Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Interpretation of ISO 9001:2008 Requirements: Guardian Independent Certification

Caricato da

nwohapeterTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Interpretation of ISO 9001:2008 Requirements: Guardian Independent Certification

Caricato da

nwohapeterCopyright:

Formati disponibili

Guardian Independent Certification

Chapter 3

Interpretation of ISO 9001:2008 Requirements

©Guardian Independent Certification Pte Ltd Page 1 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

Application

An organisation is allowed to exclude requirements based on

the following rules:-

Rule 1:

Exclusion can be from Clause 7 only (Product Realisation)

Rule 2:

Exclusion must not affect the organisation’s ability, or

responsibility to provide products that meet all requirements.

©Guardian Independent Certification Pte Ltd Page 2 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

Exclusion

• Design (7.3)

• Customer Property (7.5.4)

• Control of Monitoring and Measuring

Equipment (7.6)

4. QMS REQUIREMENTS

Quality Management System Requirements (Clause 4.1)

General

Documentation Requirements (Clause 4.2)

General

a) quality policy and quality objectives

b) quality manual

c) documented procedures required by this International

Standard

d) documents required by the organisation to ensure

effective planning, operation and control of its processes

e) Records required by this International Standard

©Guardian Independent Certification Pte Ltd Page 3 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

4.1 General Requirement

- Establish, document, implement and maintain a QMS and

continually improve its effectiveness

New Note

-“Outsourced process” is a process needed by organization’s QMS

but performed by external party

-Responsible to ensure the outsourced processes meet all the

requirements

-Define the type and extent of CONTROL on outsourced processes

(those affect product conformity)

-Determine any potential impacts of the outsourced processes on the

organization’s capability to provide product that conforms to

requirements.

4.2 .1 Documentation Requirements

N

• Quality policy and objectives IO

CT

• Quality manual

RU

• 6 Documented procedures ( 4.2.1 Note 1)

ST

i. Control of Documents

IN

RK

ii. Control of Quality Records

WO

iii. Internal Quality Audit

iv. Control of Non-Conforming Product

v. Corrective and Preventive Action

•Documents needed by company to ensure effective planning, operations

and control of its processes (4.2.1 Note 2)

• Records required by this standard (e.g. minutes of management review;

training records; records of design input; records of results of design

verification & review; calibration records and internal audit results)

©Guardian Independent Certification Pte Ltd Page 4 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

4.2.1 Documentation Requirement

Where the term “documented procedure” whenever appears

within the standard, this means that the procedure is

established, documented, implemented and maintained.

New Note

-Provide flexibility in creation of “documented procedure”

with the stated condition that a single document may address

the requirements for one or more procedures.

-Likewise, a requirement for a “documented procedure” may

be covered by more than one documents

4.2.2 Quality Manual

• Scope of Quality Management System, including details of

and justification for any exclusions

• reference to the documented procedures

• description of interaction between processes of

Quality Management System

©Guardian Independent Certification Pte Ltd Page 5 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

4.2.3 Control of Documents

• review and approval of (new and revised) document

for adequacy

• identify changes & current revision status of documents

• availability of relevant versions of applicable documents

at point of use

• prevent un-intended use of obsolete documents

• documents of external origin are identified and

their distribution controlled

• suitably identify obsolete documents if they are

retained for any purpose

• remain legible and readily identifiable

4.2.3 Control of Documents

4.2.3 (f) to ensure that documents of external origin are

identified and their distribution controlled ….

Clarification

- Determine if the “document of external origin” is necessary for

the planning and operation of the quality management system

©Guardian Independent Certification Pte Ltd Page 6 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

4.2.4 Control of Quality Records

• Records required to demonstrate conformity to requirements and effective

operations of Quality Management System

• Records remain legible, readily identifiable and retrievable

• Documented procedure for identifying, storing, protecting, retrieving,

retaining (retention time) and disposing of records

MANAGEMENT RESPONSIBILITY

Continual Improvement of the Quality Management Systems

Customer Management Customer

Customer

Customer

Responsibility

Measurement

Analysis and Satisfaction

Satisfaction

Resource Improvement

Management

Output

Requirements Product

Requirements Product

Realization

©Guardian Independent Certification Pte Ltd Page 7 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

5. MANAGEMENT RESPONSIBILITY

Management commitment (Clause 5.1)

Customer focus (Clause 5.2)

Quality policy (Clause 5.3)

Planning (Clause 5.4)

>Quality objectives

>Quality management system planning

Responsibility, authority and communication (Clause 5.5)

>Responsibility and authority

>Management Representative (MR)

>Internal Communication

Management Review (Clause 5.6)

>General

>Review input

>Review output

5. Management Responsibility

5.1 Management Commitment

--- To the development and implementation of an effective

QMS

--- Management Review, Policy, objectives

--- The importance of meeting customer,

statutory and regulatory requirements

.

5.2 Customer Focus

Ensure that customer requirements are determined and are met

with the aim of enhancing customer satisfaction

©Guardian Independent Certification Pte Ltd Page 8 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

5.3 Quality Policy

Top Management shall ensure that:

--- Appropriate to the purpose of organization

--- Commitment to comply with requirements and

continually improve effectiveness of QMS

--- Framework to establish and review Quality

Objectives

--- Communicated & understood within company

--- Reviewed for continuing suitability

5.4.1 Quality Objectives

Establish Quality objectives at relevant functions

and levels within organization

Consider requirement related to the product

Consistent with Quality Policy and measurable

5.4.2 QMS Planning

Top Management shall ensure that:

--- Planning of QMS meet the general requirement

and Quality Objectives

--- Integrity of QMS is maintained when changes to

QMS are planned & implemented

--- Improve effectiveness of QMS via use of Quality

policy, Quality objectives, audit results, corrective

/ preventive action & management review

©Guardian Independent Certification Pte Ltd Page 9 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

5.5.1 Responsibility and Authority

Top management shall ensure that the Responsibility

and Authority are defined and communicated

5.5.2 Management Representative

Top management shall appoint a member of

management who, irrespective of other

responsibilities, shall have responsibility and

authority that includes ……

Clarification

- Member of Management must be a member of the

organization’s management team, and not an external

member of management

©Guardian Independent Certification Pte Ltd Page 10 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

5.5.3 Internal Communication

Top management shall ensure:

• communication processes are established within company

Communication takes place regarding effectiveness of QMS

Communicate:

• Quality policy

• Promote awareness of customer

requirements within company

• Responsibilities and authorities

• Aware of relevance & importance

of their activities & how they

contribute to achievement

of Quality Objectives

5.6 Management Review

Top Management:

Review QMS at planned interval to ensure its continuing suitability,

adequacy and effectiveness

Review Input

(1) Follow-up actions from previous management reviews

(2) Results of audits ( Internal + External )

(3) Customer Feedback ( Survey/Complaint / Compliment )

(4) Process Performance & Product Conformity

(5) Status of Corrective/Preventive Actions

(6) Change that could affect the QMS

(7) Recommendations for Improvement

(8) Review Quality Policy & Objectives

(9) Review Supplier Performance

©Guardian Independent Certification Pte Ltd Page 11 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

5.6 Management Review

Review Output

(1) Improvement of the effectiveness of the QMS

(2) Improvement of the Product

(3) Resource Needs

RESOURCE MANAGEMENT

Continual Improvement of the Quality Management Systems

Customer Management Customer

Customer

Customer

Responsibility

Measurement

Analysis and Satisfaction

Satisfaction

Resource Improvement

Management

Output

Requirements Product

Requirements Product

Realization

©Guardian Independent Certification Pte Ltd Page 12 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

6. RESOURCE MANAGEMENT

Provision of resources (Clause 6.1)

Human resources (Clause 6.2)

Infrastructure (Clause 6.3)

Work environment (Clause 6.4)

6. Resources Management

6.1 Provision of Resources

Determine and provide resources needed

--- to implement and maintain QMS and continually

improve its effectiveness

--- to enhance customer satisfaction by meeting customer

requirements

©Guardian Independent Certification Pte Ltd Page 13 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

6.2.1 Human Resources ( General )

Personnel performing work affecting product quality shall be

competent on the basis of appropriate education, training,

skills and experience

New Note

“conformity to product requirement” ( replaced “product

quality” above ) can be affected either directly or indirectly by

personnel performing any task within the quality management

system )

6.2.2 Competence, Awareness & Training

Determine competency of staff performing work affecting product quality

Provide training or take other actions to satisfy these needs

Evaluate effectiveness of action taken

Ensure personnel are aware of relevance and

importance of their activities & how they contribute

to achieving Quality Objectives

Maintain records of education training, skills and

experience

©Guardian Independent Certification Pte Ltd Page 14 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

6.3 Infrastructure

Determine, provide and maintain infrastructure needed to

achieve conformity to product requirements.

Such as building, workspace, utilities, equipment, supporting

services ( such as transport and communication)

Clarification

“Information systems” can

also be an example of the

support services

6.4 Work Environment

The organization shall determine and manage the work

environment needed to achieve conformity to product

requirements.

New Note

The term “work environment” relates to those conditions,

under which work is performed, including physical,

environments and other factors ( such as noise, temperature,

humidity, lighting or weather )

©Guardian Independent Certification Pte Ltd Page 15 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

PRODUCT REALIZATION

Continual Improvement of the Quality Management Systems

Customer Management Customer

Customer

Customer

Responsibility

Measurement

Analysis and Satisfaction

Satisfaction

Resource Improvement

Management

Output

Requirements Product

Requirements Product

Realization

7. PRODUCT REALIZATION

Planning of realization (Clause 7.1)

Customer-related processes (Clause 7.2)

>Determination of requirements related to the product

>Review of requirements related to the product

>Customer communication

Design and development (Clause 7.3)

Purchasing (Clause 7.4)

>Purchasing process

>Purchasing information

>Verification of purchased product

Production and service provision (Clause 7.5)

>Control

>Validation of processes

>Identification and traceability

>Customer property

>Preservation of product

Control of monitoring and measuring devices (Clause 7.6)

©Guardian Independent Certification Pte Ltd Page 16 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7. Product Realization

7.1 Planning of Product Realization

Plan and develop the processes needed for product

realization

Determine the following :

--- quality objectives, requirements for the product

--- the need to establish processes, documents, resources

--- verification, validation, monitoring, inspection and test

activities specific to the product

--- records needed to provide evidence that realization

processes and resulting product meet requirements

7.2.1 Determination of Requirements related to

product

(a) Requirements specified by the customer, including the

requirements for delivery and post-delivery activities

New Note

“Post-delivery activities” include actions under warranty

provision, contractual

Obligations (such as maintenance services ) and

supplementary services ( such as recycling or final disposal

).

©Guardian Independent Certification Pte Ltd Page 17 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.2.2 Review requirements related to product

Review conducted prior to commitment to supply

… ensure requirements are defined

… order requirements and those previously expressed

are not different

… company has ability to meet requirements

… where product requirements are changed, ensure

relevant documents are amended and affected personnel

are informed

7.2.3 Customer Communication

Determine & implement effective arrangements for communicating with

customers in relation to:

• Product Information

• Enquiries, contracts or order handling

• Customer feedback and complaints

©Guardian Independent Certification Pte Ltd Page 18 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.3.1 Design and Development Planning

The organization shall manage the interfaces between

different groups involved in design and

development to ensure effective communication

and clear assignment of responsibility …..

New Note

Design and Development review, verification and

validation have distinct purposes. They can be

conducted and recorded separately or in any

combination, as suitable for the product and the

organization

7.3.2 Design and Development Inputs

7.3.3 Design and Development Outputs

Design and development outputs shall

(b) Provide appropriate information for purchasing, production and

for service provision …..

New Note

Information for “production and service provision” can include

details for the product of preservation.

7.3.4 Design and Development Review

• evaluate the ability of the results of the design and

development to meet requirements

• identify problems and propose necessary actions

©Guardian Independent Certification Pte Ltd Page 19 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.3.5 Design and Development Verification

Ensure that design & development outputs have met design & development

input requirements

7.3.6 Design and Development Validation

Ensure that resulting product is capable of meeting the requirements for the

specified application or intended use, where known

7.3.7 Control of Design and Development Changes

Changes shall be reviewed, verified and validated, as appropriate, and

approved before implementation

7.4 Purchasing

7.4.1 Purchasing Process

• Ensure purchased product conforms to specified requirements

• Evaluate and select suppliers based on their ability to supply product (service) in

accordance with company’s requirements

• Criteria for selection, evaluation and re-evaluation shall be established

7.4.2 Purchasing Information

• Describe the product to be purchased

• Ensure adequacy of the specified purchase requirements prior to communication

to the supplier

7.4.3 Verification of Purchased Product

• Inspection to ensure that purchased product meets specified purchase

requirements.

• When performing verification at supplier’s premises, verification

arrangement and method of product release shall be stated in purchasing

information

©Guardian Independent Certification Pte Ltd Page 20 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.5 Production and Service Provision

7.5.1 Control of Production and Service Provision

Plan and carry out production and service provision under

controlled condition that may include following applicable

items:

• availability of works instructions

• availability of information that describes

characteristics of product

• the availability and use of monitoring and

measuring devices

• implementation of monitoring and

measurement

• use of suitable equipment

7.5.2 Validation of Processes for Production and Service

Provision

Validate any processes for production and service provision where resulting

output can’t be verified by subsequent monitoring or measured.

Define criteria for review and approval of processes

Approval of equipment and qualification of personnel

Re-validation (e.g. periodic evaluation on

the skill of operator)

Use of specific methods and procedures

©Guardian Independent Certification Pte Ltd Page 21 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.5.3 Identification and Traceability

The organization shall identify the product status

with respect to monitoring and measurement

requirement.

Where traceability is a requirement, the

organization shall control and record the unique

identification of the product.

Clarification

Identification of Product status is to be applied

throughout product realization.

Records for traceability ( when it is a requirement )

shall be maintained

7.5.4 Customer Property

Identify, verify, protect and safeguard customer property

Report to customer when it is lost, damaged or unsuitable for use

Clarification

Beside intellectual property, customer property can also be personal

data

7.5.5 Preservation of Product

Preserve conformity of product during internal processing and delivery

It shall include identification, handling, packaging, storage and protection

©Guardian Independent Certification Pte Ltd Page 22 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.6 Control of Monitoring and Measuring Equipment

When used in the monitoring and measurement of specified

requirements, the ability of computer software to satisfy the

intended application shall be confirmed. This shall be

undertaken prior to initial use and re-confirmed as necessary

New Note

Confirmation of the ability of computer software to satisfy the

intended application would typically include its verification and

configuration management to maintain its suitability for use

Devices renamed as “equipment”

MEASUREMENT, ANALYSIS AND IMPROVEMENT

Continual Improvement of the Quality Management Systems

Customer Management Customer

Customer

Customer

Responsibility

Measurement

Analysis and Satisfaction

Satisfaction

Resource Improvement

Management

Output

Requirements Product

Requirements Product

Realization

©Guardian Independent Certification Pte Ltd Page 23 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

8. MEASUREMENT, ANALYSIS AND IMPROVEMENT

General (Clause 8.1)

Monitoring and measurement (Clause 8.2)

>Customer satisfaction

>Internal audit

>Monitoring and measurement of processes

>Monitoring and measurement of product

Control of nonconforming product (Clause 8.3)

Analysis of data (Clause 8.4)

Improvement (Clause 8.5)

>Continual improvement

>Corrective action

>Preventive action

8.1 Plan and Implement Monitoring, Measurement,

Analysis and Improvement Processes

• to demonstrate conformity of product

• to ensure conformity of QMS

• to continually improve the effectiveness of QMS

©Guardian Independent Certification Pte Ltd Page 24 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

8.2.1 Customer Satisfaction

As one of the measurements of the performance of the quality

management system, the organization shall monitor information

relating to customer perception as to whether the organization has

met customer requirements. The methods for obtaining and using this

information shall be determines.

New Note

Monitoring customer perception can include obtaining input from

sources, such as:

- customer Satisfaction Surveys

- customer Data ( on delivered product quality )

- user opinion surveys

- lost business analysis Customer

- dealer’s reports survey

- compliments

-warranty claims

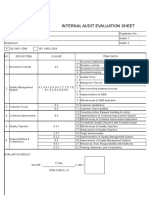

8.2.2 Internal Audit

Conduct Internal Audit at planned intervals

Consider the status and importance of the processes and areas

to be audited, as well as results of the previous audits

Audit criteria, scope, frequency and methods shall be defined

Auditors shall not audit their own work

Management responsible for the area shall ensure actions are

taken, promptly

Follow up activities shall include verification of actions taken

and reporting verification results

©Guardian Independent Certification Pte Ltd Page 25 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

8.2.2 Internal Audit

The responsibilities and requirements for

planning and conducting audits, and for

reporting results and maintaining records

shall be defined in a documented procedure.

Clarification

Records of the audit and their results shall

be maintained

8.2.3 Monitoring and Measurement of

Processes

The organization shall apply suitable methods for monitoring and

where applicable, measurement of the quality management system

processes. These methods shall demonstrate the ability of the

processes to achieve planned results. When planned results are not

achieved, correction and corrective action shall be taken, as

appropriate, to ensure conformity of the product

New Note

When determining “suitable methods”, it is advisable that the

organization consider the type and extent of monitoring or

measurement appropriate to each of its processes in relation to their

impact on the conformity to product requirements, and on the

effectiveness of the quality management system

©Guardian Independent Certification Pte Ltd Page 26 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

8.2.4 Monitoring and Measurement of Product

Product release and service delivery shall not proceed until the

planned arrangement have been satisfactorily completed,

unless otherwise approved by relevant authority and, where

applicable, the customer.

Clarification

The release of product and delivery of service ( to the customer

) shall not proceed ……

8.3 Control of Non-

Non-conforming Product

Identify and control to prevent un-intended use or delivery of non

conforming product.

Dealing with non-conformity include:

• Take correction

• Grant concession

• Determine alternative use

Record nature of non-conformity and

action taken (if any)

- subject corrected product to re-verification

©Guardian Independent Certification Pte Ltd Page 27 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

8.4 Analysis of Data

Determine, collect and analyze appropriate data to evaluate:

• suitability and effectiveness of QMS

• continual improvement of effectiveness of QMS

Analysis of Data shall provide information relating to:

• Customer satisfaction

• Conformity to Product Requirements

• Characteristics and trends of processes and products

• Suppliers

8.5 Improvement

8.5.1 Continual Improvement

Continually improve the effectiveness of QMS through the use of quality

policy, objectives, audit results, analysis of data, Corrective and preventive

actions and management review.

8.5.2 Corrective Action

(f) Reviewing corrective action taken

Clarification

Reviewing the “effectiveness” of the corrective action taken

8.5.3 Preventive Action

(f) Reviewing preventive action taken

Clarification

Reviewing the ”effectiveness” of the preventive action taken

©Guardian Independent Certification Pte Ltd Page 28 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

NOTES

SUMMARY OF ISO 9001:2008

ISO 9001:2008 has been produced in nine sections as follow:

Clause 0 This deals with the introduction of the standard refers to compatibility with ISO

14001:2004 and other related documents. It also refers to ‘the process approach’,

defines it in general terms and refers the reader to figure 1 which is the model of ISO

9001:2008.

Clause 1 This deals with General (1.1) and defines the use of the standard where an

organisation needs to demonstrate its ability to consistently provide product meeting

customers and regulatory requirements and where it aims to enhance customer

satisfaction.

Reference to Application (1.2), an organisation is allowed to exclude requirements which

are not applicable with the following caveats: -

a) The exclusion can be from Clause 7 only (Product Realization)

b) The exclusion must not affect the organisation’s ability, or responsibility to

provide products that meet all requirements.

Examples of such exclusions are: -

i). ‘Design’ (7.3) which may not be applicable to some organisation, where it may

have already been established by somebody else.

ii). ‘Customer Property’ (7.5.4) which may not always be used by many organisation.

iii). Control of Monitoring and Measuring Devices’ (7.6) which may not be applicable

to training organisation.

Clause 2 This deals with Normative references and refers the reader to ISO 9000:2008.

Clause 3 This deals with specific terms and definitions such as ‘organisation’, ‘suppliers’

and ‘customers’. Reference is also made to ISO 9000:2008.

©Guardian Independent Certification Pte Ltd Page 29 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

Clause 4-8 inclusively deal with the specific requirements.

Clause 4 is entitled ‘Quality Management System’ and contains the following sub

clauses: -

4.1 General requirements

4.2 Documentation requirements

4.2.1 General

4.2.2 Quality manual

4.2.3 Control of documents

4.2.4 Control of records

4.1 requires a documented system in line with the ISO 9001:2008. 4.1 (b) requires the

‘sequence and interaction’ of these processes that make up the system to be identified.

4.2.1 requires document(s) to include quality policy, objectives and manual, procedures,

other documents as required and records.

4.2.2 requires a quality manual including or referring to procedures and a description of

the interaction between the processes of the QMS.

4.2.3 requires QMS documents to be controlled and a list of requirements provided.

4.2.4 requires QMS records to be controlled and a list of requirements provided.

©Guardian Independent Certification Pte Ltd Page 30 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

Clause 5 is management responsibility and contain the following sub clauses: -

5.1 Management commitment

5.2 Customer focus

5.3 Quality policy

5.4 Planning

5.4.1 Quality objectives

5.4.2 Quality management system planning

5.5 Responsibility, authority and communication

5.5.1 Responsibility and authority

5.5.2 Management representative

5.5.3 Internal communication

5.6 Management review

5.6.1 General

5.6.2 Review input

5.6.3 Review output

5.1 requires top management to provide evidence of commitment to system and

improvement by communication of customer and regulatory requirements, policy and

objectives’ establishment, conducting management reviews and ensuring resources are

available.

Auditors may request top managers to illustrate commitment by example, involvement

and participation, leading specific discussions and initiatives in the organisation, leading

quality improvement teams etc.

5.2 requires a constant effort to improve the way the customer perceives the

organisation’s services.

5.3 requires top management to ensure that the policy is appropriate, includes

commitments to compliance and improvement, provides a framework for reviewing

quality objectives, is communicated and understood at all levels and is reviewed.

©Guardian Independent Certification Pte Ltd Page 31 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

5.4.1 requires that top management establish objectives at relevant levels; that they are

measurable and consistent with policy, contain continual improvement and product

requirements.

Auditors may ask on how these are established, measured and acted upon i.e. reviewed

and updated.

5.4.2 requires top management to plan to meet 4.1 and quality objectives; also ensure

that any changes to the system do not affect its ability to meet requirements.

5.5.1 requires that the responsibility, authority and interrelation are defined and

communicated. Typically, this would be in role or job descriptions, flow charts,

organisational charts etc.

5.5.2 requires top management to appoint a member or members of management to

ensure for QMS is maintained, report to top management on the performance of the

QMS and needs for improvement and ensure that customer awareness is promoted

throughout the organisation.

5.5.3 requires top management to ensure that processes for internal communication are

established. These may take the form of regular meetings, briefings, staff surveys,

availability of formal systems e.g. e-mail, written memos, minutes of meetings etc.

Auditors can ask how this occurs and for evidence.

5.6.1 requires top management reviews the QMS at planned intervals. 5.6.2 lists the

required inputs and 5.6.3 lists the required outputs.

©Guardian Independent Certification Pte Ltd Page 32 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

Clause 6 is Resource management and has sub clauses as follow:

6.1 Provision of resources

6.2 Human resources

6.2.1 General

6.2.2 Competence, awareness and training

6.3 Infrastructure

6.4 Work environment

6.1 requires resources to maintain the QMS, improve its effectiveness and enhance

customer satisfaction.

6.2.1 requires organisations to have competent and qualified people. ISO 9004 focuses

more on people involvement than basic competence but does provide numerous

examples of ways by which competence may be enhanced.

6.2.2 requires organisation to determine competence needs, provide training where

necessary, evaluate its effectiveness, ensure that people are aware of how they affect

objectives and maintain records for employees’ education, training, skills and

experience.

6.3 requires infrastructure to be in place e.g. buildings, workspace, associated utilities,

process equipment, hardware and software and supporting services.

6.4 requires work conditions to achieve product conformity. ISO 9004 provide examples

of both human and physical factors.

©Guardian Independent Certification Pte Ltd Page 33 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

Clause 7 is Product realization and has sub clauses as follows:

7.1 Planning of product realization

7.2 Customer-related processes

7.2.1 Determination of requirements related to the product

7.2.2 Review of requirements related to the product

7.2.3 Customer communication

7.3 Design and development

7.3.1 Design and development planning

7.3.2 Design and development inputs

7.3.3 Design and development outputs

7.3.4 Design and development review

7.3.5 Design and development verification

7.3.6 Design and development validation

7.3.7 Design and development changes

7.4 Purchasing

7.4.1 Purchasing process

7.4.2 Purchasing information

7.4.3 Verification of purchased product

7.5 Production and service provision

7.5.1 Control of production and service provision

7.5.2 Validation of processes for production and service provision

7.5.3 Identification and traceability

7.5.4 Customer property

7.5.5 Preservation of product

7.6 Control of monitoring devices

7.1 requires planning of ‘product realization’.

Control of process is effected, as is well established, by controlling all the inputs i.e.

competence of people, capability of the equipment, compliance of materials used,

approval of the processes and procedures and restrictions on the environment.

©Guardian Independent Certification Pte Ltd Page 34 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.2.1 requires that all product requirements are defined.

7.2.2 requires that the product requirements are reviewed as to whether the organisation

can comply.

7.2.3 requires a mechanism for ensuring customers can be kept advised and in touch.

7.3.1 to 7.3.7 cover the processes of design/development.

7.4.1 requires evaluation and selection of suppliers against defined criteria with

evaluation records.

7.4.2 requires information to be on purchasing documents like process control principles

and QMS requirements.

7.4.3 requires verification of what is purchased.

7.5.1 requires that production and service are controlled by information being provided

about instructions and/or the product, suitable equipment being available, suitable

measuring devices being available etc.

7.5.2 requires that any ‘special processes’ are validated i.e. controlled to the extent that

they will produce good output.

7.5.3 requires identification of product to the extent necessary; also that the status of

product regarding inspection/test is know at any time.

7.5.4 requires that ‘customer property’ is protected and looked after and if damaged or

lost is reported to the customer. The emphasis here is not on specific material to be

incorporated into the final product but customer property generally.

7.5.5 requires protection of materials and product throughout the production processes.

©Guardian Independent Certification Pte Ltd Page 35 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

7.6 requires that measurements of products are defined and made with equipment

whose accuracy compared to (inter)national standards is known; also that records are

kept; reference is made to ISO 10012.

Clause 8 is Measurement, analysis and improvement and has sub clauses as follows:

8.1 General

8.2 Monitoring and measurement

8.2.1 Customer satisfaction

8.2.2 Internal audit

8.2.3 Monitoring and measurement or processes

8.2.4 Monitoring and measurement of product

8.3 Control of nonconforming product

8.4 Analysis of data

8.5 Improvement

8.5.1 Continual improvement

8.5.2 Corrective action

8.5.3 Prevention action

8.1 requires the organisation to think about the kinds of checking of product, system and

effectiveness of the QMS required.

8.2.1 requires measurements of customers’ perceptions of whether the organisation has

fulfilled requirements.

8.2.2 requires internal audits at planned intervals, frequency dependent on status and

importance and previous audit results. Auditors shall not audit their own work. A

documented procedure is required with responsibilities and reporting methods.

8.2.3 requires monitoring of processes. The standard doesn’t say which processes, just

those of the QMS. This requires objectives (outputs) to be specified for any process in

the QMS and measurement (and records) of that.

©Guardian Independent Certification Pte Ltd Page 36 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Guardian Independent Certification

8.2.4 requires that the appropriate checks of product i.e. inspection and test are carried

out as planned and be recorded.

8.3 requires that any product which does not conform is identified to prevent use or

delivery. Options for dealing with such material are given. A documented procedure is

requires.

8.4 requires that appropriate data are identified, collected and analysed to evaluate

where continual improvement can be made.

8.5.1 requires continual improvement of the QMS to occur through policy, objectives,

audits, analysis of data, corrective and preventive action and management reviews.

8.5.2 requires that when something is found not to conform it is corrected by applying a

disciplined and comprehensive problem solving process. A documented procedure is

required.

8.5.3 requires a documented procedure to eliminate the causes of potential

nonconformities. A good initial procedure should of course prevent nonconformities

along with analysis of real data on objectives, trends, measurements of critical and non-

critical processes etc.

©Guardian Independent Certification Pte Ltd Page 37 of 37

Lead Assessor / Assessor Revision: 5 (July 2010)

Chapter 3

Potrebbero piacerti anche

- Manual de QualidadeDocumento30 pagineManual de QualidadeClonar Soluções GráficasNessuna valutazione finora

- International Register of Certificated AuditorsDocumento11 pagineInternational Register of Certificated AuditorsnwohapeterNessuna valutazione finora

- International Register of Certificated AuditorsDocumento11 pagineInternational Register of Certificated AuditorsnwohapeterNessuna valutazione finora

- ISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKDocumento20 pagineISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKroelly100% (2)

- IQA Training Workshop PPSCDocumento221 pagineIQA Training Workshop PPSCChristianieAnn100% (2)

- Checklist of Documentation As Per IATF 16949:2016Documento10 pagineChecklist of Documentation As Per IATF 16949:2016Arun Kumar Sharma100% (2)

- Document Management Guidance ExampleDocumento6 pagineDocument Management Guidance ExampleISO 9001 Checklist100% (6)

- DBFS IA Course NotesDocumento33 pagineDBFS IA Course NotesAnnie ChanNessuna valutazione finora

- Checklist of Documentation For IATF 16949 - 2016Documento11 pagineChecklist of Documentation For IATF 16949 - 2016Deepak kumarNessuna valutazione finora

- Mandatory Documentation IATF 16949 enDocumento20 pagineMandatory Documentation IATF 16949 enrajaNessuna valutazione finora

- Module-2 Overview of ISO 9001Documento16 pagineModule-2 Overview of ISO 9001baluNessuna valutazione finora

- Document Control Training 1Documento94 pagineDocument Control Training 1Fathi MonamiNessuna valutazione finora

- ISO 17025 R EquirementsDocumento47 pagineISO 17025 R EquirementsJoseNessuna valutazione finora

- IMS Checklist 3 - Mod 2Documento10 pagineIMS Checklist 3 - Mod 2Febin C.S.100% (1)

- Internal Quality Management System Audit ChecklistDocumento48 pagineInternal Quality Management System Audit Checklistsharif1974Nessuna valutazione finora

- Quality Manual SampleDocumento8 pagineQuality Manual SampleAhmed ShalabyNessuna valutazione finora

- Audit Iso 9001Documento64 pagineAudit Iso 9001raya100% (1)

- IMS Internal Audit ChecklistDocumento11 pagineIMS Internal Audit ChecklistBoby BobyNessuna valutazione finora

- ISO 15189 - 2012 Management RequirementsDocumento56 pagineISO 15189 - 2012 Management RequirementsAhmed AdemNessuna valutazione finora

- Internal Audit Planning and Scheduling Sample FormatDocumento3 pagineInternal Audit Planning and Scheduling Sample Formatsameh100% (2)

- ISO 13485-2016 Raga PresentationDocumento17 pagineISO 13485-2016 Raga PresentationSuresh AnandNessuna valutazione finora

- Quality Manual 9001-2008 Elsmar 1Documento13 pagineQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzNessuna valutazione finora

- Task Week2 QualityManagementDocumento24 pagineTask Week2 QualityManagementScribdTranslationsNessuna valutazione finora

- ISO 13485 2003 Audit ChecklistDocumento38 pagineISO 13485 2003 Audit Checklisttousifaslam100% (1)

- Aud Agile Eng m01 Pnotes Background Terms and DefinitionsDocumento5 pagineAud Agile Eng m01 Pnotes Background Terms and DefinitionsMohamed ElsawyNessuna valutazione finora

- Quality Management System and AuditingDocumento72 pagineQuality Management System and Auditingrtiyer1970Nessuna valutazione finora

- Quality System Manual ISO 9001:2008 Internal Audit Check ListDocumento14 pagineQuality System Manual ISO 9001:2008 Internal Audit Check ListDivakar Panigrahi100% (1)

- Internal Audit Evaluation ReviewDocumento16 pagineInternal Audit Evaluation ReviewHarnani Nanik100% (1)

- GE2022 TQM UNIT V NotesDocumento13 pagineGE2022 TQM UNIT V NotespushpenderNessuna valutazione finora

- Quality System Audit Report TemplateDocumento5 pagineQuality System Audit Report TemplateIshara VithanaNessuna valutazione finora

- Internal Quality Assurance: Assesment Process & Practice MethodDocumento11 pagineInternal Quality Assurance: Assesment Process & Practice MethodWaiyan Htet AungNessuna valutazione finora

- ISO 13485 Internal Audit ChecklistDocumento23 pagineISO 13485 Internal Audit ChecklistGary Jheferson Salazar Rondon60% (5)

- Audit Checklist - ISO 22000 Food Safety ManagementDocumento18 pagineAudit Checklist - ISO 22000 Food Safety ManagementChoirul HudaNessuna valutazione finora

- Iqoqpq RMG PDFDocumento11 pagineIqoqpq RMG PDFsrinivas rNessuna valutazione finora

- ISO 9001 2008 Gap AssessmentDocumento65 pagineISO 9001 2008 Gap AssessmentChinh Le DinhNessuna valutazione finora

- What Is The ISO 9001:2008 Audit Checklist?Documento38 pagineWhat Is The ISO 9001:2008 Audit Checklist?John SoaresNessuna valutazione finora

- PRE AUDIT MEETING DOCUMENT REVIEWDocumento4 paginePRE AUDIT MEETING DOCUMENT REVIEWDaun KelorNessuna valutazione finora

- Appendix A - Supplier ISO-TS16949 Checklist-Rev.1 PDFDocumento45 pagineAppendix A - Supplier ISO-TS16949 Checklist-Rev.1 PDFPurushothama Nanje GowdaNessuna valutazione finora

- Implementat ION: Induction TrainingDocumento23 pagineImplementat ION: Induction TrainingRam PrasanthNessuna valutazione finora

- BSI ISO 9001 2015 Gap Analysis Tool CANDocumento14 pagineBSI ISO 9001 2015 Gap Analysis Tool CANchaouch.najehNessuna valutazione finora

- ISO 13485:2016 Quick Reference: ISO 13485:2016 Clauses Requirement Key WordsDocumento2 pagineISO 13485:2016 Quick Reference: ISO 13485:2016 Clauses Requirement Key WordsHong Xuyen100% (2)

- Documented InformationDocumento23 pagineDocumented Informationestherrossi2008Nessuna valutazione finora

- Internal Audit ISO 9001Documento6 pagineInternal Audit ISO 9001Mufmuf Mufti SyahidNessuna valutazione finora

- ISO 9001 RecordsDocumento3 pagineISO 9001 RecordsganandmailNessuna valutazione finora

- ISO 9001 SGC audit questions and evidenceDocumento58 pagineISO 9001 SGC audit questions and evidenceMauricio CruzNessuna valutazione finora

- IMS - Internal Audit ChecklistDocumento11 pagineIMS - Internal Audit ChecklistAli TavakoliNessuna valutazione finora

- Iso Clouse Wise CheckpointsDocumento24 pagineIso Clouse Wise CheckpointsAbhinav SinghNessuna valutazione finora

- ISO 9001 Internal Audit ChecklistDocumento6 pagineISO 9001 Internal Audit Checklistjmwaweru71% (7)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationDa EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationValutazione: 5 su 5 stelle5/5 (1)

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsDa EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNessuna valutazione finora

- Establishing A CGMP Laboratory Audit System: A Practical GuideDa EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNessuna valutazione finora

- Comprehensive Manual of Internal Audit Practice and Guide: The Most Practical Guide to Internal Auditing PracticeDa EverandComprehensive Manual of Internal Audit Practice and Guide: The Most Practical Guide to Internal Auditing PracticeValutazione: 5 su 5 stelle5/5 (1)

- Ensuring Quality to Gain Access to Global Markets: A Reform ToolkitDa EverandEnsuring Quality to Gain Access to Global Markets: A Reform ToolkitNessuna valutazione finora

- How to Comply with Sarbanes-Oxley Section 404: Assessing the Effectiveness of Internal ControlDa EverandHow to Comply with Sarbanes-Oxley Section 404: Assessing the Effectiveness of Internal ControlNessuna valutazione finora

- Automotive Quality Systems Handbook: ISO/TS 16949:2002 EditionDa EverandAutomotive Quality Systems Handbook: ISO/TS 16949:2002 EditionValutazione: 3 su 5 stelle3/5 (5)

- Requirements Management: A Practice GuideDa EverandRequirements Management: A Practice GuideValutazione: 3.5 su 5 stelle3.5/5 (2)

- Thread Profile Gages: Profile Gage # Will Check The Following Connections Thread FormDocumento1 paginaThread Profile Gages: Profile Gage # Will Check The Following Connections Thread FormnwohapeterNessuna valutazione finora

- Auditor Selection, Competency and Auditor Registration: Guardian Independent CertificationDocumento28 pagineAuditor Selection, Competency and Auditor Registration: Guardian Independent CertificationnwohapeterNessuna valutazione finora

- Sparksinnovationseptember 200924065821 PDFDocumento11 pagineSparksinnovationseptember 200924065821 PDFnwohapeterNessuna valutazione finora

- Thread Profile Gages: Profile Gage # Will Check The Following Connections Thread FormDocumento1 paginaThread Profile Gages: Profile Gage # Will Check The Following Connections Thread FormnwohapeterNessuna valutazione finora

- 10 - Chapter 04Documento9 pagine10 - Chapter 04nwohapeterNessuna valutazione finora

- Training Schedule - 2018Documento2 pagineTraining Schedule - 2018Akash NarayananNessuna valutazione finora

- ConnectionsDocumento82 pagineConnectionsseabrake83% (12)

- UH Final Presentation 1 - Sept 9, 2013 - PrintingDocumento68 pagineUH Final Presentation 1 - Sept 9, 2013 - PrintingTauqeer IqbalNessuna valutazione finora

- Paint DefectDocumento2 paginePaint Defectanurag_4013100% (4)

- Quality Control Form "Sample"Documento23 pagineQuality Control Form "Sample"BernathTurnipNessuna valutazione finora

- Introduction of ISO 9001:2008 & Related Standards: Guardian Independent CertificationDocumento9 pagineIntroduction of ISO 9001:2008 & Related Standards: Guardian Independent CertificationnwohapeterNessuna valutazione finora

- VAM Must Sumitomo 1209 PDFDocumento4 pagineVAM Must Sumitomo 1209 PDFnwohapeterNessuna valutazione finora

- 13 - Chapter 07 - Change in Page 2 of 21 (1st Slide)Documento21 pagine13 - Chapter 07 - Change in Page 2 of 21 (1st Slide)nwohapeterNessuna valutazione finora

- 13 - Chapter 07 - Change in Page 2 of 21 (1st Slide)Documento21 pagine13 - Chapter 07 - Change in Page 2 of 21 (1st Slide)nwohapeterNessuna valutazione finora

- SI HandbookDocumento52 pagineSI Handbookcal2_uniNessuna valutazione finora

- 2020 June and October-API 570 EXAM Publications Effectivity Sheet FinalDocumento1 pagina2020 June and October-API 570 EXAM Publications Effectivity Sheet FinalInstech Premier Sdn BhdNessuna valutazione finora

- Tweakyourresume 130818213000 Phpapp02 PDFDocumento76 pagineTweakyourresume 130818213000 Phpapp02 PDFnwohapeterNessuna valutazione finora

- Material Science and Metallurgy Ala O: N "Non Destructive Testing"Documento37 pagineMaterial Science and Metallurgy Ala O: N "Non Destructive Testing"nwohapeterNessuna valutazione finora

- The Quality Principles: Guardian Independent CertificationDocumento6 pagineThe Quality Principles: Guardian Independent CertificationnwohapeterNessuna valutazione finora

- API 570 Exam Publications Effectivity Sheet: February 2019 Through February 2020Documento1 paginaAPI 570 Exam Publications Effectivity Sheet: February 2019 Through February 2020GHULAM FAREEDNessuna valutazione finora

- UT Guide PDFDocumento22 pagineUT Guide PDFHatem JafouraNessuna valutazione finora

- Fabricationandqualitycontrolofstructuralsteel 141125014840 Conversion Gate02 PDFDocumento16 pagineFabricationandqualitycontrolofstructuralsteel 141125014840 Conversion Gate02 PDFnwohapeterNessuna valutazione finora

- Tubular and Equipment Inspection Services PDFDocumento1 paginaTubular and Equipment Inspection Services PDFnwohapeterNessuna valutazione finora

- GP Tool Joint Dimensional ValueDocumento3 pagineGP Tool Joint Dimensional ValuecalamarejoNessuna valutazione finora

- Rotary Shouldered Connection Thread Inspection SystemDocumento18 pagineRotary Shouldered Connection Thread Inspection SystemLewis Tan LimNessuna valutazione finora

- Committee # 1. CII Code of Desirable Corporate Governance (1998)Documento11 pagineCommittee # 1. CII Code of Desirable Corporate Governance (1998)Vaidehi ShuklaNessuna valutazione finora

- Build Today For A Better Tomorrow: Annual ReportDocumento88 pagineBuild Today For A Better Tomorrow: Annual ReportkokueiNessuna valutazione finora

- Internal and Governmental Financial Auditing and Operational AuditingDocumento20 pagineInternal and Governmental Financial Auditing and Operational Auditingputri retnoNessuna valutazione finora

- Internal Audit Guidance ExampleDocumento2 pagineInternal Audit Guidance Examplesunderrajan100% (1)

- Auditing & Assurance Services 8E: ©Mcgraw-Hill EducationDocumento33 pagineAuditing & Assurance Services 8E: ©Mcgraw-Hill EducationRon CraftonNessuna valutazione finora

- AT Reviewer Part III (Questions and Answer) PDFDocumento48 pagineAT Reviewer Part III (Questions and Answer) PDFVictor RamirezNessuna valutazione finora

- Quantity Book Title Publication YearDocumento36 pagineQuantity Book Title Publication Yearmabkhout aliwiNessuna valutazione finora

- Auditing SkillsDocumento5 pagineAuditing SkillsDr.Sivakumar SelvarajNessuna valutazione finora

- Case 1 - Argon BankDocumento5 pagineCase 1 - Argon BankLiyana IzyanNessuna valutazione finora

- Chapter 2 The International Professional Practice Framework Authoritative Guidance For The Internal Audit ProfessDocumento61 pagineChapter 2 The International Professional Practice Framework Authoritative Guidance For The Internal Audit ProfessJust JhexNessuna valutazione finora

- Internal AuditorDocumento2 pagineInternal Auditorapi-79025151Nessuna valutazione finora

- Enterprise Risk Management-The COSO Framework: A Primer and Tool For The Audit CommitteeDocumento12 pagineEnterprise Risk Management-The COSO Framework: A Primer and Tool For The Audit Committeemlce26Nessuna valutazione finora

- Shared Services GuideDocumento10 pagineShared Services GuideGibson DC DaenNessuna valutazione finora

- ISO 45001 2018 Versus OHSAS 18001 ClausewiseDocumento6 pagineISO 45001 2018 Versus OHSAS 18001 ClausewiseEngilsh Iso80% (10)

- Internal Audit ReportsDocumento35 pagineInternal Audit ReportsCQMS 5S Division79% (14)

- Tax Audit U/s 44 AB' AY 2015-16: Bycarssharma RSRV & AssociatesDocumento83 pagineTax Audit U/s 44 AB' AY 2015-16: Bycarssharma RSRV & AssociatesSunil KumarNessuna valutazione finora

- Ethics and Corporate Social Responsibility in The Corporate World Are Very ImportantDocumento10 pagineEthics and Corporate Social Responsibility in The Corporate World Are Very ImportantSeroney JustineNessuna valutazione finora

- Safaricom PLC Annual Report and Financial Statements 2021Documento255 pagineSafaricom PLC Annual Report and Financial Statements 2021Mark M'rabuNessuna valutazione finora

- Internal Audit Scheduling Tool3Documento1 paginaInternal Audit Scheduling Tool3BharathNessuna valutazione finora

- KPMG Risk Management Survey 2011Documento36 pagineKPMG Risk Management Survey 2011Arindam ChakrabortyNessuna valutazione finora

- ICAI - Audit MCQ BookletDocumento266 pagineICAI - Audit MCQ BookletYuva LakshmiNessuna valutazione finora

- Acctg. 325 - PF Quiz#1Documento6 pagineAcctg. 325 - PF Quiz#1JoyluxxiNessuna valutazione finora

- 2 AgileAuditingDBSDocumento18 pagine2 AgileAuditingDBSmalcNessuna valutazione finora

- Audit Committee 20feb18Documento52 pagineAudit Committee 20feb18Anupam KulshreshthaNessuna valutazione finora

- Risk Matrix Assessment Bank Risk Matrix AssessmentDocumento3 pagineRisk Matrix Assessment Bank Risk Matrix Assessmentabdullahsaleem91Nessuna valutazione finora

- ISO 27001 Gap Analysis: Sample Client Report (Redacted)Documento17 pagineISO 27001 Gap Analysis: Sample Client Report (Redacted)Blanche Almond100% (5)

- Ch1 - Auditing and Internal ControlDocumento41 pagineCh1 - Auditing and Internal ControlCELRenn100% (2)

- Flipkart India Private Limited: (700300) Disclosure of General Information About CompanyDocumento209 pagineFlipkart India Private Limited: (700300) Disclosure of General Information About CompanyAryan MaxNessuna valutazione finora

- Coordinating Risk Management and AssuranceDocumento14 pagineCoordinating Risk Management and AssuranceDizzyDudeNessuna valutazione finora

- 11 - 20180221 - Materi Auditor PDFDocumento128 pagine11 - 20180221 - Materi Auditor PDFYan SuryoNessuna valutazione finora