Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Magnum 3904 Datasheet

Caricato da

bobTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Magnum 3904 Datasheet

Caricato da

bobCopyright:

Formati disponibili

Technical Information

MAGNUM™ 3904

ABS Resin

Overview MAGNUM* 3904 is a resin with super-high impact. It is used in a wide range of technical applications. It can be

processed by injection moulding, extrusion or thermoforming. The mass (continuous process) ABS technology ensures

an ABS resin that combines excellent processability with a stable light base colour that is ideal for self-colouring.

Applications:

• Transportation

• Protective covers

• Leisure

• Automotive interior trim

• Luggage

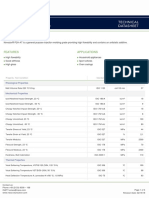

Physical Nominal Value (English) Nominal Value (SI) Test Method

Density 1.05 g/cm³ 1.05 g/cm³ ISO 1183/B

Apparent Density 0.65 g/cm³ 0.65 g/cm³ ISO 60

Melt Mass-Flow Rate (MFR) (220°C/10.0 kg) 4.5 g/10 min 4.5 g/10 min ISO 1133

Melt Volume-Flow Rate (MVR) (220°C/10.0 kg) 0.287 in³/10min 4.70 cm³/10min ISO 1133

Molding Shrinkage - Flow 4.0E-3 to 7.0E-3 in/in 0.40 to 0.70 % ISO 294-4

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Modulus ISO 527-2

0.126 in (3.20 mm), Injection Molded 264000 psi 1820 MPa

Tensile Stress

Yield, 0.126 in (3.20 mm), Injection Molded 5370 psi 37.0 MPa ISO 527-2/50

Yield, 0.126 in (3.20 mm), Injection Molded 5660 psi 39.0 MPa ISO 527-2/100

Tensile Strain

Yield, 0.126 in (3.20 mm), Injection Molded 2.6 % 2.6 % ISO 527-2/50

Yield, 0.126 in (3.20 mm), Injection Molded 2.8 % 2.8 % ISO 527-2/100

Flexural Modulus ISO 178 1, 2

0.126 in (3.20 mm), Injection Molded 276000 psi 1900 MPa

Flexural Stress ISO 178 1, 2

0.126 in (3.20 mm), Injection Molded 8410 psi 58.0 MPa

Impact Nominal Value (English) Nominal Value (SI) Test Method

Charpy Notched Impact Strength

-22°F (-30°C), Injection Molded 5.7 ft·lb/in² 12 kJ/m² ISO 179/2C

-22°F (-30°C), Injection Molded 8.6 ft·lb/in² 18 kJ/m² ISO 179/1eA

73°F (23°C), Injection Molded 18 ft·lb/in² 37 kJ/m² ISO 179/1eA

73°F (23°C), Injection Molded 10 ft·lb/in² 22 kJ/m² ISO 179/2C

Notched Izod Impact Strength ISO 180/A

-22°F (-30°C), Injection Molded 8.1 ft·lb/in² 17 kJ/m²

73°F (23°C), Injection Molded 20 ft·lb/in² 42 kJ/m²

Thermal Nominal Value (English) Nominal Value (SI) Test Method

Heat Deflection Temperature ISO 75-2/A

264 psi (1.8 MPa), Annealed 207 °F 97.0 °C

Vicat Softening Temperature 207 °F 97.0 °C ISO 306/B50

Flammability Nominal Value (English) Nominal Value (SI) Test Method

Burning Rate (0.0787 in (2.00 mm)) 1.6 in/min 40 mm/min ISO 3795 3

Flame Rating UL 94 3

0.0591 in (1.50 mm) HB HB

0.118 in (3.00 mm) HB HB

Page: 1 of 3 Form No. 500-00031913en

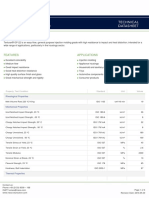

Flammability Nominal Value (English) Nominal Value (SI) Test Method

Carbon Emission 20.0 µg/g 20.0 µg/g VDA 277 3

Notes

These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests.

1

0.079 in/min (2.0 mm/min)

2

3-points

3

This rating not intended to reflect hazards presented by this or any other material under actual fire conditions.

Page: 2 of 3 Form No. 500-00031913en

Product Styron LLC, Styron HoldCo B.V., and subsidiaries (“Styron”) have a fundamental concern for all who make,

distribute, and use its products and for the environment in which we live. This concern is the basis for our Product

Stewardship Stewardship philosophy by which we assess the safety, health and environmental information on our products to

protect employee and public health and our environment. The success of our product stewardship program rests

with each and every individual involved with Styron products – from the initial concept and research, to

manufacture, use, sales, disposal and recycle of each product

Customer Customers are responsible for reviewing their manufacturing processes and their applications of Styron products

from the standpoint of human health and environmental quality to ensure that Styron products are not used in

Notice ways for which they are not suitable. Styron personnel are available to answer questions and to provide

reasonable technical support. Styron product literature, including safety data sheets, should be consulted prior to

the use of Styron products. Current safety data sheets are available from Styron.

Notice Regarding Styron requests that customers considering the use of Styron products in medical applications notify Styron so

that appropriate assessments may be conducted.

Medical Application

Restrictions Styron does not endorse or claim suitability of its products for specific medical applications and does not

knowingly sell or sample its products or services for certain medical applications. It remains the responsibility of

the medical device or pharmaceutical manufacturer to determine that the Styron product is safe, lawful, and

technically suitable for the intended use.

Disclaimer No freedom from infringement of any patent owned by Styron or others is to be inferred. Because use conditions

and applicable laws may differ from one location to another and may change with time, the Customer is

responsible for determining whether products and the information in this document are appropriate for the

Customer’s use and for ensuring that the Customer’s workplace and disposal practices are in compliance with

applicable laws and other governmental enactments. STYRON ASSUMES NO OBLIGATION OR LIABILITY FOR

THE INFORMATION IN THIS DOCUMENT. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

If products are described as “experimental” or “developmental”: 1.) product specifications may not be fully

determined; 2.) analysis of hazards and caution in handling and use are required; 3.) there is greater potential for

Styron to change specifications and/or discontinue production; and 4.) although Styron may from time to time

provide samples of such products, Styron is not obligated to supply or otherwise commercialize such products for

any use of application whatsoever.

Responsible Care® Our top priority is to provide the highest quality products and services, and to focus on the American Chemistry

Council’s Responsible Care® initiative and safety in all of our facilities.

Additional North America Europe/Middle East +800 444 11 444

Information U.S. & Canada: 1-888-STYRON1

1-989-633-1718 Germany:

+31-11567-2626

+8001811361

Mexico: +1-800-441-4369

Latin America Asia Pacific +800-7776-7776

Argentina: +54-11-4319-0100 +603-7965-5319

Brazil: +55-11-5188-9000

Colombia: +57-1-219-6000

Mexico: +52-55-5201-4700

www.styron.com This document is intended for use within Asia Pacific, Europe, Latin America, North America

Published: November 2014

© 2014 Styron LLC, Styron HoldCo B.V., and subsidiaries

Page: 3 of 3

™Trademark

®Responsible Care is a service mark of the American Chemistry Council. Form No. 500-00031913en

Potrebbero piacerti anche

- Magnum 3904 SmoothDocumento3 pagineMagnum 3904 SmoothbobNessuna valutazione finora

- The Science and Engineering of Thermal Spray CoatingsDa EverandThe Science and Engineering of Thermal Spray CoatingsNessuna valutazione finora

- 300.056 Magnum 3416 SCDocumento3 pagine300.056 Magnum 3416 SCEnrique ChavezNessuna valutazione finora

- Pulse A 35-105 BlackDocumento3 paginePulse A 35-105 BlackTaoufik KheddarNessuna valutazione finora

- Styron ATECH 1175 DatasheetDocumento3 pagineStyron ATECH 1175 DatasheetbobNessuna valutazione finora

- Exxonmobil™ Axo3Be3: Polypropylene Impact CopolymerDocumento2 pagineExxonmobil™ Axo3Be3: Polypropylene Impact CopolymermosesNessuna valutazione finora

- Document PDFDocumento2 pagineDocument PDFAnthony KasenaNessuna valutazione finora

- MAGNUM™ 3416 SC: ABS ResinDocumento3 pagineMAGNUM™ 3416 SC: ABS ResinEduardo MazariegosNessuna valutazione finora

- PC Calibre Technical DataDocumento4 paginePC Calibre Technical DataMitja GorseNessuna valutazione finora

- PC - Trinseo Emerge 8701HH GF10Documento3 paginePC - Trinseo Emerge 8701HH GF10armandoNessuna valutazione finora

- Exxonmobil™ Pp7905E1: Polypropylene Impact CopolymerDocumento2 pagineExxonmobil™ Pp7905E1: Polypropylene Impact CopolymermosesNessuna valutazione finora

- 300.002 Abs3416naDocumento3 pagine300.002 Abs3416naEnriqueNessuna valutazione finora

- Elix Ultra hh4115Documento3 pagineElix Ultra hh4115DiegoTierradentroNessuna valutazione finora

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocumento2 pagineAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNessuna valutazione finora

- Achieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymerDocumento2 pagineAchieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymermosesNessuna valutazione finora

- Product PDF 398216Documento2 pagineProduct PDF 398216Bruno CastroNessuna valutazione finora

- Elix Pc-Abs 5130Documento4 pagineElix Pc-Abs 5130DiegoTierradentroNessuna valutazione finora

- PC Lexan HP6NR Healthcare - ProspectorDocumento5 paginePC Lexan HP6NR Healthcare - ProspectorcountzeroaslNessuna valutazione finora

- Elix ABS E401: Technical InformationDocumento3 pagineElix ABS E401: Technical InformationDiegoTierradentroNessuna valutazione finora

- Pulse GX50Documento3 paginePulse GX50Daniel Lack PendásNessuna valutazione finora

- Elix ABS P2M-AT: Technical InformationDocumento3 pagineElix ABS P2M-AT: Technical InformationDiegoTierradentroNessuna valutazione finora

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocumento2 paginePOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNessuna valutazione finora

- Hostacom G3 N01 102297Documento2 pagineHostacom G3 N01 102297Sumit BishtNessuna valutazione finora

- PC Lexan 104Documento4 paginePC Lexan 104countzeroaslNessuna valutazione finora

- SABIC Cycolac MG47FDocumento3 pagineSABIC Cycolac MG47FChu ChuNessuna valutazione finora

- Sabic® Pmma 20HRDocumento2 pagineSabic® Pmma 20HRNguyễn Hồng NamNessuna valutazione finora

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNessuna valutazione finora

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocumento3 pagineCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNessuna valutazione finora

- 2186 - Pc-Abs Pulse gx70Documento3 pagine2186 - Pc-Abs Pulse gx70mikeburnsthrowaccNessuna valutazione finora

- Polyflam Rabs 90000 Uv5 LS (E128762)Documento3 paginePolyflam Rabs 90000 Uv5 LS (E128762)simonNessuna valutazione finora

- Elix ABS M220: Technical InformationDocumento3 pagineElix ABS M220: Technical InformationDiegoTierradentroNessuna valutazione finora

- Novodur P2H-ATDocumento3 pagineNovodur P2H-ATavinashchauhan2695Nessuna valutazione finora

- SABIC® PC Resin PC0703R - AsiaDocumento4 pagineSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNessuna valutazione finora

- LEXAN FST3403tDocumento3 pagineLEXAN FST3403tJose Ramon Florez OrdizNessuna valutazione finora

- 202-Trinseo Calibre Megarad 2081-15 TDSDocumento3 pagine202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNessuna valutazione finora

- Datasheet-Ultra Hh-4115-Hi-IsoDocumento3 pagineDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNessuna valutazione finora

- LEXAN™ Resin - 141R - Europe - Technical - Data - SheetDocumento2 pagineLEXAN™ Resin - 141R - Europe - Technical - Data - SheetMinh Quãng PhạmNessuna valutazione finora

- Vesbo PPR EnglishDocumento50 pagineVesbo PPR Englishcool.boys4200Nessuna valutazione finora

- Kumho 750SWDocumento1 paginaKumho 750SWChu ChuNessuna valutazione finora

- Styrolution Basf Terluran GP-22Documento3 pagineStyrolution Basf Terluran GP-22medo.k016Nessuna valutazione finora

- ELITE™ 5230G: Enhanced Polyethylene ResinDocumento3 pagineELITE™ 5230G: Enhanced Polyethylene ResinRoberto De Mesa PNessuna valutazione finora

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Documento1 paginaABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNessuna valutazione finora

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNessuna valutazione finora

- TASNEE 100 Black Polyethylene: DescriptionDocumento2 pagineTASNEE 100 Black Polyethylene: DescriptionHassanNessuna valutazione finora

- Covestro Bayblend® FR3000 PC - ABS BlendDocumento2 pagineCovestro Bayblend® FR3000 PC - ABS Blendavinashchauhan2695Nessuna valutazione finora

- Styro Lution Tds 401200140448Documento3 pagineStyro Lution Tds 401200140448scribdNessuna valutazione finora

- Flow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Documento4 pagineFlow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Guilherme Dos Santos SouzaNessuna valutazione finora

- Styro Lution Tds 400900240714Documento3 pagineStyro Lution Tds 400900240714vrjrNessuna valutazione finora

- StarexDocumento1 paginaStarexGuille FormosoNessuna valutazione finora

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Documento3 pagineEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNessuna valutazione finora

- Chi Mei Polylac PA 709S ABS ExtrusionDocumento2 pagineChi Mei Polylac PA 709S ABS ExtrusionSayyid AbulkhairNessuna valutazione finora

- CYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetDocumento2 pagineCYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetKishore Gowda A SNessuna valutazione finora

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNessuna valutazione finora

- DOWLEX™ 2047G: Polyethylene ResinDocumento3 pagineDOWLEX™ 2047G: Polyethylene Resinujang sukartaNessuna valutazione finora

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNessuna valutazione finora

- Makrolon 2407 - en - 86286874 00009645 19213223Documento4 pagineMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNessuna valutazione finora

- ULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetDocumento2 pagineULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetKishore Gowda A SNessuna valutazione finora

- Makrolon 2407 - en - 56977361 00009645 19213223Documento4 pagineMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNessuna valutazione finora

- PC1220R Infino LotteDocumento1 paginaPC1220R Infino LotteSCAR GONZALEzNessuna valutazione finora

- GUR Uhmw-Pe: Ultra High Performance Polyethylene PowderDocumento36 pagineGUR Uhmw-Pe: Ultra High Performance Polyethylene PowderbobNessuna valutazione finora

- Expancel DU Specification JAN2019Documento2 pagineExpancel DU Specification JAN2019bobNessuna valutazione finora

- SDS - Expancel 930 MB 120 - 20190626Documento13 pagineSDS - Expancel 930 MB 120 - 20190626bobNessuna valutazione finora

- PE-UHMW - Celanese - GUR 5129Documento2 paginePE-UHMW - Celanese - GUR 5129bobNessuna valutazione finora

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Documento3 pagineLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNessuna valutazione finora

- Sheet Extrusion Processing Guide: 1.0 Safety and Handling PrecautionsDocumento8 pagineSheet Extrusion Processing Guide: 1.0 Safety and Handling PrecautionsbobNessuna valutazione finora

- Luran S 797SE Q440: Acrylonitrile Styrene Acrylate (ASA)Documento3 pagineLuran S 797SE Q440: Acrylonitrile Styrene Acrylate (ASA)bobNessuna valutazione finora

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Documento3 pagineLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNessuna valutazione finora

- GUR Uhmw-Pe: Ultra High Performance Polyethylene PowderDocumento36 pagineGUR Uhmw-Pe: Ultra High Performance Polyethylene PowderbobNessuna valutazione finora

- Zytel® Lc6601 Bk551: Dupont Transportation & IndustrialDocumento2 pagineZytel® Lc6601 Bk551: Dupont Transportation & IndustrialbobNessuna valutazione finora

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNessuna valutazione finora

- Terluran or Novodur HI-10Documento2 pagineTerluran or Novodur HI-10bobNessuna valutazione finora

- Corrugated Compression Strength PDFDocumento25 pagineCorrugated Compression Strength PDFAnonymous 8lxxbNcA0sNessuna valutazione finora

- Luran S 797SE Q440: Acrylonitrile Styrene Acrylate (ASA)Documento3 pagineLuran S 797SE Q440: Acrylonitrile Styrene Acrylate (ASA)bobNessuna valutazione finora

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNessuna valutazione finora

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Documento2 pagineAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNessuna valutazione finora

- Sheet Extrusion Processing Guide: 1.0 Safety and Handling PrecautionsDocumento8 pagineSheet Extrusion Processing Guide: 1.0 Safety and Handling PrecautionsbobNessuna valutazione finora

- LEXAN™ Resin ML3290 - SABICDocumento5 pagineLEXAN™ Resin ML3290 - SABICbobNessuna valutazione finora

- Emerge™ Pc/Abs 7740: Technical InformationDocumento3 pagineEmerge™ Pc/Abs 7740: Technical InformationbobNessuna valutazione finora

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Documento3 pagineTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNessuna valutazione finora

- Calibre™ 603-3Documento3 pagineCalibre™ 603-3bobNessuna valutazione finora

- Diakon® ST35G8: Lucite International Holland BVDocumento3 pagineDiakon® ST35G8: Lucite International Holland BVbobNessuna valutazione finora

- PE-UHMW - Celanese - GUR 5129Documento2 paginePE-UHMW - Celanese - GUR 5129bobNessuna valutazione finora

- Xiran Heatboosters High Heat ABSDocumento2 pagineXiran Heatboosters High Heat ABSbobNessuna valutazione finora

- Plastic Marking DocumentDocumento21 paginePlastic Marking DocumentbobNessuna valutazione finora

- K-Resin KR01: Styrene Butadiene Copolymer (SBC)Documento2 pagineK-Resin KR01: Styrene Butadiene Copolymer (SBC)bobNessuna valutazione finora

- Terluran or Novodur HI-10Documento2 pagineTerluran or Novodur HI-10bobNessuna valutazione finora

- Extrusion Molding: Description ApplicationsDocumento2 pagineExtrusion Molding: Description ApplicationsbobNessuna valutazione finora

- Appendix 7 PDFDocumento4 pagineAppendix 7 PDFcm08909Nessuna valutazione finora

- Generic CPVC PDFDocumento2 pagineGeneric CPVC PDFbobNessuna valutazione finora

- Complainant Vs Vs Respondent: First DivisionDocumento7 pagineComplainant Vs Vs Respondent: First DivisionMaureen AntallanNessuna valutazione finora

- JurisprudenceDocumento11 pagineJurisprudenceParyushi KoshalNessuna valutazione finora

- Nation and NationalismDocumento3 pagineNation and NationalismAiden CabanogNessuna valutazione finora

- CONSOLIDATED BANK Vs DEL MONTE MOTOR WORKSDocumento26 pagineCONSOLIDATED BANK Vs DEL MONTE MOTOR WORKSdonna manaloNessuna valutazione finora

- SK Sto Domingo Charter 2022Documento5 pagineSK Sto Domingo Charter 2022Tabeng Pollin100% (1)

- New Microsoft Word DocumentDocumento7 pagineNew Microsoft Word DocumentHakam HazeemNessuna valutazione finora

- Canadian Passport Application For Canadian Adults Living AbroadDocumento8 pagineCanadian Passport Application For Canadian Adults Living AbroadRuslan DavidenkoNessuna valutazione finora

- About The Student: JochebedDocumento11 pagineAbout The Student: JochebedJochebed MukandaNessuna valutazione finora

- Relationship of Banks To Various CustomersDocumento35 pagineRelationship of Banks To Various CustomersBaby PinkNessuna valutazione finora

- Fundamentals of World Regional Geography. by Hobbs, Joseph J.Documento609 pagineFundamentals of World Regional Geography. by Hobbs, Joseph J.Minh KhôiNessuna valutazione finora

- The Forces On TheDocumento8 pagineThe Forces On ThehachanNessuna valutazione finora

- Rizal's ChildhoodDocumento31 pagineRizal's ChildhoodMichael ArdizoneNessuna valutazione finora

- 508 Vs 501Documento6 pagine508 Vs 501Koop Got Da KeysNessuna valutazione finora

- IICLE Employment Discrimination 2012 PDFDocumento72 pagineIICLE Employment Discrimination 2012 PDFAndy Williams Jr.100% (1)

- Institution of Valuers: Orissa BranchDocumento4 pagineInstitution of Valuers: Orissa Branchbiswashree10Nessuna valutazione finora

- Help To Buy Scheme - Listing of Registered Qualifying ContractorsDocumento21 pagineHelp To Buy Scheme - Listing of Registered Qualifying ContractorsReal NationNessuna valutazione finora

- Balindong Vs CADocumento9 pagineBalindong Vs CAEj CalaorNessuna valutazione finora

- Of Pakistan in The Light of Statements of Quaid-e-Azam & Allama IqbalDocumento16 pagineOf Pakistan in The Light of Statements of Quaid-e-Azam & Allama Iqbalmahnoor javaidNessuna valutazione finora

- Public-Private Partnership Bangladesh PerspectiveDocumento21 paginePublic-Private Partnership Bangladesh PerspectiveNafis Ahmed ChowdhuryNessuna valutazione finora

- Property Law Notes (Ownership)Documento13 pagineProperty Law Notes (Ownership)AizaFerrerEbina100% (2)

- Oldi1 - The Philippine Diplomacy in The Context of Public Diplomacy - Chua and CuarteroDocumento11 pagineOldi1 - The Philippine Diplomacy in The Context of Public Diplomacy - Chua and CuarteroQUIARYZA AINHAR CUARTERONessuna valutazione finora

- MJMC 4 SEM PAPER 403 (4) Development Communication TheoriesDocumento10 pagineMJMC 4 SEM PAPER 403 (4) Development Communication TheoriesTEI- Aadarsh Pandey.Nessuna valutazione finora

- FULL Download Ebook PDF International Business The New Realities 4th Global Edition PDF EbookDocumento41 pagineFULL Download Ebook PDF International Business The New Realities 4th Global Edition PDF Ebookscott.ramirez644100% (28)

- Why We Stuck - Biafra WarDocumento12 pagineWhy We Stuck - Biafra Warkunle kayode100% (1)

- Governance Quarter 1 - Module 5: Evolution of Philippine Politics andDocumento31 pagineGovernance Quarter 1 - Module 5: Evolution of Philippine Politics andCeasar Epsilonian MundalaNessuna valutazione finora

- Public Sector AccountingDocumento1 paginaPublic Sector AccountingKansaanah Tierong JaphethNessuna valutazione finora

- IG1 Element 1Documento22 pagineIG1 Element 1ali rezaNessuna valutazione finora

- BSP OPS Registration FormDocumento2 pagineBSP OPS Registration FormbiklatNessuna valutazione finora

- Jmi Admit CardDocumento2 pagineJmi Admit CardMohd YafiNessuna valutazione finora

- Wollo University: Student'SDocumento1 paginaWollo University: Student'SWøñdë Ðç BøîîNessuna valutazione finora

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDa EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNessuna valutazione finora

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- Waste: One Woman’s Fight Against America’s Dirty SecretDa EverandWaste: One Woman’s Fight Against America’s Dirty SecretValutazione: 5 su 5 stelle5/5 (1)

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (52)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDa EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseValutazione: 5 su 5 stelle5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Building Construction Technology: A Useful Guide - Part 1Da EverandBuilding Construction Technology: A Useful Guide - Part 1Valutazione: 4 su 5 stelle4/5 (3)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDa EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionValutazione: 3 su 5 stelle3/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Civil Engineer's Handbook of Professional PracticeDa EverandCivil Engineer's Handbook of Professional PracticeValutazione: 4.5 su 5 stelle4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Real Life: Construction Management Guide from A-ZDa EverandReal Life: Construction Management Guide from A-ZValutazione: 4.5 su 5 stelle4.5/5 (4)

- Field Guide for Construction Management: Management by Walking AroundDa EverandField Guide for Construction Management: Management by Walking AroundValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDa EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishValutazione: 4 su 5 stelle4/5 (3)

- Construction Project Management 101: For Beginners & New GraduatesDa EverandConstruction Project Management 101: For Beginners & New GraduatesNessuna valutazione finora

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDa EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyValutazione: 4 su 5 stelle4/5 (1)

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDa EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEValutazione: 4 su 5 stelle4/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDa EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyValutazione: 4 su 5 stelle4/5 (1)