Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Keystone Butterfly Valves - KEYMC-0025-US PDF

Caricato da

ThomasFrenchTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Keystone Butterfly Valves - KEYMC-0025-US PDF

Caricato da

ThomasFrenchCopyright:

Formati disponibili

Keystone Butterfly Valves Figure AR1/AR2

General Purpose Valve

Resilient seated butterfly valves

AR1 (wafer) (2" to 36"), 2" to 12", to 175 psi

AR2 (lug) (2" to 24"), 14" to 36", to 150 psi

Features and Benefits

• Triple function resilient seat helps

provide bi-directional drop-tight

shut-off, designed to totally isolate

the valve body and stem from the

line media.

• Molded-in O-ring seat design serves

as flange seals, eliminating the need

for gaskets between the flanges and

the valve.

• Unique dovetail seat retention design

allows for convenient and economical

field replacement.

• Superior one-piece through shaft

design provides high strength and

positive disc control.

• Internal shaft seal is designed to

prevent external media from entering

valve and it also adjusts for pressure

and shaft rotation.

• Heavy-duty, corrosion resistant top

bushing delivers upper stem support,

absorbs actuator side-loading and

extends valve cycle life.

• Polished disc edge helps ensure

optimal performance and maximum

seat life.

• Stainless steel torque plug (2" to 12"),

disc screws (14" to 20") and taper

pins (24" to 36") provide positive leak-

proof connections while allowing for

quick and easy disassembly.

• One-piece body with extended

neck allows clearance for flanges General Application Technical Data

and insulation. Ideally suited for many high Size Range:

performance applications, such Figure AR1 (wafer style) 2" to 36"

• Each valve is factory-tested to

as fire protection, water treatment, Figure AR2 (lugged style) 2" to 24"

110 percent of the manufacturer’s

cooling systems, food and beverage

pressure rating. Flange Standard:

and bulk product handling. Consult your

ANSI Class 125/150

sales representative for appropriate

materials and specific services. (Consult your sales representative for additional

drilling standards.)

Keystone is either a trademark or registered trademark of Tyco International Services AG or its affiliates in the

Flow Control United States and/or other countries. All other brand names, product names, or trademarks belong to their

respective holders.

Copyright © 2010 Tyco Flow Control. All rights reserved. KEYMC-0025-US-1001

Keystone Butterfly Valves Figure AR1/AR2

General Purpose Valve

Parts and Materials

Materials

Part Standard Material Material Specification Optional Material

1 Body Cast iron ASTM A-126, Class B Carbon steel

Ductile iron ASTM A-395 GR 60/40/18 Stainless steel

2 Disc Ductile iron ASTM A-536 GR 65/45/12

Aluminum bronze ASTM B-148, UNS C95200 Grade A

316 Stainless steel ASTM A-743, CF8M

3 Stem 316 Stainless steel (2" to 12") ASTM A-276 UNS S31600

18-8 Stainless steel (14" to 20") ASTM A-276 UNS S30400

17-4 PH Stainless steel (24" to 36") ASTM A-564 UNS S17400 Phosphate treated steel

(2" to 20") ASTM A-108 UNS G10450

4 Seat NBR food grade (0°F to 212°F) Fluoroelastomer (FKM)

EPDM food grade (-40°F to 250°F) White NBR

5 Upper stem bushing Polyester (2" to 20")

Bronze (24" to 36")

6 Stem packing NBR

7 Torque plug (2" to 12") 316 Stainless steel ASTM A-276 UNS S31600 condition A

Disc screws (14" to 20") 316 Stainless steel ASTM F-593 Group 2 condition CW1

Taper pins (24" to 36") 17-4 PH Stainless steel ASTM A564 UNS S17400 H1075

8 Bearings (2" to 12") Sintered metal

Copyright © 2010 Tyco Flow Control. All rights reserved. KEYMC-0025

2

Keystone Butterfly Valves Figure AR1/AR2

General Purpose Valve

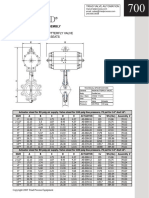

H G H

H

F

DD

45∞

45°

Q A

EE

Figure AR1 Wafer Figure AR2 Lugged

Figure AR1 – Dimensions (inches)

Top Plate Drilling

Bolt No. Hole Weight Adapt.

Size A B C D E F G H Q Key Circle Holes Dia. (lbs) Code

2 2 41/8 51/2 15/8 4 11/4 9/16 3/8 13/8 N/A 31/4 4 7/16 6.3 BAB

21/2 21/2 45/8 6 13/4 4 11/4 9/16 3/8 21/16 N/A 31/4 4 7/16 8.5 BAB

3 3 51/8 61/4 13/4 4 11/4 9/16 3/8 2 9/16 N/A 31/4 4 7/16 10.0 BAB

4 4 63/8 7 2 4 11/4 5/8 7/16 3 5/8 N/A 31/4 4 7/16 14.0 BAC

5 5 73/8 71/2 21/8 4 11/4 3/4 1/2 4 3/4 N/A 31/4 4 7/16 18.0 BAD

6 5 3/4 81/2 8 21/8 4 11/4 3/4 1/2 51/2 N/A 31/4 4 7/16 22.0 BAD

8 7 3/4 1011/16 91/2 21/2 6 11/4 7/8 5/8 71/2 N/A 5 4 9/16 38.0 CAE

10 9 3/4 13 10 3/4 21/2 6 2 11/8 N/A 919/32 1/4x 1/4 5 4 9/16 51.0 CAF

12 113/4 1413/16 121/4 3 6 2 11/8 N/A 119/16 1/4 x 1/4 5 4 9/16 71.0 CAF

14 131/4 16 3/4 12 3 6 3 13/8 N/A 131/8 5/16 x 5/16 5 4 9/16 114.0 CAG

16 151/4 191/4 12 61/64 4 6 3 15/8 N/A 15 3/8 x 3/8 5 4 9/16 193.0 CAH

18 171/4 211/2 14 1/2 4 1/4 8 41/4 17/8 N/A 16 7/8 1/2 x 3/8 61/2 4 13/16 222.0 DAJ

20 191/4 23 3/4 15 7/8 5 8 41/4 17/8 N/A 18 3/4 1/2 x 3/8 61/2 4 13/16 315.0 DAJ

24 231/4 28 1/4 191/2 515/16 8 41/4 1 7/8 N/A 22 5/8 1/2 x 3/8 61/2 4 13/16 506.0 DAJ

30 291/4 34 5/8 23 6 9/16 8 41/4 2 1/4 N/A 28 11/16 1/2 x 3/8 61/2 4 13/16 610.0 DAK

36 351/4 411/4 27 3/4 7 7/8 8 51/4 2 7/8 N/A 34 1/2 3/4 x 1/2 61/2 4 13/16 1,185.0 DAV

Figure AR2 – Dimensions (inches)

Top Plate Drilling Tapped Lug Data

Bolt No. Hole Bolt No. Weight Adapt.

Size A B C D E F G H Q Key Circle Holes Dia. Circle Holes Tap (lbs) Code

2 2 41/8 51/2 15/8 4 11/4 9/16 3/8 13/8 N/A 31/4 4 7/16 4 3/4 4 5/8 - 11 UNC 7.0 BAB

21/2 21/2 4 5/8 6 13/4 4 11/4 9/16 3/8 21/16 N/A 31/4 4 7/16 5 1/2 4 5/8 - 11 UNC 10.0 BAB

3 3 5 3/16 61/4 13/4 4 11/4 9/16 3/8 2 9/16 N/A 31/4 4 7/16 6 4 5/8 - 11 UNC 11.5 BAB

4 4 6 3/8 7 2 4 11/4 5/8 7/16 3 5/8 N/A 31/4 4 7/16 7 1/2 8 5/8 - 11 UNC 18.0 BAC

5 5 7 3/8 71/2 21/8 4 11/4 3/4 1/2 4 3/4 N/A 31/4 4 7/16 81/2 8 3/4 - 10 UNC 22.5 BAD

6 5 3/4 81/2 8 21/8 4 11/4 3/4 1/2 51/2 N/A 31/4 4 7/16 91/2 8 3/4 - 10 UNC 28.5 BAD

8 7 3/4 1011/16 91/2 21/2 6 11/4 7/8 5/8 71/2 N/A 5 4 9/16 113/4 8 3/4 - 10 UNC 49.0 CAE

10 9 3/4 13 10 3/4 21/2 6 2 11/8 N/A 919/32 1/4 x 1/4 5 4 9/16 141/4 12 7/8 - 9 UNC 69.0 CAF

12 11 3/4 1413/16 121/4 3 6 2 11/8 N/A 119/16 1/4 x 1/4 5 4 9/16 17 12 7/8 - 9 UNC 107.0 CAF

14 13 1/4 16 3/4 12 3 6 3 13/8 N/A 131/8 5/16 x 5/16 5 4 9/16 18 3/4 12 1 - 8 NC 143.0 CAG

16 15 1/4 19 12 61/64 4 6 3 15/8 N/A 15 3/8 x 3/8 5 4 9/16 211/4 16 1 - 8 NC 238.0 CAH

18 17 1/4 213/8 141/2 41/4 8 41/4 17/8 N/A 16 7/8 1/2 x 3/8 61/2 4 13/16 22 3/4 16 11/8 - 7 NC 261.0 DAJ

20 19 1/4 231/2 15 7/8 5 8 41/4 17/8 N/A 18 3/4 1/2 x 3/8 61/2 4 13/16 25 20 11/8 - 7 NC 366.0 DAJ

24 23 1/4 281/4 19 1/2 515/16 8 41/4 17/8 N/A 22 5/8 1/2 x 3/8 61/2 4 13/16 291/2 20 11/4 - 7 NC 576.0 DAJ

Notes:

1. “H” Dimension refers to flat on stem.

2. “Q” dimension is the minimum allowable pipe or flange inside diameter at the centered body face to

protect the disc sealing edge against damage when opening the valve.

Copyright © 2010 Tyco Flow Control. All rights reserved. KEYMC-0025

3

Keystone Butterfly Valves Figure AR1/AR2

General Purpose Valve

Valve Sizing

Rate of flow through a valve depends

Table 1

upon the pressure drop. The most

common method of presenting this Cv Chart (Water @ 70°F, Specific Gravity = 1.00)

information is by Cv. The Cv is the Valve Disc position (Degrees Open)

valve coefficient of flow and represents Size 20 30 40 50 60 70 80 90

the flow of water in gallons per minute 2" 1.3 5 14 26 40 52 59 60

(GPM) with a 1 psi pressure drop 2.5" 1.4 6 21 44 74 107 138 151

through the valve. The higher the Cv,

3" 1.5 8 29 67 115 175 234 262

the greater the flow and the better the

control characteristics. Throttling 4" 15 48 107 196 318 463 589 647

characteristics are shown in the same 5" 32 99 206 362 579 832 1045 1141

manner with Cv’s at the various disc 6" 47 145 295 510 810 1160 1450 1580

openings. See Table 1 for tabulated Cv’s

for the Figure AR1/AR2 Butterfly Valve. 8" 84 239 450 751 1190 1754 2385 2892

10" 133 360 652 1064 1683 2524 3596 4593

12" 192 509 899 1449 2288 3470 5085 6682

14" 340 770 1400 2200 3400 5600 7900 10000

16" 440 1000 1800 2800 4500 7400 10800 13000

18" 570 1300 2300 3600 5800 9600 15000 18000

20" 710 1600 2900 4600 7200 12000 18400 22000

24" 1000 2300 4000 6400 10000 16500 25900 30000

30" 1500 3600 6200 9900 16000 26000 42500 47000

36" 2600 5200 9100 15000 23000 38000 65000 70000

Torque Data

Torque is the rotary effort required to

Table 2

operate a valve. This turning force in

a butterfly valve is determined by three Seating and Unseating Torques

factors – the friction of the disc and seat Category 2 (Normal Conditions)

due to interference for sealing, bearing Valve

friction, and fluid dynamic torque. Size 50 100 150 175

Breakaway torque at 70°F 2" 224 229 233 235

Breakaway torque is the total of the 2.5" 277 284 291 264

torques resulting from bearing friction 3" 330 340 350 355

and disc/seat interference friction at a 4" 500 519 539 549

given pressure differential. See Table 2 5" 687 724 761 779

for torques to open and close the valve

6" 953 1006 1059 1086

at pressures shown in wet services with

8" 1610 1720 1830 1885

minimum operating frequency of one

per week (normal conditions). 10" 2521 2751 2963 3074

Note: These values are valid for water and 12" 3418 3737 4055 4214

lubricating fluids only at 70°F. Since torques are 14" 5147 5995 6842 –

greatly increased for dry and nonlubricating

fluids and temperature variations, contact your 16" 6808 8116 9424 –

Keystone representative for accurate values in 18" 8810 10720 12630 –

Tathese applications.

20" 11172 13845 16517 –

24" 13372 16994 20616 –

30" 22074 29148 36222 –

36" 33224 45448 57672 –

www.keystonevalves.com

Tyco Flow Control (TFC) provides the information herein in good faith but makes no representation as to its comprehensiveness or accuracy. This data sheet is intended only as a guide to TFC products and services.

Individuals using this data sheet must exercise their independent judgment in evaluating product selection and determining product appropriateness for their particular purpose and system requirements. TFC MAKES NO

REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE INFORMATION SET FORTH HEREIN OR THE PRODUCT(S) TO WHICH THE INFORMATION REFERS. ACCORDINGLY, TFC WILL NOT BE RESPONSIBLE FOR DAMAGES (OF ANY KIND OR NATURE, INCLUDING

INCIDENTAL, DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES) RESULTING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION. Patents and Patents Pending in the U.S. and foreign countries. Tyco

reserves the right to change product designs and specifications without notice. All registered trademarks are the property of their respective owners. Printed in the USA.

Copyright © 2010 Tyco Flow Control. All rights reserved. KEYMC-0025 www.tycoflowcontrol.com

4

Potrebbero piacerti anche

- Asme b16.36Documento0 pagineAsme b16.36IPINessuna valutazione finora

- G-4202 GoratorPump Brochure PDFDocumento12 pagineG-4202 GoratorPump Brochure PDFThomasFrenchNessuna valutazione finora

- Pneumatic Lugged Butterfly Valve - Spring Return PDFDocumento1 paginaPneumatic Lugged Butterfly Valve - Spring Return PDFThomasFrenchNessuna valutazione finora

- Passivating & Pickling Stainless SteelDocumento16 paginePassivating & Pickling Stainless Steelfeki2607Nessuna valutazione finora

- Demco Butterfly Valves BrochureDocumento44 pagineDemco Butterfly Valves BrochureOndRechTacLetMovNessuna valutazione finora

- Flex It Alex Spiral Wound GasketsDocumento38 pagineFlex It Alex Spiral Wound GasketsYrvin Enrique Romero ArteagaNessuna valutazione finora

- Lugged Butterfly Valve 2-12 PDFDocumento1 paginaLugged Butterfly Valve 2-12 PDFThomasFrenchNessuna valutazione finora

- Of-Pla NF00074 1001D PDFDocumento8 pagineOf-Pla NF00074 1001D PDFNigin ParambathNessuna valutazione finora

- Nicholson Mechanical Steam Traps PDFDocumento24 pagineNicholson Mechanical Steam Traps PDFThomasFrenchNessuna valutazione finora

- Catalogo Niple Swage 03Documento1 paginaCatalogo Niple Swage 03BuenDíaNessuna valutazione finora

- Koio - Forged Steel Valve PDFDocumento42 pagineKoio - Forged Steel Valve PDFThomasFrenchNessuna valutazione finora

- Lugged Butterfly Valve 14-24 PDFDocumento1 paginaLugged Butterfly Valve 14-24 PDFThomasFrenchNessuna valutazione finora

- CheckAll Valve PDFDocumento63 pagineCheckAll Valve PDFThomasFrenchNessuna valutazione finora

- Bonney Forge BrochureDocumento22 pagineBonney Forge BrochureAnonymous dvrhf5Nessuna valutazione finora

- HANCOCK - Needle Valve 2500 PDFDocumento4 pagineHANCOCK - Needle Valve 2500 PDFThomasFrenchNessuna valutazione finora

- API602 Forged Steel Gate & Globe ValvesDocumento4 pagineAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNessuna valutazione finora

- Dimensions, Sizes and Specification of ANSI ASME Reducing Flanges PDFDocumento3 pagineDimensions, Sizes and Specification of ANSI ASME Reducing Flanges PDFThomasFrenchNessuna valutazione finora

- API 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFDocumento22 pagineAPI 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFThomasFrenchNessuna valutazione finora

- BUTTERFLY Lever PDFDocumento1 paginaBUTTERFLY Lever PDFThomasFrenchNessuna valutazione finora

- Masoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesDocumento9 pagineMasoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesisctomaslopezNessuna valutazione finora

- Ball Valves PDFDocumento34 pagineBall Valves PDFThomasFrenchNessuna valutazione finora

- Ball Valves 3Documento44 pagineBall Valves 3ThomasFrenchNessuna valutazione finora

- Valbart: API 6D & 6A Trunnion Mounted Ball ValvesDocumento36 pagineValbart: API 6D & 6A Trunnion Mounted Ball Valvesbabis1980Nessuna valutazione finora

- Ball Valve Gear Actuator PDFDocumento2 pagineBall Valve Gear Actuator PDFThomasFrenchNessuna valutazione finora

- Ball Valves - R43/R44 Trunnion MountedDocumento10 pagineBall Valves - R43/R44 Trunnion MountedThomasFrenchNessuna valutazione finora

- Be301 02 PDFDocumento56 pagineBe301 02 PDFNikita SharmaNessuna valutazione finora

- Forged Steel Check Valves - Bs 5352, Ansi B16.34 CLASS-600,800,1500 & 2500Documento2 pagineForged Steel Check Valves - Bs 5352, Ansi B16.34 CLASS-600,800,1500 & 2500ThomasFrenchNessuna valutazione finora

- Range of Trim MaterialsDocumento1 paginaRange of Trim MaterialsAbu___AbdullahNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Flans ASME B16.5 PDFDocumento47 pagineFlans ASME B16.5 PDFMircea Dan StanciuNessuna valutazione finora

- Project On Pressure VesselDocumento72 pagineProject On Pressure Vesselfanus100% (2)

- Genie Direct Drive 750 Installation & Operation InstructionsDocumento4 pagineGenie Direct Drive 750 Installation & Operation InstructionsGMSNessuna valutazione finora

- SURE - Gas Turbine Flowmeter Manual - V2 LWQDocumento24 pagineSURE - Gas Turbine Flowmeter Manual - V2 LWQMichael roa parra100% (1)

- Dimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchDocumento6 pagineDimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchPozii Ziipunii PaulNessuna valutazione finora

- zg05 1407 PDFDocumento29 paginezg05 1407 PDFgiovanni perozziNessuna valutazione finora

- Iso9001-2015 31 05 2020oati-Lazkao-SantxoengDocumento2 pagineIso9001-2015 31 05 2020oati-Lazkao-SantxoengPepitofloro69Nessuna valutazione finora

- TDC46M Carbon Steel Thermodynamic Steam Trap With Maintainable Seat-Technical InformationDocumento5 pagineTDC46M Carbon Steel Thermodynamic Steam Trap With Maintainable Seat-Technical InformationDavid Bottassi PariserNessuna valutazione finora

- TM1529 Test Manual On A 644GDocumento736 pagineTM1529 Test Manual On A 644Gmiguel cordero100% (4)

- Oim UlncDocumento38 pagineOim UlncHendi HendriansyahNessuna valutazione finora

- Grizzly 700Documento97 pagineGrizzly 700mafeNessuna valutazione finora

- Flanged Immersion Heaters Design GuideDocumento7 pagineFlanged Immersion Heaters Design GuidecamspsNessuna valutazione finora

- High Pressure Movitec PumpsDocumento60 pagineHigh Pressure Movitec PumpsBerhanu Zemecha HabteNessuna valutazione finora

- EHB en File 10.5.1 PressureTemperature Ratings Acc To JIS B 2220 2239Documento4 pagineEHB en File 10.5.1 PressureTemperature Ratings Acc To JIS B 2220 2239wholenumberNessuna valutazione finora

- Swing Bolt CalculationDocumento2 pagineSwing Bolt CalculationNicolaSavili100% (2)

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocumento23 pagineAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNessuna valutazione finora

- Series: Masoneilan Spring Diaphragm Actuators Instruction ManualDocumento155 pagineSeries: Masoneilan Spring Diaphragm Actuators Instruction ManualWade WaderNessuna valutazione finora

- 3203T Accesorii Hunter EchilibratDocumento16 pagine3203T Accesorii Hunter EchilibratCiprian TarataNessuna valutazione finora

- Asme Ii B SB-366 2008Documento10 pagineAsme Ii B SB-366 2008الGINIRAL FREE FIRENessuna valutazione finora

- Mag-Gage The Superior Magnetic Level Gauge: Process Level Technology, Ltd. 281.332.6241Documento12 pagineMag-Gage The Superior Magnetic Level Gauge: Process Level Technology, Ltd. 281.332.6241BYRON ENRIQUE AGUILERA CHIMARRONessuna valutazione finora

- Pipe Thickness CalculationDocumento4 paginePipe Thickness CalculationHarryNessuna valutazione finora

- Breathers: Threaded Adapters For Creating Tank BreathersDocumento11 pagineBreathers: Threaded Adapters For Creating Tank BreathersAmjedNessuna valutazione finora

- Assembly - FlayerDocumento8 pagineAssembly - FlayerIbrahim MesfinNessuna valutazione finora

- JTB RJJ 000 L0 Spe 900 10001 2 1 2Documento788 pagineJTB RJJ 000 L0 Spe 900 10001 2 1 2Ro DiroNessuna valutazione finora

- Tatlee GasketsDocumento6 pagineTatlee GasketsjerickNessuna valutazione finora

- Technical Specification of VSK PDFDocumento28 pagineTechnical Specification of VSK PDFmaran.suguNessuna valutazione finora

- SMT Technology Co., Ltd. Hydraulic Breaker Parts CatalogDocumento78 pagineSMT Technology Co., Ltd. Hydraulic Breaker Parts CatalogSerhidra SASNessuna valutazione finora

- Excel PV 2016 Demo VersionDocumento6 pagineExcel PV 2016 Demo Versionahmadlie0% (1)

- The Above-Ground Sulfur Seal From The Makers of Controtrace®Documento2 pagineThe Above-Ground Sulfur Seal From The Makers of Controtrace®Javier GarcíaNessuna valutazione finora

- p10 3283pdfDocumento4 paginep10 3283pdfsrinuvoodiNessuna valutazione finora