Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ASTM C 217 Standard Test Method For Weather Resistance of Slate

Caricato da

Ryan LasacaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASTM C 217 Standard Test Method For Weather Resistance of Slate

Caricato da

Ryan LasacaCopyright:

Formati disponibili

Designation: C 217 – 94 (Reapproved 1999)

Standard Test Method for

Weather Resistance of Slate1

This standard is issued under the fixed designation C 217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope blade shall be ground to a plane surface perpendicular to the

1.1 This test method covers two procedures for weather length of the tool to form a sharp edge with either side of the

--`-`-`,,`,,`,`,,`---

resistance of slate in all outdoor installations by determining blade. These sharp edges will be referred to as the “cutting

the depth of softening by an abraser or by hand scraping. edges.”

NOTE 1—The test is based on the fact that slates containing pyrite, 6. Sampling

calcite, and carbon undergo a chemical weathering which results in the

6.1 The samples shall be selected by the purchaser or his

conversion of the calcite particles to gypsum. The swelling action that

results causes disintegration of the slate. The extent of this action on authorized representative so as to be truly representative of the

various slates in the test has been found to correlate with the durability of consignment under consideration. Six shingles of roofing from

the materials in actual weathering. each carload or fraction thereof or similar quantities from other

1.2 This standard does not purport to address all of the kinds of slate shall constitute a sample.

safety concerns, if any, associated with its use. It is the NOTE 2—Six shingles 10 in. (254 mm) or more in length and of any

responsibility of the user of this standard to establish appro- standard width are sufficient for this test and also for modulus of rupture

priate safety and health practices and determine the applica- and absorption tests.

bility of regulatory limitations prior to use. 7. Test Specimens

2. Referenced Documents 7.1 Prepare at least three specimens, each 2 by 4 in. (50.8 by

2.1 ASTM Standards: 101.6 mm) measured along the cleavage faces, for determining

C 119 Terminology Relating to Dimension Stone2 the depth of softening in a 1 % solution of sulfuric acid. The 2

by 4-in. faces shall be ground smooth and finished with No. 80

3. Terminology abrasive. Specimens cut from sheared or punched slate shall

3.1 Definitions—All definitions are in accordance with Ter- have no saw cut nearer than 1 in. (25.4 mm) from the edges or

minology C 119. nail holes.

4. Significance and Use 8. Procedure with Shear/Scratch Tester

4.1 This test method is useful in indicating the differences in 8.1 In this procedure determine the depth of softening in

weather resistance between various slates. This test method acid with the shear/scratch tester (described in 5.1.1). The test

also provides one element in the comparison of slates. involves measuring the depth of a groove made by the shearing

tool in fresh specimens and also in the same specimens after

5. Apparatus soaking 7 days in 1 % sulfuric acid.

5.1 Either one of the following shall be used: 8.2 Draw with a pencil compass, on at least three of the 2 by

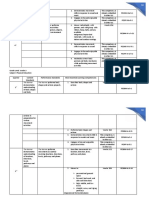

5.1.1 Shear/Scratch Tester, Taber Model 203 or 502,3 with 4-in. (50.8 by 101.6-mm) specimens, an arc of a circle of the

the shear hardness tool, Model S-20, or its equivalent. same radius as that made by the shearing tool. Mark each arc

5.1.2 Hand Scraping Tool—The scraping tool shall be made at four points for thickness measurements, as indicated in Fig.

by grinding down the blade of a putty knife to a length of 3 in. 1. Measure the thickness at each point to the nearest 0.0001 in.

(76.2 mm) and a width of 3⁄4in. (19.05 mm). The end of the (0.0025 mm). With a 2.2-lbf (9.8-N) load on the shearing tool,

groove each specimen along the penciled arc by rotating the

1

turntable slowly and steadily by hand in a counter clockwise

This test method is under the jurisdiction of ASTM Committee C-18 on

Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test

direction. Then repeat the thickness measurements at the same

Methods. four points to determine the depth of groove made by the

Current edition approved Dec. 15, 1994. Published February 1995. Originally shearing tool in fresh specimens.

published as C 217 – 48 T. Last previous edition C 217 – 85 (1990). 8.3 Then put the specimens in a glass vessel and completely

2

Annual Book of ASTM Standards, Vol 04.07.

3

Described in the 1962 Bulletin 62203–502 of the Taber Instrument Co., North cover with 1 % sulfuric acid solution. Space the specimens in

Tonawanda, NY. the container so that the acid has free access to the 2 by 4-in.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 217

FIG. 1 Diagram of Slate Specimen Prepared for Test with Taber Shear/Scratch Tester

(50.8 by 101.6-mm) faces. Pour off the acid solution each day test. This seemingly crude test gives reasonably concordant results for the

and replace with fresh solution. At the end of 7 days remove reason that the softened layer of slate is easily scraped off but the sound

the specimens from the acid, thoroughly wash with water, and slate underneath is removed very slowly. Since the specified number of

strokes is considerably more than necessary to remove the softened layer,

dry for 24 h at 105 6 2°C.

--`-`-`,,`,,`,`,,`---

it is more important to apply a constant pressure than one of a definite

NOTE 3— Example—A convenient means of determining the amount of amount.

H2SO4 required for the test is as follows: Suppose one has 96 % H2SO4 9.3 Scrape three or more specimens of each sample (as

(sp gr 1.84) and the volume of diluted acid necessary for the test is 2000

described in Section 6) in the original condition at the center of

mL. Let X equal the weight of 96 % H2SO4 required. Then:

one 2 by 4-in. (50.8 by 101.6-mm) face. Locate the center by

0.96X/~X 1 2000! 5 0.01 (1) drawing the diagonals of the rectangle, and do the thickness

measurements before and after scraping to the nearest 0.0001

From this equation, X is determined as 21.05 g. The volume of this weight

of 96 % H2SO4 is 21.05/1.84 = 11.4 mL. (The error due to assuming the in. (0.0025 mm). After soaking the specimens for 7 days in acid

weight of 1 mL of water as 1 g is not appreciable.) (as described in 8.3), measure the thickness before scraping,

then scrape the other faces of the specimens to determine the

8.4 When the specimens have cooled, repeat the same

depth of softening. Reduce the second depth of scraping by the

procedure as outlined in 8.2 on the faces opposite to those

depth scraped off before the acid treatment. Record the average

scored before the treatment.

of all specimens of each sample as the depth of softening of the

8.5 Record the depth of softening for the specimen as the

sample.

average depth of groove for each specimen after the acid

9.4 The depth of softening is the depth of scraping after the

treatment minus that for the specimen before the treatment.

acid treatment minus the depth of scraping before the acid

9. Procedure by Hand Scraping treatment. Record the average of all specimens of each sample

as the depth of softening of the sample.

9.1 In this procedure the depth of softening in acid is

determined by hand scraping. The scraping shall be done with NOTE 5—Thickness measurements are required before scraping in the

the “cutting edges” of the tool. acid soak condition because in some cases, there is swelling of the

9.2 Apply approximately a 3-lbf (13-N) pressure on the“ specimen that could result in an erroneous depth of softening.

cutting edge” (Note 4). Hold the blade on the top surface of the 10. Report

specimen at an angle of approximately 30°. Move the cutting

edge forward about 11⁄2in. (38.1 mm) for each stroke, and let 10.1 The report shall include the following:

each stroke follow the same path. Make eight strokes with one 10.1.1 The procedure used,

cutting edge and eight with the other. Before each specimen is 10.1.2 The average depth of softening of all individual

scraped, sharpen the cutting edge. specimens of each sample reported as the depth of softening of

that sample,

NOTE 4—In this test the pressure on the blade is estimated but not 10.1.3 Identification of each sample, including name and

definitely controlled. The following guide in applying the proper pressure location of the quarry, name and position of the ledge, date

is suggested: Grasp the handle of the tool in the same way as in scraping

a specimen. Press a “cutting edge” on the weighing table of a small

when sample was taken, and trade name or grade of the slate,

platform scale when the weighing beam is loaded for 3 lbf (13 N). The 10.1.4 Size and shape of the test specimens, and

pressure on the tool and also the amount of bending of the blade required 10.1.5 Description of the way in which the specimens were

to raise the beam are used as criteria in judging the pressure to apply in the prepared.

Copyright ASTM International

2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 217

11. Precision and Bias 12. Keywords

11.1 Individual variations in a natural product may result in 12.1 dimension stone; slate; stone; weather resistance

deviation from accepted values. A precision section will be

added when sufficient data are available to indicate acceptable

tolerances in repeatability and reproducibility.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

--`-`-`,,`,,`,`,,`---

Copyright ASTM International

3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

Potrebbero piacerti anche

- Aci Manual of Concrete InspectionDocumento218 pagineAci Manual of Concrete InspectionRyan Lasaca100% (1)

- ASTM C 266 Standard Test Method For Time of Setting of Hydraulic-Cement Paste by Gillmore NeedlesDocumento4 pagineASTM C 266 Standard Test Method For Time of Setting of Hydraulic-Cement Paste by Gillmore NeedlesRyan LasacaNessuna valutazione finora

- ASTM C 279 Standard Specification For Chemical-Resistant Masonry UnitsDocumento3 pagineASTM C 279 Standard Specification For Chemical-Resistant Masonry UnitsRyan LasacaNessuna valutazione finora

- ASTM C 267 Standard Test Methods For Chemical Resistance of Mortars, Grouts, and Monolithic SurfaDocumento6 pagineASTM C 267 Standard Test Methods For Chemical Resistance of Mortars, Grouts, and Monolithic SurfaRyan LasacaNessuna valutazione finora

- ASTM C 260 Standard Specification For Air-Entraining Admixtures For ConcreteDocumento3 pagineASTM C 260 Standard Specification For Air-Entraining Admixtures For ConcreteRyan LasacaNessuna valutazione finora

- ASTM C 233 Standard Test Method For Air-Entraining Admixtures For ConcreteDocumento6 pagineASTM C 233 Standard Test Method For Air-Entraining Admixtures For ConcreteRyan LasacaNessuna valutazione finora

- ASTM C 242 Standard Terminology of Ceramic Whitewares and Related ProductsDocumento10 pagineASTM C 242 Standard Terminology of Ceramic Whitewares and Related ProductsRyan Lasaca100% (1)

- ASTM C 222 Standard Specification For Asbestos-Cement Roofing ShinglesDocumento3 pagineASTM C 222 Standard Specification For Asbestos-Cement Roofing ShinglesRyan LasacaNessuna valutazione finora

- ASTM C 230-C 230M Standard Specification For Flow Table For Use in Tests of Hydraulic Cement PDFDocumento7 pagineASTM C 230-C 230M Standard Specification For Flow Table For Use in Tests of Hydraulic Cement PDFRyan LasacaNessuna valutazione finora

- ASTM C 226 Standard Specification For Air-Entraining Additions For Use in The Manufacture of Air PDFDocumento4 pagineASTM C 226 Standard Specification For Air-Entraining Additions For Use in The Manufacture of Air PDFRyan LasacaNessuna valutazione finora

- ASTM C 219 Standard Terminology Relating To Hydraulic CementDocumento3 pagineASTM C 219 Standard Terminology Relating To Hydraulic CementRyan LasacaNessuna valutazione finora

- ASTM C 215 Standard Test Method For Fundamental Transverse, Longitudinal, and Torsional ResonantDocumento7 pagineASTM C 215 Standard Test Method For Fundamental Transverse, Longitudinal, and Torsional ResonantRyan LasacaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- General Chemistry 2 Q1 Lesson 5 Endothermic and Exotheric Reaction and Heating and Cooling CurveDocumento19 pagineGeneral Chemistry 2 Q1 Lesson 5 Endothermic and Exotheric Reaction and Heating and Cooling CurveJolo Allexice R. PinedaNessuna valutazione finora

- Case Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityDocumento5 pagineCase Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityluxoftNessuna valutazione finora

- Editan - Living English (CD Book)Documento92 pagineEditan - Living English (CD Book)M Luthfi Al QodryNessuna valutazione finora

- Binary OptionsDocumento24 pagineBinary Optionssamsa7Nessuna valutazione finora

- Ci Thai RiceDocumento4 pagineCi Thai RiceMakkah Madina riceNessuna valutazione finora

- Cyclic MeditationDocumento8 pagineCyclic MeditationSatadal GuptaNessuna valutazione finora

- Introduction To DifferentiationDocumento10 pagineIntroduction To DifferentiationaurennosNessuna valutazione finora

- Open Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaDocumento3 pagineOpen Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaProf. Prithvi Singh KandhalNessuna valutazione finora

- Chemistry Investigatory Project (R)Documento23 pagineChemistry Investigatory Project (R)BhagyashreeNessuna valutazione finora

- ADC of PIC MicrocontrollerDocumento4 pagineADC of PIC Microcontrollerkillbill100% (2)

- Top 100 Chemical CompaniesDocumento11 pagineTop 100 Chemical Companiestawhide_islamicNessuna valutazione finora

- Logiq v12 SM PDFDocumento267 pagineLogiq v12 SM PDFpriyaNessuna valutazione finora

- Odisha State Museum-1Documento26 pagineOdisha State Museum-1ajitkpatnaikNessuna valutazione finora

- Advertising II Marathi VersionDocumento91 pagineAdvertising II Marathi VersionHarsh Sangani100% (1)

- 2016 W-2 Gross Wages CityDocumento16 pagine2016 W-2 Gross Wages CityportsmouthheraldNessuna valutazione finora

- BMGT 200 Assignment 2 Answer KeysDocumento3 pagineBMGT 200 Assignment 2 Answer Keysharout keshishianNessuna valutazione finora

- Antibiotic Zone Interpretation Guide PDFDocumento2 pagineAntibiotic Zone Interpretation Guide PDFFarandy Insan Sejati100% (2)

- Product NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Documento14 pagineProduct NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Paras ShardaNessuna valutazione finora

- Practising Modern English For Life Sciences Students Caiet Exercitii-1Documento77 paginePractising Modern English For Life Sciences Students Caiet Exercitii-1Robert BobiaNessuna valutazione finora

- 레벨 테스트Documento2 pagine레벨 테스트BNessuna valutazione finora

- Student Management SystemDocumento232 pagineStudent Management Systemslu_mangal73% (37)

- EdisDocumento227 pagineEdisThong Chan100% (1)

- Binge Eating Disorder ANNADocumento12 pagineBinge Eating Disorder ANNAloloasbNessuna valutazione finora

- TFGDocumento46 pagineTFGAlex Gigena50% (2)

- Gaming Ports MikrotikDocumento6 pagineGaming Ports MikrotikRay OhmsNessuna valutazione finora

- Playing With Pop-Ups - The Art of Dimensional, Moving Paper DesignsDocumento147 paginePlaying With Pop-Ups - The Art of Dimensional, Moving Paper DesignsSara100% (4)

- Satish Gujral - FinalDocumento23 pagineSatish Gujral - Finalsatya madhuNessuna valutazione finora

- Wallem Philippines Shipping Inc. v. S.R. Farms (Laxamana)Documento2 pagineWallem Philippines Shipping Inc. v. S.R. Farms (Laxamana)WENDELL LAXAMANANessuna valutazione finora

- PE MELCs Grade 3Documento4 paginePE MELCs Grade 3MARISSA BERNALDONessuna valutazione finora

- Data Asimilasi Untuk PemulaDocumento24 pagineData Asimilasi Untuk PemulaSii Olog-olog PlonkNessuna valutazione finora