Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UEC-MS-BR466-IST-007-Instrumentation Test

Caricato da

MAYMODERN STEELCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UEC-MS-BR466-IST-007-Instrumentation Test

Caricato da

MAYMODERN STEELCopyright:

Formati disponibili

METHOD STATEMENT Page No.

: Page 1 of 6

Revision : 0

Issued : Dec 2001

UE Construction Sdn Bhd UEC-MS-BR466-IST-007

ELECTRIFIED DOUBLE TRACK PROJECT BETWEEN RAWANG AND IPOH

METHOD STATEMENT FOR

INSTRUMENT TEST PILE USING

VIBRATING WIRE STRAIN GAUGES AT

PRELIMINARY TEST PILE

(BR 466- SG KLEDANG)

Prepared by Date Reviewed by Date Approved by Date

GTH 17th DEC TYK 18th DEC TYK 18th DEC

2001 2001 2001

IMPORTANT:

The information contained herein is the proprietary of UE CONSTRUCTION SDN. BHD.

The holder agrees to the following:

1. Not to reproduced; reveal; publish; or distribute it in whole or any portion of it without authorisation; and,

2. To maintain this document in confidence.

METHOD STATEMENT Page No. : Page 2 of 6

Revision : 0

Issued : Dec 2001

UE Construction Sdn Bhd UEC-MS-BR466-IST-007

ELECTRIFIED DOUBLE TRACK PROJECT BETWEEN RAWANG AND IPOH

CONTENTS

1.0 SCOPE

2.0 MATERIALS

3.0 EQUIPMENT & RESOURCES

4.0 METHOD OF INSTALLATION

5.0 QUALITY CONTROL PROCEDURE

6.0 HEALTH, SAFETY AND ENVIRONMENT

7.0 TRACK POSSESSION

8.0 SUMMARY OF FORMS

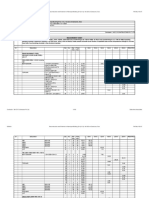

ATTACHMENT 1 : STRAIN GAUGES LOCATION

METHOD STATEMENT Page No. : Page 3 of 6

Revision : 0

Issued : Dec 2001

UE Construction Sdn Bhd UEC-MS-BR466-IST-007

ELECTRIFIED DOUBLE TRACK PROJECT BETWEEN RAWANG AND IPOH

1.0 SCOPE

The following Method Statement describes the procedures to be followed

in conducting the instrument test pile using vibrating wire strain gauges

at the proposed preliminary test pile.

The aim of instrumenting the bore pile with strain gauges is to

determine the load distribution characteristics along the pile shaft.

The vibrating wire type strain gauge works on the principle that the

natural frequency of a wire changes as its length changes. Thus, by

measuring the change in frequency, the deformation can be obtained

and hence the strain. Most modern readouts will be able to give the

strains directly, eliminating the need to do any calculation or calibration

(sample calibrations would have been carried out by the manufacturer).

From the strain, the stress can be calculated and thus the load

distribution along the pile shaft is known if the strain gauges are

installed at intervals along the pile shaft length.

2.0 MATERIALS

Not required.

3.0 EQUIPEMENT & RESOURCES

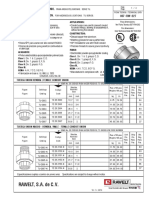

i) Vibrating wire type Welded Strain Gauge. Steel wire of gauge

length 62mm, and frequency range 0.8 to 2.4kHz

ii) Micro-bond welder

iii) Electrical cable 7/0.2mm x 4C PVC Braided

iv) VWP Indicator

v) 3M Scotchcast Insulating Resin 4

METHOD STATEMENT Page No. : Page 4 of 6

Revision : 0

Issued : Dec 2001

UE Construction Sdn Bhd UEC-MS-BR466-IST-007

ELECTRIFIED DOUBLE TRACK PROJECT BETWEEN RAWANG AND IPOH

4.0 METHOD OF INSTALLATION

4.1 The strain gauges are mounted on 600mm long, 20mm diameter high

tensile steel bars (Y20).

4.2 At their midpoints, the steel bars are polished using a hand held

electrical grinder to obtain a flat surface for the strain gauges to be

placed on. Polishing is completed by hand using silicon carbide paper.

The surfaces of the polished bars are then cleaned using acetone.

4.3 The weldable strain gauges are next bonded to the steel bars using a

micro-bond welder. Then, the strain gauge sensors are placed on the

strain gauges and tied firmly to the steel bars with wires. Short lengths

of PVC protective pipe are placed over the strain gauge locations and

they are filled with insulating resin.

4.4 The electrical lead wires from the sensors are brought to the top of the

pile through PVC pipes tied to the steel cage.

4.5 The gauges are checked before and after micro-welding, after

installation, after placement of the cage in the borehole, and after

concreting.

4.6 The shaft resistance at any level of the pile is calculated from:

0.25 EE d

fs

e

where;

fs = Shaft Resistance

E = Modulus of Elasticity of the pile

E = Difference in measured strains

e = Distance between strain gauge levels

d = Diameter of the pile

and where

Applied Load 1

E

Sectional area of pile Measured strains at Level 1

4.0 METHOD OF INSTALLATION (Con't)

METHOD STATEMENT Page No. : Page 5 of 6

Revision : 0

Issued : Dec 2001

UE Construction Sdn Bhd UEC-MS-BR466-IST-007

ELECTRIFIED DOUBLE TRACK PROJECT BETWEEN RAWANG AND IPOH

4.7 The proposed location for the gauges is attached in Attachment 1.

5.0 QUALITY CONTROL PROCEDURE

Not required.

6.0 HEALTH, SAFETY AND ENVIROMENT

Not required.

7.0 TRACK POSSESION

Not required.

8.0 SUMMARY OF FORMS

Standard forms will be used for the test.

METHOD STATEMENT Page No. : Page 6 of 6

Revision : 0

Issued : Dec 2001

UE Construction Sdn Bhd UEC-MS-BR466-IST-007

ELECTRIFIED DOUBLE TRACK PROJECT BETWEEN RAWANG AND IPOH

ATTACHMENT 1

STRAIN GAUGES LOCATION

Potrebbero piacerti anche

- UEC-MS-BR466-MLT-006-Load TestDocumento18 pagineUEC-MS-BR466-MLT-006-Load TestMAYMODERN STEELNessuna valutazione finora

- UEC-MS-BR466-SLT-008-Sonic Logging TestDocumento6 pagineUEC-MS-BR466-SLT-008-Sonic Logging TestMAYMODERN STEELNessuna valutazione finora

- Post Tensioned I-Beam RB011, RBO12Documento13 paginePost Tensioned I-Beam RB011, RBO12MAYMODERN STEELNessuna valutazione finora

- Method Statement For Precast Post Tensioned I-Beams atDocumento8 pagineMethod Statement For Precast Post Tensioned I-Beams atMAYMODERN STEELNessuna valutazione finora

- Method Statement For Pile Driving Analyser Test at Preliminary Test Pile (BR 466-Sg Kledang)Documento7 pagineMethod Statement For Pile Driving Analyser Test at Preliminary Test Pile (BR 466-Sg Kledang)Trương Văn ĐồngNessuna valutazione finora

- MS Sheet Piling RB011Documento9 pagineMS Sheet Piling RB011Mahtab HossainNessuna valutazione finora

- MS For MLT On 300 Spun Pile Test Pile BR457Documento7 pagineMS For MLT On 300 Spun Pile Test Pile BR457MAYMODERN STEELNessuna valutazione finora

- Method Statement For Installation, Monitoring and Maintenance of Geotechnical InstrumentationDocumento11 pagineMethod Statement For Installation, Monitoring and Maintenance of Geotechnical InstrumentationMAYMODERN STEELNessuna valutazione finora

- Electrified Double Track Project Between Rawang and Ipoh: Method Statement For Sonic Logging Test atDocumento5 pagineElectrified Double Track Project Between Rawang and Ipoh: Method Statement For Sonic Logging Test atMAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Piles At:: UEC/MS/BP/001Documento13 pagineMethod Statement For Bored Piles At:: UEC/MS/BP/001MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at BR 583 - Sg. Chikus (CH 239.165)Documento12 pagineMethod Statement For Bored Pile at BR 583 - Sg. Chikus (CH 239.165)MAYMODERN STEELNessuna valutazione finora

- MS For MLT On 300 Spun Pile Br583Documento21 pagineMS For MLT On 300 Spun Pile Br583giyat_prcNessuna valutazione finora

- Method Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangDocumento12 pagineMethod Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangMAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)Documento12 pagineMethod Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)Documento11 pagineMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)MAYMODERN STEELNessuna valutazione finora

- Geotech Instrumentation-Rb012Documento12 pagineGeotech Instrumentation-Rb012MAYMODERN STEELNessuna valutazione finora

- Method Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangDocumento11 pagineMethod Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangMAYMODERN STEELNessuna valutazione finora

- Method Statement FOR Launching of Prestressed I-18 Beams at BR 570 (SG Batang Padang)Documento8 pagineMethod Statement FOR Launching of Prestressed I-18 Beams at BR 570 (SG Batang Padang)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Construction of Access Road To BR 570 (Sg. Batang Padang)Documento7 pagineMethod Statement For Construction of Access Road To BR 570 (Sg. Batang Padang)MAYMODERN STEELNessuna valutazione finora

- BR570 - Rev 1Documento15 pagineBR570 - Rev 1MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Documento11 pagineMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNessuna valutazione finora

- Method Statement FOR Launching of Prestressed I Beams AT RB 014, Jalan Tapah - Teluk Intan (Pier 2 To Abutment 2)Documento14 pagineMethod Statement FOR Launching of Prestressed I Beams AT RB 014, Jalan Tapah - Teluk Intan (Pier 2 To Abutment 2)MAYMODERN STEELNessuna valutazione finora

- Distributed Optical Fibre Strain Sensing of Geotechnical StructuresDocumento6 pagineDistributed Optical Fibre Strain Sensing of Geotechnical StructuresAhmad MubarakNessuna valutazione finora

- Method Statement For Construction of Access Road To BR 570 - Sg. Batang Padang (CH 232.316)Documento6 pagineMethod Statement For Construction of Access Road To BR 570 - Sg. Batang Padang (CH 232.316)MAYMODERN STEELNessuna valutazione finora

- Method Statement: Launching of Precast I-Beams at Rb011 (Jalan Kampar - Teluk Intan)Documento9 pagineMethod Statement: Launching of Precast I-Beams at Rb011 (Jalan Kampar - Teluk Intan)MAYMODERN STEELNessuna valutazione finora

- Method Statement: Launching of Precast Slab at Br562 (Sg. Chenderiang)Documento11 pagineMethod Statement: Launching of Precast Slab at Br562 (Sg. Chenderiang)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Construction of Bridge No 562 Across Sg. ChenderiangDocumento14 pagineMethod Statement For Construction of Bridge No 562 Across Sg. ChenderiangMAYMODERN STEELNessuna valutazione finora

- Method Statement For Construction of Access Road To BR 583 (Sg. Chikus)Documento7 pagineMethod Statement For Construction of Access Road To BR 583 (Sg. Chikus)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Installation of Electrical PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsDocumento12 pagineMethod Statement For Installation of Electrical PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsMohammed Ghareib NasrNessuna valutazione finora

- Approval Project Manager: Ministry of Electricity (Moe) Republic of IraqDocumento5 pagineApproval Project Manager: Ministry of Electricity (Moe) Republic of IraqAlinaIordacheNessuna valutazione finora

- Seismic Analysis of Elevated Metro BridgeDocumento7 pagineSeismic Analysis of Elevated Metro BridgeIJRASETPublicationsNessuna valutazione finora

- Pile Driving Analyser Test-Rev 1Documento6 paginePile Driving Analyser Test-Rev 1MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)Documento11 pagineMethod Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)MAYMODERN STEEL100% (1)

- UEC-MS-BR484-PV-016-Laying of ACWC, Rev (1) .1Documento6 pagineUEC-MS-BR484-PV-016-Laying of ACWC, Rev (1) .1MAYMODERN STEELNessuna valutazione finora

- Beam Launching RB014 A1-P1Documento14 pagineBeam Launching RB014 A1-P1MAYMODERN STEEL100% (1)

- Static Analysis On Tied Arch BridgeDocumento7 pagineStatic Analysis On Tied Arch BridgeIJRASETPublicationsNessuna valutazione finora

- Beam Launching RB014 A1-P1 Rev1Documento14 pagineBeam Launching RB014 A1-P1 Rev1MAYMODERN STEELNessuna valutazione finora

- Production MergedDocumento9 pagineProduction MergedThomas Ramirez CastilloNessuna valutazione finora

- UT - EXWI-NDT-21103 - Rev.00 - AWS D1.1Documento14 pagineUT - EXWI-NDT-21103 - Rev.00 - AWS D1.1Cherdchai nuntariNessuna valutazione finora

- 1.4.9 - M.O.S For Hacking Work at WallDocumento2 pagine1.4.9 - M.O.S For Hacking Work at Wallkasyfil azizNessuna valutazione finora

- Method Statement For Pavement Works at Approach of VBC Kg. Titi Besi (CH 232.457)Documento7 pagineMethod Statement For Pavement Works at Approach of VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELNessuna valutazione finora

- Power & Control CableDocumento15 paginePower & Control CablekarimNessuna valutazione finora

- Approval Project Manager: Ministry of Electricity (Moe) Republic of IraqDocumento5 pagineApproval Project Manager: Ministry of Electricity (Moe) Republic of IraqAlinaIordacheNessuna valutazione finora

- MS - Casting of I Beam - Double Track - UEDocumento9 pagineMS - Casting of I Beam - Double Track - UEMAYMODERN STEELNessuna valutazione finora

- Verificat Installation of Power and Control Cables - CELIN - Black Sea - IrakDocumento8 pagineVerificat Installation of Power and Control Cables - CELIN - Black Sea - IrakAlinaIordacheNessuna valutazione finora

- Vallurupalli Nageswara Rao Vignana Jyothi Institute of Engineering and TechnologyDocumento6 pagineVallurupalli Nageswara Rao Vignana Jyothi Institute of Engineering and TechnologyGenius Billionaire PlayBoyNessuna valutazione finora

- MS - Pulling Out Pipe r02 - 1Documento14 pagineMS - Pulling Out Pipe r02 - 1Mallikarjun DevarapalliNessuna valutazione finora

- WMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1Documento8 pagineWMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1tanaNessuna valutazione finora

- Analysis and Design of Cellular Beam and Its Verification: SciencedirectDocumento8 pagineAnalysis and Design of Cellular Beam and Its Verification: Sciencedirectvenkata369Nessuna valutazione finora

- Experimental Study On Fiber Reinforced Self Compacting ConcreteDocumento7 pagineExperimental Study On Fiber Reinforced Self Compacting ConcreteIJRASETPublicationsNessuna valutazione finora

- SECTION 16060 Grounding and BondingDocumento18 pagineSECTION 16060 Grounding and BondingMARIANNessuna valutazione finora

- Method Statement For Trench Cable Tray InstallationDocumento11 pagineMethod Statement For Trench Cable Tray Installationafzal empirestateNessuna valutazione finora

- MST Installation of Cable Containment Including Support BracketDocumento19 pagineMST Installation of Cable Containment Including Support BracketmieadidassNessuna valutazione finora

- Peterm ProjectDocumento15 paginePeterm Projectptaahmulti64Nessuna valutazione finora

- Method Statement For Bored Piles atDocumento15 pagineMethod Statement For Bored Piles atMAYMODERN STEELNessuna valutazione finora

- MOS Temporary HoardingDocumento4 pagineMOS Temporary Hoardinganiesbaek88% (8)

- P-003 Ultrasonic Testing ProcedureDocumento24 pagineP-003 Ultrasonic Testing ProcedureSaheb Yadav100% (2)

- Engineering Final Year Project Report OnDocumento65 pagineEngineering Final Year Project Report Onkoushik.naskar108Nessuna valutazione finora

- Calculation of Capacitive-Based Sensors of Rotating Shaft Vibration For Fault Diagnostic Systems of Powerful GeneratorsDocumento20 pagineCalculation of Capacitive-Based Sensors of Rotating Shaft Vibration For Fault Diagnostic Systems of Powerful GeneratorsDeutMbNessuna valutazione finora

- A State-of-the-Art Guide for Post-Installed ReinforcementDa EverandA State-of-the-Art Guide for Post-Installed ReinforcementNessuna valutazione finora

- Method Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)Documento7 pagineMethod Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Earthworks at VBC Kg. Titi Besi (CH 232.457)Documento6 pagineMethod Statement For Earthworks at VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELNessuna valutazione finora

- Zone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)Documento25 pagineZone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)Documento7 pagineMethod Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)MAYMODERN STEELNessuna valutazione finora

- Quotation Temp - RoadDocumento1 paginaQuotation Temp - RoadMAYMODERN STEELNessuna valutazione finora

- Sub-Base and Road BaseDocumento7 pagineSub-Base and Road BaseMAYMODERN STEELNessuna valutazione finora

- MS For MLT On 300 Spun Pile Test Pile BR457Documento7 pagineMS For MLT On 300 Spun Pile Test Pile BR457MAYMODERN STEELNessuna valutazione finora

- MS For MLT On 300 Spun Pile Test Pile BR457Documento7 pagineMS For MLT On 300 Spun Pile Test Pile BR457MAYMODERN STEELNessuna valutazione finora

- Method Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangDocumento11 pagineMethod Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangMAYMODERN STEELNessuna valutazione finora

- Method Statement For Construction of Bridge No 562 Across Sg. ChenderiangDocumento14 pagineMethod Statement For Construction of Bridge No 562 Across Sg. ChenderiangMAYMODERN STEELNessuna valutazione finora

- MS For MLT On 300 Spun Pile Br583Documento21 pagineMS For MLT On 300 Spun Pile Br583giyat_prcNessuna valutazione finora

- Method Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangDocumento12 pagineMethod Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangMAYMODERN STEELNessuna valutazione finora

- Zone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)Documento25 pagineZone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)MAYMODERN STEELNessuna valutazione finora

- Pile Driving Analyser Test-Rev 1Documento6 paginePile Driving Analyser Test-Rev 1MAYMODERN STEELNessuna valutazione finora

- Electrified Double Track Project Between Rawang and Ipoh: Method Statement For Sonic Logging Test atDocumento5 pagineElectrified Double Track Project Between Rawang and Ipoh: Method Statement For Sonic Logging Test atMAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Documento11 pagineMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)Documento11 pagineMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at Rb013: Jalan Air Kuning - Banir (CH 229.424)Documento14 pagineMethod Statement For Bored Pile at Rb013: Jalan Air Kuning - Banir (CH 229.424)MAYMODERN STEELNessuna valutazione finora

- Pile Driving Analyser TestDocumento5 paginePile Driving Analyser TestMAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)Documento11 pagineMethod Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)MAYMODERN STEEL100% (1)

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Documento11 pagineMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at BR 583 - Sg. Chikus (CH 239.165)Documento12 pagineMethod Statement For Bored Pile at BR 583 - Sg. Chikus (CH 239.165)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)Documento12 pagineMethod Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)MAYMODERN STEELNessuna valutazione finora

- BR570 - Rev 1Documento15 pagineBR570 - Rev 1MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Documento11 pagineMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNessuna valutazione finora

- Method Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)Documento12 pagineMethod Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)MAYMODERN STEELNessuna valutazione finora

- Ge700-2020-Gc16-Part1 Plot 26Documento2 pagineGe700-2020-Gc16-Part1 Plot 26Daniel CryerNessuna valutazione finora

- CommentiDocumento36 pagineCommentifabio manenteNessuna valutazione finora

- Reinforcement Steel FormatDocumento18 pagineReinforcement Steel FormatRASCON BUILDNessuna valutazione finora

- 170057-TBO-FIRE - BOQ Calculation - PO - 181210Documento49 pagine170057-TBO-FIRE - BOQ Calculation - PO - 181210Minh TanNessuna valutazione finora

- Improvised C-ClampDocumento22 pagineImprovised C-ClampWinser BelzaNessuna valutazione finora

- (Presentation) Contemporary ArchitectsDocumento12 pagine(Presentation) Contemporary Architectsalexu artNessuna valutazione finora

- UntitledDocumento12 pagineUntitledgm29Nessuna valutazione finora

- Data Sheet: 4x2x0,22snDocumento2 pagineData Sheet: 4x2x0,22snSerhiy ShvaykaNessuna valutazione finora

- 2023 Domestic Technical HandbookDocumento550 pagine2023 Domestic Technical HandbookdamianNessuna valutazione finora

- Union Universal RAWELTDocumento4 pagineUnion Universal RAWELTLuisDonairesNessuna valutazione finora

- Dr. Danilo A. Domingo: Project Memo Code DateDocumento2 pagineDr. Danilo A. Domingo: Project Memo Code Datechristopher john natividadNessuna valutazione finora

- Fire Sprinkler SystemsDocumento83 pagineFire Sprinkler Systemsrams789Nessuna valutazione finora

- ULTEGRA Front Chainwheel FC-6600Documento1 paginaULTEGRA Front Chainwheel FC-6600jack87hornistNessuna valutazione finora

- GUIDELINES FOR APPLICATIONS RDA MauritiusDocumento3 pagineGUIDELINES FOR APPLICATIONS RDA MauritiusYashas SridatNessuna valutazione finora

- ASTM C 143-C 143M-00 TM For Slump of Hydraulic ConcreteDocumento4 pagineASTM C 143-C 143M-00 TM For Slump of Hydraulic ConcretetariqkhanNessuna valutazione finora

- Lattice GirderDocumento3 pagineLattice GirdermvssrajuNessuna valutazione finora

- Tender Drawings Merged and Numbered - Final - 153 PagesDocumento153 pagineTender Drawings Merged and Numbered - Final - 153 PagesTamilkumar D (Tamil)Nessuna valutazione finora

- 2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsDocumento4 pagine2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsMORELLI silvioNessuna valutazione finora

- PVC Water Stops - Kanta Rubber Pvt. LTDDocumento2 paginePVC Water Stops - Kanta Rubber Pvt. LTDabdul khaderNessuna valutazione finora

- Cable Structures PDFDocumento44 pagineCable Structures PDFsindhura50% (2)

- Experiment 2Documento11 pagineExperiment 2MD Shadikul Huq ShezanNessuna valutazione finora

- Trench Excavation Productive RateDocumento1 paginaTrench Excavation Productive RateIshan AththanayakeNessuna valutazione finora

- Take A Chance With MeDocumento5 pagineTake A Chance With MeOsidhdosodjNessuna valutazione finora

- SOP For Sampling On PaverDocumento5 pagineSOP For Sampling On Pavermalique ayetNessuna valutazione finora

- Concrete Exposures ClassesDocumento4 pagineConcrete Exposures ClasseshamidkarimpourNessuna valutazione finora

- Worked Example 1:: SolutionDocumento3 pagineWorked Example 1:: SolutionARVIND SINGH RAWATNessuna valutazione finora

- 2.ac - 004Documento1 pagina2.ac - 004Ferry WijiantaraNessuna valutazione finora

- 7tc1 Top FixedDocumento2 pagine7tc1 Top FixedEmily ShumNessuna valutazione finora

- Olympic Industries Product BrochureDocumento28 pagineOlympic Industries Product BrochureGaurav PopatNessuna valutazione finora

- 567198004Documento8 pagine567198004JAGUAR GAMINGNessuna valutazione finora