Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Failure Mode Effect Analysis (FMEA)

Caricato da

Wixi MundoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Failure Mode Effect Analysis (FMEA)

Caricato da

Wixi MundoCopyright:

Formati disponibili

Leanmap.

com

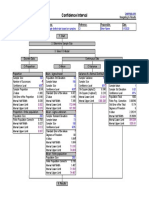

Failure Mode Effect Analysis (FMEA) Navigating to Results

Item: Function: Reference: Responsible: Date:

Vacuum cleaner Model #321 Remove dirt effectively FMEA Enter Name 1/1/2020

Process Failure Mode Failure Effects S Potential O Present D R Correction Responsible p p p p

Step (Local) (System) E Causes C Controls E P (Action) (Owner) S O D R

V C T N E C E P

V C T N

add "Bag-Full"

open vacuum cleaner Engineering

dirt-removal is slow indicator (blinking

Vacuum floor low vacuum 7 dirt-bag is full 7 and check if bag is 9 441 department, M 7 6 6 252

and inefficient LED) to advise user

full Janson by 1/1/2020

to change the bag

customer used

Documentation

dirt-removal is slow vacuum cleaner to add warning in

Vacuum floor low vacuum 7 6 none 10 420 department, K. 7 3 10 210

and inefficient removed spilled operation manual

Morrison by 1/1/2020

water

add mesh in front of

loss of vacuum, large item (cloth) is

none, detected only the vacuum inlet to Engineering

loss of vacuum, motor overheats, sucked into the

Vacuum floor 9 5 by change of sound 8 360 prevent larger items department, M 5 5 8 200

motor runs motor burns out = vacuum hose and

(motor works harder) to be sucked into the Janson by 1/1/2020

total failure blocks the air flow

hose

motor overheated,

add thermal-fuse to

burned-out by none, detected only Engineering

loss of vacuum, total loss of function, prevent the motor

Vacuum floor 9 extensive non-stop 2 by smell of 9 162 department, M 9 1 1 9

motor does not run requires repair from

use over several overheated motor Janson by 1/1/2020

overheating/failure

hours

bag fits too tight =

For review with

needs strong force to redesign fitting,

floor dirty, needs to product designer J.

Replace dirt bag dirt spills out 2 be removed = 7 none 8 112 include a bag-release 2 5 8 80

be vacuumed again Pittner, due by

uncontrolled, dirt clamp

1/1/2020

spills out

0 0

0 0

Potrebbero piacerti anche

- Essential Calculus Skills Practice Workbook With Full SolutionsDocumento528 pagineEssential Calculus Skills Practice Workbook With Full SolutionsGerardo Navarro Sánchez94% (65)

- Failure Mode Effects Analysis of A Pressure TankDocumento1 paginaFailure Mode Effects Analysis of A Pressure TankjaleNessuna valutazione finora

- Sample Appellant BriefDocumento6 pagineSample Appellant BriefKaye Pascual89% (9)

- Simio APIDocumento6 pagineSimio APIAndré AlbrechtNessuna valutazione finora

- Manual GA 55 VSD Atlas CompresorDocumento114 pagineManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

- Failure Modes Effect AnalysisDocumento33 pagineFailure Modes Effect AnalysisAkhmas MerajNessuna valutazione finora

- Problem Solving With Data Structures Using Java: A Multimedia ApproachDocumento79 pagineProblem Solving With Data Structures Using Java: A Multimedia ApproachJoswa CaxtonNessuna valutazione finora

- 4.1 Control ChartDocumento59 pagine4.1 Control Chartsurendhar sekarNessuna valutazione finora

- BOS QOS Chart AdaptiveBMSDocumento14 pagineBOS QOS Chart AdaptiveBMSarunradNessuna valutazione finora

- Digit TwinDocumento22 pagineDigit TwinritsNessuna valutazione finora

- Lean CTR TrainingDocumento36 pagineLean CTR TrainingSanjib KumarNessuna valutazione finora

- OA Final Pulau Sambu Guntung 120605Documento53 pagineOA Final Pulau Sambu Guntung 120605GastongCannavaroNessuna valutazione finora

- Warehouse Confidential FinalDocumento42 pagineWarehouse Confidential Finalmctmc100% (1)

- TPM Kick-Off: Newsletter From CII TPM Club IndiaDocumento6 pagineTPM Kick-Off: Newsletter From CII TPM Club IndiaNarendran100% (1)

- HW 2 CoraDocumento1 paginaHW 2 Coraapi-266881154Nessuna valutazione finora

- Value Stream Mapping, 5S& Visual ManagementDocumento58 pagineValue Stream Mapping, 5S& Visual ManagementShrishti GuptaNessuna valutazione finora

- Industrial Color Guide - WebDocumento1 paginaIndustrial Color Guide - Webayad60Nessuna valutazione finora

- Early Detection of Breast Cancer Using Microstrip Patch AntennaDocumento6 pagineEarly Detection of Breast Cancer Using Microstrip Patch AntennaAline DiasNessuna valutazione finora

- Production Tracking For Equipment: Filter Machine 3: Miss Raw Material Miss Tools Miss People Punctual Lack of LoadDocumento4 pagineProduction Tracking For Equipment: Filter Machine 3: Miss Raw Material Miss Tools Miss People Punctual Lack of Loadsitam_nitj4202Nessuna valutazione finora

- Importance of Process Safety Testing For Identifying Chemical Reactions HazardsDocumento60 pagineImportance of Process Safety Testing For Identifying Chemical Reactions HazardsSarsuhNessuna valutazione finora

- Error Proof AssemblyDocumento30 pagineError Proof AssemblySergioRiveroSalcidoNessuna valutazione finora

- HSE Activities - FinalDocumento59 pagineHSE Activities - FinalRajanish BiswasNessuna valutazione finora

- PPCEDocumento31 paginePPCEbsamantonyNessuna valutazione finora

- PMAR Back To Basics Pt1Documento13 paginePMAR Back To Basics Pt1Hero VinothNessuna valutazione finora

- Safety Signs: Danger DangerDocumento3 pagineSafety Signs: Danger DangerBaharudin HelmyNessuna valutazione finora

- Six Sigma Approach For Replenishment in Supply ChainDocumento52 pagineSix Sigma Approach For Replenishment in Supply ChainAbhishek KumarNessuna valutazione finora

- Industry 4.0 PPT / PDF Iiot For Smart ManufacturingDocumento26 pagineIndustry 4.0 PPT / PDF Iiot For Smart ManufacturingSreejith S NairNessuna valutazione finora

- Kaizen: LK Pex AbDocumento3 pagineKaizen: LK Pex AbSead ZejnilovicNessuna valutazione finora

- 02 Integrating TQM, TPM & Lean Manufacturing - V R JanardhanDocumento30 pagine02 Integrating TQM, TPM & Lean Manufacturing - V R JanardhanRajiv NatarajNessuna valutazione finora

- Measurement System AnalysisDocumento2 pagineMeasurement System AnalysispsathishthevanNessuna valutazione finora

- Measure 6 Gage R&R - Short MethodDocumento2 pagineMeasure 6 Gage R&R - Short Methodanjo0225Nessuna valutazione finora

- 16 LossesDocumento26 pagine16 LossesAbhijit Bhattacherjee100% (1)

- Measurement System AnalysisDocumento1 paginaMeasurement System AnalysisPrakash KancharlaNessuna valutazione finora

- Histogram Box Plot Statistics AdaptiveBMSDocumento13 pagineHistogram Box Plot Statistics AdaptiveBMSashutoshrvNessuna valutazione finora

- Research ArticleDocumento13 pagineResearch ArticleChinaski BukowskiNessuna valutazione finora

- QRG 5S Color Code (5scolor)Documento2 pagineQRG 5S Color Code (5scolor)josé_filipe_35Nessuna valutazione finora

- NCR FormatDocumento5 pagineNCR FormatSakib KhanNessuna valutazione finora

- 2007-06-17 TPC DD BasicStatisticsDocumento91 pagine2007-06-17 TPC DD BasicStatisticsRavichandran SrinivasanNessuna valutazione finora

- SPCDocumento49 pagineSPCJosephi_abbasNessuna valutazione finora

- WCM Roi PDFDocumento20 pagineWCM Roi PDFjackpedro_surf2Nessuna valutazione finora

- Level I - Corporate Finance: Cost of CapitalDocumento33 pagineLevel I - Corporate Finance: Cost of CapitaltrumpNessuna valutazione finora

- How To Calculate OEE - TutorialDocumento11 pagineHow To Calculate OEE - Tutorialccabral81Nessuna valutazione finora

- Ptools WCM SaaSDocumento9 paginePtools WCM SaaSpToolsNessuna valutazione finora

- Process Design and Facility Layout: Mcgraw-Hill/IrwinDocumento30 pagineProcess Design and Facility Layout: Mcgraw-Hill/IrwinRosalie PintadoNessuna valutazione finora

- LSS Tools 2020Documento6 pagineLSS Tools 2020Varun KumarNessuna valutazione finora

- GM 1927 87 Special Nonconforming Material AuditDocumento6 pagineGM 1927 87 Special Nonconforming Material AuditNeumar Neumann100% (1)

- 02b. Manufacturing OperationsDocumento27 pagine02b. Manufacturing OperationsUnmesh UnnikrishnanNessuna valutazione finora

- Scorpio - N - Accessories Catalogue - Rev - 1.9Documento70 pagineScorpio - N - Accessories Catalogue - Rev - 1.9Kunal GuptaNessuna valutazione finora

- Arena TutorialDocumento8 pagineArena TutorialCoxa100NocaoNessuna valutazione finora

- 6W2H For Side Wrinkles MY17 - RearDocumento4 pagine6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghNessuna valutazione finora

- ARM CLIT New FormatDocumento65 pagineARM CLIT New FormatnasikroadNessuna valutazione finora

- Robotech - Company ProfileDocumento41 pagineRobotech - Company Profilerobotech automationNessuna valutazione finora

- 2 Tables Charts Review PDFDocumento71 pagine2 Tables Charts Review PDFCloie ChavezNessuna valutazione finora

- Lecture1 - Robust DesignDocumento31 pagineLecture1 - Robust Designds_srinivasNessuna valutazione finora

- F M E A M S A A V: Ailure Odes & Ffects Nalysis Easurement Ystems Nalysis ND AlidationDocumento20 pagineF M E A M S A A V: Ailure Odes & Ffects Nalysis Easurement Ystems Nalysis ND AlidationViswanathan SrkNessuna valutazione finora

- Environment EventDocumento90 pagineEnvironment EventRonald Abadi TariganNessuna valutazione finora

- Chapter 10. Initial Flow Control ManualDocumento10 pagineChapter 10. Initial Flow Control ManualVivek KumarNessuna valutazione finora

- Lecture 04 PDFDocumento24 pagineLecture 04 PDFanonNessuna valutazione finora

- FactoryflowDocumento54 pagineFactoryflowh_eijy2743Nessuna valutazione finora

- 01 - PSEQ-1500P Introduction BR01Documento16 pagine01 - PSEQ-1500P Introduction BR01angel_granadoNessuna valutazione finora

- 3.PMGSY Ongoing VIII To IIIDocumento2 pagine3.PMGSY Ongoing VIII To IIIK KARTHIKNessuna valutazione finora

- Item 311 UBI Angel RegionDocumento11 pagineItem 311 UBI Angel RegionFil Conol iiiNessuna valutazione finora

- Geo Tracking of Waste 2Documento3 pagineGeo Tracking of Waste 2amanNessuna valutazione finora

- P-Control Chart: 1. Start: Enter Limits 4. Result: CapabilityDocumento2 pagineP-Control Chart: 1. Start: Enter Limits 4. Result: CapabilityWixi MundoNessuna valutazione finora

- Saturated Design of Experiment (DOE) : 1. Start: Experiment Setup 2. Enter Input ParametersDocumento2 pagineSaturated Design of Experiment (DOE) : 1. Start: Experiment Setup 2. Enter Input ParametersWixi MundoNessuna valutazione finora

- Leanmap SEE Confidence Interval CalculatorDocumento1 paginaLeanmap SEE Confidence Interval CalculatorWixi MundoNessuna valutazione finora

- Full Design of Experiment (DOE)Documento1 paginaFull Design of Experiment (DOE)Wixi MundoNessuna valutazione finora

- Leanmap SEE Cost of Quality CalculatorDocumento1 paginaLeanmap SEE Cost of Quality CalculatorWixi MundoNessuna valutazione finora

- Kanban Database: Process: Purpose: ReferenceDocumento3 pagineKanban Database: Process: Purpose: ReferenceWixi MundoNessuna valutazione finora

- Leanmap FREE Six Sigma Project CharterDocumento1 paginaLeanmap FREE Six Sigma Project CharterWixi MundoNessuna valutazione finora

- Leanmap FREE Regression Analysis CalculatorDocumento2 pagineLeanmap FREE Regression Analysis CalculatorWixi MundoNessuna valutazione finora

- Leanmap FREE Quality Processes OverviewDocumento2 pagineLeanmap FREE Quality Processes OverviewWixi MundoNessuna valutazione finora

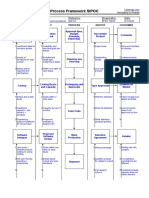

- Process Framework SIPOC: Supplier Input Process Output CustomerDocumento1 paginaProcess Framework SIPOC: Supplier Input Process Output CustomerWixi MundoNessuna valutazione finora

- Regression Analysis: Plastic Injection Molding Predict Yield at High Temp RGRN Enter Name 1/1/2020Documento2 pagineRegression Analysis: Plastic Injection Molding Predict Yield at High Temp RGRN Enter Name 1/1/2020Wixi MundoNessuna valutazione finora

- Quality Function Deployment (QFD) : (A) Feature/Specification Assessment (B) Competitive AssessmentDocumento2 pagineQuality Function Deployment (QFD) : (A) Feature/Specification Assessment (B) Competitive AssessmentWixi MundoNessuna valutazione finora

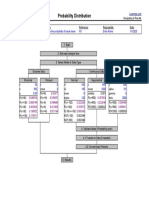

- Leanmap FREE Probability Distribution CalculatorDocumento1 paginaLeanmap FREE Probability Distribution CalculatorWixi MundoNessuna valutazione finora

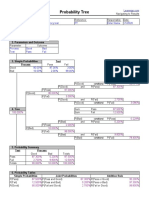

- Leanmap FREE Probability Tree CalculatorDocumento2 pagineLeanmap FREE Probability Tree CalculatorWixi MundoNessuna valutazione finora

- Control Plan: Navigating To Results Description: Reference: Owner: DateDocumento1 paginaControl Plan: Navigating To Results Description: Reference: Owner: DateWixi MundoNessuna valutazione finora

- Leanmap FREE Hypothesis Testing CalculatorDocumento1 paginaLeanmap FREE Hypothesis Testing CalculatorWixi MundoNessuna valutazione finora

- Parameter Measurement Data Type Data Collection SamplingDocumento2 pagineParameter Measurement Data Type Data Collection SamplingWixi MundoNessuna valutazione finora

- Correlation Analysis: Compare Data Check Relationship CORRN-050330 Enter Name 1/1/2020Documento2 pagineCorrelation Analysis: Compare Data Check Relationship CORRN-050330 Enter Name 1/1/2020Wixi MundoNessuna valutazione finora

- Lean Excel Causa EfectoDocumento2 pagineLean Excel Causa EfectoWixi MundoNessuna valutazione finora

- Lean Excel Causa EfectoDocumento2 pagineLean Excel Causa EfectoWixi MundoNessuna valutazione finora

- BITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball TesterDocumento10 pagineBITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball Testerakash chNessuna valutazione finora

- Gondola CalculationDocumento6 pagineGondola CalculationBudi SusantoNessuna valutazione finora

- Climbing FormworkDocumento4 pagineClimbing FormworkAshwin B S RaoNessuna valutazione finora

- Petersen Coils Basic 20principle and ApplicationDocumento3 paginePetersen Coils Basic 20principle and ApplicationasotozuazuaNessuna valutazione finora

- Eco JetDocumento15 pagineEco JetJustin CoyNessuna valutazione finora

- Psle Science Keywords !Documento12 paginePsle Science Keywords !Aftertea CarousellNessuna valutazione finora

- LinkageDocumento9 pagineLinkageHarshu JunghareNessuna valutazione finora

- Crma Unit 1 Crma RolesDocumento34 pagineCrma Unit 1 Crma Rolesumop3plsdn0% (1)

- Metal Workers BizHouse - UkDocumento3 pagineMetal Workers BizHouse - UkAlex BekeNessuna valutazione finora

- Carinthia Katalog DownloadDocumento16 pagineCarinthia Katalog DownloadOperator_010100% (2)

- Reading Part 2Documento14 pagineReading Part 2drama channelNessuna valutazione finora

- Test09 Eoc Algebra2 ReducedDocumento33 pagineTest09 Eoc Algebra2 ReducedkristymadimikeNessuna valutazione finora

- Islam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamDocumento18 pagineIslam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamLoveth KonniaNessuna valutazione finora

- Diagnosis of TrypanosomiasisDocumento82 pagineDiagnosis of TrypanosomiasisDrVijayata Choudhary100% (1)

- Orbitol Motor TMTHWDocumento20 pagineOrbitol Motor TMTHWRodolfo ErenoNessuna valutazione finora

- CulvertsDocumento18 pagineCulvertsAmmar A. Ali100% (1)

- Science Magazine February 2020Documento133 pagineScience Magazine February 2020Elena González GonzálezNessuna valutazione finora

- Tokyo Guidelines 2018Documento115 pagineTokyo Guidelines 2018Alik Razi100% (1)

- Kimi No Na Wa LibropdfDocumento150 pagineKimi No Na Wa LibropdfSarangapani BorahNessuna valutazione finora

- VavDocumento8 pagineVavkprasad_56900Nessuna valutazione finora

- G10Mapeh Exam First QuaterDocumento8 pagineG10Mapeh Exam First QuaterJonas LamcisNessuna valutazione finora

- Notes Transfer of Thermal EnergyDocumento12 pagineNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- 500 TransDocumento5 pagine500 TransRodney WellsNessuna valutazione finora

- Raneem AlbazazDocumento33 pagineRaneem AlbazazGordana PuzovicNessuna valutazione finora

- Metaphysics of LucretiusDocumento6 pagineMetaphysics of LucretiusChristopher BennettNessuna valutazione finora

- Flow Zone Indicator Guided Workflows For PetrelDocumento11 pagineFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- English Class Vii PDFDocumento101 pagineEnglish Class Vii PDFpannapurohitNessuna valutazione finora