Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ottocoll® P83: The PU Adhesive/sealant

Caricato da

JoeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ottocoll® P83: The PU Adhesive/sealant

Caricato da

JoeCopyright:

Formati disponibili

P 83 The PU adhesive/sealant

OTTOCOLL®

P 83

Technical Datasheet

Characteristics: - 1-component adhesive / sealant based on polyurethane

- Cures practically shrink-free without foaming

- Elastic and stress-compensating

- Non-corrosive

- Silicone-free

- Compatible with coatings according to DIN 52452

- Grindable and paintable after curing

- Extremely high resistance to impact load, shock load and peeling load

- Resistant to water, salt water, weak acids and alkaline, aquaeous cleaning agents

Fields of application: - Vibration- and movement-compensating bonding and sealing

- Sealing of air condition and ventilation systems

- For the bodywork and vehicle construction, waggon and container construction, metal construction

and apparatus engineering, ship building

Standards and tests: - Declaration of no objection – tested for use in food-related area (ISEGA Forschungs- und

Untersuchungs-Gesellschaft mbH, Aschaffenburg, Germany)

- Suitable for applications according to IVD instruction sheet no. 12+19-1+21+25+30+35 (IVD =

German industry association sealants)

- French VOC-emission class A+

- Certified according to GOS

- EMICODE® EC 1 Plus R - very low emission

Important information: Before applying this product the user has to ensure that the materials in the area of contact (solid, liquid

and gaseous) are compatible with it and also amongst each other and do not damage or alter (e. g.

discolour) each other. As for the materials that will be used at a later stage in the surrounding area of the

product the user has to clarify beforehand that the substances of content or evaporations do not lead to

an impairment or alteration (e. g. discolouration) of the product. In case of doubt the user should consult

the respective manufacturer of the material.

Paints, lacquers, plastics and any other coatings must be compatible to the adhesive/sealant.

Not or only temporarily resistant to organic solvents and acids, concentrated alkaline solutions and

mineral acids, lacquer solvents and paint thinners.

A binding statement concerning resistance can be given only after an application related testing.

According to relevant standards, elastic sealants should generally not be painted all-over, since

mechanical stress and movement can cause cracks in the non-elastic-paints.

Curing depends on thickness of layer, temperature and air humidity. At temperatures below + 5 °C

curing speed reduces immensly.

In case of UV-radiation stress discolourations may occur.

Not suitable for the bonding of glass, polyethylene (PE), polypropylene (PP), polyamide (PA),

polyfluoroethylene (PTFE), bituminous, waxy or oily substrates or similar.

EMICODE® is a registered trademark of GEV e. V. (Düsseldorf, Germany)

Technical properties: Skin-forming time at 23 °C/50 % RAH [minutes] ~ 50

Technical Datasheet OTTOCOLL® P 83

Page 1

version: 34 / 28gb (25.05.2016, 11:44 h)

Hermann Otto GmbH · Krankenhausstr. 14 · 83413 Fridolfing, GERMANY

Tel.:+49 8684-908-0 · Fax: +49 8684-12-60

e-mail: info@otto-chemie.de · Internet: www.otto-chemie.com

Curing in 24 hours at 23 °C/50 % RAH [mm] ~2-3

Processing temperature from/to [°C] + 5 / + 35

Viscosity at 23 °C pasty, stable

Density at 23 °C according to ISO 1183-1 [g/cm³] ~ 1,3

Shore-A-hardness according to ISO 868 ~ 40

Permissible movement capability [%] 20

Stress expansion modulus at 100 % according to ISO 37, S3A [N/mm²] ~ 0,6

Tensile expansion according to ISO 37, S3A [%] ~ 600

Tensile strength according to ISO 37, S3A [N/mm²] ~ 3,0

Retroactivity according to ISO 7389 [%] > 80

Temperature resistance from/to [°C] - 40 / + 80

Shelf life at 23 °C/50 % RAH for cartridge/foil bag [months] 12

These data are not suitable for the issue of specifications. Please contact OTTO-CHEMIE before issuing

specifications.

Pretreatment: All adherent surfaces must be clean and any contaminant such as release agents, preserving agents,

grease, oil, dust, water, old adhesives or sealants and other substances which could affect adhesion,

should be removed. Cleaning of non-porous substrates: Apply OTTO Cleaner T (airing time approx. 1

minute) using a clean, lint-free cotton cloth. Cleaning porous substrates: Clean surfaces with steel-wire

brush e. g. or a grinding disk to remove loose particles.

The adherent surfaces have to be clean, free from dust and grease as well as sustainable.

Primer Table: The requirements for elastic sealing and bonding depend on external influences. Extreme changes in

temperature, expansibility and tensile strenght, repeated contact with water, etc. demand a lot from a

bonding.Therefor the use of mentioned primers is absolutely necessary.

Aluminium 1226

Aluminium anodized 1226

Aluminium powder-coated 1226 / T

Concrete 1225

Stainless steel 1226

Fibre cement 1225

PVC unplasticized 1227

Zinc, galvanised iron 1226

+ = good adherence without primer

- = not suitable

T = Test/pilot test advised

Application information: Due to the many possible influences during and after application, the customer always has to carry out

trials first.

Please observe the recommended shelf life which is printed on the packaging.

We recommend to store our products in unopened original packagings dry (< 60 % RAH) at

temperatures of +15 °C up to +25 °C. If the products are stored and / or transported at higher

temperatures / air humidity for longer periods (some weeks), a diminuition of durability or a change of

material characteristics may arise.

Packaging: 310 ml aluminium cartridge 580 ml aluminium foil bag

black P83-20-C04 on request

grey P83-20-C02 P83-08-C02

white P83-20-C01 on request

Packaging unit 20 20

Pieces per pallet 1200 600

Safety precautions: Please observe the material safety data sheet.

Disposal: Information about disposal: Please refer to the material safety data sheet.

Technical Datasheet OTTOCOLL® P 83

Page 2

version: 34 / 28gb (25.05.2016, 11:44 h)

Hermann Otto GmbH · Krankenhausstr. 14 · 83413 Fridolfing, GERMANY

Tel.:+49 8684-908-0 · Fax: +49 8684-12-60

e-mail: info@otto-chemie.de · Internet: www.otto-chemie.com

Warranty information: All information in this publication is based on our current technical knowledge and experience. However,

since conditions and methods of use and application of our products are beyond our control, we suggest

that you test the product before final use. Information given in this technical data sheet and explanations

of OTTO-CHEMIE in connection with this technical data sheet (e.g. service description, reference to DIN

regulations etc.) is not to be seen as a warranty. Warranties require a separate written declaration of

OTTO-CHEMIE to prove their validity. The characteristics stated in this data sheet define the

characteristics of the article broadly and concludingly. Suggestions of use are not to be taken as

confirmation of the appropriateness for the recommended intended use. We reserve the right to alter the

product, adjusting it according to technical progress and new developments. We are at your disposal

both for inquiries as well as specific application problems. If a governmental approval or clearance is

necessary for the application of our products, the user is responsible for the obtainment of such. Our

recommendations do not excuse the user from the obligation to take into consideration the possibility of

infringement of third parties' rights and - if necessary - resolving it. For the rest our general terms and

conditions apply, in particular regarding a possible liability for defects. You can find our general terms

and conditions on our homepage: http://www.otto-chemie.com.

Technical Datasheet OTTOCOLL® P 83

Page 3

version: 34 / 28gb (25.05.2016, 11:44 h)

Hermann Otto GmbH · Krankenhausstr. 14 · 83413 Fridolfing, GERMANY

Tel.:+49 8684-908-0 · Fax: +49 8684-12-60

e-mail: info@otto-chemie.de · Internet: www.otto-chemie.com

Potrebbero piacerti anche

- CAPE Chemistry Unit 2 Paper 2 2017 AnswersDocumento12 pagineCAPE Chemistry Unit 2 Paper 2 2017 Answersemanuel coates100% (9)

- Detailers Dictionary Volume 2: The Industry StandardDa EverandDetailers Dictionary Volume 2: The Industry StandardNessuna valutazione finora

- NanoSteel Technology Overview - Lincoln PDFDocumento74 pagineNanoSteel Technology Overview - Lincoln PDFrajeevkrishna10Nessuna valutazione finora

- Ottocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionDocumento4 pagineOttocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionJoeNessuna valutazione finora

- Ottocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingDocumento3 pagineOttocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingJoeNessuna valutazione finora

- Tds Ottoseal A 205-67-50gbDocumento4 pagineTds Ottoseal A 205-67-50gbGalih MedanNessuna valutazione finora

- Ottocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantDocumento4 pagineOttocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantJoeNessuna valutazione finora

- Tds OTTOCOLL M 500 42 - 28gb PDFDocumento4 pagineTds OTTOCOLL M 500 42 - 28gb PDFJoeNessuna valutazione finora

- Ottoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsDocumento3 pagineOttoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsJoeNessuna valutazione finora

- Tds OTTOCOLL M 580 36 - 34gbDocumento4 pagineTds OTTOCOLL M 580 36 - 34gbBos KiNessuna valutazione finora

- E1738-1609-ATT.20 Sellador OTTOSEALDocumento3 pagineE1738-1609-ATT.20 Sellador OTTOSEALmarcosNessuna valutazione finora

- Ottocoll® A 265 Topfix: Technical DatasheetDocumento3 pagineOttocoll® A 265 Topfix: Technical DatasheetGalih MedanNessuna valutazione finora

- TDS Pattex BondsealfillDocumento5 pagineTDS Pattex BondsealfilldknisNessuna valutazione finora

- Whitechem Polyurea Pa 1005-EnDocumento4 pagineWhitechem Polyurea Pa 1005-EnBien PangilinanNessuna valutazione finora

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocumento4 pagineSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNessuna valutazione finora

- iKOTE AC 40 (DEC-2023) V1.3Documento2 pagineiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNessuna valutazione finora

- AlphaSeal PU25VLS NGDocumento3 pagineAlphaSeal PU25VLS NGMuthukumar JayaveerapandianNessuna valutazione finora

- Tankguard StorageDocumento5 pagineTankguard StorageBiju_PottayilNessuna valutazione finora

- ID2920 - Silirub 908Documento2 pagineID2920 - Silirub 908hhnp204Nessuna valutazione finora

- Flexible Pu SealantDocumento2 pagineFlexible Pu SealantGi GoNessuna valutazione finora

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocumento6 pagineSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatmilanbrasinaNessuna valutazione finora

- 001 PDS Sikafloor-261 SystemDocumento10 pagine001 PDS Sikafloor-261 SystemdebojyotihatiNessuna valutazione finora

- Marathon 500 Technical Data SheetDocumento5 pagineMarathon 500 Technical Data SheetGurdeep Sungh AroraNessuna valutazione finora

- Otto Primer 1216: The Primer For Natural Stone and MetalDocumento2 pagineOtto Primer 1216: The Primer For Natural Stone and MetalJoeNessuna valutazione finora

- Tankguard 412 Jotun PaintDocumento6 pagineTankguard 412 Jotun PaintGurdeep Sungh AroraNessuna valutazione finora

- Solvalitt ALU - TDS.eng PDFDocumento5 pagineSolvalitt ALU - TDS.eng PDFsaiful anwarNessuna valutazione finora

- Ottoseal® S94: Technical DatasheetDocumento3 pagineOttoseal® S94: Technical DatasheetJoeNessuna valutazione finora

- Sikafloor - 264 EngDocumento5 pagineSikafloor - 264 Engbassem kooliNessuna valutazione finora

- Soudaflex 40FC - DatasheetDocumento2 pagineSoudaflex 40FC - DatasheetsouravrobinNessuna valutazione finora

- Silicone U - TDSDocumento2 pagineSilicone U - TDShadeer youns0% (1)

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocumento3 pagineCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANessuna valutazione finora

- Jotafloor EP SLDocumento4 pagineJotafloor EP SLEduardo Vera portocarreroNessuna valutazione finora

- Jotatemp 540 Zinc Technical Data SheetDocumento5 pagineJotatemp 540 Zinc Technical Data SheetGurdeep Sungh AroraNessuna valutazione finora

- Build: Builders Silicone SealantsDocumento3 pagineBuild: Builders Silicone SealantsAhmed KhameisNessuna valutazione finora

- Tankguard StorageDocumento5 pagineTankguard Storageabdulgafoor54Nessuna valutazione finora

- TDS Penguard Pro JotunDocumento5 pagineTDS Penguard Pro JotunLuka BornaNessuna valutazione finora

- Conseal Touch-Up: Technical Data SheetDocumento4 pagineConseal Touch-Up: Technical Data SheetSyilla ShopeNessuna valutazione finora

- Marathon 1000XHB Technical Data SheetDocumento5 pagineMarathon 1000XHB Technical Data SheetGurdeep Sungh AroraNessuna valutazione finora

- Gasket RTV Silicone 310 ML: Applications BenefitsDocumento4 pagineGasket RTV Silicone 310 ML: Applications BenefitsNurcan BozkurtNessuna valutazione finora

- Sikalastic 836 DWDocumento3 pagineSikalastic 836 DWHaniNessuna valutazione finora

- Sikaflex Pro 3 I CureDocumento5 pagineSikaflex Pro 3 I Curemuhammad aliNessuna valutazione finora

- Tankguard HB Classic Jotun PaintDocumento5 pagineTankguard HB Classic Jotun PaintGurdeep Sungh AroraNessuna valutazione finora

- DESMOFLEX TOP COΑΤ v2 ENDocumento3 pagineDESMOFLEX TOP COΑΤ v2 ENprestigebuild888Nessuna valutazione finora

- Wacker WN - Weatherseal NeutralDocumento4 pagineWacker WN - Weatherseal NeutralMohammad SaadehNessuna valutazione finora

- Barrier 80 PDFDocumento5 pagineBarrier 80 PDFBalaji GuruNessuna valutazione finora

- Chemflake SpecialDocumento5 pagineChemflake SpecialBiju_PottayilNessuna valutazione finora

- Datasheet Jotun-Tankguard StorageDocumento5 pagineDatasheet Jotun-Tankguard Storagebudi handoyoNessuna valutazione finora

- TDS 25740 Jotafloor EP SL Euk GBDocumento5 pagineTDS 25740 Jotafloor EP SL Euk GBDavid TumboimbelaNessuna valutazione finora

- TDS GB BeetDocumento5 pagineTDS GB BeetRonnalyn TorresNessuna valutazione finora

- Jotashield Colourlast SilkDocumento3 pagineJotashield Colourlast Silkمحمد عزتNessuna valutazione finora

- Soudaflex Construction FCDocumento2 pagineSoudaflex Construction FCAvijitSinharoyNessuna valutazione finora

- TDS 429 Conseal Touch-Up Euk GBDocumento4 pagineTDS 429 Conseal Touch-Up Euk GBGalih WicaksonoNessuna valutazione finora

- Sikalastic®-8440: Product Data SheetDocumento3 pagineSikalastic®-8440: Product Data SheetGeorge EnescuNessuna valutazione finora

- Safeguard Universal ES: Technical Data SheetDocumento5 pagineSafeguard Universal ES: Technical Data SheetIsaacNarendraAkbarNessuna valutazione finora

- Tankguard SF: Technical Data SheetDocumento5 pagineTankguard SF: Technical Data SheetRifki ArifinNessuna valutazione finora

- Jotatemp 1000 Ceramic Technical Data SheetDocumento5 pagineJotatemp 1000 Ceramic Technical Data SheetGurdeep Sungh AroraNessuna valutazione finora

- Novo Flex Pu 40Documento1 paginaNovo Flex Pu 40mohamedNessuna valutazione finora

- Geotextiles and Geomembranes HandbookDa EverandGeotextiles and Geomembranes HandbookT.S. IngoldValutazione: 5 su 5 stelle5/5 (1)

- GRP and Buildings: A Design Guide for Architects and EngineersDa EverandGRP and Buildings: A Design Guide for Architects and EngineersNessuna valutazione finora

- Corrosion and Fouling Control in Desalination IndustryDa EverandCorrosion and Fouling Control in Desalination IndustryNessuna valutazione finora

- S 70 Eurofins Leed Conformation Eq 4 1 20101015 e 1Documento2 pagineS 70 Eurofins Leed Conformation Eq 4 1 20101015 e 1JoeNessuna valutazione finora

- Ottoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsDocumento3 pagineOttoseal® S69: The Acetate Silicone For Clean Rooms and Room Ventilation SystemsJoeNessuna valutazione finora

- S 10 Eurofins Leed Confirmation Eq 4 1 20101019 e 1Documento2 pagineS 10 Eurofins Leed Confirmation Eq 4 1 20101019 e 1JoeNessuna valutazione finora

- Ottoseal® S94: Technical DatasheetDocumento3 pagineOttoseal® S94: Technical DatasheetJoeNessuna valutazione finora

- Ottoseal® S70: The Premium Natural Stone SiliconeDocumento5 pagineOttoseal® S70: The Premium Natural Stone SiliconeJoeNessuna valutazione finora

- Ottoseal® S 120: The Premium Alkoxy Window SiliconeDocumento5 pagineOttoseal® S 120: The Premium Alkoxy Window SiliconeJoeNessuna valutazione finora

- Otto Cleanprimer 1101: The Adhesion ImproverDocumento2 pagineOtto Cleanprimer 1101: The Adhesion ImproverJoeNessuna valutazione finora

- Otto Primer 1216: The Primer For Natural Stone and MetalDocumento2 pagineOtto Primer 1216: The Primer For Natural Stone and MetalJoeNessuna valutazione finora

- Sika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairDocumento3 pagineSika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairJoeNessuna valutazione finora

- Sikadur - 52: Low Viscosity Injection ResinDocumento3 pagineSikadur - 52: Low Viscosity Injection ResinJoeNessuna valutazione finora

- The ASTM D4263 Concrete Moisture TestDocumento4 pagineThe ASTM D4263 Concrete Moisture TestJoe100% (1)

- Sikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveDocumento4 pagineSikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveJoeNessuna valutazione finora

- CH 1.1 - Single Stage Equilibrium Operations - Part 1Documento26 pagineCH 1.1 - Single Stage Equilibrium Operations - Part 1Boon NgNessuna valutazione finora

- Experience With Lined and Clad PipelinesDocumento17 pagineExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (1)

- Astm D5453 - 2004Documento10 pagineAstm D5453 - 2004Teymur Regenmaister100% (1)

- Ti Corrosion in AlkalineDocumento10 pagineTi Corrosion in AlkalineGeetha ThiruvengadamNessuna valutazione finora

- Electro-Etching Made EasyDocumento52 pagineElectro-Etching Made Easyedhykoes100% (1)

- Drager Vapor 2000Documento76 pagineDrager Vapor 2000Vinicius Belchior da SilvaNessuna valutazione finora

- Tangential Flow Filtration BasicsDocumento19 pagineTangential Flow Filtration BasicsKarthik VijayakumarNessuna valutazione finora

- Lactic Acid Production From Glycerol Using CaO As Solid Base CatalystDocumento8 pagineLactic Acid Production From Glycerol Using CaO As Solid Base CatalystlarguedasNessuna valutazione finora

- Local Anesthetics 2006Documento22 pagineLocal Anesthetics 2006Shashikant DrShashikant BagadeNessuna valutazione finora

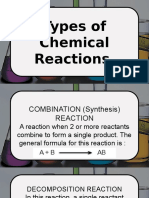

- Types of Chemical ReactionsDocumento36 pagineTypes of Chemical ReactionsAira Villarin100% (3)

- Chapter15 Siva PDFDocumento25 pagineChapter15 Siva PDFlinaNessuna valutazione finora

- Drug MetabolismDocumento46 pagineDrug Metabolismأحمد عاطفNessuna valutazione finora

- Biofilm OceanOptics TemplateDocumento83 pagineBiofilm OceanOptics TemplateSatyaki MajumdarNessuna valutazione finora

- Ari 560-2000Documento25 pagineAri 560-2000rajat vermaNessuna valutazione finora

- Lines Technical Document Admixtures For Concrete enDocumento30 pagineLines Technical Document Admixtures For Concrete enJoseph ChenNessuna valutazione finora

- Lab Waste ManagementDocumento29 pagineLab Waste ManagementMohamed AslamNessuna valutazione finora

- 34 Qualitative Analysis Formula Sheets QuizrrDocumento11 pagine34 Qualitative Analysis Formula Sheets QuizrrSwapnil SharmaNessuna valutazione finora

- LI-PO SizesDocumento17 pagineLI-PO SizesmariorossiNessuna valutazione finora

- Energy Storage SystemDocumento22 pagineEnergy Storage Systemmikkumar5Nessuna valutazione finora

- Water - Viscosity Table and Viscosity ChartDocumento4 pagineWater - Viscosity Table and Viscosity ChartJokoSuswonoNessuna valutazione finora

- Maks GTC 1000Documento1 paginaMaks GTC 1000Chiheb Eddine KourasNessuna valutazione finora

- Strengthening MechanismsDocumento17 pagineStrengthening Mechanismspkn_pnt9950Nessuna valutazione finora

- ACV-12 Adjustable Choke Valves: For Wide Applications in Oil, Gas, and Water ServiceDocumento2 pagineACV-12 Adjustable Choke Valves: For Wide Applications in Oil, Gas, and Water ServiceDeyokeNessuna valutazione finora

- Pit Iagi37 Sdg043 Lambok Full Paper Gas Geochemistry Final PDFDocumento12 paginePit Iagi37 Sdg043 Lambok Full Paper Gas Geochemistry Final PDFakun cadanganNessuna valutazione finora

- Plastic Fuel Alka ZadgaonkarDocumento60 paginePlastic Fuel Alka Zadgaonkarprashanth2812Nessuna valutazione finora

- Practice Test-03 For AIATS-05Documento16 paginePractice Test-03 For AIATS-05Urja Moon0% (1)

- Material PropertiesDocumento42 pagineMaterial PropertiesDr_M_Soliman100% (2)

- 5lab - Serial DilutionDocumento3 pagine5lab - Serial DilutionBianca ANessuna valutazione finora