Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1 ST - Generral Notes

Caricato da

mandeep gautamDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1 ST - Generral Notes

Caricato da

mandeep gautamCopyright:

Formati disponibili

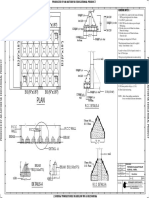

NOTES:

40

Lap portion: minimum 8mmØ-100mm C/C

3 NOS.-8mmØ U-SHAPED TIES MAY BE 1. Any discrepancy in the drawing to be immediately

10

*Ø

GENERAL NOTE: PROVIDED IN CASE OF DIFFICULTY reported to the consultant or concerned engineer.

b

40

IN PROVIDING CLOSE STIRRUPS 2. Drawing are not to be directly measured.

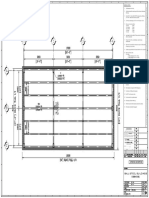

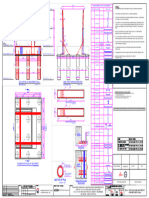

1. USE M20 (1:1.5:3) GRADE CONCRETE FOR SLAB, BEAM, 1:6 SLOPE RATIO Ld+10Ø TRUSS BEAM 3. Read this drawing along with other related drawings

COLUMN, FOUNDATION, SILL & LINTEL BANDS (ALL RCC WORKS) and coordinate with Structural, Electrical, Plumbing

and other services drawings.

Z

2. USE Fe500 GRADE STEEL (fy=500N/mm² ) for stirrups Fe415 N/mm2 4. Refer doors & windows schedule/elevations for size

Øb of doors & windows

Ld

3. CLEAR COVER TO BARS 5. Provide threshold at all exterior doors as per details,

a. FOR CONCRETE MEMBERS IN CONTACT WITH SOIL = MIN 50mm Min. 8mmØ -100mm C/C

h

unless otherwise indicated.

DETAIL OF HOOK

H/4

b. FOR STIRRUPS IN COLUMN = 40mm

c. FOR STIRRUPS IN BEAMS = 25mm (Not to Scale) 2 NOS.-8mmØ

d. FOR OUTER BARS IN SLAB = 20mm U-SHAPED SHAPED

4. BARS IN COLUMNS SHALL BE SPLICED ONLY AT MID HEIGHT OF COLUMN

Ld

AS PER DUCTILE DETAILING IS 13920- 2014

5. BARS SPLICING IN BEAM SHALL BE AVOIDED IN THE SPAN WHERE LAP PORTION DETAIL Min. 8mmØ - 100mm C/C

INTERMEDIATE BEAM IS CONNECTED AND SHALL BE ONLY AS SHOWN ON DWG. 1:6 SLOPE RATIO

H

6. DEVELOPMENT / LAP LENGTH (Ld.) FOR BARS.

BAR DIA-(mm) 8 10 12 16 20 25 32

NOT MORE THAN 50% BAR

SHOULD BE LAP AT ONE

Ld+10Ø

FOR M20 Ld 480 600 720 960 1200 1500 1920

POSITION

7. TEMP./DISTRIBUTION REINFORCEMENT FOR SLAB - TMT 8Ø @ 150 C/C

H/4

Min. 8mmØ -100mm C/C

8. CLEAR VERTICAL DISTANCE BETWEEN TWO ROWS (LAYERS) OF BARS=25mm.

h

50mm (MAX.) FLOOR BEAM

9. PROVIDE SHEAR REINFORCEMENT AT 100 C/C AT LAP LOCATIONS.

10. H = CLEAR SPAN OF FLOOR.

Ld+10Ø

Z

11. h = H/6 OR 450mm OR LARGER LATERAL DIMENSION OF THE MEMBER ,WHICHEVER IS GREATER.

12. Z = DEPTH OF BEAM. 3 NOS.-8mmØ

Min. 8mmØ -100mm C/C

h

13. STRUCTURAL STEEL SHALL HAVE STRENGTH Fy 345MPa U-SHAPED TIES MAY BE

H/4

14. PROVIDED IN CASE OF DIFFICULTY 50mm (MAX.)

FOUNDATION TYPE SHOULD BE DECIDED BY SITE CONDITION AFTER EXCAVATION OF FOUNDATION.

IN PROVIDING CLOSE STIRRUPS

15. IF BEARING CAPACITY IS LESS THAN 50 kN/m2, FOUNDATION SHOULD BE RE-DESIGNED. CONNECTION DETAIL

16. PROVIDE 2-16dia TORSION BARS IN 525mm DEEP BEAM 2 NOS.-8mmØ

BETWEEN U-SHAPED SHAPED

Ld

MAIN & SECONDARY BEAM

(PLAN) Min. 8mmØ - 100mm C/C

H

1:6 SLOPE RATIO

Ld

NOT MORE THAN 50% BAR

>0.25L or Ld or 2d >0.25L or Ld >0.25L or Ld SHOULD BE LAP AT ONE

whichever is greater Ld whichever is greater whichever is greater POSITION

Ld+10Ø

H/4

Min. 8mmØ -100mm C/C

h

50mm (MAX.) RCC FOUNDATION

Ld+10Ø

3 NOS.-8mmØ

U-SHAPED TIES MAY BE

2 NOS.-8mmØ

PROVIDED IN CASE OF DIFFICULTY

U-SHAPED SHAPED

IN PROVIDING CLOSE STIRRUPS

>0.25L or Ld

whichever is greater Ld

TYP. COLUMN SHEAR

REINFORCEMENT DETAIL

TYPICAL LAP LOCATION FOR BEAM BARS

SECONDARY BEAM

ALT. BARS NEGATIVE BAR (N) Ld. Ld.

0.15*L1 0.3*L1 0.3*L2 MAIN

BUL

150 SLAB THICK BEAM

2 NOS. - 16mmØ

(BENT UP BAR)

0.25*L1 0.25*L2

BLL

FLOOR BEAM CONNECTION DETAIL BETWEEN

SECONDARY BEAM Sheet Title : Sheet No.

MAIN & SECONDARY BEAM GENERAL NOTES &

L1 L2

TYPICAL DETAILS 3-12C

(MsF)

TYPICAL BENT-UP DETAIL FOR SLAB BARS Date : October, 2017

Print Sheet : A'3' Size S-00

Potrebbero piacerti anche

- Sample Structural DrawingDocumento1 paginaSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Practicing Oil AnalysisDocumento62 paginePracticing Oil AnalysisCristian SNessuna valutazione finora

- Floor Layout PlanDocumento1 paginaFloor Layout PlanDereck W MarieNessuna valutazione finora

- Computation of Area of A Closed TraversedDocumento3 pagineComputation of Area of A Closed TraversedDaryl Ballesteros100% (1)

- Compound wall structural detailsDocumento1 paginaCompound wall structural detailssandip wankhadeNessuna valutazione finora

- PHYSICS Review Guide 2D Motion: M - L B NDocumento4 paginePHYSICS Review Guide 2D Motion: M - L B Npotatoman51325Nessuna valutazione finora

- ExtraDocumento3 pagineExtraaman100% (1)

- The Supply Chain For Electric Vehicle BatteriesDocumento21 pagineThe Supply Chain For Electric Vehicle BatteriesProbonogoya Erawan Sastroredjo100% (2)

- Chartering Terms ExplainedDocumento49 pagineChartering Terms Explainedbrett1856Nessuna valutazione finora

- Surge Arrester Function and Working PrinciplesDocumento25 pagineSurge Arrester Function and Working PrinciplesMidhun Varghese100% (1)

- A History of OrnamentDocumento488 pagineA History of OrnamentBrad Sommers100% (12)

- Vakri Grahas - Effects of Retrograde Planets in Hindu AstrologyDocumento4 pagineVakri Grahas - Effects of Retrograde Planets in Hindu AstrologyBailvan100% (1)

- 4.plinth & Roof Details (With Diensions)Documento1 pagina4.plinth & Roof Details (With Diensions)barathshyamNessuna valutazione finora

- Fluent-Intro 16.0 L02 IntroCFD PDFDocumento45 pagineFluent-Intro 16.0 L02 IntroCFD PDFAnonymous 8209ZTNessuna valutazione finora

- First Periodical Mapeh 9Documento5 pagineFirst Periodical Mapeh 9Juvy Singian100% (1)

- Gambar Shop Drawing Dengan Wiremesh PDFDocumento1 paginaGambar Shop Drawing Dengan Wiremesh PDFengineer jbiNessuna valutazione finora

- TD - 50175 - Curtain Wall DetailsDocumento1 paginaTD - 50175 - Curtain Wall DetailsHasitha AthukoralaNessuna valutazione finora

- Steel Contractor Notes and Grating SpecificationsDocumento1 paginaSteel Contractor Notes and Grating SpecificationssivagnanamNessuna valutazione finora

- Ajv DPW 10 525 CL DWG 0695 03 R03Documento1 paginaAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNessuna valutazione finora

- Structural FPD P.sanchezDocumento9 pagineStructural FPD P.sanchezHailley DensonNessuna valutazione finora

- Detail - 3 Section - L: Infineum JSGP Alliance (Ija) Projects Infineum Singapore LLPDocumento1 paginaDetail - 3 Section - L: Infineum JSGP Alliance (Ija) Projects Infineum Singapore LLPdharunesh182Nessuna valutazione finora

- Profile Di Roofing 5 2 1 6: Assy Rangka Dinding 4 - 1310Documento12 pagineProfile Di Roofing 5 2 1 6: Assy Rangka Dinding 4 - 1310joseNessuna valutazione finora

- General NotesDocumento1 paginaGeneral Notesmustafa1989ocNessuna valutazione finora

- Col & Fot ScheduleDocumento1 paginaCol & Fot Schedulece mgnregsNessuna valutazione finora

- Air Purge Quick Connect Instrument PanelDocumento2 pagineAir Purge Quick Connect Instrument Panelmiguel torbellinoNessuna valutazione finora

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Documento1 paginaSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNessuna valutazione finora

- Gabion breast wall design CH:43+260 to CH:43+265Documento1 paginaGabion breast wall design CH:43+260 to CH:43+265Shaun PattersonNessuna valutazione finora

- 022 R01 Cable Schedules Multi Core cablesDocumento1 pagina022 R01 Cable Schedules Multi Core cablessreeagile.esNessuna valutazione finora

- STR 2883Documento4 pagineSTR 2883eng.yehia.omara.kbhNessuna valutazione finora

- Epe Mini Stadium Full Structural DrawingsDocumento29 pagineEpe Mini Stadium Full Structural DrawingsRahman AdedokunNessuna valutazione finora

- Det-1A (Typical) Det-1 (Typical) : Structural DrawingsDocumento1 paginaDet-1A (Typical) Det-1 (Typical) : Structural DrawingsAHMED ELMASRYNessuna valutazione finora

- Bins DetailsDocumento1 paginaBins DetailsCivil BaruneiNessuna valutazione finora

- Concrete cable trench and direct buried cable trench detailsDocumento1 paginaConcrete cable trench and direct buried cable trench detailsAbid AyubNessuna valutazione finora

- GF1 40x100 3 Buc: P.Th. Start Regional ProiectDocumento1 paginaGF1 40x100 3 Buc: P.Th. Start Regional ProiectBogdanPaiusNessuna valutazione finora

- Land Key PlanDocumento1 paginaLand Key PlanOmer HayatNessuna valutazione finora

- DG Buj 105 0000 Sca SDW Ar 000 0880001 00 1Documento1 paginaDG Buj 105 0000 Sca SDW Ar 000 0880001 00 1Siddiq mohiuddinNessuna valutazione finora

- 089 - Pagar Depan SignedDocumento5 pagine089 - Pagar Depan Signedhansen 97Nessuna valutazione finora

- Anchor Bolt Installation MethodDocumento2 pagineAnchor Bolt Installation MethodOscar WanNessuna valutazione finora

- 10 ST - Plinth Beam PlanDocumento1 pagina10 ST - Plinth Beam Planmandeep gautamNessuna valutazione finora

- 011 012 MergedDocumento12 pagine011 012 MergedAli HusseinNessuna valutazione finora

- Construction notes for reinforced concrete structureDocumento9 pagineConstruction notes for reinforced concrete structureIrene Ionie Rarangol - TengcoNessuna valutazione finora

- WH2 GaDocumento5 pagineWH2 GaRaveendra Babu CherukuriNessuna valutazione finora

- Arch 2Documento1 paginaArch 2nicholasomodingNessuna valutazione finora

- ST 01 Typical Structure DetailsDocumento1 paginaST 01 Typical Structure DetailsPrajapati JayeshNessuna valutazione finora

- Product Manual - R 3EL 125 - PO 8584Documento71 pagineProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNessuna valutazione finora

- 1023-TRAC-CI-DWG-014-01 Different Pile Types For Pile Pull-Out Test-Layout1Documento1 pagina1023-TRAC-CI-DWG-014-01 Different Pile Types For Pile Pull-Out Test-Layout1shafiq_05Nessuna valutazione finora

- D E F G H: Grating SpecificationsDocumento1 paginaD E F G H: Grating SpecificationssivagnanamNessuna valutazione finora

- Canopy DetailsDocumento2 pagineCanopy Detailssydney augustNessuna valutazione finora

- Detail Detail: Issued For Public CommentDocumento1 paginaDetail Detail: Issued For Public CommentChilakamarri SrikamalNessuna valutazione finora

- T.DANDA SIBUGAY Model2Documento1 paginaT.DANDA SIBUGAY Model2Bryan Lloyd PallegaNessuna valutazione finora

- North wall construction detailsDocumento1 paginaNorth wall construction detailsDareen BaredNessuna valutazione finora

- 046 M8 Male To Male, Double Ended, Molded Cable, 360° EMI-shieldedDocumento1 pagina046 M8 Male To Male, Double Ended, Molded Cable, 360° EMI-shieldedAndrew LowNessuna valutazione finora

- MNF. Name PlateDocumento2 pagineMNF. Name PlateSuper 7Nessuna valutazione finora

- Typical Joint Box With U-Ditch: Weephole DetailDocumento1 paginaTypical Joint Box With U-Ditch: Weephole DetailAbid AyubNessuna valutazione finora

- Balu Steel Buildings: CoimbatoreDocumento1 paginaBalu Steel Buildings: CoimbatoreParamesWaranNessuna valutazione finora

- E111-Db Schematic Kiosk-SchematicDocumento1 paginaE111-Db Schematic Kiosk-Schematicdavid abbreyNessuna valutazione finora

- Elevation: NotesDocumento1 paginaElevation: NotesErika Faye GutierrezNessuna valutazione finora

- 230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Documento1 pagina230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Mateen JawreNessuna valutazione finora

- Huus 5.17.23Documento9 pagineHuus 5.17.23Civil BuildersNessuna valutazione finora

- Approved For Construction: AusencoDocumento1 paginaApproved For Construction: AusencoamirNessuna valutazione finora

- P203 Sie DWG 008 Arc 610010Documento1 paginaP203 Sie DWG 008 Arc 610010viswanathanNessuna valutazione finora

- 09 000-Bcl2000298-El-Dr-1 - AfcDocumento1 pagina09 000-Bcl2000298-El-Dr-1 - AfcYousab JacobNessuna valutazione finora

- 3-Y12 (Thro) 2-Y12 (Thro) Y8@200C/C 2-Y12 (Thro) : End Span (L.H.S) Mid Span End Span (R.H.S) Remarks Beam Sizes S.NoDocumento1 pagina3-Y12 (Thro) 2-Y12 (Thro) Y8@200C/C 2-Y12 (Thro) : End Span (L.H.S) Mid Span End Span (R.H.S) Remarks Beam Sizes S.NoParamesWaranNessuna valutazione finora

- Innovance H2U Data SheetDocumento2 pagineInnovance H2U Data SheetAmr samir ShahinNessuna valutazione finora

- 02.MRTCPL - Reinf - RCC Box-Ret, Wall-Ch-362.231Documento1 pagina02.MRTCPL - Reinf - RCC Box-Ret, Wall-Ch-362.231kumardityaNessuna valutazione finora

- First Floor Slab ReinforcementsDocumento1 paginaFirst Floor Slab ReinforcementsAlhassan Sani NajumeNessuna valutazione finora

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Documento3 pagineType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatNessuna valutazione finora

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0Documento2 pagineField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0hugoNessuna valutazione finora

- RUB-72-1 Abutment (A1) Reinforcement DetailDocumento1 paginaRUB-72-1 Abutment (A1) Reinforcement DetailYatin DoshiNessuna valutazione finora

- Uci Mce Stru D S-20.6Documento1 paginaUci Mce Stru D S-20.6Thanh Đạt NguyễnNessuna valutazione finora

- User ManualDocumento40 pagineUser Manualmandeep gautamNessuna valutazione finora

- Manual Service: 21C-F8197-EODocumento267 pagineManual Service: 21C-F8197-EOMark Escalante CotrinaNessuna valutazione finora

- 12 ST - 1st and 2nd Floor Beam PlanDocumento1 pagina12 ST - 1st and 2nd Floor Beam Planmandeep gautamNessuna valutazione finora

- 11 ST - Plinth Beam DetailsDocumento1 pagina11 ST - Plinth Beam Detailsmandeep gautamNessuna valutazione finora

- 10 ST - Plinth Beam PlanDocumento1 pagina10 ST - Plinth Beam Planmandeep gautamNessuna valutazione finora

- Notes:: 0 0.2M 0.4M 0.6M 0.8M 1M 1:20Documento1 paginaNotes:: 0 0.2M 0.4M 0.6M 0.8M 1M 1:20mandeep gautamNessuna valutazione finora

- English 4 Q2 Weeks 1-4Documento36 pagineEnglish 4 Q2 Weeks 1-4Em AdrianoNessuna valutazione finora

- Anggraeni Kusuma Dewi Xii Iis Bahasa Inggris (UH 4/SOAL REPORT TEXT)Documento7 pagineAnggraeni Kusuma Dewi Xii Iis Bahasa Inggris (UH 4/SOAL REPORT TEXT)prabaswara xxNessuna valutazione finora

- Small ScienceDocumento368 pagineSmall Sciencereach27Nessuna valutazione finora

- Assignment On Computer HardwareDocumento9 pagineAssignment On Computer HardwareMuktadirhasan100% (1)

- Li HongDocumento4 pagineLi HongJiwen SalimNessuna valutazione finora

- Neem CofA 141019-4Documento1 paginaNeem CofA 141019-4Rahayuteuk Elf100% (1)

- K.P.Mondal & Sons: Quality Assurance PlanDocumento1 paginaK.P.Mondal & Sons: Quality Assurance PlanTanmoy DuttaNessuna valutazione finora

- Purposive Communication, Assignment 2Documento3 paginePurposive Communication, Assignment 2Myles Ninon LazoNessuna valutazione finora

- Anemia Defisiensi Besi Pada Pasien Dengan Ulkus Peptikum: Laporan KasusDocumento4 pagineAnemia Defisiensi Besi Pada Pasien Dengan Ulkus Peptikum: Laporan KasusAzura SyahadatiNessuna valutazione finora

- KS1 A Good Bubbling CauldronDocumento11 pagineKS1 A Good Bubbling CauldronViktoriia PolushkoNessuna valutazione finora

- R/C Soaring Digest - May 2009Documento80 pagineR/C Soaring Digest - May 2009Aviation/Space History LibraryNessuna valutazione finora

- Mitsubishi: Technical Service BulletinDocumento11 pagineMitsubishi: Technical Service BulletinKonstantinNessuna valutazione finora

- 10 1108 - JPBM 07 2022 4070Documento19 pagine10 1108 - JPBM 07 2022 4070erikNessuna valutazione finora

- Presentation by Harshal Sethiya N Mitul UpadhyayDocumento26 paginePresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- Working Principle Iwind Wind TurbinesDocumento25 pagineWorking Principle Iwind Wind TurbinesKarbonKaleNessuna valutazione finora

- Tzu Chi Medical Journal: Xiao-Jun Lin, I-Mei Lin, Sheng-Yu FanDocumento5 pagineTzu Chi Medical Journal: Xiao-Jun Lin, I-Mei Lin, Sheng-Yu Fanperisici4_535458722Nessuna valutazione finora

- DMAE Powder Safety Data SheetDocumento3 pagineDMAE Powder Safety Data SheetAInhoaNessuna valutazione finora

- Latihan Akuntansi Perusahaan DagangDocumento3 pagineLatihan Akuntansi Perusahaan DagangTheresya HutajuluNessuna valutazione finora

- Donna's Score During The Third Quarter ExaminationDocumento7 pagineDonna's Score During The Third Quarter ExaminationGeraldine Valdez CacabilosNessuna valutazione finora