Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

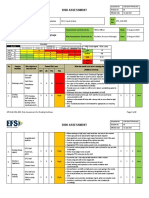

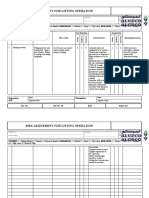

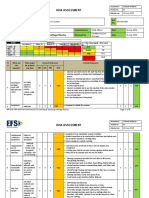

Risk Assessment Register: Prepared By: Toolpusher / Hse Advisor

Caricato da

cmrig74Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Risk Assessment Register: Prepared By: Toolpusher / Hse Advisor

Caricato da

cmrig74Copyright:

Formati disponibili

Prepared By: ToolPusher / HSE Advisor

Risk Assessment Register

Reviewed By: Drilling Superintendent

Approved By: HSE Manager Date : 1st November, 2015 Rev. No. 1

INITIAL RISK CONTROL MEASURES RESIDUAL RISK

Risk Number

HAZARDS Effect

Main Activity Sub Activity HAZARDS

Likelihood

Likelihood

Risk Level

Risk Level

( If the Hazard is Released )

Severity

Severity

Class

Class

Prevention & Mitigation Recovery Measures

1 Electrical Work Electrical Work Static electricity Fire A 5P 5P H Raise permit to work and implement lock out and tag out system if required. ERP, A 1P A1P L

High Voltage Equipment damage Conduct TBT and discuss about electrical hazards, risks and controls. MEDEVAC,

Slippery surface Electrical burns Confirm that the electricity is isolated by testing the ON switch. Medical

Inadequate hand Personnel injury Double checking of isolation by using fluke multi meter. facilities

tools Fatality Use proper electrical tester (amp meter/volt meter) to confirm that electricity is

Down time off.

Effecting Company Technical training for all electricians.

reputation Proper grounding system and lay out

Electric shock Use special PPE’s for electrical works if required.

Provision of good quality electrical wires

Controlled power supply area.

Inspect all electric cables regularly and ensure all cables are wrapped and in

good condition.

Provision of STOP, HSE induction and PTW trainings.

Training and awareness campaign on electric risks.

Only authorized personnel to isolate and execute repairs.

Rescue rod to be available in main electrical room.

Use quality product and certified items suitable for specified hazardous zones 1

& 2.

Each installation shall have one common earth grid connected to at least two

groups of earth electrodes.

The earth grid shall extend throughout the installation in the form of a ring

circuit with branch connections to the equipment and structures to be earthed.

Use non-conductive hand tools

Provision of preventive maintenance system

Maintain good housekeeping after completing any electrical job.

Refer to the following documentations:

PDO Haz-ID Section # 12.Electrical.

PDO SP-1099 Electrical Safety Rules.

PDO SP-1111 Specification for Temporary Electrical Supplies for Construction &

Maintenance Work.

NDSC PTW Procedure.

Hazard Identification STOP SYSTEM.

RA-R9-01-003-01

Potrebbero piacerti anche

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocumento1 paginaRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig74Nessuna valutazione finora

- Working During (Ramadhan) and Hot Atmosphere - RA-R9-01-007-01Documento2 pagineWorking During (Ramadhan) and Hot Atmosphere - RA-R9-01-007-01cmrig74Nessuna valutazione finora

- Deshuttering WorkDocumento1 paginaDeshuttering WorkAhmed AbdulfatahNessuna valutazione finora

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocumento2 pagineEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNessuna valutazione finora

- Risk Assessment For Lifting OperationDocumento2 pagineRisk Assessment For Lifting OperationdsadasNessuna valutazione finora

- CuringDocumento1 paginaCuringChandruNessuna valutazione finora

- 9 - Risk Assessment - PaintingDocumento8 pagine9 - Risk Assessment - Paintingmahmoud nadaNessuna valutazione finora

- Deshuttering WorkDocumento1 paginaDeshuttering WorkAhmed AbdulfatahNessuna valutazione finora

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Documento3 pagineRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNessuna valutazione finora

- TRA 13 Loading or Unloading Chems With ForkliftDocumento2 pagineTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- Hydro Static Test: Risk AssessmentDocumento10 pagineHydro Static Test: Risk Assessmentmohammed a hseNessuna valutazione finora

- Ra02 - Container OffloadingDocumento3 pagineRa02 - Container OffloadingSamNessuna valutazione finora

- Sand FillingDocumento1 paginaSand FillingGyanendra Narayan NayakNessuna valutazione finora

- 04, Use of Hand ToolsDocumento2 pagine04, Use of Hand ToolsFrancis K BonfulNessuna valutazione finora

- Safe Lifting Procedure 2Documento6 pagineSafe Lifting Procedure 2angelaNessuna valutazione finora

- JSO Cable Drum (02 Sept.'07)Documento2 pagineJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNessuna valutazione finora

- JSP For Over Head Crane (JSP-HHI-Comm-07)Documento4 pagineJSP For Over Head Crane (JSP-HHI-Comm-07)Farooq MohammadNessuna valutazione finora

- 003 SWMS - ExcavationDocumento11 pagine003 SWMS - Excavationsasi kumar50% (2)

- Risk Assessment Hollowcore WF-ALLDocumento8 pagineRisk Assessment Hollowcore WF-ALLChoubi ChoubacaNessuna valutazione finora

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Documento12 pagineCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNessuna valutazione finora

- Baseline Risk Assessment: Phindile Kula (Project Coordinator)Documento9 pagineBaseline Risk Assessment: Phindile Kula (Project Coordinator)EmilNessuna valutazione finora

- EFS-SLB-SRA-006 Risk Assessment For General Waste CollectionDocumento2 pagineEFS-SLB-SRA-006 Risk Assessment For General Waste Collectionmohammed ayazNessuna valutazione finora

- Jsa-046 Highway Crossing and Steel CasingDocumento11 pagineJsa-046 Highway Crossing and Steel CasingMajdiSahnounNessuna valutazione finora

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Documento1 paginaRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Shifting of Materials by Double HydraDocumento1 paginaShifting of Materials by Double HydraShahid RazaNessuna valutazione finora

- Risk Assessment - Fixation GRP Panel Water TanksDocumento9 pagineRisk Assessment - Fixation GRP Panel Water TanksMohamed AtefNessuna valutazione finora

- Risk Assessment of Fire Pipe Flange T ConnectionDocumento5 pagineRisk Assessment of Fire Pipe Flange T Connectionimran aliNessuna valutazione finora

- Generic RA Gas CylindersDocumento6 pagineGeneric RA Gas CylindersShahid RazaNessuna valutazione finora

- Job Hazard Analysis PermitDocumento1 paginaJob Hazard Analysis PermitKhorchnoi Abaja CalimlimNessuna valutazione finora

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocumento1 paginaRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Risk Assessment For Installation of Toilet Exhaust FanDocumento10 pagineRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilNessuna valutazione finora

- Plant and Equipment Risk Assessment Fgoc - NewDocumento13 paginePlant and Equipment Risk Assessment Fgoc - Newmajid khanNessuna valutazione finora

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocumento13 pagineF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo Oshin100% (1)

- Risk Assessment - House and Office CleaningDocumento6 pagineRisk Assessment - House and Office CleaningVimal Thomas100% (1)

- Ra FormDocumento5 pagineRa FormEngrHazrat MaazNessuna valutazione finora

- Self Leveling - Epoxy Work (R-A)Documento3 pagineSelf Leveling - Epoxy Work (R-A)anisaanNessuna valutazione finora

- 1 23 Forklift SafetyDocumento4 pagine1 23 Forklift SafetykhurramNessuna valutazione finora

- RA - (LPG System)Documento26 pagineRA - (LPG System)Md ShahinNessuna valutazione finora

- Risk Assessment-Pnuematic Test. DraftDocumento3 pagineRisk Assessment-Pnuematic Test. DraftKono Nor AtanNessuna valutazione finora

- EFS-SLB-SRA-003 Risk Assessment For Garbage Room CleaningDocumento2 pagineEFS-SLB-SRA-003 Risk Assessment For Garbage Room Cleaningmohammed ayaz100% (1)

- Hazard Identification, Risk Assessment and Risk Control, HIRARCDocumento2 pagineHazard Identification, Risk Assessment and Risk Control, HIRARCMiguel AlvaradoNessuna valutazione finora

- Welding SopDocumento6 pagineWelding SopNikhil VaidyaNessuna valutazione finora

- KFV-SR-050 (IT SHE Risk Register 2017 For NDT Services ContractDocumento3 pagineKFV-SR-050 (IT SHE Risk Register 2017 For NDT Services ContractChris ProevoNessuna valutazione finora

- SOP SOP0022 Concrete Core DrillDocumento3 pagineSOP SOP0022 Concrete Core Drillkristian08Nessuna valutazione finora

- Hirac 1Documento1 paginaHirac 1Agape PrintshopNessuna valutazione finora

- Manual Handling RubbishDocumento1 paginaManual Handling RubbishScribder0% (1)

- Risk Assesment Form ScaffoldDocumento10 pagineRisk Assesment Form ScaffoldRejin PradeepNessuna valutazione finora

- Environmental, Health and Safety Risks AnalysisDocumento3 pagineEnvironmental, Health and Safety Risks AnalysisKrishna PatilNessuna valutazione finora

- Risk Assessment of Trees MaintenanceDocumento9 pagineRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- k3 Bore Pile DenganBIMDocumento6 paginek3 Bore Pile DenganBIMrhoewiebNessuna valutazione finora

- Safe Plan of Action Ramsu EnterpriseDocumento5 pagineSafe Plan of Action Ramsu EnterpriseSanjeev Kumar100% (1)

- 01 WI HSE 001 - Risk Assessment GroutingDocumento4 pagine01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- RA Excavation For Trial TrenchDocumento9 pagineRA Excavation For Trial TrenchSasi KumarNessuna valutazione finora

- Mid West Ports Authority 4.6 Working On, Over or Near WaterDocumento9 pagineMid West Ports Authority 4.6 Working On, Over or Near Waterqualiman1Nessuna valutazione finora

- RA For Builders Work A59Documento11 pagineRA For Builders Work A59Sajid ShahNessuna valutazione finora

- Cutting WorkDocumento1 paginaCutting WorkGudduNessuna valutazione finora

- Environmental, Health and Safety Risks AnalysisDocumento2 pagineEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Brazing (Oxygen and Acetylene)Documento6 pagineBrazing (Oxygen and Acetylene)My Zain100% (1)

- Crane-Hydra-deployment For Lifting-Lowering-Risk AssessmentDocumento4 pagineCrane-Hydra-deployment For Lifting-Lowering-Risk AssessmentAhmed El-sherpiniNessuna valutazione finora

- MD Totco Rig Electricians TrainingDocumento1 paginaMD Totco Rig Electricians Trainingcmrig74Nessuna valutazione finora

- Parts List: TYPE 110-UE DrawworksDocumento62 pagineParts List: TYPE 110-UE Drawworkscmrig74Nessuna valutazione finora

- Budgetary Quotation Summary - Sensor Update: M/D TotcoDocumento8 pagineBudgetary Quotation Summary - Sensor Update: M/D Totcocmrig74Nessuna valutazione finora

- Budgetary Quotation Summary - Rigsense Spectrum Instrumentation SystemDocumento16 pagineBudgetary Quotation Summary - Rigsense Spectrum Instrumentation Systemcmrig74Nessuna valutazione finora

- 155 Clients 0501 27718-0Documento5 pagine155 Clients 0501 27718-0cmrig74Nessuna valutazione finora

- Read ItDocumento1 paginaRead Itcmrig74Nessuna valutazione finora

- Lesson 23: Special Well Control Applications Underbalanced Drilling (UBD)Documento63 pagineLesson 23: Special Well Control Applications Underbalanced Drilling (UBD)cmrig74Nessuna valutazione finora

- Assessing Risk Precautionary Approach: and TheDocumento24 pagineAssessing Risk Precautionary Approach: and Thecmrig74Nessuna valutazione finora

- MD TrackDocumento1 paginaMD Trackcmrig74Nessuna valutazione finora

- Circulation Kill TechniquesDocumento71 pagineCirculation Kill Techniquescmrig74Nessuna valutazione finora

- 21.well Control ComplicationsDocumento65 pagine21.well Control Complicationscmrig74Nessuna valutazione finora

- Motion CompensationDocumento39 pagineMotion Compensationdriller22100% (1)

- MD Totco Drilling Instrumentation SpecDocumento2 pagineMD Totco Drilling Instrumentation Speccmrig74Nessuna valutazione finora

- Lesson 22: Introduction To Underbalanced Drilling TechnologyDocumento65 pagineLesson 22: Introduction To Underbalanced Drilling Technologycmrig74Nessuna valutazione finora

- Remon Ahdy ,: Professional Diplomas in Sales Management and MarketingDocumento60 pagineRemon Ahdy ,: Professional Diplomas in Sales Management and Marketingcmrig74Nessuna valutazione finora

- PETE 661: Drilling EngineeringDocumento50 paginePETE 661: Drilling Engineeringcmrig74Nessuna valutazione finora

- Kick Detection and ControlDocumento63 pagineKick Detection and Controlcmrig74Nessuna valutazione finora

- Injection and Disposal Wells: - What Is Different - How To Convert Producers To InjectorsDocumento49 pagineInjection and Disposal Wells: - What Is Different - How To Convert Producers To Injectorsdriller22Nessuna valutazione finora

- Injection Well ProblemsDocumento12 pagineInjection Well Problemsdriller2250% (2)

- Injection Wellwork ValueDocumento7 pagineInjection Wellwork Valuedriller22Nessuna valutazione finora

- LinerDocumento15 pagineLinerdriller22100% (1)

- Methods of Artificial Lift: Presented To: Prof DR: El Ayouty - ElsaidDocumento11 pagineMethods of Artificial Lift: Presented To: Prof DR: El Ayouty - Elsaidcmrig74Nessuna valutazione finora

- Tight Gas 2Documento59 pagineTight Gas 2cmrig74Nessuna valutazione finora

- PerforatingDocumento65 paginePerforatingdriller22100% (1)

- Jars and Accelerators.Documento10 pagineJars and Accelerators.driller22100% (1)

- TAMU - Pemex Offshore DrillingDocumento42 pagineTAMU - Pemex Offshore Drillingdriller22100% (1)

- TAMU - Pemex: Well ControlDocumento54 pagineTAMU - Pemex: Well Controldriller22100% (2)

- Station KeepingDocumento67 pagineStation Keepingdriller22Nessuna valutazione finora

- Deepwater Drilling and Well Control Course OutlineDocumento2 pagineDeepwater Drilling and Well Control Course Outlinemahdi_esmNessuna valutazione finora

- Wellheads and CasingDocumento102 pagineWellheads and Casingdriller22100% (4)

- TR Eim NC Ii UpdatedDocumento79 pagineTR Eim NC Ii UpdatedLoreto Barrot100% (1)

- JSA TemplateDocumento3 pagineJSA TemplateJob MateusNessuna valutazione finora

- BSBLDR502 AnswersDocumento16 pagineBSBLDR502 AnswersDuminda Kottahachchi50% (2)

- HIRA 018 Boarding of Vessels.Documento4 pagineHIRA 018 Boarding of Vessels.srinibas mohapatraNessuna valutazione finora

- Comprehensive Investigation of Ob Practices in Jazz: Group MembersDocumento19 pagineComprehensive Investigation of Ob Practices in Jazz: Group MembersSadaqat AhsanNessuna valutazione finora

- 2 - Code of ConductDocumento5 pagine2 - Code of ConductarkcgemNessuna valutazione finora

- Good Research Practice - 2014-GuidelinesDocumento15 pagineGood Research Practice - 2014-GuidelinesGuyver FixNessuna valutazione finora

- Heritage Advice LetterDocumento3 pagineHeritage Advice LetterMiguel AlexandreNessuna valutazione finora

- AHA - Working On Slope RoofDocumento2 pagineAHA - Working On Slope RoofTopsun EnergyNessuna valutazione finora

- Providing Equal Employment Opportunity and A Safe WorkplaceDocumento31 pagineProviding Equal Employment Opportunity and A Safe WorkplaceJenny NavalNessuna valutazione finora

- HS Interlac 665 NegroDocumento9 pagineHS Interlac 665 Negrofacturacion.ecmelNessuna valutazione finora

- Stats 2006-07 PDFDocumento32 pagineStats 2006-07 PDFdesbestNessuna valutazione finora

- Wa0007.Documento9 pagineWa0007.Paranjay MahayNessuna valutazione finora

- HIRARC CompleteDocumento39 pagineHIRARC CompleteasrizalNessuna valutazione finora

- JSA - Field Instruments InstallationDocumento4 pagineJSA - Field Instruments InstallationSagar PadhiyarNessuna valutazione finora

- CM Tle 7Documento3 pagineCM Tle 7Teacher Arvin OfficialNessuna valutazione finora

- Front Page RAMS-Loading, Unloading and Shifting of MaterialDocumento7 pagineFront Page RAMS-Loading, Unloading and Shifting of MaterialEm NiaxNessuna valutazione finora

- Articulated Truck SOPDocumento6 pagineArticulated Truck SOPVarlee KamaraNessuna valutazione finora

- Method Statement InstallationDocumento2 pagineMethod Statement InstallationSonukrishnaNessuna valutazione finora

- BSBRSK501 Manage Risk - Learner Workbook - v2.0 - March 2021Documento52 pagineBSBRSK501 Manage Risk - Learner Workbook - v2.0 - March 2021Paras ManiNessuna valutazione finora

- Confined Space EntryDocumento2 pagineConfined Space Entryaudit jogiNessuna valutazione finora

- Business Ethics and Social Responsibility: Quarter 2, LAS 1Documento11 pagineBusiness Ethics and Social Responsibility: Quarter 2, LAS 1jaslorNessuna valutazione finora

- Gas Welding Risk AssessmentDocumento8 pagineGas Welding Risk AssessmentvictorNessuna valutazione finora

- Samzun Nizar Ahamed Sabry: Mobile: +94-757707366Documento3 pagineSamzun Nizar Ahamed Sabry: Mobile: +94-757707366Ahamed MinverNessuna valutazione finora

- Falls Wah Residential Roofing Root Cause Analysis Phase 1Documento19 pagineFalls Wah Residential Roofing Root Cause Analysis Phase 1nirashaNessuna valutazione finora

- Lamp Sesi 8.2 Investigasi SCATDocumento2 pagineLamp Sesi 8.2 Investigasi SCATaab kanayaNessuna valutazione finora

- MSDS - 1736u-19840Documento14 pagineMSDS - 1736u-19840Ganesh R NairNessuna valutazione finora

- Kohinoor Mills Limited: Internship Report Hira TariqDocumento33 pagineKohinoor Mills Limited: Internship Report Hira TariqZeeshan MunawarNessuna valutazione finora

- Prevention of Occupational Hazards: Management of International Financial ServicesDocumento8 paginePrevention of Occupational Hazards: Management of International Financial ServicesMorvinNessuna valutazione finora

- NR 33 Work in Confined Space PDFDocumento11 pagineNR 33 Work in Confined Space PDFp100% (1)