Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

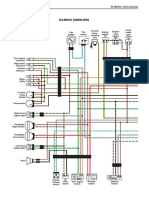

ANPQP Structure Diagram: Alliance Supplier Guide

Caricato da

游祥輝Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ANPQP Structure Diagram: Alliance Supplier Guide

Caricato da

游祥輝Copyright:

Formati disponibili

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

1. Organisation & Planning 2. Design Completion 3. Off-Tool 4. Off-Process 5. Post SOP

2.1 - Analysis of Design Failure & 2.2 - Design for Manufacture and 3.1 - Supplier Packaging

1.1 - Product & Process Concept 4.1 - Supplier Production Trial Run 5.1 - Reduce Process Variation

Effects Assembly Requirements

1.2 - Product Quality & Reliability 2.4 - Supplier's Internal Product & 5.2 - Customer Satisfaction based

2.3 - Design Verification 3.2 - Quality Systems Procedures / 4.2 - Process Capability Study

Targets Study Plan Process Design Review upon Renault and / or Nissan

Quality Plan Review

Feedback

2.6 - Engineering Product

1.3 - Sub Supplier Management 2.5 - Prototype Control Plan 4.3 - Production Part Approval

Specification / Drawing

3.3 - Process Flow Chart 5.3 - Activities During Ramp Up

(Implementation of Ramp Up Plan)

1.4 - Senior Management Support 2.7 - Drawing & Specification 2.8 - Equipment, Tooling, Gauges 4.4 - Product & Process Validation

& Quality Plan Change Requirement and Facility Requirements Testing

3.4 - Floor Plan Layout

5.4 - Control of Process / Facility

1.5 - Review of Customer 2.9 - Special Product & Process Site Transfer Changes

2.10 - Senior Management Support 4.5 - Packaging Evaluation

Satisfaction Characteristics 3.5 - Analysis of Process Failure &

Effects

5.5 - Control of Design Changes

2.12 - Preliminary Process Flow

1.6 - Pre-Contract Logistics Study 2.11 - Logistics Review 4.6 - Production Control Plan

Chart 3.6 - Pre-production / Pre-launch

Control Plan

5.6 - Senior Management Support

2.13 - Design Assurance Plan 2.14 - Supplier Master Schedule 4.7 - Senior Management Support

3.7 - Process Instructions

5.7 - Non Conforming Product

2.16 - Design Fix & Tooling Management

2.15 - Concern Management 4.8 - Confirmation of Full Volume

Release 3.8 - Final Process Capability

Condition & Ramp Up Plan

Study Plan

2.17 - Part & Process 2.18 - Initial Process Capability

Characteristics and Manufacturing Study Plan 4.9 - Production Preparation

3.9 - Senior Management Support

Step Relationship Monitoring

2.19 - Production Preparation 3.10 - Validation of Off-Tool 4.10 - Supplier's Internal Product &

Monitoring Condition Process Design review

3.11 - Production Preparation

Monitoring

3.12 - Supplier's Internal Product &

Process Design Review

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

1. Organisation & Planning

1.1 - Product & Process 1.2 - Product Quality &

Concept Reliability Targets Study Plan

1.3 - Sub Supplier 1.4 - Senior Management

Management Support & Quality Plan

1.5 - Review of Customer 1.6 - Pre-Contract Logistics

Satisfaction Study

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

2. Design Completion

2.4 - Supplier's Internal

2.1 - Analysis of Design 2.2 - Design for Manufacture

2.3 - Design Verification Product & Process Design

Failure & Effects and Assembly

Review

2.8 - Equipment, Tooling,

2.6 - Engineering Product 2.7 - Drawing & Specification

2.5 - Prototype Control Plan Gauges and Facility

Specification / Drawing Change Requirement

Requirements

2.9 - Special Product & 2.10 - Senior Management 2.12 - Preliminary Process

2.11 - Logistics Review

Process Characteristics Support Flow Chart

2.14 - Supplier Master 2.16 - Design Fix and Tooling

2.13 - Design Assurance Plan 2.15 - Concern Management

Schedule Release

2.17 - Part & Process

2.18 - Initial Process 2.19 - Production Preparation

Characteristics and

Capability Study Plan Monitoring

Manufacturing Step Analysis

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

3. Off- Tool

3.2 - Quality Systems

3.1 - Supplier Packaging

Procedures / Quality Plan

Requirements

Review

3.3 - Process Flow Chart 3.4 - Floor Plan Layout

3.5 - Analysis of Process 3.6 - Pre-Production / Pre-

Failure & Effects Launch Control Plan

3.8 - Final Process Capability

3.7 - Process Instructions

Study Plan

3.9 - Senior Management 3.10 - Validation of Off Tool

Support Condition

3.12 - Supplier's Internal

3.11 - Production Preparation

Product & Process Design

Monitoring

Review

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

4. Off-Process

4.1 - Supplier Production Trial

4.2 - Process Capability Study

Run

4.4 - Product & Process

4.3 - Production Part Approval

Validation Testing

4.5 - Packaging Evaluation 4.6 - Production Control Plan

4.8 - Confirmation of Full

4.7 - Senior Management

Volume Condition & Ramp Up

Support

Plan

4.10 - Supplier's Internal

4.9 - Production Preparation

Product & Process Design

Monitoring

Review

ANPQP Structure Diagram

Alliance Supplier Guide

ISO / TS 16949 A.N.P.Q.P Other Supply requirements

5. Post SOP

5.2 - Customer Satisfaction

5.1 - Reduce Process

based upon Renault and / or

Variation

Nissan Feedback

5.3 - Activities During Ramp

5.4 - Control of Process /

up (Implementation of Ramp

Facility Site Transfer Changes

Up Plan)

5.5 - Control of Design 5.6 - Senior Management

Changes Support

5.7 - Non Conforming Product

Management

Potrebbero piacerti anche

- ANPQP - 3.0 - Category 1Documento6 pagineANPQP - 3.0 - Category 1jefry sitorusNessuna valutazione finora

- ANPQP - 3.0 - Category 5Documento27 pagineANPQP - 3.0 - Category 5jefry sitorusNessuna valutazione finora

- ANPQP Ver 3.0Documento232 pagineANPQP Ver 3.0BESNessuna valutazione finora

- Alliance Supplier Guide 2.3Documento3 pagineAlliance Supplier Guide 2.3MNessuna valutazione finora

- Kit Comunicatie ANPQP-V23Documento20 pagineKit Comunicatie ANPQP-V23djclaudiuNessuna valutazione finora

- Fit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) DefinitionsDocumento3 pagineFit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) Definitions57641Nessuna valutazione finora

- VDA Volume 6.3 Figure 2.1Documento1 paginaVDA Volume 6.3 Figure 2.1SudhagarNessuna valutazione finora

- Iatf TrainingDocumento10 pagineIatf TrainingAniket JadhavNessuna valutazione finora

- ANPQP Category 6 Product ConfirmationDocumento7 pagineANPQP Category 6 Product Confirmationjefry sitorusNessuna valutazione finora

- Supplier APQP TrainingDocumento29 pagineSupplier APQP Trainingfdsa01Nessuna valutazione finora

- 1 - What Is ASES, 2 - Explanation of The QuestionnaireDocumento50 pagine1 - What Is ASES, 2 - Explanation of The QuestionnaireCarlos AguilarNessuna valutazione finora

- ZF QD83-2018 - English-French - WebDocumento70 pagineZF QD83-2018 - English-French - WebBESNessuna valutazione finora

- IATF 16949 GM CSR Aug 2023Documento30 pagineIATF 16949 GM CSR Aug 2023Cisca NattNessuna valutazione finora

- VDA 2 Quality Assurance For SuppliesDocumento58 pagineVDA 2 Quality Assurance For SuppliesMaria del Carmen García GómezNessuna valutazione finora

- CQI 9 3rd Edition Errata SheetDocumento2 pagineCQI 9 3rd Edition Errata SheetANONIMONessuna valutazione finora

- Volkswagen Group Customer Specific Requirements Feb 2022Documento6 pagineVolkswagen Group Customer Specific Requirements Feb 2022Ivonete VieiraNessuna valutazione finora

- SFMEA Check ListDocumento16 pagineSFMEA Check ListIgnacioNessuna valutazione finora

- Template Q-Offer v1 2Documento25 pagineTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- Q1 Rules Ref CardDocumento10 pagineQ1 Rules Ref Cardparigomo2Nessuna valutazione finora

- Customer Specific Requirements - PPAP (2014!03!05)Documento7 pagineCustomer Specific Requirements - PPAP (2014!03!05)diablo2250Nessuna valutazione finora

- QSP-D&D-02 APQP ProcedureDocumento6 pagineQSP-D&D-02 APQP ProcedureDeepak Kumar100% (1)

- Procedure - Special CharacteristicsDocumento13 pagineProcedure - Special Characteristicsalexandru.ghiniaNessuna valutazione finora

- Bmw Spqm 供应商管理Documento30 pagineBmw Spqm 供应商管理isolong100% (1)

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDocumento1 paginaOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochNessuna valutazione finora

- APQP ENG SiemensDocumento12 pagineAPQP ENG SiemensVikash KumarNessuna valutazione finora

- PDF Process Audit Vda 63Documento9 paginePDF Process Audit Vda 63Shahrazed ZineNessuna valutazione finora

- SRG Global PPAP ChecklistDocumento61 pagineSRG Global PPAP Checklistanamika tripathiNessuna valutazione finora

- Capacity Training PDFDocumento103 pagineCapacity Training PDFKaya Eralp Asan100% (1)

- Minimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFDocumento9 pagineMinimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFFer Jesus Nieves UribeNessuna valutazione finora

- Core ToolsDocumento1 paginaCore Toolsbil bilNessuna valutazione finora

- VDA6.3 QuestionsDocumento17 pagineVDA6.3 QuestionsSónia Queiroz100% (1)

- Requirements Comparison TS16949 VDA61Documento22 pagineRequirements Comparison TS16949 VDA61TarunaiNessuna valutazione finora

- Production Part Approval ProcessDocumento6 pagineProduction Part Approval ProcessleonardoNessuna valutazione finora

- CSR AdientDocumento17 pagineCSR AdientRoberto S. InagakiNessuna valutazione finora

- Sop On Apqp & Ppap WRT Iatf 16949-2016Documento1 paginaSop On Apqp & Ppap WRT Iatf 16949-2016balakumar rajaram100% (1)

- PPAP 101 - What You Need To KnowDocumento9 paginePPAP 101 - What You Need To KnowQGFNessuna valutazione finora

- Escalation Procedure Updated 020915Documento30 pagineEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- enDocumento50 pagineenIonelMiocNessuna valutazione finora

- Ppap Worksheet (GM 1411) : S Master Status: Lab StatusDocumento6 paginePpap Worksheet (GM 1411) : S Master Status: Lab Statuscong daNessuna valutazione finora

- MATRIXDocumento5 pagineMATRIXSerchecko JaureguiNessuna valutazione finora

- Training Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enDocumento3 pagineTraining Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enjpaulNessuna valutazione finora

- Aptiv Customer Specific Requirements June 20th 2022Documento15 pagineAptiv Customer Specific Requirements June 20th 2022Hosam Elden Mostafa MasaranyNessuna valutazione finora

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocumento3 pagineRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanNessuna valutazione finora

- Special Process: Coating System Assessment Version 3 Issued 07/2020Documento10 pagineSpecial Process: Coating System Assessment Version 3 Issued 07/2020r arumugamNessuna valutazione finora

- Volkswagen Group Customer Specific Requirements March 2022 1Documento6 pagineVolkswagen Group Customer Specific Requirements March 2022 1Tania HernandezNessuna valutazione finora

- MACE - Formats - 015 - APQP Matrix Sign OffDocumento3 pagineMACE - Formats - 015 - APQP Matrix Sign OffMohit KaushikNessuna valutazione finora

- 1) PPAP YHA VIBRACOUSTIC Production)Documento31 pagine1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalNessuna valutazione finora

- Layout Inspection Report XH5DR June 20 2012Documento17 pagineLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- CQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Documento24 pagineCQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Jintara KaewrayaNessuna valutazione finora

- Field Failures Analysis: HeribertDocumento17 pagineField Failures Analysis: Heribertmirosek100% (1)

- Control Plan FormatDocumento1 paginaControl Plan FormatMagesh WaranNessuna valutazione finora

- Apqp Advanced Product Quality PlanningDocumento27 pagineApqp Advanced Product Quality PlanningRajesh KumarNessuna valutazione finora

- What Is ASES PDFDocumento7 pagineWhat Is ASES PDFmvelsky100% (3)

- Supplier APQP Requirements Matrix: D & C These Items To Be Included On Gap Analysis Sheet With ActionsDocumento4 pagineSupplier APQP Requirements Matrix: D & C These Items To Be Included On Gap Analysis Sheet With ActionsOmkar waghuleNessuna valutazione finora

- Anpqp 3.0 en Day-2 FinDocumento134 pagineAnpqp 3.0 en Day-2 Fintomyclau100% (3)

- Apqp Stages AIAG-1Documento49 pagineApqp Stages AIAG-1Jose Antonio Santoyo RayaNessuna valutazione finora

- GQADocumento26 pagineGQARaduz HaduzNessuna valutazione finora

- Supplier Quality Manual TennecoDocumento36 pagineSupplier Quality Manual TennecoMohit AggarwalNessuna valutazione finora

- ANPQP - 3.0 - Category 4Documento27 pagineANPQP - 3.0 - Category 4jefry sitorus100% (1)

- Karet Susu Hino 500Documento3 pagineKaret Susu Hino 500JokoNessuna valutazione finora

- A Report On Fee Management Project Class 12Documento11 pagineA Report On Fee Management Project Class 12Atul DybeyNessuna valutazione finora

- Acct Statement - XX4534 - 10042024Documento39 pagineAcct Statement - XX4534 - 100420247898081578shivamNessuna valutazione finora

- Conducting Market ResearchDocumento28 pagineConducting Market ResearchHimadri JanaNessuna valutazione finora

- Scripting Guide - Porting ManualDocumento7 pagineScripting Guide - Porting ManualYashanshu GautamNessuna valutazione finora

- 8810A Operations ManualDocumento34 pagine8810A Operations ManualJoão LopesNessuna valutazione finora

- Radovan Damjanović Srbsko Srbski Rečnik: Download NowDocumento9 pagineRadovan Damjanović Srbsko Srbski Rečnik: Download NowTinamou0001Nessuna valutazione finora

- Konica Minolta CSR Report: Fulfilling Our Social ResponsibilityDocumento28 pagineKonica Minolta CSR Report: Fulfilling Our Social ResponsibilityAbhinay AbhiNessuna valutazione finora

- B737-B787 QRH Differences: 787 NNC Includes Emergency DescentDocumento13 pagineB737-B787 QRH Differences: 787 NNC Includes Emergency DescentUfuk AydinNessuna valutazione finora

- Am - Is - Are - Was - Were WorksheetDocumento1 paginaAm - Is - Are - Was - Were WorksheetВалентин КечкоNessuna valutazione finora

- Method Statement For Installation of Dewatering PumpDocumento4 pagineMethod Statement For Installation of Dewatering PumpDelta akathehuskyNessuna valutazione finora

- Unit I IntroductionDocumento15 pagineUnit I IntroductionMUKILANNessuna valutazione finora

- Solving Rational InequalityDocumento67 pagineSolving Rational Inequalityjeremee balolongNessuna valutazione finora

- Concrete Pipes and Portal Culverts HandbookDocumento52 pagineConcrete Pipes and Portal Culverts HandbookKenya Ayallew Asmare100% (3)

- Transmission Removal and Installation at PDFDocumento3 pagineTransmission Removal and Installation at PDFUgratara AutoNessuna valutazione finora

- X30011 - C90 Parts Catalog ContinentalDocumento54 pagineX30011 - C90 Parts Catalog ContinentalLeonardo Martedi100% (1)

- Invitation and Detailed Programme 17 March 23 ConferenceDocumento5 pagineInvitation and Detailed Programme 17 March 23 ConferenceNeerajNessuna valutazione finora

- Voluson S10 - Brochure (En) 2Documento2 pagineVoluson S10 - Brochure (En) 2Zákány ZoltánNessuna valutazione finora

- ELCOMA Diractory 2022 2024 1Documento96 pagineELCOMA Diractory 2022 2024 1Unmesh ThoratNessuna valutazione finora

- Lead Scoring Case Study PresentationDocumento11 pagineLead Scoring Case Study PresentationDevanshi100% (2)

- B Evolution Cisco Jabber and Migration of Jabber To Webex Lab v3 LabDocumento136 pagineB Evolution Cisco Jabber and Migration of Jabber To Webex Lab v3 LabFerdinand LouisNessuna valutazione finora

- Mechanical Instruction ManualDocumento16 pagineMechanical Instruction ManualMorarescu AndreiNessuna valutazione finora

- Unit Progress Test 3 - Version BDocumento12 pagineUnit Progress Test 3 - Version BluisNessuna valutazione finora

- Wind Load: K Z S Z 0Documento1 paginaWind Load: K Z S Z 0MechanicalNessuna valutazione finora

- Small Engine Repair Reference Center Wiring Diagram KawasakiDocumento3 pagineSmall Engine Repair Reference Center Wiring Diagram Kawasakiotto moranNessuna valutazione finora

- Local Balloon Professional Earns Recognition As Certified Balloon ArtistDocumento2 pagineLocal Balloon Professional Earns Recognition As Certified Balloon ArtistPR.comNessuna valutazione finora

- Bangalore House Price PredictionDocumento5 pagineBangalore House Price Predictionnavjyoti choudharyNessuna valutazione finora

- Parcel Perfect Integration Service - v7Documento8 pagineParcel Perfect Integration Service - v7Ross SaundersNessuna valutazione finora

- Arab Health 14-01-20Documento96 pagineArab Health 14-01-20Alaa AljghamiNessuna valutazione finora

- ComNet CNGE2FE8MSPOEPLUS Instruction ManualDocumento107 pagineComNet CNGE2FE8MSPOEPLUS Instruction ManualJMAC SupplyNessuna valutazione finora