Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Optimization Module for Chemical Engineering Degree

Caricato da

kudra emmanuel0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

696 visualizzazioni3 pagineTitolo originale

Module Descriptor

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

696 visualizzazioni3 pagineProcess Optimization Module for Chemical Engineering Degree

Caricato da

kudra emmanuelCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

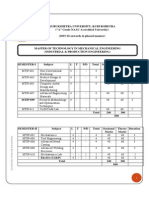

MALAWI UNIVERSITY OF SCIENCE AND TECHNOLOGY

MALAWI INSTITUTE OF TECHNOLOGY

ENGINEERING DEPARTMENT

1. Programme(s): BEng (Hon) Chemical Engineering

2. Module Title: Process Optimisation

3. Module code: PROP-520

4. Level: 5

5. Credit: 10

6. Presented to: Senate

7. Presented by: Malawi Institute of Technology

8. Lecture (hours/week): 3

9. Tutorial/Laboratory (hrs/wk): 1

10. Prerequisites: PRDC-410, MATH 322

11. Co-requisites:

12. Module Aims

To introduce process engineering system optimization techniques

13. Intended Learning Outcomes

On completion of this module the student should be able to:

a. demonstrate understanding of the basic concepts of process optimization

and corresponding methodologies

b. demonstrate understanding of linear programming, nonlinear

programming, mixed-integer linear/nonlinear programming and the main

solution techniques

c. formulate optimization problems: variables, objective, constraints

d. apply mathematical programming methods in the area of process

integration

e. use compute packages for solving optimization problems

Curriculum Document: BEng. (Hons) in Chemical Engineering Page 181

14. Indicative Content

a. Linear Programming and applications

Basic concepts, Graphical simplex method, revised simplex method, duality

and transportation problems.

b. Introduction to chemical engineering system optimization:

Nature and organization of optimization problems: scope and hierarchy of

optimization, examples of applications of optimization, Objective Function

and Decision variables; general procedure for solving optimization

problems. Optimization models building and fitting.

c. Optimisation theory and concepts:

Basic concepts of optimization: Continuity of functions; Quadratic

approximation of the objective function; Convexity and its applications;

extremum of an unconstrained function. Unconstrained one dimensional

search: Newton, Quasi Newton and Secant method for uni-dimensional

search, region elimination methods (Golden Section, Fibonacci,

Dichotomous etc). Unconstrained multi-variable search, direct methods,

indirect method, Finite difference approximation

d. Applications of optimization in chemical engineering:

Optimization of unit operations: recovery of waste heat, shell and tube

heat exchangers, evaporator design, liquid-liquid extraction process,

optimal design of staged distillation column, optimal pipe diameter,

optimal residence time for maximum yield in an ideal isothermal batch

reactor, chemostat, optimization of thermal cracker using liner

programming, optimal design of an ammonia reactor.

15. Assessment

Coursework: 40%

End of modules examination: 60%

16. Teaching and Learning Methods / Activities

Lectures, tutorials, exercises

17. Prescribed Texts

Edgar, T.F, Himmelblau, D.M & Lasdon, L.S 2001, Optimisation of chemical

processes, 2nd edn, McGraw-Hill.

Chong, E.K.P& Zak, S.H 2008, An introduction to optimization, 3rd edn, John

Curriculum Document: BEng. (Hons) in Chemical Engineering Page 182

Wiley and Sons

Rao, S.S 2009, Engineering optimization: Theory and practice, 4th edn, John Wiley

18. Recommended Texts

Murty K. G. (1983), Linear Programming. John Wiley, Berkeley

Dantzig,

Seborg D. E., Edgar T. F. & Mellichamp D. A. (2006). Process Dynamics and

Control , John Wiley. India

Deb, K.M 2000, Optimization for Engineering Design: algorithms and examples,

Prentice-Hall.

Güller, O (2010), Foundations of optimisation, (1st Ed.), Springer.

Joshi, M.C & Moudgalya, K.M (2004), Optimization: Theory and Practice, Alpha

Science International Limited.

Onwubolu, G. C & Babu, B.V (2004), New Optimization techniques in

engineering, Springer.

Pandu, G.R (2009), Multi-objective optimisation: Techniques and application in

Chemical Engineering, World Scientific Publishing.

Pike, R.W (1986), Optimization for engineering systems, Van Nostrand Reinhold.

19. Date: June 2016

Curriculum Document: BEng. (Hons) in Chemical Engineering Page 183

Potrebbero piacerti anche

- GTU Process Modelling, Simulation and OptimizationDocumento4 pagineGTU Process Modelling, Simulation and Optimizationdpatel 2310Nessuna valutazione finora

- Fundamentals of Optimization Techniques with AlgorithmsDa EverandFundamentals of Optimization Techniques with AlgorithmsValutazione: 5 su 5 stelle5/5 (1)

- Optimization TechniquesDocumento3 pagineOptimization Techniques2020001873.gcetNessuna valutazione finora

- Chemical Engineering Process SimulationDa EverandChemical Engineering Process SimulationDominic FooNessuna valutazione finora

- PROCESS PLANNING COST ESTIMATIONDocumento3 paginePROCESS PLANNING COST ESTIMATIONVpr NaturalsNessuna valutazione finora

- Python For Chemical Engineers An Efficient Approach To Teach Non Programmers To ProgramDocumento12 paginePython For Chemical Engineers An Efficient Approach To Teach Non Programmers To ProgramAbhijit BNessuna valutazione finora

- Chemical Engineering Dynamics: Modelling with PC SimulationDa EverandChemical Engineering Dynamics: Modelling with PC SimulationNessuna valutazione finora

- CBCS - MTech - Design of Mechanical Equipments - Syllabus 271218Documento106 pagineCBCS - MTech - Design of Mechanical Equipments - Syllabus 271218Ranjan KumarNessuna valutazione finora

- 2EE71OE3 - Optimization TechniquesDocumento2 pagine2EE71OE3 - Optimization TechniquesVinod RajNessuna valutazione finora

- PMSO SyllabusDocumento5 paginePMSO Syllabusuvesh shaikhNessuna valutazione finora

- B.Tech I & II Semester Syllabus - 2018-19 PDFDocumento41 pagineB.Tech I & II Semester Syllabus - 2018-19 PDFDatta YallapuNessuna valutazione finora

- Bmee211l Engineering-Optimization TH 1.0 67 Bmee211lDocumento2 pagineBmee211l Engineering-Optimization TH 1.0 67 Bmee211lForgot PasswordNessuna valutazione finora

- CEPD101 study guide for 2024Documento14 pagineCEPD101 study guide for 2024Sydney Jaydean KhanyileNessuna valutazione finora

- Gujarat Technological University: Page 1 of 3Documento3 pagineGujarat Technological University: Page 1 of 3jpbhimaniNessuna valutazione finora

- M.tech Mechanical Engg. (I &P)Documento44 pagineM.tech Mechanical Engg. (I &P)Upender DhullNessuna valutazione finora

- PDFDocumento3 paginePDFMilan MoradiyaNessuna valutazione finora

- MoM of DLOC-I - Sem V Mechanical Automobile - R2019 C SchemeDocumento11 pagineMoM of DLOC-I - Sem V Mechanical Automobile - R2019 C Schemeshaikh javedNessuna valutazione finora

- J.B. Institute of Engineering and Technology: Course Code: C322 Finite Element MethodDocumento82 pagineJ.B. Institute of Engineering and Technology: Course Code: C322 Finite Element MethodGopinath GangadhariNessuna valutazione finora

- Department: Production Engineering LaboratoryDocumento70 pagineDepartment: Production Engineering LaboratorySourabh PradhanNessuna valutazione finora

- Gujarat Technological University: W.E.F. AY 2018-19Documento3 pagineGujarat Technological University: W.E.F. AY 2018-19Priyank ChhatriwalaNessuna valutazione finora

- CAD/CAM Lab Manual for Mechanical EngineeringDocumento83 pagineCAD/CAM Lab Manual for Mechanical EngineeringPasupathi KumarNessuna valutazione finora

- TE-I-Course Handout2022Documento9 pagineTE-I-Course Handout2022rambabuNessuna valutazione finora

- First Year Common SyllabusDocumento61 pagineFirst Year Common Syllabusharshitsuwan27Nessuna valutazione finora

- Optimization of Chemical ProcessesDocumento2 pagineOptimization of Chemical ProcessesAmol RastogiNessuna valutazione finora

- VIIIth Semester Scheme and SyllabusDocumento21 pagineVIIIth Semester Scheme and SyllabusJitesh DewanganNessuna valutazione finora

- Nba Ug Cs B 3 6 SyllabusDocumento48 pagineNba Ug Cs B 3 6 SyllabusAnkit AnandNessuna valutazione finora

- 3712018-Structural OptimizationDocumento2 pagine3712018-Structural OptimizationTime passNessuna valutazione finora

- CPS 410 Process Synthesis 410: School of Engineering Department of Chemical EngineeringDocumento7 pagineCPS 410 Process Synthesis 410: School of Engineering Department of Chemical EngineeringLourens SwartNessuna valutazione finora

- OptimizationDocumento2 pagineOptimizationsiddhardha9010Nessuna valutazione finora

- Design Lab (18MEL77) Updated ManualDocumento57 pagineDesign Lab (18MEL77) Updated ManualSagar SagNessuna valutazione finora

- CAD Course Student HandoutDocumento17 pagineCAD Course Student HandoutDarshanNessuna valutazione finora

- ES5xx - Course Outline - Sp2024Documento3 pagineES5xx - Course Outline - Sp2024Aamir ShehzadNessuna valutazione finora

- Principles of Management - En010 402 (Me)Documento43 paginePrinciples of Management - En010 402 (Me)Arjun KrNessuna valutazione finora

- M.tech Syllabus PDFDocumento51 pagineM.tech Syllabus PDFAnonymous MR8PLYNessuna valutazione finora

- Computational Chemical EngineeringDocumento3 pagineComputational Chemical EngineeringjournalNessuna valutazione finora

- Approved by AICTE & Affiliated To Anna University, ChennaiDocumento7 pagineApproved by AICTE & Affiliated To Anna University, ChennaiSAMUEL SANJAY RAJA R MECHNessuna valutazione finora

- PE VI-MEG347A-CFD Syllabus 2020Documento5 paginePE VI-MEG347A-CFD Syllabus 2020Vaibhav AnandNessuna valutazione finora

- BTech Mechanical - 2020-24 ADMDocumento4 pagineBTech Mechanical - 2020-24 ADMKanu SharmaNessuna valutazione finora

- 1ET1010709 Optimization TechniquesDocumento2 pagine1ET1010709 Optimization TechniquesDivyNessuna valutazione finora

- Mee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015Documento3 pagineMee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015manoj smNessuna valutazione finora

- Course File For NBADocumento15 pagineCourse File For NBAJananicharlesraj0% (1)

- Refrigeration & Air - Conditioning LabDocumento60 pagineRefrigeration & Air - Conditioning LabDevendra kumarNessuna valutazione finora

- BME LAB ManualDocumento88 pagineBME LAB ManualNeeraj SainiNessuna valutazione finora

- Design and Analysis of Algorithm Lab (BSCS2351) Lab ManualDocumento46 pagineDesign and Analysis of Algorithm Lab (BSCS2351) Lab ManualvintNessuna valutazione finora

- Arjun College of Technology: Course PlanDocumento12 pagineArjun College of Technology: Course PlanKanagaraj PalaniaapanNessuna valutazione finora

- Applied Chemistry (Non IT)Documento5 pagineApplied Chemistry (Non IT)himanshuchawla654Nessuna valutazione finora

- DKOM Lab ManualDocumento24 pagineDKOM Lab Manualaakash chakrabortyNessuna valutazione finora

- MTech Machine Design PDFDocumento41 pagineMTech Machine Design PDFswapnilNessuna valutazione finora

- STLD Course File Dr. SKFDocumento28 pagineSTLD Course File Dr. SKFSHAIK FAIROOZNessuna valutazione finora

- Maintanence Assignment - 9917002008Documento26 pagineMaintanence Assignment - 9917002008LOKESHWARAN K CHEM-UG- 2017 BATCHNessuna valutazione finora

- CH - CSE2014 - Software Engineering - As Per NAACDocumento10 pagineCH - CSE2014 - Software Engineering - As Per NAACNuman ManiyarNessuna valutazione finora

- VJTI B.Tech. Mechanical Engineering curriculumDocumento74 pagineVJTI B.Tech. Mechanical Engineering curriculumROHAN NAGRUTNessuna valutazione finora

- ECE 3270 SyllabusDocumento2 pagineECE 3270 SyllabusGem Catalan-CalmaNessuna valutazione finora

- New9 Page MSO B.E. Chem. Engg. Sem. VIIIDocumento9 pagineNew9 Page MSO B.E. Chem. Engg. Sem. VIIIAakashNessuna valutazione finora

- Introduction To OptimizationDocumento126 pagineIntroduction To OptimizationMustafaMahdi100% (1)

- 14 KCS151P 251P Prog For Prob SolvingDocumento25 pagine14 KCS151P 251P Prog For Prob SolvingSARKARI BABUNessuna valutazione finora

- Gujarat Technological University: W.E.F. AY 2018-19Documento3 pagineGujarat Technological University: W.E.F. AY 2018-19Pradeep SutharNessuna valutazione finora

- Aa CMPN III Am3 (Div1)Documento12 pagineAa CMPN III Am3 (Div1)Nasir AnsariNessuna valutazione finora

- Unit Number 1: Introduction To Chemical Engineering System OptimizationDocumento6 pagineUnit Number 1: Introduction To Chemical Engineering System Optimizationkudra emmanuelNessuna valutazione finora

- Low-NOx Burners for Emission ReductionDocumento1 paginaLow-NOx Burners for Emission Reductionkudra emmanuelNessuna valutazione finora

- Solutions Manual For An Introduction To Combustion Concepts and Applications 3rd Edition by Turns PDFDocumento42 pagineSolutions Manual For An Introduction To Combustion Concepts and Applications 3rd Edition by Turns PDFkudra emmanuel100% (1)

- Linear Programming ProblemsDocumento1 paginaLinear Programming Problemskudra emmanuelNessuna valutazione finora

- Lecture 4 Combustion Engines and Efficiencies Part 2Documento21 pagineLecture 4 Combustion Engines and Efficiencies Part 2kudra emmanuelNessuna valutazione finora

- (Compressed) Process Defined ApplicationDocumento2 pagine(Compressed) Process Defined Applicationvsquare55Nessuna valutazione finora

- Hints and Tips For Implementing Storwize V7000 V3.1 30 - JulyDocumento35 pagineHints and Tips For Implementing Storwize V7000 V3.1 30 - JulyFerdinand HalimNessuna valutazione finora

- Vodafone India's Marketing Strategy EvolutionDocumento19 pagineVodafone India's Marketing Strategy EvolutionNishant GroverNessuna valutazione finora

- San Vicente Elementary School, NabuaDocumento248 pagineSan Vicente Elementary School, NabuarrpenolioNessuna valutazione finora

- Unit 1: Introduction: © 2013 IBM CorpDocumento11 pagineUnit 1: Introduction: © 2013 IBM CorpAsif KhanNessuna valutazione finora

- Debug 1214Documento4 pagineDebug 1214Anggun Mutia SariNessuna valutazione finora

- Software Development With Visual QP BankDocumento11 pagineSoftware Development With Visual QP BankveluswamiNessuna valutazione finora

- ADC 0808 8-Bit Analog to Digital Converter GuideDocumento6 pagineADC 0808 8-Bit Analog to Digital Converter Guidesrc e-solutionsNessuna valutazione finora

- User Manual: ACT2000 All-Electric ActuatorDocumento64 pagineUser Manual: ACT2000 All-Electric ActuatorMilo TigNessuna valutazione finora

- FLEXIBOWL V2.0 - Electrical Panel (EN)Documento7 pagineFLEXIBOWL V2.0 - Electrical Panel (EN)Adolfo ReverteNessuna valutazione finora

- Understanding the CES SPF RecordDocumento2 pagineUnderstanding the CES SPF RecordKshitij DaveNessuna valutazione finora

- Effective Use of Instagram For BusinessDocumento10 pagineEffective Use of Instagram For BusinessDemand MetricNessuna valutazione finora

- Ehr Recommendation ReportDocumento8 pagineEhr Recommendation Reportapi-356200224Nessuna valutazione finora

- T 3Documento22 pagineT 3keyexiaNessuna valutazione finora

- College of Computer Studies: Software Project Management PlanDocumento23 pagineCollege of Computer Studies: Software Project Management PlanZeus GanfallNessuna valutazione finora

- 10067-Material-ConstantsDocumento10 pagine10067-Material-ConstantsSrinivas SherpallyNessuna valutazione finora

- UCO Reporter, September 2016Documento64 pagineUCO Reporter, September 2016ucopresidentNessuna valutazione finora

- N Health Department Government of Balochistan Job OpportunitiesDocumento2 pagineN Health Department Government of Balochistan Job OpportunitiesMuhammadFarhanShakeeNessuna valutazione finora

- Basic Fiber Optic Systems: Calculating Parameters and Link DesignDocumento27 pagineBasic Fiber Optic Systems: Calculating Parameters and Link DesignDani CasNessuna valutazione finora

- Maptek Vulcan 9.1 Whats New PDFDocumento2 pagineMaptek Vulcan 9.1 Whats New PDFSatria Ega PutraNessuna valutazione finora

- Data Protection Laws of The World: UkraineDocumento8 pagineData Protection Laws of The World: UkraineНаталья Лобкова Переводчик АнглийскогоNessuna valutazione finora

- Degrees of Freedom Analysis in Process Control: PergamonDocumento7 pagineDegrees of Freedom Analysis in Process Control: PergamonPriyam NayakNessuna valutazione finora

- User ManualDocumento21 pagineUser ManualJuan David GilNessuna valutazione finora

- Ladder Diagram: Rung 1 Rung 2 Rung 3Documento26 pagineLadder Diagram: Rung 1 Rung 2 Rung 3abdullah 3mar abou reashaNessuna valutazione finora

- Instant Download Quickbooks Online For Accounting 1st Edition Glenn Owen Solutions Manual PDF Full ChapterDocumento29 pagineInstant Download Quickbooks Online For Accounting 1st Edition Glenn Owen Solutions Manual PDF Full Chapterdariusluyen586100% (4)

- Employee Roster with Company, Name, TitleDocumento12 pagineEmployee Roster with Company, Name, TitleMahesh MalveNessuna valutazione finora

- Isolated Foundation Design SampleDocumento58 pagineIsolated Foundation Design SampleVladSimionNessuna valutazione finora

- CS CP1 R105 1L2WFDocumento2 pagineCS CP1 R105 1L2WFcomprasjrcoltradeNessuna valutazione finora

- AI - For-EveryoneDocumento19 pagineAI - For-EveryoneZeeshan ArifNessuna valutazione finora

- Percentix Inc Acquired by Prithvi Information SolutionsDocumento2 paginePercentix Inc Acquired by Prithvi Information Solutionsskin1900Nessuna valutazione finora

- The Fabric of Civilization: How Textiles Made the WorldDa EverandThe Fabric of Civilization: How Textiles Made the WorldValutazione: 4.5 su 5 stelle4.5/5 (57)

- Sully: The Untold Story Behind the Miracle on the HudsonDa EverandSully: The Untold Story Behind the Miracle on the HudsonValutazione: 4 su 5 stelle4/5 (103)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDa EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureValutazione: 5 su 5 stelle5/5 (124)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesDa EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesNessuna valutazione finora

- Pale Blue Dot: A Vision of the Human Future in SpaceDa EverandPale Blue Dot: A Vision of the Human Future in SpaceValutazione: 4.5 su 5 stelle4.5/5 (586)

- Highest Duty: My Search for What Really MattersDa EverandHighest Duty: My Search for What Really MattersNessuna valutazione finora

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDa EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNessuna valutazione finora

- The Weather Machine: A Journey Inside the ForecastDa EverandThe Weather Machine: A Journey Inside the ForecastValutazione: 3.5 su 5 stelle3.5/5 (31)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (241)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Da Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Valutazione: 4 su 5 stelle4/5 (21)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsDa EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNessuna valutazione finora

- Packing for Mars: The Curious Science of Life in the VoidDa EverandPacking for Mars: The Curious Science of Life in the VoidValutazione: 4 su 5 stelle4/5 (1395)

- The Future of Geography: How the Competition in Space Will Change Our WorldDa EverandThe Future of Geography: How the Competition in Space Will Change Our WorldValutazione: 4.5 su 5 stelle4.5/5 (4)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDa EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationValutazione: 4.5 su 5 stelle4.5/5 (46)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (50)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDa EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseValutazione: 3.5 su 5 stelle3.5/5 (12)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDa EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterValutazione: 5 su 5 stelle5/5 (3)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsDa EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNessuna valutazione finora

- Mental Math for Pilots: A Study GuideDa EverandMental Math for Pilots: A Study GuideValutazione: 0.5 su 5 stelle0.5/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDa EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellValutazione: 4.5 su 5 stelle4.5/5 (80)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- Artificial Intelligence: A Guide for Thinking HumansDa EverandArtificial Intelligence: A Guide for Thinking HumansValutazione: 4.5 su 5 stelle4.5/5 (30)

- Reality+: Virtual Worlds and the Problems of PhilosophyDa EverandReality+: Virtual Worlds and the Problems of PhilosophyValutazione: 4 su 5 stelle4/5 (24)