Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Section 8005: Removal and Installation of The Attachement Cylinders

Caricato da

Jefferson PaixãoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Section 8005: Removal and Installation of The Attachement Cylinders

Caricato da

Jefferson PaixãoCopyright:

Formati disponibili

Section

8005

REMOVAL AND INSTALLATION

8005

OF THE ATTACHEMENT CYLINDERS

Copyright © 2007 CNH America LLC.

All rights reserved.

CNH Lep SM160B8005-0NA Printed in USA.

May 2007

8005-2

TABLE OF CONTENTS

SPECIFICATIONS .......................................................................................................................................................... 2

PREPARATION BEFORE REMOVAL/INSTALLATION.................................................................................................. 2

BOOM CYLINDER .......................................................................................................................................................... 3

Description .................................................................................................................................................................. 3

Removal ...................................................................................................................................................................... 4

DIPPER CYLINDER........................................................................................................................................................ 7

Description .................................................................................................................................................................. 7

Removal ...................................................................................................................................................................... 8

BUCKET CYLINDER..................................................................................................................................................... 11

Description ................................................................................................................................................................ 11

Removal .................................................................................................................................................................... 12

SPECIFICATIONS

See Section 1002

PREPARATION BEFORE REMOVAL/INSTALLATION

- Park the machine on hard, flat ground.

- Completely retract the bucket and dipper cylinder rods and lower the attachment to the ground.

- Release pressure in the hydraulic system and install a vacuum pump on the hydraulic reservoir (see Section 8000).

Lep SM160B8005-0NA Issued 05-07

8005-3

BOOM CYLINDER

Description

3

1

4

5

6

10

9

2 5 8

1

9

5 3

2 7

6

11 10

JS00593B

1 LUBRICATING HOSE 7 WASHER

2 NUT 8 SCREW

3 SCREW 9 PIN

4 LOCKING BUSHING 10 BOOM CYLINDER

5 SHIM 11 PIN

6 HYDRAULIC HOSE

Lep SM160B8005-0NA Issued 05-07

8005-4

Removal STEP 4

STEP 1

Use a bar hammer (1) and the holding-up bar (2) to

push out the pin (3).

Attach a suitable lifting device (1) to the boom cylinder Start the engine to perform the boom-down operation at

(2). Take up all the slack to ensure the boom cylinder is idling rotation, and retract the rod of the boom cylinder.

fully supported before starting to remove the boom

cylinder. STEP 5

STEP 2

Remove hoses (1) and (2). To facilitate reassembly,

attach identification labels to all hoses, pipes and

electric wires. Use caps or plugs to cover the hoses

Remove the grease hose (1). Use caps or plugs to and pipes to prevent the entry of water, dust or dirt.

prevent the entry of water, dust or dirt. Clean the hoses and pipes by spraying with a parts

cleaner to prevent scratches and prevent dirt from

STEP 3 accumulating on the connectors.

STEP 6

Remove 2 lock nuts (1), pull out the bolt (2), and also Remove the lock bolt (1).

remove the securing ring (3).

Lep SM160B8005-0NA Issued 05-07

8005-5

STEP 7 STEP 9

(Only if the machine is equipped with cylinder

safety valves)

Use a pinch bar to remove the pin (1).

STEP 8

Remove the hoses (1), (2), (3) and (4). To facilitate

reassembly, attach identification labels to all hoses,

pipes and electric wires. Use caps or plugs to cover

HBCV and the pipes to prevent the entry of water, dust

or dirt. Clean each of HBCV and pipe connections by

spraying with a parts cleaner to prevent scratches and

prevent dirt from accumulating on the connectors.

STEP 10

Carefully raise the boom cylinder (1) and move it away

from the machine. Place the boom cylinder on suitable

stands.

NOTE: Lift the cylinder carefully. The cylinder is heavy,

the weight should be carefully distributed on the slings

when lifting.

Remove screws (1) and remove the pipe (2). Use caps

or plugs to cover HBCV and the pipes to prevent the

entry of water, dust or dirt. Clean each of HBCV and

pipe connections by spraying with a parts cleaner to

prevent scratches and prevent dirt from accumulating

on the connectors.

Lep SM160B8005-0NA Issued 05-07

8005-6

STEP 11 STEP 14

Remove screws (1) and remove the boom HBCV (2).

STEP 12 Remove screws (1) and remove the boom HBCV (2).

NOTE: When installing, proceed in the reverse order

from that of removal

Remove the hoses (1), (2), (3) and (4). Remove the

boom bottom sensor (5). To facilitate reassembly,

attach identification labels to all hoses, pipes and

electric wires. Use caps or plugs to cover HBCV and

the pipes to prevent the entry of water, dust or dirt.

Clean each of HBCV and pipe connections by spraying

with a parts cleaner to prevent scratches and prevent

dirt from accumulating on the connectors.

STEP 13

Remove screws (1) and remove the pipe (2). Use caps

or plugs to cover HBCV and the pipes to prevent the

entry of water, dust or dirt. Clean each of HBCV and

pipe connections by spraying with a parts cleaner to

prevent scratches and prevent dirt from accumulating

on the connectors.

Lep SM160B8005-0NA Issued 05-07

8005-7

DIPPER CYLINDER

Description

5 4 7

6

9

8

4

6

3

1

2

1

2

JS00603B

1 WASHER 6 O-RING

2 SCREW 7 O-RING

3 PIN 8 DIPPER CYLINDER

4 HYDRAULIC HOSE 9 SHIM

5 LUBRICATION HOSE

Lep SM160B8005-0NA Issued 05-07

8005-8

Removal STEP 4

STEP 1

Remove the hose (1) and (2). Use caps or plugs to

cover the hoses and pipes to prevent the entry of water,

dust or dirt. Clean the hoses and pipes by spraying with

Attach a suitable lifting device (1) to the dipper cylinder a parts cleaner to prevent scratches and prevent dirt

(2). Take up all the slack to ensure the dipper cylinder is from accumulating on the connectors.

fully supported before starting to remove the dipper

cylinder. STEP 5

STEP 2

Remove the grease hose (1).

Use a caps or plugs to prevent the entry of water, dust

Remove the lock bolt (1). or dirt.

STEP 3 STEP 6

Use a bar hammer (1) and the holding-up bar (2) to Remove the lock bolt (1).

push out the pin (3).

Lep SM160B8005-0NA Issued 05-07

8005-9

STEP 7 STEP 9

(Only if the machine is equipped with cylinder

safety valves)

Use a bar hammer (1) and the holding-up bar (2) to

push out the pin (3). If the pin is difficult to pull out, it is

being loaded. When pulling out a pin, take care not to

damage the installed O-ring and dust seal. When Remove hoses (1) and (2).

installing parts, clean the pin and pin opening of each To facilitate reassembly, attach identification labels to

part, and firmly rub them with grease. all hoses, pipes and electric wires. Use caps or plugs to

cover the hoses and HBCV to prevent the entry of

STEP 8 water, dust or dirt. Clean the hoses and HBCV by

spraying with a parts cleaner to prevent scratches and

prevent dirt from accumulating on the connectors.

STEP 10

Carefully raise the dipper cylinder (1) and move it away

from the machine. Place the dipper cylinder on suitable

stands.

NOTE: Lift the cylinder carefully. The cylinder is heavy, Remove screws (1) and remove the pipe (2). Use caps

the weight should be carefully distributed on the slings or plugs to cover HBCV and the pipes to prevent the

when lifting. entry of water, dust or dirt. Clean each of HBCV and

pipe connections by spraying with a parts cleaner to

prevent scratches and prevent dirt from accumulating

on the connectors.

Lep SM160B8005-0NA Issued 05-07

8005-10

STEP 11

Remove screws (1) and remove the arm HBCV (2).

NOTE: When installing, proceed in the reverse order

from that of removal

Lep SM160B8005-0NA Issued 05-07

8005-11

BUCKET CYLINDER

Description

3 2 4

15 1

10

13

16

7 5

12 13

14

10

8

14

12

11 7

9

CS00F534B

1 BUCKET CYLINDER 9 NUT

2 WASHER 10 SHIM

3 PIN 11 COMPENSATOR

4 SCREW 12 O-RING

5 HYDRAULIC HOSE 13 BUSHING

6 SHIM 14 SEAL

7 CONNECTING ROD 15 PIN

8 SCREW 16 O-RING

Lep SM160B8005-0NA Issued 05-07

8005-12

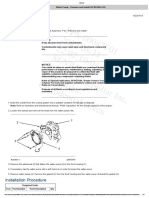

Removal STEP 3

STEP 1

Place the bucket link (1) parallel to the ground.

STEP 4

Place the back surface of the bucket parallel to the

ground. Remove the ring of lock pin (1) using a

screwdriver, and pull out the lock pin (2) in the bucket

side and the lock pin (3) in the arm side.

STEP 2

Remove double nuts (1) and (2), and then pull out bolts

(3) and (4).

Use bar hammer (1) and holding-up bar (2) to push out

pin (3) in the bucket side and pin (4) in the arm side,

and remove bucket (5). If the pin is difficult to pull out, it

is being loaded. When pulling out a pin, take care not to

damage the installed O-ring and dust seal. When

installing parts, clean the pin and pin opening of each

part, and firmly rub them with grease.

Lep SM160B8005-0NA Issued 05-07

8005-13

STEP 5 STEP 7

Allow the tip of arm (1) to touch the ground.

STEP 8

Use the bar hammer (1) and the holding-up bar (2) to

push out the pin (3), and remove the bucket link (4).

STEP 6

Remove hoses (1) and (2) while fixing the pipe. Use

caps or plugs to cover the hoses and pipes to prevent

the entry of water, dust or dirt. Clean the hoses and

pipes by spraying with a parts cleaner to prevent

scratches and prevent dirt from accumulating on the

connectors.

STEP 9

Use a bar hammer (1) and the holding-up bar (2) to

push out the pin (3), and remove arm links (4) and (5).

If the pin is difficult to pull out, it is being loaded.

When pulling out a pin, take care not to damage the

installed O-ring and dust seal. When installing parts,

clean the pin and pin opening of each part, and firmly

rub them with grease.

Use a crane and nylon sling (1) to secure the bucket

cylinder (2). Wrap the nylon sling inside the pipes to

prevent them from getting crushed.

Lep SM160B8005-0NA Issued 05-07

8005-14

STEP 10 STEP 12

Remove the lock bolt (1). Carefully raise the bucket cylinder (2) and move it away

from the machine. Place the dipper cylinder on suitable

STEP 11 stands.

NOTE: When installing, proceed in the reverse order

from that of removal

Use the bar hammer (1) and holding-up bar (2) to push

out the pin (3). If the pin is difficult to pull out, it is being

loaded. When pulling out a pin, take care not to

damage the installed O-ring and dust seal. When

installing parts, clean the pin and pin opening of each

part, and firmly rub them with grease.

Lep SM160B8005-0NA Issued 05-07

Potrebbero piacerti anche

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PDa EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNessuna valutazione finora

- 8005Documento14 pagine8005Renato Assis da SilvaNessuna valutazione finora

- Water PumpDocumento7 pagineWater Pumpma.powersourceNessuna valutazione finora

- Rocker Shaft Assembly and Push RodsDocumento3 pagineRocker Shaft Assembly and Push Rodsma.powersourceNessuna valutazione finora

- Group 9 Boom, Arm and Bucket CylinderDocumento17 pagineGroup 9 Boom, Arm and Bucket CylinderАлексейNessuna valutazione finora

- Overhaul: 1. Remove Oil Filler Cap Sub Assy 2. Remove Oil Filler Cap Gasket 3. Remove Ventilation Valve Sub AssyDocumento36 pagineOverhaul: 1. Remove Oil Filler Cap Sub Assy 2. Remove Oil Filler Cap Gasket 3. Remove Ventilation Valve Sub AssyHenry SilvaNessuna valutazione finora

- 8277e200 g004Documento38 pagine8277e200 g004CRUCUERNessuna valutazione finora

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Documento26 pagineCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduNessuna valutazione finora

- Air Release and Hydraulic ReleaseDocumento20 pagineAir Release and Hydraulic ReleaseWilber Anibal MoralesNessuna valutazione finora

- Caterpillar Cat 330B L Excavator (Prefix 6DR) Service Repair Manual (6DR00001 and Up)Documento27 pagineCaterpillar Cat 330B L Excavator (Prefix 6DR) Service Repair Manual (6DR00001 and Up)kfm8seuuduNessuna valutazione finora

- Caterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)Documento27 pagineCaterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)kfm8seuudu100% (1)

- Hidraulic Fluid Reservoir System 1Documento14 pagineHidraulic Fluid Reservoir System 1Iwa KartiwaNessuna valutazione finora

- Section 2000: Engine and Radiator Removal and Installation 580Sm, 580Sm+, 590SM, AND 590SM+ SERIES 3Documento16 pagineSection 2000: Engine and Radiator Removal and Installation 580Sm, 580Sm+, 590SM, AND 590SM+ SERIES 3Michel BayardelleNessuna valutazione finora

- 10-Special ProceduresDocumento10 pagine10-Special ProceduresRonal MoraNessuna valutazione finora

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Documento14 pagineJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNessuna valutazione finora

- Caterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)Documento27 pagineCaterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)kfm8seuudu100% (1)

- Valve Mechanism Cover - Remove and Install - Composite Valve Mechanism Cover (KENR6081-15)Documento4 pagineValve Mechanism Cover - Remove and Install - Composite Valve Mechanism Cover (KENR6081-15)Anderson Oliveira SilvaNessuna valutazione finora

- Culata Motor 3406Documento3 pagineCulata Motor 3406Julio GuillenNessuna valutazione finora

- Group 9 Boom, Arm and Bucket CylinderDocumento20 pagineGroup 9 Boom, Arm and Bucket CylinderDenNessuna valutazione finora

- Sis 2.0 3Documento1 paginaSis 2.0 3kqgy9s6sgvNessuna valutazione finora

- Final Drive, Steering Differential, and Brake (Left Side) - Remove and Install (M0076745-04)Documento5 pagineFinal Drive, Steering Differential, and Brake (Left Side) - Remove and Install (M0076745-04)alejandro castañoNessuna valutazione finora

- Front Suspension Cylinder Cap Capscrew ImprovementDocumento4 pagineFront Suspension Cylinder Cap Capscrew ImprovementSandro GastanagaNessuna valutazione finora

- Cylinder LinersDocumento4 pagineCylinder Linersma.powersourceNessuna valutazione finora

- MODEL 1900D Airliner: Maintenance ManualDocumento3 pagineMODEL 1900D Airliner: Maintenance ManualAdel KhelifiNessuna valutazione finora

- Removal Procedure: Table 1Documento4 pagineRemoval Procedure: Table 1JebrodNessuna valutazione finora

- Automatic Transaxle Assy (U34#E Series) : OverhaulDocumento46 pagineAutomatic Transaxle Assy (U34#E Series) : Overhaulvipper king2012Nessuna valutazione finora

- Automatic Transaxle Assy (U34#E Series) : OverhaulDocumento46 pagineAutomatic Transaxle Assy (U34#E Series) : Overhaulvipper king2012Nessuna valutazione finora

- Group 9 Boom, Arm and Bucket Cylinder (Up To #1621)Documento34 pagineGroup 9 Boom, Arm and Bucket Cylinder (Up To #1621)ANDREI26Nessuna valutazione finora

- 2000 Remoção Instalação MotorDocumento40 pagine2000 Remoção Instalação MotorHelioNessuna valutazione finora

- Group 9 Boom, Arm and Bucket CylinderDocumento17 pagineGroup 9 Boom, Arm and Bucket CylinderkrisnantoNessuna valutazione finora

- Telescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPDocumento14 pagineTelescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPdaryanto widodoNessuna valutazione finora

- Komatsu 5Documento114 pagineKomatsu 5mondaijankaNessuna valutazione finora

- Magpower B25 B50 BrakesDocumento4 pagineMagpower B25 B50 BrakesJuan CaceresNessuna valutazione finora

- Cylinder Head InstallDocumento6 pagineCylinder Head Installboosterdaily16Nessuna valutazione finora

- Motor M14 ControlDocumento6 pagineMotor M14 ControlROBERSON ROMERÒNessuna valutazione finora

- Removal PDFDocumento5 pagineRemoval PDFkarlosNessuna valutazione finora

- Turbocharger - Remove - Turbocharger Top Mounted (KENR6081-15)Documento4 pagineTurbocharger - Remove - Turbocharger Top Mounted (KENR6081-15)Anderson Oliveira SilvaNessuna valutazione finora

- 330C L Excavator - 9 Engine PDFDocumento26 pagine330C L Excavator - 9 Engine PDFRICHARDNessuna valutazione finora

- Front Strut Assembly: Front Suspension System SS - 27Documento7 pagineFront Strut Assembly: Front Suspension System SS - 27Bùi Xuân ThắngNessuna valutazione finora

- Ripper Tilt Cylinder - Remove and Install (RENR2054-04)Documento8 pagineRipper Tilt Cylinder - Remove and Install (RENR2054-04)connor.millsNessuna valutazione finora

- Cilindro de Direccion 416DDocumento9 pagineCilindro de Direccion 416DjulianmatabajoyNessuna valutazione finora

- Sis 2.0Documento3 pagineSis 2.0Rui ArezesNessuna valutazione finora

- Instructions: Headlamp Visor KitDocumento2 pagineInstructions: Headlamp Visor KitPaco JonesNessuna valutazione finora

- Caterpillar Cat 225D LC EXCAVATOR (Prefix 6RG) Service Repair Manual (6RG00001 and UP)Documento24 pagineCaterpillar Cat 225D LC EXCAVATOR (Prefix 6RG) Service Repair Manual (6RG00001 and UP)rpoy9396615Nessuna valutazione finora

- Group 9 Boom, Arm and Bucket CylinderDocumento17 pagineGroup 9 Boom, Arm and Bucket CylinderHậu MinhNessuna valutazione finora

- Overhaul: Partial Engine Assy (1Gr Fe)Documento50 pagineOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNessuna valutazione finora

- Flywheel Housing - Remove and Install: 'Lvdvvhpeo/Dqg$VvhpeoDocumento6 pagineFlywheel Housing - Remove and Install: 'Lvdvvhpeo/Dqg$VvhpeoToispuoliNessuna valutazione finora

- Caterpillar Cat 232 SKID STEER LOADER (Prefix CAB) Service Repair Manual (CAB00001 and Up)Documento24 pagineCaterpillar Cat 232 SKID STEER LOADER (Prefix CAB) Service Repair Manual (CAB00001 and Up)rpoy9396615Nessuna valutazione finora

- Valve Mechanism Cover Base - Remove and Install (KENR6081-15)Documento6 pagineValve Mechanism Cover Base - Remove and Install (KENR6081-15)Anderson Oliveira SilvaNessuna valutazione finora

- Crankshaft removeSMCS - 1202 - 011Documento3 pagineCrankshaft removeSMCS - 1202 - 011Ama AttaNessuna valutazione finora

- 2012 Fork Service ManualDocumento36 pagine2012 Fork Service ManualFer SabidongNessuna valutazione finora

- Caterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN00001-06749)Documento22 pagineCaterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN00001-06749)rpoy9396615Nessuna valutazione finora

- Fanuc R30iA LR Mate 200 IC J3 Motor and Reducer ReplacementDocumento5 pagineFanuc R30iA LR Mate 200 IC J3 Motor and Reducer ReplacementAndrés M. ReyesNessuna valutazione finora

- 303-08 P1396 RepairDocumento6 pagine303-08 P1396 Repairmarcelo ustarezNessuna valutazione finora

- Caterpillar Cat 330-A L Excavator (Prefix 5YM) Service Repair Manual (5YM00001 and Up)Documento26 pagineCaterpillar Cat 330-A L Excavator (Prefix 5YM) Service Repair Manual (5YM00001 and Up)kfm8seuuduNessuna valutazione finora

- Cilindro de Direccion - 4Documento13 pagineCilindro de Direccion - 4agarlab02Nessuna valutazione finora

- Group 9 Boom, Arm and Bucket CylinderDocumento17 pagineGroup 9 Boom, Arm and Bucket CylinderJorge Iván Villaseñor LozanoNessuna valutazione finora

- Desemsamble de FrenoDocumento28 pagineDesemsamble de FrenoRogelio GonzalezNessuna valutazione finora

- Air Dryer - Maint - Manual - Rev - 1 PDFDocumento34 pagineAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuNessuna valutazione finora

- Sis 2.0Documento3 pagineSis 2.0Mly ObrequeNessuna valutazione finora

- CartazDocumento1 paginaCartazVitor HugoNessuna valutazione finora

- Hydraulic Control System: PART NO. 4034399 2200 SRM 1481Documento60 pagineHydraulic Control System: PART NO. 4034399 2200 SRM 1481JIM CAMPBELL83% (6)

- 1300SRM1455 (06 2017) Us en PDFDocumento42 pagine1300SRM1455 (06 2017) Us en PDFJIM CAMPBELL100% (6)

- 2111236-Jcb 1cx 208s Backhoe Loader Workshop Service Manual PDFDocumento242 pagine2111236-Jcb 1cx 208s Backhoe Loader Workshop Service Manual PDFJefferson Paixão100% (5)

- Diagrama Elec Caterpillar cb534d PDFDocumento6 pagineDiagrama Elec Caterpillar cb534d PDFAlexis Centu83% (6)

- Electric Fan: Consumer ElectronicsDocumento53 pagineElectric Fan: Consumer ElectronicsBerlin AlcaydeNessuna valutazione finora

- Illumination and Electrification of Building (Elective) - Sample-Question-Paper (Msbte-Study-Resources) PDFDocumento5 pagineIllumination and Electrification of Building (Elective) - Sample-Question-Paper (Msbte-Study-Resources) PDFHarshal Vaidya100% (1)

- Snubber Circuit Workshop-DikompresiDocumento22 pagineSnubber Circuit Workshop-DikompresiNafila WidyaNessuna valutazione finora

- Crumar Spirit Service Manual PDFDocumento11 pagineCrumar Spirit Service Manual PDFFlaco Depaulo CarlosNessuna valutazione finora

- NGR LittlefuseDocumento9 pagineNGR Littlefuse0502208864Nessuna valutazione finora

- 9xv 9xr Engine PartsDocumento66 pagine9xv 9xr Engine PartsPaul Mendoza HuaraychiriNessuna valutazione finora

- 5th Bill External Development Work Around GurdwaraDocumento4 pagine5th Bill External Development Work Around Gurdwara41 Shaivya ManaktalaNessuna valutazione finora

- Ansi - c37.20 & Nema SG - 5Documento20 pagineAnsi - c37.20 & Nema SG - 5Subrat Das100% (1)

- Hydraulic Elevator Installation Checklist: Schindler 330ADocumento4 pagineHydraulic Elevator Installation Checklist: Schindler 330AMMMOH200Nessuna valutazione finora

- Vacuum Contactor SpecDocumento5 pagineVacuum Contactor SpecAkhilesh AnandNessuna valutazione finora

- Water Tank Seat Slab DesignDocumento2 pagineWater Tank Seat Slab DesignMesfin Derbew100% (2)

- Informacion KenwoodDocumento21 pagineInformacion KenwoodJavier Ruíz PalafoxNessuna valutazione finora

- Forgotten Firearms of August CoendersDocumento12 pagineForgotten Firearms of August CoendersRoddy PfeifferNessuna valutazione finora

- Die Protection ClinicDocumento82 pagineDie Protection ClinicMario FaridNessuna valutazione finora

- Appendix - Yanamr - Tier4 Fail Safe List For V191R46Documento6 pagineAppendix - Yanamr - Tier4 Fail Safe List For V191R46MontyNessuna valutazione finora

- Complete Overview of Lightning Arresters Part 3Documento7 pagineComplete Overview of Lightning Arresters Part 3Robert GalarzaNessuna valutazione finora

- Perbandingan Produk Car Lift PD Sarana Jaya 2018Documento1 paginaPerbandingan Produk Car Lift PD Sarana Jaya 2018Syaifudin IsharNessuna valutazione finora

- Diagrama Electrico 345BDocumento2 pagineDiagrama Electrico 345BRichard QuispeNessuna valutazione finora

- Gennex Retail Price October 2019Documento2 pagineGennex Retail Price October 2019Gare OdezimeNessuna valutazione finora

- Strand Century Lighting CCR 600 Series Dimmer Modules Spec Sheet 6-77Documento2 pagineStrand Century Lighting CCR 600 Series Dimmer Modules Spec Sheet 6-77Alan MastersNessuna valutazione finora

- SCORPIO VLX at WIRING MANUAL Rev1 PDFDocumento51 pagineSCORPIO VLX at WIRING MANUAL Rev1 PDFNavin GomesNessuna valutazione finora

- Introduction To Servo MotorsDocumento21 pagineIntroduction To Servo MotorsGeetha VenugopalNessuna valutazione finora

- Toyota Camry Body ElectricalDocumento10 pagineToyota Camry Body ElectricalJohn100% (49)

- Fuse MCB Elc DifferenceDocumento3 pagineFuse MCB Elc DifferencemaniNessuna valutazione finora

- Exam On AC Apparatus (Transformer)Documento2 pagineExam On AC Apparatus (Transformer)Kristine ManilagNessuna valutazione finora

- KP Turbine Engine Ignition SystemsDocumento7 pagineKP Turbine Engine Ignition SystemsNana ZainiNessuna valutazione finora

- LRK - Estimation1Documento58 pagineLRK - Estimation1Ragul KumarNessuna valutazione finora

- Orange Brent Hinds Terror Manual 1Documento4 pagineOrange Brent Hinds Terror Manual 1J.R. RiversNessuna valutazione finora

- Architecture GlossaryDocumento11 pagineArchitecture GlossarycristinaNessuna valutazione finora

- Pasos Cambio Correa Distribucion Chevrolet Aveo 1Documento17 paginePasos Cambio Correa Distribucion Chevrolet Aveo 1Gustavo Adolfo Muñoz VNessuna valutazione finora

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDa EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingValutazione: 4.5 su 5 stelle4.5/5 (846)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeDa EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeValutazione: 5 su 5 stelle5/5 (2)

- Simplified Organization: Learn to Love What Must Be DoneDa EverandSimplified Organization: Learn to Love What Must Be DoneNessuna valutazione finora

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Da EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Valutazione: 4 su 5 stelle4/5 (17)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingDa EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingValutazione: 4 su 5 stelle4/5 (2997)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterDa EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterValutazione: 4 su 5 stelle4/5 (467)

- The Martha Manual: How to Do (Almost) EverythingDa EverandThe Martha Manual: How to Do (Almost) EverythingValutazione: 4 su 5 stelle4/5 (11)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeDa EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeValutazione: 4.5 su 5 stelle4.5/5 (164)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyDa EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyValutazione: 4 su 5 stelle4/5 (40)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesDa EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesValutazione: 4 su 5 stelle4/5 (11)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiDa EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiValutazione: 4.5 su 5 stelle4.5/5 (5)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyDa EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyValutazione: 4 su 5 stelle4/5 (277)

- Organizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlDa EverandOrganizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlValutazione: 4.5 su 5 stelle4.5/5 (204)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritDa EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritValutazione: 4.5 su 5 stelle4.5/5 (3)

- Nobody Wants Your Sh*t: The Art of Decluttering Before You DieDa EverandNobody Wants Your Sh*t: The Art of Decluttering Before You DieValutazione: 4.5 su 5 stelle4.5/5 (22)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffDa EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffValutazione: 4.5 su 5 stelle4.5/5 (578)

- Simplicity at Home: Japanese Rituals, Recipes, and Arrangements for Thoughtful LivingDa EverandSimplicity at Home: Japanese Rituals, Recipes, and Arrangements for Thoughtful LivingValutazione: 5 su 5 stelle5/5 (2)

- The Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeDa EverandThe Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeValutazione: 3 su 5 stelle3/5 (1)

- The Clutter-Free Home: Making Room for Your LifeDa EverandThe Clutter-Free Home: Making Room for Your LifeValutazione: 4.5 su 5 stelle4.5/5 (54)

- Identity Clutter: The Whats, Whys, and Hows of Every Angle of DeclutteringDa EverandIdentity Clutter: The Whats, Whys, and Hows of Every Angle of DeclutteringValutazione: 5 su 5 stelle5/5 (44)

- Starting Your Career as an Interior DesignerDa EverandStarting Your Career as an Interior DesignerValutazione: 5 su 5 stelle5/5 (1)

- Lighter Living: The Essential Guide to Clutter-Free and Light Living , Learn Useful Ways on How to Declutter Your Life and Enjoy The Things That Really Matter To YouDa EverandLighter Living: The Essential Guide to Clutter-Free and Light Living , Learn Useful Ways on How to Declutter Your Life and Enjoy The Things That Really Matter To YouValutazione: 4.5 su 5 stelle4.5/5 (27)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosDa EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosValutazione: 3.5 su 5 stelle3.5/5 (8)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsDa EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsValutazione: 5 su 5 stelle5/5 (339)

- Minimalist Moms: Living and Parenting with SimplicityDa EverandMinimalist Moms: Living and Parenting with SimplicityValutazione: 4 su 5 stelle4/5 (2)

- Let It Go: Downsizing Your Way to a Richer, Happier LifeDa EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeValutazione: 4.5 su 5 stelle4.5/5 (67)