowledge

Crane Operator and Safety

1. The crane is usually mounted to a ____________ or ____________ ____________.

2. What is important for safe operation? ____________ ____________ ____________.

3. The crane is used to place the ____________ and to support the ____________.

4. The purpose of the outriggers is to provide ____________ when lifting ____________ ____________.

5. If contact is lost between crane operator and signalman the crane operator must ____________ ____________

any function in progress.

12 • 8 Coiled Tubing Essentials

Halliburton

Potrebbero piacerti anche

- Mobile Crane Inspection GuidelinesDocumento11 pagineMobile Crane Inspection GuidelinesMohammed Atef0% (2)

- Overhead Crane Load Test ProceduresDocumento6 pagineOverhead Crane Load Test ProceduresMeritorious Khan100% (5)

- Ford Tractor Models 2000 3000 4000 and 5000 Operators Service Manual TextDocumento59 pagineFord Tractor Models 2000 3000 4000 and 5000 Operators Service Manual TextRicardo Quendera100% (2)

- CAT - C-10 (Prefix 2PN)Documento8 pagineCAT - C-10 (Prefix 2PN)Phil B.100% (2)

- Lifting Plan Checklist and Method Statement SkeletonDocumento7 pagineLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesNessuna valutazione finora

- Material Handling by CraneDocumento16 pagineMaterial Handling by Cranenitin369100% (1)

- Load Test ProcedureDocumento5 pagineLoad Test ProcedureAlzaki Abdullah83% (6)

- PS Form 3877 - Firm Mailing For Accountable MailDocumento1 paginaPS Form 3877 - Firm Mailing For Accountable MailLaLa Banks100% (1)

- Mechanical Tubing Cutters Review Outcome PDFDocumento2 pagineMechanical Tubing Cutters Review Outcome PDFKhalid ZaeemNessuna valutazione finora

- Lifting PlanDocumento66 pagineLifting Planklibi100% (6)

- E & M of E.O.T.Documento10 pagineE & M of E.O.T.bisweswar100% (1)

- Sand Management GuideDocumento3 pagineSand Management GuideKhalid ZaeemNessuna valutazione finora

- Transmission System: Pictures Produced With Kind PermissionDocumento23 pagineTransmission System: Pictures Produced With Kind PermissionABCDefNessuna valutazione finora

- Section 4 - Basic Hydraulics PDFDocumento25 pagineSection 4 - Basic Hydraulics PDFKhalid ZaeemNessuna valutazione finora

- Lifting Work PresantationDocumento30 pagineLifting Work PresantationIrfanadi PratomoNessuna valutazione finora

- Electric Overhead Traveling Crane Erection and Maintenance PDFDocumento10 pagineElectric Overhead Traveling Crane Erection and Maintenance PDFSalman KhanNessuna valutazione finora

- Construction SafetyDocumento30 pagineConstruction SafetyBharath CjNessuna valutazione finora

- Upper Mast Section Lifting PlanDocumento7 pagineUpper Mast Section Lifting PlanDurgham Adel EscanderNessuna valutazione finora

- Setting ToolDocumento41 pagineSetting ToolKhalid ZaeemNessuna valutazione finora

- Century t500 Parts 55145Documento482 pagineCentury t500 Parts 55145Luis OrellanaNessuna valutazione finora

- Risk Assessment - Use of Mobile Crane & Boom TruckDocumento3 pagineRisk Assessment - Use of Mobile Crane & Boom TruckSarfraz Randhawa100% (3)

- CranesDocumento80 pagineCranesjoenediath9345Nessuna valutazione finora

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerDa EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerValutazione: 5 su 5 stelle5/5 (1)

- KR Webinar For EEXI & CII - 210517Documento112 pagineKR Webinar For EEXI & CII - 210517PrinceSadhotraNessuna valutazione finora

- Safe Working Loads and Operating Conditions: 12.1 Mode of Operation and ControlDocumento21 pagineSafe Working Loads and Operating Conditions: 12.1 Mode of Operation and ControlBayu Arya SNessuna valutazione finora

- Cranes IntroductionDocumento55 pagineCranes Introductiondsn_sarmaNessuna valutazione finora

- Schiffer Military History - The Eight Ballers Eyes of The Fifth Air Force The 8th Photo Reconnaissance Squadron in World WarDocumento183 pagineSchiffer Military History - The Eight Ballers Eyes of The Fifth Air Force The 8th Photo Reconnaissance Squadron in World WarNickiedeposie100% (1)

- 1631617166934-EOT Maintenance PDFDocumento16 pagine1631617166934-EOT Maintenance PDFMohd Haidi100% (1)

- Volkswagen Lupo Fuse Box Diagram Fuse DiagramDocumento8 pagineVolkswagen Lupo Fuse Box Diagram Fuse DiagramAnderson MagnoNessuna valutazione finora

- Gas Lift ValvesDocumento9 pagineGas Lift ValvesKhalid Zaeem100% (1)

- Pengenalan CranesDocumento55 paginePengenalan CranesekoimampNessuna valutazione finora

- Use and Maintenance Manual EFFER 455 Part 2Documento192 pagineUse and Maintenance Manual EFFER 455 Part 2Nando nadando100% (3)

- Safe Use of CranesDocumento33 pagineSafe Use of Craneswasim Akram100% (1)

- Affidavit of Driver - AdalaDocumento1 paginaAffidavit of Driver - AdalaAreez Nur Ijin100% (1)

- Variable Speed Electric Chain Hoist: Operating, Maintenance & Parts ManualDocumento68 pagineVariable Speed Electric Chain Hoist: Operating, Maintenance & Parts ManualScottNessuna valutazione finora

- Depth Control PDFDocumento11 pagineDepth Control PDFKhalid Zaeem100% (1)

- PS64692 PDFDocumento2 paginePS64692 PDFKhalid ZaeemNessuna valutazione finora

- Engine Room CraneDocumento22 pagineEngine Room CraneNarendra KatdareNessuna valutazione finora

- Link Belt HTC 8660Documento8 pagineLink Belt HTC 8660Diana Gabriela VillaNessuna valutazione finora

- CICA Position Paper Articulated Crane Operator Requirements: Lifting Industry StandardsDocumento13 pagineCICA Position Paper Articulated Crane Operator Requirements: Lifting Industry StandardsReza fahliwiNessuna valutazione finora

- Fassi/f800 900XP 22Documento54 pagineFassi/f800 900XP 22Henrry Huarcaya BallonNessuna valutazione finora

- Overhead Crane Manual 10tonDocumento71 pagineOverhead Crane Manual 10tonBuddhika MarasinghaNessuna valutazione finora

- Services Quick Reference Guide: QRG-2021-02-26-revision - Indd 1Documento104 pagineServices Quick Reference Guide: QRG-2021-02-26-revision - Indd 1MahmoudNessuna valutazione finora

- CAT 3 Crane Course AnswersDocumento4 pagineCAT 3 Crane Course AnswersGlenn Howes100% (7)

- Link Belt Rough Terrain Cranes Spec 9d470bDocumento96 pagineLink Belt Rough Terrain Cranes Spec 9d470bMauro BatalhaNessuna valutazione finora

- ErectionDocumento16 pagineErectionÞÜšhpendra JAñgidNessuna valutazione finora

- Bridge and Gantry Cranes: Information SheetDocumento3 pagineBridge and Gantry Cranes: Information Sheetedn_mj1645Nessuna valutazione finora

- Camera Dollies and Crane SafetyDocumento2 pagineCamera Dollies and Crane SafetyflorelmagNessuna valutazione finora

- Hsbei 1412Documento2 pagineHsbei 1412Heru WibowoNessuna valutazione finora

- Information Sheet: Bridge and Gantry CranesDocumento3 pagineInformation Sheet: Bridge and Gantry CranesPaulo GomesNessuna valutazione finora

- Sany CranDocumento118 pagineSany Cransunthron somchaiNessuna valutazione finora

- CPA TCIG Safety Alert Cranes Out of and Back Into Service Rev 2 200514Documento3 pagineCPA TCIG Safety Alert Cranes Out of and Back Into Service Rev 2 200514NageswarNessuna valutazione finora

- On Site RTC 80130 R3K4-3399Documento308 pagineOn Site RTC 80130 R3K4-3399srikanthc85Nessuna valutazione finora

- TB 9 2330 381 14 1Documento108 pagineTB 9 2330 381 14 1pavannnNessuna valutazione finora

- TB 9 2330 381 14 1Documento107 pagineTB 9 2330 381 14 1Advocate100% (1)

- Qualified Rigger & Signal Person Training Program: Cornerstone Environmental Contractors, IncDocumento10 pagineQualified Rigger & Signal Person Training Program: Cornerstone Environmental Contractors, IncEric JamesNessuna valutazione finora

- Fassi Crane: Use and MaintenanceDocumento60 pagineFassi Crane: Use and Maintenanceניקולאי איןNessuna valutazione finora

- Lifting Capacities: Series IIDocumento28 pagineLifting Capacities: Series IIsrikanthc85Nessuna valutazione finora

- Assembly & OperationDocumento24 pagineAssembly & OperationANDREYNessuna valutazione finora

- RTC8040-SII Linkbelt CapsDocumento12 pagineRTC8040-SII Linkbelt CapsMongia MoghiNessuna valutazione finora

- Crane Safety InstructionsDocumento8 pagineCrane Safety InstructionsAnil kumarNessuna valutazione finora

- vYMeuoP5WRyc8NIv - Jltnw0O1UgbBz9sp-OSHA 10 Construction - Module 11 - Study GuideDocumento7 paginevYMeuoP5WRyc8NIv - Jltnw0O1UgbBz9sp-OSHA 10 Construction - Module 11 - Study GuideBelkacem BouazzaNessuna valutazione finora

- Porta GantryDocumento48 paginePorta GantrySyNessuna valutazione finora

- Employer Information: Crane Company DateDocumento3 pagineEmployer Information: Crane Company DatekaniniuserNessuna valutazione finora

- SRC400C Load Charts ManualDocumento20 pagineSRC400C Load Charts ManualLautaroNessuna valutazione finora

- Lta Gs (Lifting)Documento11 pagineLta Gs (Lifting)Chan NaingNessuna valutazione finora

- Ankaegybunpedvbjfassi F380a.24 Knuckleboom Crane NetworkDocumento66 pagineAnkaegybunpedvbjfassi F380a.24 Knuckleboom Crane NetworkEdgar GonzalezNessuna valutazione finora

- Care & Use Assembly Instructions: Gantry CranesDocumento12 pagineCare & Use Assembly Instructions: Gantry CranesThein MaungNessuna valutazione finora

- Slewing Jib Cranes SI 18.3Documento2 pagineSlewing Jib Cranes SI 18.3reda mesbahNessuna valutazione finora

- Link Belt HTC 8670 Charts PDFDocumento8 pagineLink Belt HTC 8670 Charts PDFJose MorenoNessuna valutazione finora

- International Regulations for Preventing Collisions at SeaDa EverandInternational Regulations for Preventing Collisions at SeaNessuna valutazione finora

- When To Use The Data Converter ObjectDocumento18 pagineWhen To Use The Data Converter ObjectKhalid ZaeemNessuna valutazione finora

- Packer SettingDocumento10 paginePacker SettingKhalid ZaeemNessuna valutazione finora

- TCP30234Documento1 paginaTCP30234Khalid ZaeemNessuna valutazione finora

- TCP30281Documento1 paginaTCP30281Khalid ZaeemNessuna valutazione finora

- Coiled Tubing I: Halliburton Energy Institute Duncan, OklahomaDocumento1 paginaCoiled Tubing I: Halliburton Energy Institute Duncan, OklahomaKhalid ZaeemNessuna valutazione finora

- TCP30227Documento1 paginaTCP30227Khalid ZaeemNessuna valutazione finora

- TCP30228Documento1 paginaTCP30228Khalid ZaeemNessuna valutazione finora

- PS41518Documento1 paginaPS41518Khalid ZaeemNessuna valutazione finora

- TRSCSSSV Check List Cemented CompletionDocumento4 pagineTRSCSSSV Check List Cemented CompletionKhalid ZaeemNessuna valutazione finora

- Coiled Tubing Technical Data: Section 18Documento10 pagineCoiled Tubing Technical Data: Section 18Khalid ZaeemNessuna valutazione finora

- Basic Bottomhole Assemblies (Bhas) : Section 13Documento10 pagineBasic Bottomhole Assemblies (Bhas) : Section 13Khalid ZaeemNessuna valutazione finora

- Round I Rules - WE & CWIDocumento2 pagineRound I Rules - WE & CWIKhalid ZaeemNessuna valutazione finora

- PS64666Documento2 paginePS64666Khalid ZaeemNessuna valutazione finora

- PS78541Documento1 paginaPS78541Khalid ZaeemNessuna valutazione finora

- PS78560Documento2 paginePS78560Khalid ZaeemNessuna valutazione finora

- 1.0 Boleum Profile 2022Documento63 pagine1.0 Boleum Profile 2022ikechukwu.otuyaNessuna valutazione finora

- Asking For and Giving Directions Using Adverbs of Worksheet Templates Layouts 97331Documento2 pagineAsking For and Giving Directions Using Adverbs of Worksheet Templates Layouts 97331ChrisGalarzaNessuna valutazione finora

- Pointers To Review Local TourDocumento8 paginePointers To Review Local Tourۦۦ ۦۦNessuna valutazione finora

- SMM7 6A External WorksDocumento15 pagineSMM7 6A External WorksChee HernNessuna valutazione finora

- LB95B 110B 115B (E31)Documento4 pagineLB95B 110B 115B (E31)Agro SipotNessuna valutazione finora

- 3 - Idt Af - BKMDocumento106 pagine3 - Idt Af - BKMVishnuNessuna valutazione finora

- Vehicle No. SMK4159M Has Been Successfully Transferred To YouDocumento4 pagineVehicle No. SMK4159M Has Been Successfully Transferred To YouKiran KumarNessuna valutazione finora

- Crimson Tide SummaryDocumento3 pagineCrimson Tide SummaryPragya AgarwalNessuna valutazione finora

- F - REF104804G - Brake & Inching ControlDocumento3 pagineF - REF104804G - Brake & Inching ControlJANONNessuna valutazione finora

- 18bcp111 - ProjectDocumento96 pagine18bcp111 - Project21BA040- Renuga ANessuna valutazione finora

- 3964 PDFDocumento356 pagine3964 PDFraviNessuna valutazione finora

- Direct: 40 Packed Pages of Releases!Documento21 pagineDirect: 40 Packed Pages of Releases!Alper Tunga SümertekinNessuna valutazione finora

- Jaso Equipos de Obras Y Construcciones, S.L.: Tower CraneDocumento4 pagineJaso Equipos de Obras Y Construcciones, S.L.: Tower CraneKoko PhellipeNessuna valutazione finora

- MDG-1009-free Steered VahiclesDocumento32 pagineMDG-1009-free Steered VahiclesPradhith KattaNessuna valutazione finora

- Power & Pride: CNH Industrial (India) Pvt. LTDDocumento2 paginePower & Pride: CNH Industrial (India) Pvt. LTDNayaGaadi DavangereNessuna valutazione finora

- Purvanchal Exp Third Ac (3A)Documento2 paginePurvanchal Exp Third Ac (3A)Techno PrasadNessuna valutazione finora

- 01 CR Id Locater AssyDocumento1 pagina01 CR Id Locater Assysiva dhamotharanNessuna valutazione finora

- Mewprescueplanss 190627074305 PDFDocumento13 pagineMewprescueplanss 190627074305 PDFVinoth SudalaiNessuna valutazione finora

- Scissor Lift Suri CheclistDocumento4 pagineScissor Lift Suri CheclistErnest Ngosa SawasawaNessuna valutazione finora

- D K Sanyal Marine Diesel EnginesDocumento253 pagineD K Sanyal Marine Diesel EnginesG SaiNessuna valutazione finora

- Listening BCDocumento251 pagineListening BCChu Thức100% (1)

- Haldex Air SuspDocumento8 pagineHaldex Air SuspVincent PriceNessuna valutazione finora