Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Needle Valves D Series (MS-01-42) Rev 3

Caricato da

herysyam1980Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Needle Valves D Series (MS-01-42) Rev 3

Caricato da

herysyam1980Copyright:

Formati disponibili

www.swagelok.

com

N o n rotating-Stem Needle Valves

D Series

■ Pressures up to 3000 psig (206 bar)

■ Temperatures up to 450°F (232°C) with PEEK stem tip

■ Stainless steel, brass, and alloy 400 materials

2 Nonrotating-Stem Needle Valves

Features Positive stem retraction

promotes consistent flow control

■ Compact, rugged design is available

in straight and angle flow patterns. Safety back

seating seals in Actuation threads

■ Protective handle prevents

fully open position isolated from system

contaminants from entering fluid enhance thread life

functional valve parts. O-ring stem seal needs

Nonrotating

■ Orifice sizes from 0.093 to 0.218 in. stem provides no adjustment

(2.4 to 5.6 mm) are available. repetitive shutoff

■ Flow coefficients (Cv) from 0.12 to Replaceable stem tip

0.53 are available. facilitates maintenance

■ Female NPT, male NPT, Swagelok®

tube fitting, and mixed end

connections are available.

Materials of Construction

Valve Body Materials

316 SS Brass Alloy 400

Component Material Grade/ASTM Specification

1 Handle Anodized aluminum/B221

1 Set screw Nickel cadmium-plated steel

2 Retaining ring Zinc-plated steel

3 Spool Aluminum/B209, B211

Molybdenum Molybdenum Molybdenum

2 4 Packing bolt disulfide-coated disulfide-coated disulfide-coated

316 SS/A276 brass 360/B16 alloy R-405/B164

5 Backup ring PTFE/D1710

3

6 O-ring Fluorocarbon FKM

Fluorocarbon-coated Fluorocarbon-coated

7 Washer Aluminum 5052/B209

316 SS/A167 alloy 400/B127

8 Stem 316 SS/A276 Alloy R-405/B164

4 8

Stem tip PCTFE/D1430

Machine screw 316 SS/A276 Alloy R-405/B164

5 9 Body 316 SS/A182 Brass 377/B283 Alloy 400/B564

Molybdenum disulfide in hydrocarbon carrier; O-ring—silicone-based;

6 Lubricants

machine screw—hydrocarbon thread lock

7 Wetted components listed in italics.

Pressure-Temperature Ratings

9

Ratings are limited to:

■ 250°F (121°C) max with Buna N, silicone, and ethylene propylene O-rings.

■ –65 to 250°F (–53 to 121°C) with Buna C O-rings.

ASME Class 1250 N/A 1500

Material Group 2.2 N/A 3.4

Material Name 316 SS Brass Alloy 400

Stem Tip Material PCTFE PEEK PCTFE PEEK PCTFE PEEK

Temperature, °F (°C) Working Pressure, psig (bar)

–20 (–28) to 100 (37) 3000 (206) 3000 (206) 3000 (206) 3000 (206) 3000 (206) 3000 (206)

150 (65) 2790 (192) 2790 (192) 2675 (184) 2675 (184) 2820 (194) 2820 (194)

200 (93) 2580 (177) 2580 (177) 2350 (161) 2350 (161) 2640 (181) 2640 (181)

250 (121) — 2455 (169) — 2200 (151) — 2555 (176)

300 (148) — 2330 (160) — 2050 (141) — 2470 (170)

350 (176) — 2235 (153) — 1220 (84.0) — 2430 (167)

400 (204) — 2140 (147) — 390 (26.8) — 2390 (164)

450 (232) — 2065 (142) — — — 2380 (163)

For more information about pressure ratings of valves with tube fitting end connections, see Swagelok

Tubing Data, MS-01-107.

Nonrotating-Stem Needle Valves 3

Flow Data at 100°F (37°C) Testing

Flow Coefficient at Turns Open Every Swagelok nonrotating-stem needle valve is factory

tested with nitrogen at 1000 psig (69 bar). Seats have a

maximum allowable leak rate of 0.1 std cm3/min. Shell testing

Orifice is performed to a requirement of no detectable leakage

0.218 in. with a liquid leak detector.

Flow Coefficient (Cv)

(5.6 mm)

Cleaning and Packaging

0.156 in.

(4.0 mm)

Every Swagelok nonrotating-stem needle valve is cleaned

and packaged in accordance with Swagelok standard

0.093 in. cleaning and packaging specification (SC-10), MS-06-62.

(2.4 mm)

Number of Turns Open

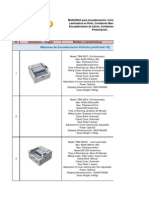

Ordering Information and Dimensions

Straight Pattern Angle Pattern

Stainless Steel Valve H

F B

Select an ordering number. open

Alloy 400 or Brass Valves

B1

Replace SS with M for alloy 400 or B C

H

for brass. open

F

Example: M-ODKS2

E

PEEK Stem Tip

E

Replace K with P. Angle-Pattern Valves

Example: SS-ODPS2 B B1 Select a valve with a C dimension listed

A

and add -A to the ordering number.

Example: SS-ODKS2-A

End Connections Dimensions, in. (mm)

Orifice Ordering

Inlet/Outlet Size Cv in. (mm) Number A B B1 C E F H

1/8 in. 0.12 0.093 (2.4) SS-ODKS2 2.20 (55.9) 1.10 (27.9) 1.41 (35.8) 0.31 (7.9)

1.12 (28.4) 1.86 (47.2)

Swagelok 1/4 in. 0.27 0.156 (4.0) SS-14DKS4 2.27 (57.6) 1.13 (28.7) 1.51 (38.4) 0.38 (9.7)

tube fittings 3/8 in. 0.53 0.218 (5.6) SS-16DKS6 2.58 (65.5) 1.29 (32.8) 1.79 (45.5) 0.50 (12.7) 1.25 (31.8) 2.02 (51.3)

6 mm 0.27 0.156 (4.0) SS-14DKS6MM 2.27 (57.6) 1.13 (28.7) 1.51 (38.4) 0.38 (9.7) 1.12 (28.4) 1.86 (47.2)

Female NPT 1/4 in. 0.53 0.218 (5.6) SS-16DKF4 2.12 (53.8) 1.06 (26.9) — 0.50 (12.7) 1.25 (31.8) 2.02 (51.3)

1/4 in. 0.27 0.156 (4.0) SS-14DKM4 1.97 (50.0) 0.98 (24.9) 1.36 (34.5) 0.38 (9.7) 1.12 (28.4) 1.86 (47.2)

Male NPT 1/4 in. SS-16DKM4 0.50 (12.7)

0.53 0.218 (5.6) 2.25 (57.2) 1.12 (28.4) — 1.25 (31.8) 2.02 (51.3)

3/8 in. SS-16DKM6 0.56 (14.2)

1/8 to

0.12 0.093 (2.4) SS-ODKM2-S4 1.85 (47.0) 0.75 (19.0) 1.10 (27.9) 1.42 (36.1) 0.31 (7.9) 1.12 (28.4) 1.86 (47.2)

1/4 in.

Male NPT/ 1/4 in. 0.27 0.156 (4.0) SS-14DKM4-S4 2.12 (53.8) 0.98 (24.9) 1.13 (28.7) 1.51 (38.4) 0.38 (9.7) 1.12 (28.4) 1.86 (47.2)

Swagelok 1/4 to

tube fitting 0.53 0.218 (5.6) SS-16DKM4-S6 2.09 (53.1) 1.12 (28.4) 1.29 (32.8) 1.79 (45.5) 0.50 (12.7) 1.25 (31.8) 2.02 (51.3)

3/8 in.

1/4 in. to

0.27 0.156 (4.0) SS-14DKM4-S6MM 2.12 (53.8) 0.98 (24.9) 1.13 (28.7) 1.51 (38.4) 0.38 (9.7) 1.12 (28.4) 1.86 (47.2)

6 mm

1/8 in. 0.12 0.093 (2.4) SS-ODKM2-F2 1.69 (42.9) 0.75 (19.0) 0.94 (23.9) 1.25 (31.8) 0.31 (7.9) 1.12 (28.4) 1.86 (47.2)

Male/female 1/4 in. SS-16DKM4-F4 2.19 (55.6) 1.12 (28.4) 1.06 (26.9) 1.56 (39.6) 0.50 (12.7)

NPT 0.53 0.218 (5.6) 1.25 (31.8) 2.02 (51.3)

1/2 to

SS-16DKM8-F4 2.50 (63.5) 1.25 (31.8) 1.81 (46.0) 0.56 (14.2)

1/4 in.

Dimensions are for reference only and are subject to change. Dimensions shown with Swagelok nuts finger-tight.

Options and Accessories

Optional O-ring Materials Handles Handle Color Designator

Fluorocarbon FKM O-rings are standard. For an optional O-ring Black aluminum knob Blue -BL

material, add an O-ring designator to the valve ordering number. handles are standard. For

Green -GR

Example: SS-ODKS2-BC handles of other colors, add

Orange -OG

a handle color designator to

O-ring Kits the valve ordering number. Red -RD

O-ring kits contain O-ring, backup ring, washer, retaining Example: SS-ODKS2-BL Yellow -YW

ring, lubricant, and instructions. To order, add a kit designator

to a kit basic ordering number. Handle Kits

Example: BC70-9K-OD Select a handle kit ordering

Valve Kit Ordering

number. For kits with Series Number

O-ring O-ring Kit Kit Basic handles of colors other than

Material Designator Designator Ordering Number OD, 14D A-5K-14D-BK

black, replace -BK with a

Buna C -BC BC70 handle color designator. 16D A-5K-16D-BK

Buna N -B BN70 -9K-OD Example: A-5K-14D-BL

Ethylene propylene -E EP70 (OD, 14D series)

Fluorocarbon FKM — VA70 -9K-16D Valves with Rupture Discs

(16D series)

Kalrez® -KZ KZ70

Be sure to use the correct pressure relief device for

Silicone -SI SI70 the gas being used.

Stem Tip Kits 16D Series Rupture disc

Kits contain stem tip, machine screw, and instructions. Certain 16D series

To order, select a kit basic ordering number and add SS for valves can be

a 316 SS or brass valve, or M for an alloy 400 valve. configured as

valves with

Examples: SS-3BK-14DK rupture discs. For

M-3BK-14DP more information,

see the Swagelok

Kit Basic Ordering Number

Valve Sample Cylinders,

Series PCTFE Tip PEEK Tip Accessories, and Outage

OD, 14D -3BK-14DK -3BK-14DP Tubes catalog, MS-01-177.

16D -3BK-16DK -3BK-16DP

Outage Tubes

Seal Maintenance Kits 14D and 16D Series

Kits contain stem tip, machine screw, retaining ring, washer, Certain 14D and 16D series

fluorocarbon FKM O-ring, backup ring, lubricants, and valves can be configured as

instructions. valves with outage tubes.

To order, select a kit basic ordering number and add SS for For more information, see the Swagelok Sample Cylinders,

a 316 SS or brass valve, or M for an alloy 400 valve. Accessories, and Outage Tubes catalog, MS-01-177.

Examples: SS-91K-14DK

M-91K-14DP

Kit Basic Ordering Number

Valve

Series PCTFE Tip PEEK Tip

OD, 14D -91K-14DK -91K-14DP

16D -91K-16DK -91K-16DP

Safe Product Selection Warranty Information

When selecting a product, the total system design must Swagelok products are backed by The Swagelok Limited

be considered to ensure safe, trouble-free performance. Lifetime Warranty. For a copy, visit swagelok.com or contact

Function, material compatibility, adequate ratings, your authorized Swagelok representative.

proper installation, operation, and maintenance are the

responsibilities of the system designer and user.

Swagelok—TM Swagelok Company

Kalrez—TM DuPont

© 2001, 2002, 2005 Swagelok Company

Caution: Do not mix or interchange parts with those of Printed in U.S.A., MI

other manufacturers. September 2005, R3

MS-01-42

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Design & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Documento58 pagineDesign & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Vaibhav Soni100% (1)

- Batching Plant Inspection Check ListDocumento2 pagineBatching Plant Inspection Check ListKhadar Basha88% (8)

- Codigos de Componente 2002 PDFDocumento134 pagineCodigos de Componente 2002 PDFJorge Luis Cervantes CarrilloNessuna valutazione finora

- Flexible Coupling For Gas Turbine ApplicationsDocumento10 pagineFlexible Coupling For Gas Turbine Applicationsherysyam1980Nessuna valutazione finora

- Needle Valves GU Series (MS-02-312-E) R1Documento6 pagineNeedle Valves GU Series (MS-02-312-E) R1herysyam1980Nessuna valutazione finora

- Pneumatic SymbolsDocumento4 paginePneumatic SymbolsBharathprabhuNessuna valutazione finora

- Heavy Duty Filtration Products: Filtration Solutions You Can Rely OnDocumento39 pagineHeavy Duty Filtration Products: Filtration Solutions You Can Rely Onherysyam1980Nessuna valutazione finora

- Seminar On Coupling PDFDocumento0 pagineSeminar On Coupling PDFsgupta_615796100% (1)

- Catalogo General 1 PDFDocumento140 pagineCatalogo General 1 PDFZulemaNessuna valutazione finora

- Oxygen System Safety (MS-06-13)Documento4 pagineOxygen System Safety (MS-06-13)herysyam1980Nessuna valutazione finora

- Needle Valves 0,1,18,29&26 Series (ms-01-164) R2Documento8 pagineNeedle Valves 0,1,18,29&26 Series (ms-01-164) R2herysyam1980Nessuna valutazione finora

- Ameriflex High Performance Couplings: Installation InstructionsDocumento37 pagineAmeriflex High Performance Couplings: Installation InstructionsHeryanto Syam100% (1)

- J6 Series, MS-02-214 R1Documento2 pagineJ6 Series, MS-02-214 R1herysyam1980Nessuna valutazione finora

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Documento2 pagineBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980Nessuna valutazione finora

- Flow Valves XS Series (MS-01-110) Rev 6Documento4 pagineFlow Valves XS Series (MS-01-110) Rev 6herysyam1980Nessuna valutazione finora

- High Pressure (MS-02-160) R0Documento6 pagineHigh Pressure (MS-02-160) R0herysyam1980Nessuna valutazione finora

- Valves GaugeDocumento2 pagineValves GaugeAbu Bilal AbdillahNessuna valutazione finora

- Relief Valves R Series (MS-01-141) Rev 7Documento8 pagineRelief Valves R Series (MS-01-141) Rev 7herysyam1980Nessuna valutazione finora

- Meetering Valves S, M, L &31 Series (MS-01-142) R3Documento8 pagineMeetering Valves S, M, L &31 Series (MS-01-142) R3herysyam1980Nessuna valutazione finora

- Remote Mount Manifold (MS 02 330)Documento2 pagineRemote Mount Manifold (MS 02 330)herysyam1980Nessuna valutazione finora

- Relief Maintenance Kits (MS-02-116-SCS) R1Documento1 paginaRelief Maintenance Kits (MS-02-116-SCS) R1herysyam1980Nessuna valutazione finora

- Maintenance Kits Rev3 (MS 02 115 E)Documento2 pagineMaintenance Kits Rev3 (MS 02 115 E)herysyam1980Nessuna valutazione finora

- Check Valves 50 Series (MS-01-98) R4Documento2 pagineCheck Valves 50 Series (MS-01-98) R4herysyam1980Nessuna valutazione finora

- Chek Valves C, CA, CH, CP & Cpa Series (Ms-01-176) r0Documento14 pagineChek Valves C, CA, CH, CP & Cpa Series (Ms-01-176) r0herysyam1980Nessuna valutazione finora

- Chek Valves CW Series (MS-02-89) R3Documento2 pagineChek Valves CW Series (MS-02-89) R3herysyam1980Nessuna valutazione finora

- Afs Ball Valve Release NoteDocumento2 pagineAfs Ball Valve Release Noteherysyam1980Nessuna valutazione finora

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Documento4 pagineBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980Nessuna valutazione finora

- Stainless Steel Tubing: Fractional SizesDocumento2 pagineStainless Steel Tubing: Fractional SizesmasimeriseNessuna valutazione finora

- Afs Ball Valve Product CatalogDocumento8 pagineAfs Ball Valve Product Catalogherysyam1980Nessuna valutazione finora

- Jacketed Tubing (MS-02-188) R1Documento6 pagineJacketed Tubing (MS-02-188) R1herysyam1980Nessuna valutazione finora

- Stainless Steel - Titanium Alloyed TubingDocumento2 pagineStainless Steel - Titanium Alloyed Tubingtoxa0707Nessuna valutazione finora

- Instalasin Jacketed Tubing (MS-CRD-ITUB)Documento7 pagineInstalasin Jacketed Tubing (MS-CRD-ITUB)herysyam1980Nessuna valutazione finora

- Standard Price List: Office of The Provincial EngineerDocumento27 pagineStandard Price List: Office of The Provincial EngineerJohn Harvy JoseNessuna valutazione finora

- Irr PD 1866 PDFDocumento33 pagineIrr PD 1866 PDFLeia VeracruzNessuna valutazione finora

- Drafting Sanitary and Plumbing Layout and DetailsDocumento17 pagineDrafting Sanitary and Plumbing Layout and DetailsStewart MagayanoNessuna valutazione finora

- Chapter 1 Start System: Section 1 SummaryDocumento13 pagineChapter 1 Start System: Section 1 Summaryharold fuenmayorNessuna valutazione finora

- Paper On Curing Methods of GPCDocumento17 paginePaper On Curing Methods of GPCKUMAR RAJUNessuna valutazione finora

- 0618a - Snow RetentionDocumento11 pagine0618a - Snow Retentionnumber_25Nessuna valutazione finora

- Lab 1Documento2 pagineLab 1ayilna_suhaila100% (4)

- Building Composite TubesDocumento3 pagineBuilding Composite TubesArmando Alvarado AraujoNessuna valutazione finora

- Earthing RodDocumento5 pagineEarthing Rodfake fNessuna valutazione finora

- Glass Data - v4 Low ResDocumento15 pagineGlass Data - v4 Low ResPatrick SyNessuna valutazione finora

- Surface Energy TestingDocumento4 pagineSurface Energy TestingvalentinarichitaNessuna valutazione finora

- Transportation Research Part E: Ya-Jun Cai, Tsan-Ming Choi TDocumento21 pagineTransportation Research Part E: Ya-Jun Cai, Tsan-Ming Choi TLucero CastañedaNessuna valutazione finora

- Knan, Knaf, Onan, OnafDocumento2 pagineKnan, Knaf, Onan, Onafponnarasu8250% (2)

- Homework - Equilibrium of ParticlesDocumento15 pagineHomework - Equilibrium of ParticlesSivaprasad DusiNessuna valutazione finora

- Tech Bull 210-1-Liquid ARDocumento2 pagineTech Bull 210-1-Liquid ARMichelle KeatingNessuna valutazione finora

- Field-Wireable Connectors: Your Global Automation PartnerDocumento19 pagineField-Wireable Connectors: Your Global Automation Partners doraiNessuna valutazione finora

- Design of Aluminum Structure 1Documento3 pagineDesign of Aluminum Structure 1Ray Coello100% (2)

- Experiment 1 - Data SheetDocumento4 pagineExperiment 1 - Data SheetApple PinpinNessuna valutazione finora

- Fringe EffectsDocumento3 pagineFringe EffectsVishnu Vardhan ReddyNessuna valutazione finora

- Datasheet Az431Documento20 pagineDatasheet Az43193082Nessuna valutazione finora

- Lista de Precios Maquinaria para Papel Nueva ChileDocumento132 pagineLista de Precios Maquinaria para Papel Nueva ChileGonzalo Ortega Millan100% (1)

- Environmental Laws and RegulationsDocumento50 pagineEnvironmental Laws and RegulationsPaul Santos NonatNessuna valutazione finora

- 카달로그 - Metal Plug ValveDocumento22 pagine카달로그 - Metal Plug Valvetazghat beghdadiNessuna valutazione finora

- Oily Water Separator Safety DevicesDocumento15 pagineOily Water Separator Safety DevicesMohammad Jahid Alam100% (6)

- Transteel Elite GetDocumento20 pagineTransteel Elite GetCharlNessuna valutazione finora

- Textileetp Sira 2016Documento64 pagineTextileetp Sira 2016Andrei PopescuNessuna valutazione finora

- John Deere 7830Documento5 pagineJohn Deere 7830Ramiro GonzálezNessuna valutazione finora