Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3 (1) Leea Advice On Eyebolts PDF

Caricato da

Reda MashalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3 (1) Leea Advice On Eyebolts PDF

Caricato da

Reda MashalCopyright:

Formati disponibili

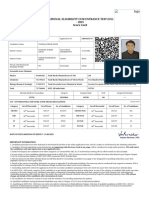

Instructions for the safe use of:

Eyebolts

The information in this leaflet should be passed to the user of the equipment

This document is issued in accordance with the requirements of Using Eyebolts Safely

Section 6 of the Health and Safety at Work etc Act 1974,

amended March 1988. It outlines the care and safe use of Do not attempt lifting operations unless you understand the use

EYEBOLTS and is based on Section 19 of the LEEA Code of and limitations to use of the equipment, the slinging procedures

Practice for the Safe Use of Lifting Equipment.* It should be and the mode factors to be applied.

read in conjunction with the requirements for general purpose Do not use defective eyebolts. Check the thread of both the

slinging practice given overleaf, the principles of which may be eyebolt and hole, ensure they are compatible, fully formed, of

applied to the use of eyebolts with or without slings. sufficient length, undamaged and clear of any debris which may

This information is of a general nature only covering the main prevent proper engagement.

points for the safe use of eyebolts which comply with BS 4278 Ensure the contact surface around the hole is flat, clean and

or the withdrawn standard BS 529 Part 1. It may be necessary perpendicular to the thread axis. Tighten the eyebolt down

to supplement this information for specific applications. firmly by hand. The eye must be in the correct plane and the

collar must sit evenly on the contact surface. Use shims but do

not machine the collar or over tighten to achieve this.

ALWAYS: A hook may be engaged directly into the eye of a dynamo

• Store and handle eyebolts correctly. eyebolt or the link of an eyebolt with link. Collar eyebolts must

• Inspect eyebolts before use and before placing into storage. be fitted with a shackle or link to accept hooks. The hooks must

fit freely so do not wedge or force them into position.

• Select the correct pattern eyebolt for the application.

Never reeve a sling through the eyes, links or shackles fitted to

• Ensure that the eyebolt and tapped hole threads are eyebolts used in pairs as this will impose a severe resultant

compatible and strong enough for the load. load to the eyebolts.

• Correctly align the plane of the eye using shims where Dynamo eyebolts must only be used for axial loading. When

necessary. using eyebolts with multi-leg slings use eyebolts with links or

• Ensure that the collar is fully seated when hand tight. collar eyebolts taking care to de-rate them correctly for angular

loading conditions.

NEVER: Where a single eyebolt is used, use a swivel or swivel hook to

• Use tommy bars, grips or wrenches to tighten eyebolts. prevent the eyebolt unscrewing.

• Use dynamo eyebolts for angular loading. In-service Inspection and Maintenance

• Use a single eyebolt to lift a load that is free to rotate. Maintenance requirements are minimal. Keep eyebolts clean,

• Reeve slings through the eyes, links or shackles fitted to pairs protect from corrosion and protect threads from damage. Do not

of eyebolts. attempt to straighten bent eyebolts or re-cut threads.

• Force hooks or other fittings into the eye; they must fit freely. Regularly inspect eyebolts and, in the event of the following

defects, refer the eyebolt to a Competent Person for thorough

• Shock load eyebolts. examination: illegible markings; distortion; worn, or bent shanks

and threads; incomplete or incorrectly formed threads;

damaged eyes; nicks, gouges, cracks, corrosion or other

Selecting the Correct Eyebolt defects.

Eyebolts to BS 4278 are available in three standard types,

eyebolt with link, collar eyebolt and dynamo eyebolt. Select the © Lifting Equipment Engineers Association 2004 SI No. 7.3

eyebolt to be used and plan the lift taking the following into

account:

Type of eyebolt - eyebolt with link for all general purpose Further information is given in:

applications, collar eyebolt for most general duties, dynamo HSE Guidance Note PM 16 – Eyebolts

eyebolt only where a truly axial load is guaranteed. (A collar * The Code of Practice for the Safe Use of Lifting Equipment,

eyebolt fitted with a link through the eye must always be published by:

considered as a collar eyebolt and not as an eyebolt with link.)

LIFTING EQUIPMENT ENGINEERS ASSOCIATION

Capacity - (rating eyebolts for angular loading) It is necessary to

3, Osprey Court, Kingfisher Way,

reduce the SWL by the following factors when using eyebolts

Hinchingbrooke Business Park, Huntingdon PE29 6FN

with two leg slings:

United Kingdom

Tel: + 44 (0) 1480 432801

Included angle α of sling legs Fax: + 44 (0) 1480 436314

E-mail: mail@leea.co.uk

Type of eyebolt 0<α≤30 30<α≤60 60<α≤90

Eyebolt with link 1.0 0.8 0.63

Collar eyebolt 0.63 0.4 0.25

Storing and Handling Eyebolts

Never return damaged eyebolts to storage. They should be dry,

clean and protected from corrosion. Care must be taken to

protect threads from damage whilst in store.

Where possible use removable plugs to exclude debris from

tapped holes.

GENERAL PURPOSE SLINGING PRACTICE Safe use of Slings

The following information is based on Section 1 - Appendix 1.5 o Good slinging practice must ensure that the load is as safe

of the LEEA Code of Practice for the Safe Use of Lifting and secure in the air as it was on the ground and that no

Equipment.* It should be read in conjunction with the harm is done to the load, lifting equipment, other property or

instructions for the safe use, given overleaf, of which it forms an persons.

integral part and with any specific instructions issued by the o Establish the weight of the load, ensure the lifting method is

supplier. suitable and inspect the sling and attachments for obvious

This information is of a general nature only covering the main defects. Prepare the landing area making sure the floor is

points for the safe use of various types of slings for general strong enough to take the load. Follow any specific

lifting purposes. instructions from the supplier.

o Ensure the lifting point is over the centre of gravity. Any loose

parts of the load should be removed or secured. Secure the

ALWAYS: sling firmly to the load by hooks onto lifting points or shackles

etc. The sling must not be twisted, knotted or kinked in any

• Plan the lift, establish the weight of the load and prepare the way.

landing area ensuring that it will take the weight.

o Use packing to prevent damage to the sling from corners or

• Check slings and equipment are free of damage, use edges and to protect the load.

slings/slinging methods suitable for the load and protect

slings from sharp edges and corners. o Do not exceed the SWL or rated angle. Any choke angle

must not exceed 120° and any basket 90°.

• Attach the sling securely to the load and appliance and

position hooks to face outwards. o Do not hammer, force or wedge slings or accessories into

position; they must fit freely.

• Ensure the load is balanced and will not tilt or fall.

o When attaching more than one sling to the hook of the

• Keep fingers, toes etc clear when tensioning slings and when appliance use a shackle to join the slings and avoid

landing loads. overcrowding the hook.

• Ensure that the load is free to be lifted. o Use an established code of signals to instruct the crane

• Make a trial lift and trial lower. driver.

o Ensure the load is free to be lifted and not, for example,

NEVER: bolted down.

• Use damaged slings or accessories. o Check that there are no overhead obstacles such as power

• Twist, knot or tie slings. lines.

• Hammer slings into position. o Keep fingers, toes etc clear ensuring they do not become

trapped when lifting, lowering or controlling loads.

• Overload slings due to the weight of the load or the mode of

use. o Make a trial lift by raising the load a little to ensure it is

balanced, stable and secure and if not lower it and adjust the

• Trap slings when landing the load. slinging arrangement.

• Drag slings over floors etc or attempt to pull trapped slings o Where appropriate use tag lines to control the load.

from under loads.

o Except where special provision is made, do not allow anyone

• Allow personnel to ride on loads. to pass under or ride upon the load. The area should be kept

clear.

o Make a trial set down, ensure the sling will not become

Sling Configurations and Rating trapped and the load will not tip when the slings are released.

Slings are available in single, two, three and four leg or endless Use supports which are strong enough to sustain the load

form. In practice it will be found that chain, wire rope and fibre without crushing.

rope slings are available in any of these configurations but that o Never drag slings over floors etc or attempt to drag a trapped

flat woven webbing is limited to single leg and endless whilst sling from under a load.

roundslings are only supplied in endless form. The maximum

load that a sling may lift in use will be governed by the slinging o Never use a sling to drag a load.

arrangement (mode of use) and may vary from the marked o Place the hooks of free legs back onto the master link and

SWL.** In the case of textile slings the SWL for the various take care to ensure that empty hooks do not become

modes of use is usually given on the information label. In other accidentally engaged.

cases it is necessary to multiply the marked SWL by a mode

factor.*** o Never use slings in contact with chemicals or heat without the

manufacturers approval.

The following three simple rules will ensure that the sling is not

overloaded. In some cases this will mean that the sling will be o Never use damaged or contaminated slings.

under utilised although this is unlikely to hinder the user unduly. o On completion of the lift return all equipment to proper

Where the maximum utilisation is required reference should be storage.

made to a Competent Person who understands the factors

involved and who can perform the necessary calculations.

(1) For straight lift never exceed the marked SWL and in the

case of multi-leg slings the specified angle or range of Further information is given in:

angles. * LEEA Code of Practice for the Safe Use of Lifting

(2) When using slings in choke hitch multiply the marked SWL Equipment.

by 0.8 to obtain the reduced maximum load the sling may ** BS 6166 Part 1 - Lifting Slings, Methods of Rating.

lift ie reduce the safe working load by 20%.

*** BS 6166 Part 3 - Selection and Safe Use of Lifting Slings

(3) With multi-leg slings, when using less than the full number for Multi-purposes.

of legs, reduce the maximum load in proportion to the

number of legs in use. Simply multiply the marked SWL by **** HSE Guidance Note GS39 - Training of Crane Drivers and

the number of legs in use expressed as a fraction of the Slingers.

total thus: one leg of a two leg sling = ½ marked SWL, Various British Standards covering individual products.

three legs of a four leg sling = ¾ marked SWL and so on.

Operative Training

Slings should only be used by trained operatives who

understand the methods of rating and application of mode

factors.****

SI GSP 1.1 (2000)

Potrebbero piacerti anche

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Documento2 pagine0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNessuna valutazione finora

- Hand Operated Chain Lever Hoists SI 12.3Documento2 pagineHand Operated Chain Lever Hoists SI 12.3reda mesbahNessuna valutazione finora

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocumento12 pagineWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNessuna valutazione finora

- Chain Slings SI 1.3Documento2 pagineChain Slings SI 1.3reda mesbahNessuna valutazione finora

- Sling Saver: 69 All Rights ReservedDocumento12 pagineSling Saver: 69 All Rights ReservedPradhipta W NurrobbiNessuna valutazione finora

- Hooks and Shackles: Clevis Grab Hook Clevis Slip HookDocumento7 pagineHooks and Shackles: Clevis Grab Hook Clevis Slip HookWade SperryNessuna valutazione finora

- Learner Guide - Supervise Metal ScaffoldDocumento170 pagineLearner Guide - Supervise Metal ScaffoldArdamitNessuna valutazione finora

- WSH Guidelines Safe Operation of Forklift TrucksDocumento35 pagineWSH Guidelines Safe Operation of Forklift TrucksYusuf ÜnlüsoyNessuna valutazione finora

- Chapter01 ShacklesDocumento38 pagineChapter01 ShacklesHamzahrudin SunandarNessuna valutazione finora

- Torch - Instructions For UseDocumento1 paginaTorch - Instructions For UseMihaelaBeatriceVladNessuna valutazione finora

- Slinger Signaller Study Guide 19-07-22Documento36 pagineSlinger Signaller Study Guide 19-07-22Dominican MontanoNessuna valutazione finora

- Conveyor SafetyDocumento18 pagineConveyor Safetyshaik sakeemNessuna valutazione finora

- Cosmo Petra-Safe Lifting Solutions - Excel Catalog - Lifting FittingsDocumento94 pagineCosmo Petra-Safe Lifting Solutions - Excel Catalog - Lifting FittingsSafe Lifting SolutionsNessuna valutazione finora

- Cement PlantDocumento4 pagineCement PlantVishnu VenugopalNessuna valutazione finora

- Cyclone Preparedness MeasuresDocumento5 pagineCyclone Preparedness MeasuresArvind BeheraNessuna valutazione finora

- Yale PE2 Lever Hoist - 40192 ADocumento16 pagineYale PE2 Lever Hoist - 40192 AAthox QhurienNessuna valutazione finora

- CPCCLSF2001 Basic ScaffoldDocumento66 pagineCPCCLSF2001 Basic ScaffoldArdamitNessuna valutazione finora

- Mazzella ShacklesAtAGlance 0919Documento3 pagineMazzella ShacklesAtAGlance 0919rahmat hidayat100% (1)

- How To Manage A Crane Accident: Guest Speaker: Joe Collins, Heavy Lift Manager, Becht EngineeringDocumento45 pagineHow To Manage A Crane Accident: Guest Speaker: Joe Collins, Heavy Lift Manager, Becht EngineeringTrainer 1 TVSNessuna valutazione finora

- Rigging Training Workshop - Lift and TurnDocumento5 pagineRigging Training Workshop - Lift and TurnAlex Sandro Borges PereiraNessuna valutazione finora

- ABC Guidelines V6-1Documento27 pagineABC Guidelines V6-1Ryler VinNessuna valutazione finora

- LEVAC Slings Instruction Manual ENGLISHDocumento20 pagineLEVAC Slings Instruction Manual ENGLISHpeachykristaNessuna valutazione finora

- Grinding SafetyDocumento19 pagineGrinding Safetyjaykotak12345Nessuna valutazione finora

- Crane Rule PresentationDocumento44 pagineCrane Rule PresentationbangladragosNessuna valutazione finora

- 2 - DSM Notes Hoisting MechanismDocumento13 pagine2 - DSM Notes Hoisting MechanismsanketNessuna valutazione finora

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDocumento22 pagineWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979Nessuna valutazione finora

- Banksman Slinging R2Documento31 pagineBanksman Slinging R2Ilyas ZeriNessuna valutazione finora

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Documento6 pagine(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNessuna valutazione finora

- ToolboxTalks D-D Ratio 041315 PDFDocumento1 paginaToolboxTalks D-D Ratio 041315 PDFkaniniuserNessuna valutazione finora

- Work Zone Traffic Control ManualDocumento31 pagineWork Zone Traffic Control ManualTrainer 1 TVSNessuna valutazione finora

- Learner Guide - RBDocumento61 pagineLearner Guide - RBEducation 2.0Nessuna valutazione finora

- Podem - Crane Components - Technical Catalogue (En)Documento32 paginePodem - Crane Components - Technical Catalogue (En)GogyNessuna valutazione finora

- Operator Manual sp4000 Na en PDFDocumento21 pagineOperator Manual sp4000 Na en PDFEmmanuel Chavez VargasNessuna valutazione finora

- Zoomlion RT60ton PDFDocumento47 pagineZoomlion RT60ton PDFYohan Nafisa NetNessuna valutazione finora

- Opito Rigger TrainingDocumento61 pagineOpito Rigger TrainingTasia DiNessuna valutazione finora

- Method Statement For Lifting Operations: 1 - IntroductionDocumento3 pagineMethod Statement For Lifting Operations: 1 - Introductiontravman1Nessuna valutazione finora

- NZ Guarding of Belt ConveyorsDocumento28 pagineNZ Guarding of Belt Conveyors450gasgasNessuna valutazione finora

- Web Slings PDFDocumento26 pagineWeb Slings PDFCesar Fernando Via SaldarriagaNessuna valutazione finora

- Material Handling On Construction Sites: HerniaDocumento4 pagineMaterial Handling On Construction Sites: HerniaCarl Kyu100% (1)

- Cargo Securement: April 2014Documento20 pagineCargo Securement: April 2014Sebastian ZarzyckiNessuna valutazione finora

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Documento6 pagineGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- Các Ví D Tai N N Xe NângDocumento36 pagineCác Ví D Tai N N Xe NânglykhanhhuyNessuna valutazione finora

- SS-22 Forklift Safety Management Training - Materi PDFDocumento54 pagineSS-22 Forklift Safety Management Training - Materi PDFAgung PramonoNessuna valutazione finora

- Sky DeckDocumento44 pagineSky DeckEyob YimerNessuna valutazione finora

- Fall Arrest: Product CatalogueDocumento60 pagineFall Arrest: Product CatalogueBorislav VulićNessuna valutazione finora

- Construction Technology-Static CranesDocumento14 pagineConstruction Technology-Static CranesPrarthana roy RNessuna valutazione finora

- Wind SpeedDocumento2 pagineWind Speeddsn_sarmaNessuna valutazione finora

- Periodic Inspection Sling GBDocumento2 paginePeriodic Inspection Sling GBjeanmichelqNessuna valutazione finora

- SBTET Project Respiratory ProtectionDocumento49 pagineSBTET Project Respiratory ProtectionAnita ChatterjeeNessuna valutazione finora

- Crane Sheave - Early FailuresDocumento14 pagineCrane Sheave - Early FailuresMichael WoodNessuna valutazione finora

- Articulated Boom Lift SafetyDocumento8 pagineArticulated Boom Lift Safetyrandhir1112Nessuna valutazione finora

- L4W - TLILIC2001A - Information Booklet - V4 PDFDocumento54 pagineL4W - TLILIC2001A - Information Booklet - V4 PDFdulshanNessuna valutazione finora

- Guide: A To & Personal FallDocumento12 pagineGuide: A To & Personal FallHaran Prabha100% (1)

- 4478 BS 7121 Part 3 2017Documento76 pagine4478 BS 7121 Part 3 2017Ahmed AliNessuna valutazione finora

- Power AscenderDocumento6 paginePower AscenderApriliando KurniawanNessuna valutazione finora

- Crane Safety ManualDocumento79 pagineCrane Safety ManualselmagisNessuna valutazione finora

- Advanced Rigging PrinciplesDocumento198 pagineAdvanced Rigging PrinciplesAbdel Rahman SalahNessuna valutazione finora

- Eyebolts SI 7.4Documento2 pagineEyebolts SI 7.4reda mesbahNessuna valutazione finora

- Safe Use of Eyeblts Dlhonline PDFDocumento2 pagineSafe Use of Eyeblts Dlhonline PDFMoetaz MohamedNessuna valutazione finora

- Distribution of Fire ExtinguishersDocumento28 pagineDistribution of Fire ExtinguishersEhab SaadNessuna valutazione finora

- HSE-BMS-002 Emergency ResponseDocumento16 pagineHSE-BMS-002 Emergency ResponseUche S OsigweNessuna valutazione finora

- Chemical SpillDocumento28 pagineChemical Spillecoenv100% (1)

- Lockout / Tag Out Program: Presented by DOSHTIDocumento21 pagineLockout / Tag Out Program: Presented by DOSHTIKanupriya100% (1)

- SilicaDocumento13 pagineSilicaWalt FlowersNessuna valutazione finora

- Crane - RiggingWorkbook PDFDocumento45 pagineCrane - RiggingWorkbook PDFNguyen Duc HieuNessuna valutazione finora

- L Dder S Fety: ObjectivesDocumento11 pagineL Dder S Fety: ObjectivesReda MashalNessuna valutazione finora

- Chemical Risk Assessment PDFDocumento8 pagineChemical Risk Assessment PDFS.h. RippendeepNessuna valutazione finora

- Area ClassificationDocumento127 pagineArea ClassificationReda MashalNessuna valutazione finora

- Igc1 Examiners Report Sept19 Final 031219 RewDocumento14 pagineIgc1 Examiners Report Sept19 Final 031219 RewdobomighieNessuna valutazione finora

- Corrosion & Cathodic Protection in Petroleum Industry Part 2Documento137 pagineCorrosion & Cathodic Protection in Petroleum Industry Part 2Reda MashalNessuna valutazione finora

- TASK 1 AnswerDocumento3 pagineTASK 1 AnswerReda Mashal60% (10)

- Corrosion & Cathodic Protection in Petroleum Industry Part 2Documento137 pagineCorrosion & Cathodic Protection in Petroleum Industry Part 2Reda MashalNessuna valutazione finora

- BP Attach B Permit To Work PDFDocumento16 pagineBP Attach B Permit To Work PDFodeinatusNessuna valutazione finora

- Unit 2 IGC Questions and AnswersDocumento95 pagineUnit 2 IGC Questions and AnswersAswin MageshNessuna valutazione finora

- Task6 PDFDocumento3 pagineTask6 PDFReda Mashal100% (1)

- HAZOP-Training PresentationDocumento47 pagineHAZOP-Training PresentationReda MashalNessuna valutazione finora

- Gamaat Al Dowal Aug SchedualDocumento2 pagineGamaat Al Dowal Aug SchedualReda MashalNessuna valutazione finora

- Shree Vijaya Engineering and Construction PVT LTD: Ehs Risk AnalysisDocumento8 pagineShree Vijaya Engineering and Construction PVT LTD: Ehs Risk AnalysisReda MashalNessuna valutazione finora

- Chapter 4 Accident Causation and PreventionDocumento38 pagineChapter 4 Accident Causation and Preventionaripally Nagarjuna100% (1)

- نموذج تحليل وتقيم المخاطر لموقع عملDocumento15 pagineنموذج تحليل وتقيم المخاطر لموقع عملReda MashalNessuna valutazione finora

- 08 PSM Auditing ChecklistDocumento18 pagine08 PSM Auditing Checklistherik100% (1)

- Unit 5 Risk Assessment PDFDocumento24 pagineUnit 5 Risk Assessment PDFReda MashalNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento1 paginaNew Microsoft Office Word DocumentMohamed AbdelghanyNessuna valutazione finora

- 000 HSE - CH 1 - Overview PDFDocumento33 pagine000 HSE - CH 1 - Overview PDFReda MashalNessuna valutazione finora

- 000 HSE - CH 3 - PST PDFDocumento35 pagine000 HSE - CH 3 - PST PDFReda MashalNessuna valutazione finora

- 000 HSE - CH 2 - HSEM PDFDocumento24 pagine000 HSE - CH 2 - HSEM PDFReda MashalNessuna valutazione finora

- Risk Assessment Template: Company Name: Assessment Carried Out By: Date of Next Review: Date Assessment Was Carried OutDocumento1 paginaRisk Assessment Template: Company Name: Assessment Carried Out By: Date of Next Review: Date Assessment Was Carried OutReda MashalNessuna valutazione finora

- 000 HSE - CH 5 - GPE PDFDocumento23 pagine000 HSE - CH 5 - GPE PDFReda MashalNessuna valutazione finora

- 000 HSE - CH 4 - Risk AssDocumento43 pagine000 HSE - CH 4 - Risk AssReda MashalNessuna valutazione finora

- Blepharitis Lid Hygiene Advice For PatientsDocumento3 pagineBlepharitis Lid Hygiene Advice For PatientsTaniaNessuna valutazione finora

- How To Deal With Dilemmas Hard Decisions and Tough Choices - Russ HarrisDocumento10 pagineHow To Deal With Dilemmas Hard Decisions and Tough Choices - Russ HarrisYong ChenNessuna valutazione finora

- Excessive Alcohol UseDocumento1 paginaExcessive Alcohol UseABC10Nessuna valutazione finora

- Đề thi TS NK Anh (chuyên) 18-19Documento10 pagineĐề thi TS NK Anh (chuyên) 18-19Trung KiênNessuna valutazione finora

- Journal On Self ConceptDocumento6 pagineJournal On Self Conceptkspsridharan4899Nessuna valutazione finora

- Round Rock ISD - Opportunity Center DAEP - 2008 Texas School Survey of Drug and Alcohol UseDocumento53 pagineRound Rock ISD - Opportunity Center DAEP - 2008 Texas School Survey of Drug and Alcohol UseTexas School Survey of Drug and Alcohol UseNessuna valutazione finora

- International Journal of Dental Science and Innovative Research (IJDSIR)Documento7 pagineInternational Journal of Dental Science and Innovative Research (IJDSIR)yusfaNessuna valutazione finora

- Legal Medicine Notes 2020Documento8 pagineLegal Medicine Notes 2020Iamharbeyy CastroNessuna valutazione finora

- TFN Notes MidtermsDocumento40 pagineTFN Notes MidtermsAlisa FujibayashiNessuna valutazione finora

- Treamis Residence Hall Rules and RegulationsDocumento5 pagineTreamis Residence Hall Rules and RegulationsHariniNessuna valutazione finora

- From Idea To MarketDocumento6 pagineFrom Idea To MarketvictorccNessuna valutazione finora

- 11th REVISION HEALTH DECLARATION FORM 11 OCT 2020Documento1 pagina11th REVISION HEALTH DECLARATION FORM 11 OCT 2020TIMMY BOYNessuna valutazione finora

- VapeDocumento2 pagineVapeVanessa MendozaNessuna valutazione finora

- NURS FPX 6618 Assessment 3 Disaster Plan With Guidelines For ImplementationDocumento5 pagineNURS FPX 6618 Assessment 3 Disaster Plan With Guidelines For Implementationjoohnsmith070Nessuna valutazione finora

- Yashraj ResultDocumento2 pagineYashraj ResultSom DevNessuna valutazione finora

- Toxic Positivity (An Essay)Documento2 pagineToxic Positivity (An Essay)Colossal HeartNessuna valutazione finora

- Theoretical Foundation of NursingDocumento36 pagineTheoretical Foundation of NursingIsmael JaaniNessuna valutazione finora

- English For Presentation CDocumento11 pagineEnglish For Presentation CeviNessuna valutazione finora

- IARCDocumento868 pagineIARCmarcosiqNessuna valutazione finora

- Physical Therapy AssessmentDocumento38 paginePhysical Therapy Assessmentnikki98% (56)

- RRL2Documento9 pagineRRL2Queen SiLogNessuna valutazione finora

- A Sports-Based Youth Development Program, Teen Mental Health, and Physical Fitness - An RCTDocumento12 pagineA Sports-Based Youth Development Program, Teen Mental Health, and Physical Fitness - An RCTLovely PoppyNessuna valutazione finora

- Dr. Asif Mian Ansari DNB Resident Dept. of General Surgery Max Hospital, MohaliDocumento25 pagineDr. Asif Mian Ansari DNB Resident Dept. of General Surgery Max Hospital, MohaliKarem Maali100% (1)

- Pengaruh Kegel Exercise Terhadap Inkontinensia Urine Pada Ibu Postpartum MultiparaDocumento8 paginePengaruh Kegel Exercise Terhadap Inkontinensia Urine Pada Ibu Postpartum MultiparaYunita RahayuNessuna valutazione finora

- Health Declaration Form A1 Whole PageDocumento1 paginaHealth Declaration Form A1 Whole PageFedelyn SemenianoNessuna valutazione finora

- Reiki Ryoho No Shiori (English Translation)Documento38 pagineReiki Ryoho No Shiori (English Translation)Robert Lip Seng KeeNessuna valutazione finora

- Guarding Belt Conveyors (MSHA)Documento71 pagineGuarding Belt Conveyors (MSHA)AnsarNessuna valutazione finora

- Leopold's ManeuverDocumento3 pagineLeopold's ManeuverPekabuNessuna valutazione finora

- CCCXXDGBN Lab Result 2022 07 22 11 - 41 - 26Documento1 paginaCCCXXDGBN Lab Result 2022 07 22 11 - 41 - 26bkimberlymarNessuna valutazione finora

- Faktor-Faktor Yang Berhubungan Dengan Terjadinya PreeklampsiaDocumento13 pagineFaktor-Faktor Yang Berhubungan Dengan Terjadinya PreeklampsiaSetiaty PandiaNessuna valutazione finora