Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Common CT Systems: System Acceptance Testing According To IEC 61223-3-5

Caricato da

Dhiraj JhaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Common CT Systems: System Acceptance Testing According To IEC 61223-3-5

Caricato da

Dhiraj JhaCopyright:

Formati disponibili

r

H

tW

u

lo

a

c

d

M

s

n

m

ie

S

Common CT Systems

CT

Quality Assurance

System

Acceptance testing according to IEC 61223-3-5

10017857

08874427

08872017

08377520

07734713

07732444

07732436

07732428

07732410

07543106

07543015

07541985

07407039

07407013

07406502

07393114

07114023

07005502

04806118

03815490

03813933

03812950

03810160

03810152

03810137

03810079

03804890

© Siemens AG 2005

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

Print No.: CT00-000.820.03.02.02 English

Replaces: CT00-000.820.03.01.02 Doc. Gen. Date: 09.05

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service pro-

cedures.

Common CT Systems CT00-000.820.03.02.02 Page 2 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Table of Contents 3

1- 0Table of Contents

1 _______ General information______________________________________________ 4

General Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Area of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Documents required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tools, text and auxiliary means . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location of identification labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Informing the expert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

When is an acceptance test required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

When is a partial acceptance test required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Determining reference values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Protection against electrical voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Radiation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 _______ Information for Acceptance Testing ________________________________ 9

Use of test phantoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Documenting the test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 _______ Preparations for the Acceptance Test ______________________________ 11

Selecting the test routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Layout of the Quality IEC acceptance platform (since VB20) . . . . . . . . . . . . . . . . . . 13

Preparations for the phantoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 _______ Description of the Acceptance Test________________________________ 16

Description of the test functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PATIENT positioning accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Preview Image Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Slice - TOMOGRAPHIC SECTION THICKNESS . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Homogeneity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

NOISE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SPATIAL RESOLUTION (MTF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table Pos.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dose Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CTDIW Head and CTDIW Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Gantry tilt: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 _______ Acceptance Reports ____________________________________________ 23

Language selected for the protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Location for storing the protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Printing out protocols.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 _______ Changes to Previous Version_____________________________________ 27

7 _______ Index _________________________________________________________ 28

Siemens AG CT00-000.820.03.02.02 Page 3 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

4 General information

2-

General Remarks

1General information

Area of application 0

The document applies to all CT SOMATOM systems.

Documents required 0

P The acceptance protocols generated electronically are part of the document.

Together with the results, they are automatically stored as pdf file during the test.(Loca-

tion for storing the protocols. / p. 24)

Currently the protocols are available in German or English only.

The language can be set under Configuration ->Technical in the service menu.(Language

selected for the protocols / p. 23)

Tools, text and auxiliary means 0

You need the following tools, test and auxiliary means for the acceptance test (the mate-

rial numbers are located in SPC) (Tab. 1 / p. 4):

Tab. 1 Tools, text and auxiliary means

Name

Weight: approx. 135 kg for weighing down the table

- Tape measure, 100 cm

Angle support for set of phantoms

Phantom support1

20 cm water phantom

30 cm water phantom

Wire phantom

Wire phantom_100

Slice thickness phantom

Support for low-contrast phantom

Low-contrast phantom

CCR combi phantom

Dosimeter Dali CT, WK92 or DIADOS

CT measurement chamber with cable and holder

Inclinometer

X-ray film AGFA STRUCTURIX D7DW 13 x 18 cm

Common CT Systems CT00-000.820.03.02.02 Page 4 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

General information 5

1. The phantom support is part of the 'Sliding Gantry' option. It is not required

for standard configurations.

CAUTION [ hz_serdoc_F13G10U01M01 ]

Poor image quality through wrong adjustment values may be cre-

ated during tune up.

Risk of misalignment!

¹ Only phantoms delivered with the CT system may be

used for system adjustments.

¹ The water phantom has to have the same temperature as

the examination room.

Location of identification labels 0

Refer to the document "Labeling" in the System Owner manual.

Informing the expert 0

We recommend that you inform the expert in a timely manner about the date planned for

the acceptance test.

Advantages:

• Timely coordination with the acceptance testing of constructional radiation protection,

possible repeat tests are eliminated.

• The customer can work with the CT system earlier than planned.

When is an acceptance test required? 0

An acceptance test is required when

• a new CT system is installed

• a CT system changes sites

• a CT system changes operators

Siemens AG CT00-000.820.03.02.02 Page 5 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

6 General information

Tab. 2 Acceptance test

Test positions 1

High-contrast resolution

Low-contrast resolution

Light localizer position

Tilting the slice plane

Positioning the table

Dose measurements

X-ray tube voltage

Slice thickness

Event

Homogeneity

Dose profile

Water value

Pixel noise

Initial installation X X X X X X X X X X X X

Change in operator X X X X X X X X X X X X

1. X = test is mandatory

When is a partial acceptance test required? 0

A partial acceptance is required after

• Repairs, replacement of parts, new adjustments,

The subsequent constancy test is out of spec's.

• Changing the operating parameters/charcteristics of a CT system

Tab. 3 Partial acceptance test

Test positions 1

High-contrast resolution

Low-contrast resolution

Light localizer position

Tilting the slice plane

Positioning the table

Dose measurements

Repair

X-ray tube voltage

Replacement

Slice thickness

Homogeneity

Dose profile

Water value

New adjustment

Pixel noise

Light beam projector X

Tilt drive

Tilt sensor X

Tilt display

Table drive

X

Table travel acquisition

Collimators

Collimator drive X X X

Collimator control

Common CT Systems CT00-000.820.03.02.02 Page 6 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

General information 7

Test positions 1

High-contrast resolution

Low-contrast resolution

Light localizer position

Tilting the slice plane

Positioning the table

Dose measurements

Repair

X-ray tube voltage

Replacement

Slice thickness

Homogeneity

Dose profile

Water value

New adjustment

Pixel noise

X-ray Tube Unit X X X

DMS module X X X

DMS X X X X X X

Changing the operating

X X X X X X X X X

parameters/characteristics

1. X = test is mandatory

Determining reference values 0

When putting a new CT system into operation or a component of the CT system, accesso-

ries or the test equipment that could change the test results, an initial constancy test has

to be performed directly after the acceptance test or status test that showed satisfactory

characteristics of the standard functions. The purpose of the initial constancy test is to

establish a new reference value (or values) for the parameter(s) tested.

Siemens AG CT00-000.820.03.02.02 Page 7 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

8 General information

Safety notes 0

WARNING [ hz_serdoc_F13G01U12M01 ]

Failure to observe the guidelines specified in this document may

lead to serious injury or loss of life.

Risk of accident and/or injury!

¹ The guidelines contained in this document have to be

strictly followed.

Carefully read through the following instructions as well as the newest version of the

• General Safety Notes (TD00-000.860.01 / General Safety Notes)

• Read through Product- specific safety notes (CT02-023.860.01 / Product-specific

safety notes)

carefully prior to working with the CT system.

Protection against electrical voltages 0

WARNING [ hz_serdoc_F13G01U13M02 ]

High voltages and/or mechanical movements (e.g. gantry rotation)

may lead to accidents and injuries when opening system covers.

Risk of accident and injury!

¹ Only authorized service personnel is allowed to open

system covers.

Radiation Safety 0

CAUTION [ hz_serdoc_F13G09U01M01 ]

Not following X-rays protective regulations may lead to radiation

exposure to you and/or other persons.

Risk of radiation exposure!

Observe radiation protection regulations when X-rays are

switched on, e.g. :

¹ Never work inside the gantry room.

¹ Do not leave the system unattended.

¹ Make sure there is no one inside the gantry room.

¹ Make sure that no person can enter the gantry room

unnoticed (e.g. lock doors if necessary).

Common CT Systems CT00-000.820.03.02.02 Page 8 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Information for Acceptance Testing 9

3-

Use of test phantoms

2Information for Acceptance Testing

• The test phantoms are attached to the angle bracket at the head end of the CT patient

table.

NOTE In case the 'Sliding Gantry' option is installed, the test phantoms

are attached to phantom holder 478022K1130.

The phantom holder is located on the tabletop of the patient table.

As counterbalance weight, insert the CCR body phantom opposite

the holder.

You can adjust the height of the phantom holder.

• The water, slice thickness and wire phantom can be combined into a phantom set.

In addition, the low-contrast phantom can be mounted to the wire phantom via an

adapter ring.

• For all measurements, the phantom set has to be centered in the measurement field

and the gantry has to be fully upright.

• If the test phantoms do not include a serial number, identify them retroactively.

The identification allows for identifying the test means for subsequent constancy tests.

Siemens AG CT00-000.820.03.02.02 Page 9 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

10 Information for Acceptance Testing

Documenting the test results 0

P • Enter the results of the acceptance test into the respective test protocol:

• The documentation of the acceptance test also includes pictures of the test bodies, the

test film of the measurements of the dose profile as well as the acceptance report on

film.

To generate the film documentation, use the camera function in the QUALITY platform.

• The respective Siemens office has to be keep the entire acceptance test documenta-

tion on file for 10 years.

A copy of the filled out test protocol has to be given to the operator of the X-ray

equipment and filed in the Owner Manual.

Common CT Systems CT00-000.820.03.02.02 Page 10 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Preparations for the Acceptance Test 11

4-

Selecting the test routines

3Preparations for the Acceptance Test

Test since VB20

1. Click the IEC ACCEPTANCE function in the QUALITY platform.

2. Follow the program instructions Click on the solid circle to select all measurements.

Tab. 4 Circle selection (solid = select all, empty = select nothing, half-moon = select default)

Fig. 1: Selection of tests

3. Start the individual tests with GO.

4. As the first step, the tester has to enter his name and the serial numbers of the test

phantoms.

Fig. 2: Enter the tester's name and the phantom serial numbers

Siemens AG CT00-000.820.03.02.02 Page 11 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

12 Preparations for the Acceptance Test

5. Follow the program instructions

Instructions on how to position the phantoms are located under (Preparations for the

phantoms / p. 14)

The description for each individual test is located in the section on(Description of the

test functions / p. 16)

Test with software versions < VB20

1. Click the ACCEPTANCE function in the QUALITY platform.

2. Follow the program instructions Select all possible measurements. The following mea-

surements are required:

- Light marker

- External light marker

- Sag / Cor. light marker

- Prev. Image Pos.

- Slice

- Homogeneity

- Noise

- MTF

- Low Contrast

- Table Pos.

- Dose Profile

- Dose

- CTDIw Body

- CTDIw Head

- Gantry tilt:

3. Start the individual tests with GO and end them with DONE . The description for each

individual test is located in the section on(Preparations for the phantoms / p. 14)

4. Call the following individual functions, one after the other: ’Dose, TopoDose, DosePro-

file and GantryTilt’ . They are not included under ACCEPTANCE.

5. Follow the program instructions The description for each individual test is included in

the sections "Measuring the dose in the system axis", "Measuring the topogram dose"

and "Measuring the dose profile."

Common CT Systems CT00-000.820.03.02.02 Page 12 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Preparations for the Acceptance Test 13

Layout of the Quality IEC acceptance platform (since VB20) 0

Fig. 3: Quality Acceptance Platform in SOMARIS/5

Siemens AG CT00-000.820.03.02.02 Page 13 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

14 Preparations for the Acceptance Test

Preparations for the phantoms 0

Fig. 4: Phantom set

Pos. 1 Holder

Pos. 2 Water phantom

Pos. 3 Slice phantom

Pos. 4 Wire phantom

Pos. 5 Low-contast-phantom or Allignment-phantom

CAUTION In addition you will need the 30 cm water phantom for the IEC ac-

ceptance test.

¹ Otherwise, the water value, homogeneity, and noise will

not be determined correctly.

1. Combine the water, slice thickness, wire and low-contrast phantom into a test phantom

set.

2. Set the gantry tilt to 0 degree (gantry is fully upright)

3. Place a weight of approx. 135 kg onto the tabletop of the patient table.

NOTE Item number 3 is omitted when the 'Sliding Gantry' option is in-

stalled.

4. Position the test phantom set in the measurement field.

Without the 'Sliding Gantry' option:

Common CT Systems CT00-000.820.03.02.02 Page 14 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Preparations for the Acceptance Test 15

- Move the CT table up to 145 mm (display)

¹ The phantom set must be centered in the measurement field and cannot be

tilted downward.

With the 'Sliding Gantry' option:

- If necessary, turn the height adjustment of the phantom holder.

¹ The phantom set must be centered in the measurement field and cannot be

tilted downward.

5. Switch the light localizer on.

6. Position the slice thickness phantom in the measurement field.

- Test the position of the phantom:

¹ The light band of the inside light markers has to be centered exactly above the

points of intersection of the re- ference markers on the phantom.

7. Follow the additional program instructions.

8. Control the results of each sub-measurement to ensure that they are within the toler-

ance margin:

NOTE The test results with the acceptable tolerance margins are shown

in the result window. After you completed the test run, the image

of a condensed test protocol is shown. The test protocol also in-

cludes the tolerances, as well as the markers (< / >) for falling be-

low or exceeding the tolerance margins.

Siemens AG CT00-000.820.03.02.02 Page 15 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

16 Description of the Acceptance Test

5-

Description of the test functions

4Description of the Acceptance Test

PATIENT positioning accuracy 0

The correlation of the axial PATIENT positioning light and scan plane is tested by posi-

tioning and scanning a thin absorber.

Test of external and sag. / Cor. light marker

1 2

Fig. 5: Phantom position after the measurement

Pos. 1 Correct phantom position

Pos. 2 Incorrect phantom position

The test phantom set is centered in the measurement field. It cannot be tilted downward.

The slice thickness phantom is positioned in the measurement field so that the light band

of the inner light markers is exactly centered above the intersection points of the reference

markers on the phantom. A measurement is made and the position of the test phantom in

the slice plane is assessed.

The position of the phantom is correct when the long and short bar "1/Evaluation of the

phantom positon after the measurement" are positioned one above the other. If the long

bar can be seen to the left of the short bar "2/Evaluation of the phantom position after the

measurement", the CT table (refer to note) has to be shifted by 1 mm with FEED IN prior

to each new measurement. If the long bar is shown on the right of the short bar, then

move the table with FEED OUT by one millimeter before each new measurement.

The deviation of the light marker from the slice plane results from the sum of the displace-

ment steps of the table (refer to note) that were required to position the phantom correctly

in the slice plane.

Common CT Systems CT00-000.820.03.02.02 Page 16 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Description of the Acceptance Test 17

NOTE Is the 'Sliding Gantry' option installed, the gantry is shifted accord-

ingly.

Preview Image Position 0

Position the quality phantom so that the light marker cuts across the front of the phantom.

The respective mode is loaded and the topogram is started.

A (green line) is displayed in the topogram that should be pulled to the center of the slice

thickness phantom.

Fig. 6: Preview Image Position

Subsequently the scan is generated and the slice position is checked. It may be neces-

sary to move the table in our out to obtain the optimal slice position(refer to the

image(Fig. 5 / p. 16)).

Siemens AG CT00-000.820.03.02.02 Page 17 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

18 Description of the Acceptance Test

Slice - TOMOGRAPHIC SECTION THICKNESS 0

The TOMOGRAPHIC SECTION THICKNESS is evaluated by measuring the width of the

image of one or more ramps of suitable material where the ramp(s) intersect with the scan

plane. The width is defined as the FULL WIDTH AT HALF MAXIMUM.

Measuring the slice thickness

The slice thicknesses are checked by using a slice thickness phantom that contains two

aluminum strips L100 mm x B25 mm x H12 mm. To correctly determine the slice thick-

ness, the following prerequisites have to be met with respect to the position of the phan-

tom in the measurement field:

1. The phantom has to be positioned exactly in the Z direction of the slice plane. The Z

position is correct if the long and the short bars lie above one another in the tomogram.

Refer to "1/Evaluation of the phantom position after the measurement" for testing the

position of the light marker.

2. - The two aluminum strips must appear lying horizontally in the tomogram image.

The program tomographs the aluminum strips for each selectable slice thickness and cal-

culates the current slice thickness from the tomograms.

Homogeneity 0

Measuring the homogeneity and the water value

A water phantom is centered in the measurement field. The CT numbers are measured in

five test surfaces in four tomograms each. Each test surface covers approx. 10% (Ø

20mm for 20 cm phantom, Ø 30mm for 30 cm phantom) of the intersecting plane of the

test body.

The maximum absolute value of the difference between the mean CT number of the cen-

tric test surface and the CT numbers of the four peripheral test surfaces is the measure of

inhomogeneity.

NOISE 0

Measuring image element noise, tube voltage

To determine the element noise in the image, a circular test body of 20 cm and 30 cm

diameter is filled with water and centered in the measurement field.

The image element noise is determined on the basis of the standard deviation of the CT

numbers in the differential images from two tomograms of the water phantom that were

scanned one after the other.

Together with MTF, the image element noise is an average measure for low-contrast res-

olution. During this test, the current value of the high tension at the X-ray tube is shown as

well.

Common CT Systems CT00-000.820.03.02.02 Page 18 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Description of the Acceptance Test 19

SPATIAL RESOLUTION (MTF) 0

SPATIAL RESOLUTION is best described by the MODULATION TRANSFER FUNC-

TION curve obtained from the Fourier transform of the point spread function.

NOTICE There are two different phantoms for:

¹ For IEC acceptance “wire in plastic”

¹ For older systems “wire in air” .

Measuring high-contrast resolution

The spatial resolution at high contrast is determined by an assessment of the modulation

transfer function (MTF). A wire phantom is used with special evaluation software for this

purpose.

Through the introduction of the quality acceptance test according to IEC 61223-3-5, the

system offers two phantoms with different wire sections: Embedded wire in air (DIN

6868-53) and embedded wire in plasticIEC 61223-3-5). The nominal values for wire in air

represent the theoretical system values better than any other. The nominal values for

wire in plastic are somewhat lower due to the larger systematic measurement errors

caused by the image noise in plastic. However both phantoms are equally suitable for

quality assurance.

The MTF measurement is performed in the standard and the high resolution mode.

Depending on the system, evaluation is for 2 or 4 images each (slices).

The resolution is represented in line pairs per centimeter ( LP/cm ) for 50% MTF, 10%

MTF and 2% MTF.

Determination of the contrast scale (CT value of air)

NOTE This measurement is not required for the acceptance test in Ger-

many!

The contrast scale CS states the change of the effective attenuation coefficient of a

water-equivalent material that is required to change the mean CT number of this material

by 1.

Two density values are required for determining the contast scale. Only an air scan is per-

formed for this. As a second value, the water value is taken over from previous measure-

ments.

Table Pos. 0

Positional accuracy of the PATIENT SUPPORT includes both longitudinal positioning and

backlash evaluation.

The accuracy of longitudinal PATIENT SUPPORT positioning is evaluated by moving the

PATIENT SUPPORT a defined distance in one direction and confirming the distance trav-

elled.

Siemens AG CT00-000.820.03.02.02 Page 19 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

20 Description of the Acceptance Test

The accuracy of moving the PATIENT SUPPORT in one direction and moving it back to

the starting position is known as backlash.

Test of table positioning

Test run with and without the 'Sliding Gantry' option:

A weight of 135 kg is positioned on the tabletop of the CT patient table. After a marker is

affixed to the stationary and moving part of the upper part of the table, the tabletop is

moved program-controlled by a defined distance horizontally in both directions.

The display is not initalized to "0".

The tabletop moves:

1. <--------300 mm-------- continuously in the direction of

the gantry

2. <--------300 mm-------- Continuously away from the gan-

try

3. <--------300 mm-------- Continuously away from the gan-

try

4. <--------300 mm-------- continuously in the direction of

the gantry

5. <--------300 mm-------- In steps of 10 mm

6. <--------300 mm-------- In steps of 10 mm

7. <--------300 mm-------- In steps of 10 mm

8. <--------300 mm-------- In steps of 10 mm

The actual distance moved is measured in each case at the table with a tape measure.

The exact measurement value (e.g. 300.5) has to be entered into the program platform.

The program takes this value and computes the difference between the actually driven

and electronically displayed travel path.

Dose Profile 0

Measuring the dose profile

The dose profile is measured in air with an X-ray film without foil. The values of the dose

profiles (full width at half maximum) refer to the decay of the axial dose function to 50%.

The base width of the dose profile in the sum of the full width at half maximum and the

flank width. The flank width is a constant size for a given focal spot size and system

geometry. For the small focal spot it is 1.9 ± /0.2 mm and for the large focal spot it is 2.8 ±

/0.2 mm.

The following relationship results

¹ Full width at half maximum = base width - flank width

Common CT Systems CT00-000.820.03.02.02 Page 20 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Description of the Acceptance Test 21

NOTE The base width closely aproximates the width of the film blacken-

ing, if the film is not too over or underexposed.

The film is positioned in the system axis perpendicular to the central ray. As the film car-

rier, a CCR combination phantom is used. The upper edge of this phantom is moved into

the center of rotation of the measurement phantom at a tolerance margin of 5 mm. The

film is shifted in Z direction before each exposure with changed slice thickness.

After the film has been developed, the base width (width of filme blackening) each individ-

ually exposed strip is measured in the center and entered manually into the input field.

For that purpose, call the DOSE PRO/EVALUATE function in the platform.

Dose 0

Measuring the dose in the axis of rotation

A dose measurement chamber is mounted to the tabletop. The dose measurement cham-

ber is positioned centrally in axial direction in the system axis so that the slice plane runs

through the center of the chamber. The measurement chamber should be aligned to the

center of rotation with a tolerance margin of 5 mm ( function ROI ). The measurement

chamber is connected with a suitable dose meter

The longitudinal dose product DLP ( mGy x cm ) shown by the dose meter after a scan

should be entered by hand in the input field.

NOTE For 80 kV, the measurement is performed in the head mode. The

body mode is used for 120/130/140 kV.

The program computes the dose in the system axis according to the following formula:

Fig. 7: Dose in the system axis (N = number of slices)

Measuring the topogram dose

A dose measurement chamber is mounted to the tabletop. The measurement chamber

should be aligned to the center of rotation with a tolerance margin of 5 mm ( function ROI

). Subsequently, position the chamber in the axial direction to the measurement field so

that the overview scan (topogram) is fully irradiated. The measurement chamber is con-

nected with a suitable dose meter

The longitudinal dose product DLP ( mGy x cm ) shown by the dose meter after a topo-

gram should be entered by hand in the input field.

Siemens AG CT00-000.820.03.02.02 Page 21 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

22 Description of the Acceptance Test

The program computes the topogram dose according to the fomula:

Fig. 8: Topogram dose

CTDIW Head and CTDIW Body 0

Test Procedure

CTDIW for the typical axial head and body conditions of operation.

Position CTDI Head (16 cm Plexi) / Body (32 cm Plexi) phantom in the center of the scan

field.

Position the phantom such that the inner light marker hits the engraved marking.

Click GO when ready.

Gantry tilt: 0

Inclination of the slice plane

This characteristic describes the angle that the slice plane forms with the vertical. This

angle is established by tilting the exposure device by a defined angle from the vertical

position.

What is being checked is the deviation between the mechanical and elecronic display at a

tilt angle of plus/minus 30° (Spirit: plus/minus 15°).

The mechanical measurement is performed with an inclination water level at the housing

of the exposure device.

The tilt angle measured with the inclination water level is entered by hand into the input

field of the platform. The program uses this value for computing the difference in angles.

NOTE The tilt shown at the exposure device cannot deviate by more than

+/- 2° from the measured value.

Common CT Systems CT00-000.820.03.02.02 Page 22 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Acceptance Reports 23

6-

Language selected for the protocols

5Acceptance Reports

Using the configuration under technical, the language for the protocols is selected in the

service menu.

Fig. 9: Select German or English as the protocol language

NOTICE Currently, only protocols in German or English are possible.

¹ If you need a protocol in the native language of the coun-

try, the regional unit should have it translated.

Additional languages will be available with subsequent software versions.

Siemens AG CT00-000.820.03.02.02 Page 23 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

24 Acceptance Reports

Location for storing the protocols. 0

During the acceptance test the protocols are automatically generated together with the

results of the measurement and stored as pdf files.

The path for the protocols is:

C:\Somaris\service\pdf\report\pdfreport

Fig. 10: Path of pdf protocols

The Explorer is selected via Utilities -> Escape to OS.

Common CT Systems CT00-000.820.03.02.02 Page 24 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Acceptance Reports 25

Fig. 11: Run the Windows Explorer via Utilities

Siemens AG CT00-000.820.03.02.02 Page 25 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

26 Acceptance Reports

Printing out protocols. 0

If the customer has a network printer with connection to the CT system, the protocols may

be printed out with this printer.

If not, the protocols can be printed with the help of the Explorer from C:\Somaris\ser-

vice\pdf\report\pdfrepor and copied to one or several floppies.

Take the floppies to a PC with a printer and print out the files.

Common CT Systems CT00-000.820.03.02.02 Page 26 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Changes to Previous Version 27

7-

6Changes to Previous Version

Section Revision Reason

(CR 050732)

3 Valid since VB20

CTTU-05-0015

Siemens AG CT00-000.820.03.02.02 Page 27 of 28 Common CT Systems

Medical Solutions 09.05 CS CS 22

28 Index

8-

H

7Index

hz_serdoc_F13G01U12M01 . . . . . . . . . 8

hz_serdoc_F13G01U13M02 . . . . . . . . . 8

hz_serdoc_F13G09U01M01 . . . . . . . . . 8

hz_serdoc_F13G10U01M01 . . . . . . . . . 5

Common CT Systems CT00-000.820.03.02.02 Page 28 of 28 Siemens AG

09.05 CS CS 22 Medical Solutions

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Instructor Clinical Evaluation ToolsDocumento11 pagineInstructor Clinical Evaluation ToolsJoric MagusaraNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Scalar Wave Morphogenetic Field Mechanic PDFDocumento135 pagineScalar Wave Morphogenetic Field Mechanic PDFMokhtar Mohd100% (7)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 1000 Calorie ChallengesDocumento25 pagine1000 Calorie ChallengesFrancesco Iavarone100% (3)

- Pest Control Risk Assessment Indoor and OutdoorDocumento72 paginePest Control Risk Assessment Indoor and OutdoorarmkarthickNessuna valutazione finora

- Aubf Quiz 2Documento8 pagineAubf Quiz 2Gene Narune GaronitaNessuna valutazione finora

- Enoxaparin (Lovenox)Documento1 paginaEnoxaparin (Lovenox)ENessuna valutazione finora

- Female Hot Spots Extragenital Erogenous Zones.4Documento8 pagineFemale Hot Spots Extragenital Erogenous Zones.4Shilpa VijeeshNessuna valutazione finora

- Intake and OutputDocumento3 pagineIntake and Outputtina100% (1)

- Ilovepdf Merged PDFDocumento134 pagineIlovepdf Merged PDFhelalNessuna valutazione finora

- NAGC 0910 Tulsa Final BTDocumento40 pagineNAGC 0910 Tulsa Final BTlparliNessuna valutazione finora

- CHF CSDocumento4 pagineCHF CSLaren CyrNessuna valutazione finora

- Note Regarding Retiring DoctorsDocumento3 pagineNote Regarding Retiring DoctorsnamankumaragrawalNessuna valutazione finora

- Ovarian CancerDocumento71 pagineOvarian CancerAyuni SallehNessuna valutazione finora

- Speaker Dr. Annisa Tridamayanti, SPJP, Fiha Sesi 5Documento3 pagineSpeaker Dr. Annisa Tridamayanti, SPJP, Fiha Sesi 5thiadinaNessuna valutazione finora

- Laboratory Test Report: Test Name Result Biological Reference Interval Fasting Plasma Glucose: 102Documento3 pagineLaboratory Test Report: Test Name Result Biological Reference Interval Fasting Plasma Glucose: 102Ramesh KumarNessuna valutazione finora

- Global Developmental DelayDocumento2 pagineGlobal Developmental DelayAtlerNessuna valutazione finora

- Abnormality in Little Miss SunshineDocumento8 pagineAbnormality in Little Miss SunshineLaurie OuNessuna valutazione finora

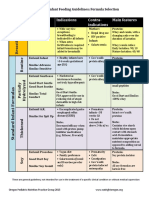

- Formula Selection OPNPGDocumento2 pagineFormula Selection OPNPGRina PratiwiNessuna valutazione finora

- Investigations in Rheumatology: What's New?Documento10 pagineInvestigations in Rheumatology: What's New?i can always make u smile :DNessuna valutazione finora

- Arya Maheswara - Stroke InfarkDocumento17 pagineArya Maheswara - Stroke InfarkdianarahimmNessuna valutazione finora

- Blood Bank GuidelinesDocumento10 pagineBlood Bank Guidelinesmanjinder singhNessuna valutazione finora

- Top 50 Global Stem Cell InfluencersDocumento25 pagineTop 50 Global Stem Cell InfluencersranasoftNessuna valutazione finora

- Patient AssesmentDocumento18 paginePatient AssesmentMarian Ioan-LucianNessuna valutazione finora

- Nausea and Vomiting in Adolescents and AdultsDocumento30 pagineNausea and Vomiting in Adolescents and AdultsPramita Ines ParmawatiNessuna valutazione finora

- Gillentine Alyssa 0362390 11 5 2020Documento2 pagineGillentine Alyssa 0362390 11 5 2020api-529380616Nessuna valutazione finora

- (Final Proposal) 20181220 Beauttah Migiro Akuma - Research Proposal - Right To Health - Version 1.0Documento14 pagine(Final Proposal) 20181220 Beauttah Migiro Akuma - Research Proposal - Right To Health - Version 1.0Brian BeauttahNessuna valutazione finora

- Computer Addiction Power Point PresentationDocumento24 pagineComputer Addiction Power Point PresentationGee A50% (4)

- Acid Base WorkshopDocumento71 pagineAcid Base WorkshopLSU Nephrology Transplant Dialysis AccessNessuna valutazione finora

- tmpD1AB TMPDocumento9 paginetmpD1AB TMPFrontiersNessuna valutazione finora

- GBSDocumento19 pagineGBSRahma ArsellaNessuna valutazione finora