Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flow Valves XS Series (MS-01-110) Rev 6

Caricato da

herysyam1980Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flow Valves XS Series (MS-01-110) Rev 6

Caricato da

herysyam1980Copyright:

Formati disponibili

www.swagelok.

com

I n d u s trial Excess Flow Valves

Stop uncontrolled release of system media

if downstream line ruptures

XS Series

■ Pressures up to 6000 psig (413 bar)

■ Temperatures up to 400°F (204°C)

■ 1/8 to 1/2 in. and 6 to 12 mm end connections

■ Stainless steel construction

2 Industrial Excess Flow Valves

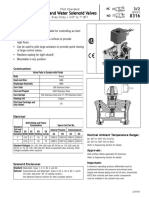

Features Slotted poppet

■ improves performance and reliability

■ provides high-flow capacity

■ eliminates nuisance tripping.

Open Position

Flow

Choice of tube, pipe,

or face seal end connections

■ eases installation

Spring-loaded actuation

■ increases system versatility

■ eases operation

■ lowers overall cost.

■ allows valve to work in any

orientation, enhancing system safety.

Tripped Position

Bleed vent All metal seat

■ eliminates complex ■ improves durability

bypass mechanisms ■ requires no

■ allows spring to reset maintenance.

poppet automatically.

Operation Pressure-Temperature Ratings

The spring-loaded poppet remains in the open position Ratings based on fluorocarbon FKM O-rings. See Optional

during normal system operation. Should an excess flow O-ring Materials, page 4. Ratings limited to:

condition occur downstream, the poppet rapidly moves to ■ 5000 psig (344 bar) for XS series valves with 3/8 in. female

the tripped position, stopping uncontrolled release of system NPT end connections.

media. When the system pressure equalizes through the

■ 4600 psig (316 bar) for XS series valves with 1/2 in. female

bleed vent, the spring automatically resets the poppet to the

NPT end connections.

open position. The flow through the bleed vent is less than

1 % of the flow rate in the trip range.

ASME Class 2500

Material Group 2.2

Material Name 316 SS

Temperature, °F (°C) Working Pressure, psig (bar)

–10 (–23) to 100 (37) 6000 (413)

200 (93) 5160 (355)

250 (121) 4910 (338)

300 (148) 4660 (321)

400 (204) 4280 (294)

For more information about valves with tube fitting end connections, see

Swagelok® Tubing Data, MS-01-107. Pressure ratings of valves with VCR ® or

VCO ® fitting end connections are based on the ratings of the mating fitting;

see the Swagelok VCR Metal Gasket Face Seal Fittings catalog, MS-01-24, or

the Swagelok VCO O-ring Face Seal Fittings catalog, MS-01-28.

Industrial Excess Flow Valves 3

Materials of Construction

1 2 6 7

5

3 4

Material Grade/ Testing

Component ASTM Specification Every XS series valve is factory tested for proper operation.

1 Inlet body 316 SS/A479

2 Identification ring Polyetherimide Cleaning and Packaging

3 Poppet 316 SS/A479 Swagelok XS series valves with VCR or VCO end connections

4 Spring 302 SS/A313 are processed in accordance with Swagelok Special Cleaning

5 O-ring Fluorocarbon FKM and Packaging (SC-11), MS-06-63, to ensure compliance with

6 Backup ring PTFE➀/D1710 product cleanliness requirements stated in ASTM G93 Level C.

7 Outlet body 316 SS/A479 Swagelok XS series valves with other end connections are

Lubricant Silicone-based

processed in accordance with Swagelok standard cleaning and

packaging specification (SC-10), MS-06-62; special cleaning

Wetted components listed in italics.

and packaging are available as an option.

➀ PEEK also available; see Ordering Information, page 4.

Flow Data at 70°F (20°C)

Springs with lower trip ranges are available. See the Swagelok XS Series Excess Flow Valve technical report, MS-06-11.

XS4 Series Air XS6 Series Air

Air Flow, std L/min Air Flow, std L/min

Open

Inlet Pressure, psig

Inlet Pressure, psig

Inlet Pressure, bar

Inlet Pressure, bar

Open

Trip

Range

Trip

Range

Tripped

Tripped

Air Flow, std ft3/min Air Flow, std ft3/min

XS8 Series Air XS4, XS6, XS8 Series Water

Air Flow, std L/min

Trip Range

Series Cv U.S. gal/min (L/min)

XS4 0.5 3.9 to 5.8 (14.7 to 21.9)

Open XS6 8.2 to 10.0 (31.0 to 37.8)

1.1

Inlet Pressure, psig

XS8 11.2 to 14.9 (42.3 to 56.3)

Inlet Pressure, bar

Trip

Range

Tripped

Air Flow, std ft3/min

Ordering Information and Dimensions

Dimensions are for reference only and

End Connections Ordering Dimensions, in. (mm)

are subject to change.

Inlet/Outlet Size Series Number A B1 B2

Select an ordering number.

Fractional 1/4 in. XS4 SS-XSS4 2.43 (61.7) 11/16

B1 B2

hex flat hex flat Swagelok 3/8 in. XS6 SS-XSS6 2.75 (69.9)

tube fitting 1

1/2 in. XS8 SS-XSS8 2.97 (75.4)

6 mm XS4 SS-XSS6MM 2.43 (61.7) 11/16

Metric 8 mm XS6 SS-XSS8MM 2.70 (68.6)

Swagelok

tube fitting 10 mm XS6 SS-XSS10MM 2.80 (71.1) 1

12 mm XS8 SS-XSS12MM 2.96 (75.2)

1/8 in. XS4 SS-XSF2 1.87 (47.5)

11/16

1/4 in. XS4 SS-XSF4 2.12 (53.8)

A Female NPT

3/8 in. XS6 SS-XSF6 2.55 (64.8) 1

1/2 in. XS8 SS-XSF8 3.03 (77.0) 1 1/16

Optional O-ring Materials 1/8 in. XS4 SS-XSM2 1.79 (45.5)

Fluorocarbon FKM O-rings are standard. 11/16

1/4 in. XS4 SS-XSM4 2.17 (55.1)

For an optional O-ring material, add a Male NPT

3/8 in. XS6 SS-XSM6 2.36 (59.9)

designator to the ordering number. 1

1/2 in. XS8 SS-XSM8 2.73 (69.3)

Male NPT/ 1/4 in. XS4 SS-XSM4S4 2.30 (58.4) 11/16

Temperature

O-ring Rating Swagelok tube 3/8 in. XS6 SS-XSM6S6 2.56 (65.0)

Material Designator °F (°C) fitting 1

1/2 in. XS8 SS-XSM8S8 2.85 (72.4)

–40 to 250 1/4 in. XS4 SS-XSM4F4 2.13 (54.1) 11/16

Buna N -BU

(–40 to 121)

Male/female NPT 3/8 in. XS6 SS-XSM6F6 2.46 (62.5) 1

Ethylene –50 to 300

-EP 1/2 in. XS8 SS-XSM8F8 2.89 (73.4) 1 1 1/16

propylene (–45 to 148)

–10 to 400 1/4 in. XS4 SS-XSM4RT 2.17 (55.1) 11/16

Kalrez® -KZ Male ISO➀

(–23 to 204) 1/2 in. XS8 SS-XSM8RT 2.74 (69.6) 1

–40 to 250 Female ISO➀ 1/2 in. XS8 SS-XSF8RT 3.29 (83.6) 1 1/16

Neoprene -NE

(–40 to 121)

Male SAE/MS 1/2 in. XS8 SS-XSM8ST 2.48 (63.0)

1

Example: SS-XSS4-BU Female SAE/MS 1/2 in. XS8 SS-XSF8ST 2.74 (69.6)

1/4 in. XS4 SS-XSVCR4 2.28 (57.9) 11/16

Male VCR fitting

PEEK Backup Ring 1/2 in. XS8 SS-XSVCR8 2.73 (69.3) 1

For a PEEK backup ring, add -PK to 1/4 in. XS4 SS-XSVCO4 1.98 (50.3) 11/16

Male VCO fitting

the ordering number. 1/2 in. XS8 SS-XSVCO8 2.36 (59.9) 1

Example: SS-XSS4-PK Dimensions shown with Swagelok nuts finger-tight.

➀ See specifications: ISO 7/1, BS EN 10226-1, DIN-2999, JIS B0203.

Special Cleaning and Packaging Oxygen Service Hazards

Swagelok XS series valves with VCR or VCO end connections For more information about hazards and risks of oxygen-

are processed in accordance with Swagelok Special Cleaning enriched systems, see the Swagelok Oxygen System Safety

and Packaging (SC-11), MS-06-63, to ensure compliance with technical report, MS-06-13.

product cleanliness requirements stated in ASTM G93 Level C.

To order special cleaning and packaging for XS series valves

with other end connections, add -SC11 to the valve ordering

number.

Example: SS-XSS4-SC11

Safe Product Selection Warranty Information

When selecting a product, the total system design must Swagelok products are backed by The Swagelok Limited

be considered to ensure safe, trouble-free performance. Lifetime Warranty. For a copy, visit swagelok.com or contact

Function, material compatibility, adequate ratings, your authorized Swagelok representative.

proper installation, operation, and maintenance are the

responsibilities of the system designer and user.

Swagelok, VCR, VCO—TM Swagelok Company

Kalrez—TM DuPont

© 2002, 2003, 2005 Swagelok Company

Caution: Do not mix or interchange parts with those of Printed in U.S.A., MI

other manufacturers. July 2005, R6

MS-01-110

Potrebbero piacerti anche

- Valvulas de RegulacionDocumento71 pagineValvulas de RegulaciondanielNessuna valutazione finora

- 3L Butterfly Valves-Technical Brochure 3 WayDocumento24 pagine3L Butterfly Valves-Technical Brochure 3 WayISHAN VERMANessuna valutazione finora

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationDa EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationValutazione: 4.5 su 5 stelle4.5/5 (21)

- Needle Valves Series Bs03Documento6 pagineNeedle Valves Series Bs03Uzair AnsariNessuna valutazione finora

- Gauge Root Valves Series Grv11Documento6 pagineGauge Root Valves Series Grv11Uzair AnsariNessuna valutazione finora

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocumento12 pagineBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNessuna valutazione finora

- Instrument ManifoldsDocumento16 pagineInstrument ManifoldsAmet koko TaroNessuna valutazione finora

- Ms-02-303 (1) Ball Valve General PurposeDocumento8 pagineMs-02-303 (1) Ball Valve General PurposeYong Lin Albon TiongNessuna valutazione finora

- Two Three Way Ball ValvesDocumento6 pagineTwo Three Way Ball ValvesUzair AnsariNessuna valutazione finora

- Dossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Documento212 pagineDossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Bureau VeritasNessuna valutazione finora

- 05.2. - Valvula de Bola Montada Sobre Muñon PDFDocumento24 pagine05.2. - Valvula de Bola Montada Sobre Muñon PDFalquimista203Nessuna valutazione finora

- QSSDocumento48 pagineQSSArvind KhapleNessuna valutazione finora

- Asco Series 316 Air Water CatalogDocumento4 pagineAsco Series 316 Air Water CatalogekoNessuna valutazione finora

- Chemical Injection Quills Nozzle: FeaturesDocumento1 paginaChemical Injection Quills Nozzle: FeaturesAmjad HaniNessuna valutazione finora

- Mooney Flexflo 887 Surge RelieversDocumento6 pagineMooney Flexflo 887 Surge RelieversSajjad MehdiNessuna valutazione finora

- Air and Water Solenoid Valves: FeaturesDocumento4 pagineAir and Water Solenoid Valves: FeaturesZuñiga AntonioNessuna valutazione finora

- Explosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetDocumento4 pagineExplosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetachmadinNessuna valutazione finora

- Vickers DCV With Manual LatchDocumento12 pagineVickers DCV With Manual LatchIon Logofătu AlbertNessuna valutazione finora

- Gas Filters: FC SeriesDocumento4 pagineGas Filters: FC SeriesHeryanto SyamNessuna valutazione finora

- Valv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsDocumento10 pagineValv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsibharNessuna valutazione finora

- Sa Series: Submersible Stainless Steel PumpsDocumento36 pagineSa Series: Submersible Stainless Steel PumpsĐình Sơn HoàngNessuna valutazione finora

- ABB Instrumentation: From The Leader in Remote Seal TransmittersDocumento26 pagineABB Instrumentation: From The Leader in Remote Seal TransmittersMorteza alizadehNessuna valutazione finora

- Switch Flujo DHDDocumento6 pagineSwitch Flujo DHDAF VMNessuna valutazione finora

- MS 01 84 Screwed Bonnet Neddle ValvesDocumento2 pagineMS 01 84 Screwed Bonnet Neddle ValvesJacques StrappeNessuna valutazione finora

- SCV-Series Excessive Flow Sensor/Check ValveDocumento1 paginaSCV-Series Excessive Flow Sensor/Check Valvemarran almarranyNessuna valutazione finora

- Meetering Valves S, M, L &31 Series (MS-01-142) R3Documento8 pagineMeetering Valves S, M, L &31 Series (MS-01-142) R3herysyam1980Nessuna valutazione finora

- Leakage Detection Butterfly Valves L Line Sudmo LeafletDocumento2 pagineLeakage Detection Butterfly Valves L Line Sudmo LeafletChemicalProgrammerNessuna valutazione finora

- Industrial Excess Flow Valves: SEFV SeriesDocumento4 pagineIndustrial Excess Flow Valves: SEFV SeriesToty DzNessuna valutazione finora

- Series Eccentric Rotary Control Valves: With PFA LinerDocumento8 pagineSeries Eccentric Rotary Control Valves: With PFA LinermarcosNessuna valutazione finora

- KUKMC 0328 US - tcm106 37618Documento15 pagineKUKMC 0328 US - tcm106 37618tuanhiena10Nessuna valutazione finora

- Control Valves Two PortDocumento16 pagineControl Valves Two Portwendelreis19746883100% (1)

- Valvula Bola 3 Pzas INLINEDocumento4 pagineValvula Bola 3 Pzas INLINERicNessuna valutazione finora

- MS-02-445 Instrument Manifold SystemsDocumento32 pagineMS-02-445 Instrument Manifold SystemsmkrzoNessuna valutazione finora

- Web ProductSheet DiamondWrap 2018 PDFDocumento2 pagineWeb ProductSheet DiamondWrap 2018 PDFRiankwnNessuna valutazione finora

- Clock Spring Diamond Wrap BrochureDocumento2 pagineClock Spring Diamond Wrap BrochuremuhammadxpNessuna valutazione finora

- 3 Valve ManifoldDocumento16 pagine3 Valve Manifoldwengjf83Nessuna valutazione finora

- WKM 370d4 Trunnion Mounted Ball Valves Brochure PDFDocumento40 pagineWKM 370d4 Trunnion Mounted Ball Valves Brochure PDFAdhie WaelacxhNessuna valutazione finora

- TRDP - SSSVDocumento23 pagineTRDP - SSSVsambhajiNessuna valutazione finora

- Asco Series 290 Angle Body CatalogDocumento10 pagineAsco Series 290 Angle Body CatalogcillongNessuna valutazione finora

- High Flow Direct Acting Valves: FeaturesDocumento2 pagineHigh Flow Direct Acting Valves: FeaturesBurhan AyubNessuna valutazione finora

- Air and Water Solenoid Valves: NC NODocumento4 pagineAir and Water Solenoid Valves: NC NODevinNessuna valutazione finora

- sv2 sv3 Series CPC Cryolab Seal Off Valve v03 OperatorDocumento2 paginesv2 sv3 Series CPC Cryolab Seal Off Valve v03 Operatoroscar garciaNessuna valutazione finora

- Purge Bleed Valves Series PFV BLVDocumento6 paginePurge Bleed Valves Series PFV BLVUzair AnsariNessuna valutazione finora

- Asco8210 PDFDocumento6 pagineAsco8210 PDFoscar_rent_torresNessuna valutazione finora

- FT - 8210 - V. SolenoideDocumento6 pagineFT - 8210 - V. SolenoideClaudia Patricia Carazas SarmientoNessuna valutazione finora

- PASCAL Check Valves CatalogueDocumento19 paginePASCAL Check Valves Cataloguecrys100% (1)

- VIM20 Flowmeters SPB1080 USDocumento6 pagineVIM20 Flowmeters SPB1080 USJoshua Balaram RaoNessuna valutazione finora

- en 3706Documento22 pagineen 3706Thanh XuanNessuna valutazione finora

- en 3706 PDFDocumento22 pagineen 3706 PDFThanh Xuan NguyenNessuna valutazione finora

- Manifold Swagelok Ms 01 178Documento16 pagineManifold Swagelok Ms 01 178papashoNessuna valutazione finora

- Industrial Valve CatalogDocumento126 pagineIndustrial Valve CatalogHung Nguyen VietNessuna valutazione finora

- Butterfly Valves - CatalogDocumento30 pagineButterfly Valves - CatalogRamzi BEN AHMEDNessuna valutazione finora

- Check Valves: SPCV SeriesDocumento2 pagineCheck Valves: SPCV SeriesToty DzNessuna valutazione finora

- Bleed & Purge Valves (MS-01-62) R4Documento4 pagineBleed & Purge Valves (MS-01-62) R4herysyam1980Nessuna valutazione finora

- KREBS Technequip Knife Gate Valves BrochureDocumento16 pagineKREBS Technequip Knife Gate Valves Brochuresf wNessuna valutazione finora

- MK 608 BPMDocumento9 pagineMK 608 BPMrogelgerardo643Nessuna valutazione finora

- Safety Valves overview-SB-S13-60-ENDocumento12 pagineSafety Valves overview-SB-S13-60-ENt0r1t0 br4v0Nessuna valutazione finora

- Heavy Duty Filtration Products: Filtration Solutions You Can Rely OnDocumento39 pagineHeavy Duty Filtration Products: Filtration Solutions You Can Rely Onherysyam1980Nessuna valutazione finora

- Oxygen System Safety (MS-06-13)Documento4 pagineOxygen System Safety (MS-06-13)herysyam1980Nessuna valutazione finora

- Pneumatic SymbolsDocumento4 paginePneumatic SymbolsBharathprabhuNessuna valutazione finora

- Catalogo General 1 PDFDocumento140 pagineCatalogo General 1 PDFZulemaNessuna valutazione finora

- Ameriflex High Performance Couplings: Installation InstructionsDocumento37 pagineAmeriflex High Performance Couplings: Installation InstructionsHeryanto Syam100% (1)

- Seminar On Coupling PDFDocumento0 pagineSeminar On Coupling PDFsgupta_615796100% (1)

- Flexible Coupling For Gas Turbine ApplicationsDocumento10 pagineFlexible Coupling For Gas Turbine Applicationsherysyam1980Nessuna valutazione finora

- Needle Valves GU Series (MS-02-312-E) R1Documento6 pagineNeedle Valves GU Series (MS-02-312-E) R1herysyam1980Nessuna valutazione finora

- J6 Series, MS-02-214 R1Documento2 pagineJ6 Series, MS-02-214 R1herysyam1980Nessuna valutazione finora

- Meetering Valves S, M, L &31 Series (MS-01-142) R3Documento8 pagineMeetering Valves S, M, L &31 Series (MS-01-142) R3herysyam1980Nessuna valutazione finora

- Needle Valves 0,1,18,29&26 Series (ms-01-164) R2Documento8 pagineNeedle Valves 0,1,18,29&26 Series (ms-01-164) R2herysyam1980Nessuna valutazione finora

- Needle Valves D Series (MS-01-42) Rev 3Documento4 pagineNeedle Valves D Series (MS-01-42) Rev 3herysyam1980Nessuna valutazione finora

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Documento2 pagineBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980Nessuna valutazione finora

- High Pressure (MS-02-160) R0Documento6 pagineHigh Pressure (MS-02-160) R0herysyam1980Nessuna valutazione finora

- Maintenance Kits Rev3 (MS 02 115 E)Documento2 pagineMaintenance Kits Rev3 (MS 02 115 E)herysyam1980Nessuna valutazione finora

- Chek Valves CW Series (MS-02-89) R3Documento2 pagineChek Valves CW Series (MS-02-89) R3herysyam1980Nessuna valutazione finora

- Relief Valves R Series (MS-01-141) Rev 7Documento8 pagineRelief Valves R Series (MS-01-141) Rev 7herysyam1980Nessuna valutazione finora

- Remote Mount Manifold (MS 02 330)Documento2 pagineRemote Mount Manifold (MS 02 330)herysyam1980Nessuna valutazione finora

- Valves GaugeDocumento2 pagineValves GaugeAbu Bilal AbdillahNessuna valutazione finora

- Relief Maintenance Kits (MS-02-116-SCS) R1Documento1 paginaRelief Maintenance Kits (MS-02-116-SCS) R1herysyam1980Nessuna valutazione finora

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Documento4 pagineBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980Nessuna valutazione finora

- Chek Valves C, CA, CH, CP & Cpa Series (Ms-01-176) r0Documento14 pagineChek Valves C, CA, CH, CP & Cpa Series (Ms-01-176) r0herysyam1980Nessuna valutazione finora

- Check Valves 50 Series (MS-01-98) R4Documento2 pagineCheck Valves 50 Series (MS-01-98) R4herysyam1980Nessuna valutazione finora

- Afs Ball Valve Product CatalogDocumento8 pagineAfs Ball Valve Product Catalogherysyam1980Nessuna valutazione finora

- Stainless Steel - Titanium Alloyed TubingDocumento2 pagineStainless Steel - Titanium Alloyed Tubingtoxa0707Nessuna valutazione finora

- Afs Ball Valve Release NoteDocumento2 pagineAfs Ball Valve Release Noteherysyam1980Nessuna valutazione finora

- Stainless Steel Tubing: Fractional SizesDocumento2 pagineStainless Steel Tubing: Fractional SizesmasimeriseNessuna valutazione finora

- Instalasin Jacketed Tubing (MS-CRD-ITUB)Documento7 pagineInstalasin Jacketed Tubing (MS-CRD-ITUB)herysyam1980Nessuna valutazione finora

- Jacketed Tubing (MS-02-188) R1Documento6 pagineJacketed Tubing (MS-02-188) R1herysyam1980Nessuna valutazione finora

- CATALOG. Baotou Steel Seamless ProductsDocumento8 pagineCATALOG. Baotou Steel Seamless ProductsEdward R KaolinNessuna valutazione finora

- Updating Bank Details For Shared Vendors in SAPDocumento5 pagineUpdating Bank Details For Shared Vendors in SAPnasuuNessuna valutazione finora

- Miniature Sensors: Advanced Global Style Miniature Photoelectic SensorDocumento6 pagineMiniature Sensors: Advanced Global Style Miniature Photoelectic SensorFrancisco RamosNessuna valutazione finora

- Flare's Pilot Flame Out - Technical AnalysisDocumento3 pagineFlare's Pilot Flame Out - Technical AnalysisWhite FlameNessuna valutazione finora

- TD190164 Ball Valves SEDDocumento12 pagineTD190164 Ball Valves SEDPablo Andres CartesNessuna valutazione finora

- 8kg 11kg 14kg: High Spin Industrial Washer ExtractorsDocumento41 pagine8kg 11kg 14kg: High Spin Industrial Washer ExtractorsAgustin FernandezNessuna valutazione finora

- Project - Charter1 Template-1Documento5 pagineProject - Charter1 Template-1Jwaone KosiNessuna valutazione finora

- Fresher ECE Resume Model 213Documento3 pagineFresher ECE Resume Model 213shanky_cs82% (17)

- Hirarc Form: Chemsain Chemsain Basement Car ParkDocumento6 pagineHirarc Form: Chemsain Chemsain Basement Car Parkpro fps116Nessuna valutazione finora

- Swivel Joint Layout - Achieving Maximum Flexibility in High Pressure Pumping SystemsDocumento15 pagineSwivel Joint Layout - Achieving Maximum Flexibility in High Pressure Pumping SystemsAquiles CNessuna valutazione finora

- Dezeen X Samsung Out of The Box Competition - Brief and Rules - Dezeen PDFDocumento5 pagineDezeen X Samsung Out of The Box Competition - Brief and Rules - Dezeen PDFVivek EadaraNessuna valutazione finora

- Chemray 240 User's Manual V1.1eDocumento67 pagineChemray 240 User's Manual V1.1eJose PersiaNessuna valutazione finora

- Mark Vies Control: Functional Safety ManualDocumento242 pagineMark Vies Control: Functional Safety ManualkirjessNessuna valutazione finora

- ZG3/ZGM/K-GPM20T Series Integrated PLC&HMI ManualDocumento56 pagineZG3/ZGM/K-GPM20T Series Integrated PLC&HMI ManualMarcosNessuna valutazione finora

- PanouDocumento2 paginePanouMihaiNeacsuNessuna valutazione finora

- Lab - 03 Task On 2D ArrayDocumento3 pagineLab - 03 Task On 2D ArrayShantoNessuna valutazione finora

- Tearsheet SavoyDocumento7 pagineTearsheet SavoyMaurie LirazanNessuna valutazione finora

- OWASP DashboardDocumento15 pagineOWASP DashboardHector VillagomezNessuna valutazione finora

- QR Code Attendance SystemDocumento6 pagineQR Code Attendance Systemjenny adlaoNessuna valutazione finora

- Instruction Manual: Fusion SplicerDocumento89 pagineInstruction Manual: Fusion SplicerIgor SetasNessuna valutazione finora

- Machine Safety: PreventaDocumento30 pagineMachine Safety: PreventaDouglasNessuna valutazione finora

- What Is Linear Text and Non Linear Text - Brainly - PHDocumento4 pagineWhat Is Linear Text and Non Linear Text - Brainly - PHElmer Villegas67% (3)

- Audit UniverseDocumento17 pagineAudit UniverseArny Maynigo0% (1)

- Literature Review On GSM NetworkDocumento6 pagineLiterature Review On GSM Networkxfeivdsif100% (1)

- Project Proposal 1Documento12 pagineProject Proposal 1GusionNessuna valutazione finora

- Gesm FDocumento2 pagineGesm Fmic.senadNessuna valutazione finora

- Rule CheckDocumento2 pagineRule CheckdanNessuna valutazione finora

- Self InspectionDocumento20 pagineSelf InspectionGanesh V GaonkarNessuna valutazione finora

- Welded Wire Reinforcement WWM WWR Common SizesDocumento2 pagineWelded Wire Reinforcement WWM WWR Common Sizesgullipalli100% (1)

- MDCG 2018-4: Medical DevicesDocumento3 pagineMDCG 2018-4: Medical Devicesjeeves_31Nessuna valutazione finora

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationDa EverandPractical Reservoir Engineering and CharacterizationValutazione: 4.5 su 5 stelle4.5/5 (3)

- Abrasive Water Jet Perforation and Multi-Stage FracturingDa EverandAbrasive Water Jet Perforation and Multi-Stage FracturingNessuna valutazione finora

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsDa EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsValutazione: 4 su 5 stelle4/5 (4)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDa EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesValutazione: 4 su 5 stelle4/5 (2)

- Casing and Liners for Drilling and Completion: Design and ApplicationDa EverandCasing and Liners for Drilling and Completion: Design and ApplicationValutazione: 5 su 5 stelle5/5 (3)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesDa EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNessuna valutazione finora

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityDa EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityValutazione: 3 su 5 stelle3/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsDa EverandWell Testing Project Management: Onshore and Offshore OperationsNessuna valutazione finora

- Fundamentals and Applications of Bionic Drilling FluidsDa EverandFundamentals and Applications of Bionic Drilling FluidsNessuna valutazione finora

- Guide to the Practical Use of Chemicals in Refineries and PipelinesDa EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesValutazione: 5 su 5 stelle5/5 (1)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsDa EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsValutazione: 3.5 su 5 stelle3.5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDa EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsValutazione: 4 su 5 stelle4/5 (6)

- Advanced Production Decline Analysis and ApplicationDa EverandAdvanced Production Decline Analysis and ApplicationValutazione: 3.5 su 5 stelle3.5/5 (4)

- Heavy and Extra-heavy Oil Upgrading TechnologiesDa EverandHeavy and Extra-heavy Oil Upgrading TechnologiesValutazione: 4 su 5 stelle4/5 (2)

- Gas-Liquid And Liquid-Liquid SeparatorsDa EverandGas-Liquid And Liquid-Liquid SeparatorsValutazione: 3.5 su 5 stelle3.5/5 (3)