Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sterility Test: Application Field

Caricato da

Sidd Salvi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaTitolo originale

40025_eurofins_biolab_ctp_laboratories_dispositivi_medici_test_sterilita

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaSterility Test: Application Field

Caricato da

Sidd SalviCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

to the characteristics of the medical device, such

Sterility Test as bacteriostatic/fungistatic activity, employing

removal of microorganisms might be necessary.

Application field At the end of the incubation period, media is

examined for macroscopic evidence of microbial

The sterility test is used to determine if a medical growth. If no evidence of microbial growth is found,

device is sterile. the product to be examined complies with the test

for sterility. If evidence of microbial growth is found

Interests the product to be examined does not comply with

Manufacturers are requested to demonstrate the the test for sterility, unless it can be clearly

sterility of theirs products. Product items produced demonstrated that the test was invalid for causes

under standard manufacturing conditions in unrelated to the product to be examined.

accordance with the requirements for quality

systems for medical devices may, prior to Normative references

sterilization, have microorganisms on them, albeit

EN ISO 11737-2:2009

in low numbers. Such product items are nonsterile.

E.P. 7th edition <2.6.1>

The purpose of sterilization processing is to

inactivate the microbiological contaminants and USP 34–NF 29 <71>

thereby transform the nonsterile items into sterile

ones. Exclusion from test

The normative EN ISO 11737-2:2000 is not

Principle of the test applicable to:

A sterile product item is one which is free of viable sterility testing for routine release of

micro-organisms. A nonsterile device burdens product that has been subjected to a

micro-organisms on it and these can easily grow in sterilization process,

an appropriate culture medium at an appropriate performance of a pharmacopoeial test for

temperature. sterility,

culturing of biological indicators, including

Test procedure inoculated products

The method of performing the test of sterility can

be broadly divided into two general categories: Expression of results

Direct immersion of product: Pass/Failed – Sterile/Non sterile

direct immersion is the preferred method of In case of contamination, the evaluation of

performing the test of sterility for medical devices. microbial contamination can be performed.

With direct immersion, the product unit or SIP

(defined part of a medical device product that is Turn around time

tested) is placed aseptically into a container of 3 weeks.

growth medium and incubated. A sufficient amount

of growth medium should be used to achieve Number of products/Quantity necessary to the

contact between the growth medium and the whole analysis

of the product unit or SIP.

The number of products necessary to the analysis

Removal of microorganisms from product: depends on the aim of the sterility test.

when it is not possible to use direct immersion due For routine control usually 20 samples are required.

Potrebbero piacerti anche

- Bacteriology Methods for the Study of Infectious DiseasesDa EverandBacteriology Methods for the Study of Infectious DiseasesNessuna valutazione finora

- 9433 - Sterlity Test Medical Devices - Web ReadyDocumento4 pagine9433 - Sterlity Test Medical Devices - Web ReadyZETTYNessuna valutazione finora

- Bacterial Identification & Source Indication of ContaminantsDocumento6 pagineBacterial Identification & Source Indication of Contaminantsstuffy1984Nessuna valutazione finora

- WHAT NOT TO DO AFTER PEST CONTROL SPRAYSDa EverandWHAT NOT TO DO AFTER PEST CONTROL SPRAYSNessuna valutazione finora

- Sterility Testing - Essential Things You Must Know: A White PaperDocumento9 pagineSterility Testing - Essential Things You Must Know: A White PaperJeevanend ArumugamNessuna valutazione finora

- Handbook of Microbiological Criteria for FoodsDa EverandHandbook of Microbiological Criteria for FoodsNessuna valutazione finora

- Sterility Testing - Essential Things You Must Know: A White PaperDocumento9 pagineSterility Testing - Essential Things You Must Know: A White PaperSonia UrbachNessuna valutazione finora

- Pharmaceutical Sterility TestingDocumento6 paginePharmaceutical Sterility TestingArsalan ZaiNessuna valutazione finora

- 62 The Basics of Bioburden TestingDocumento2 pagine62 The Basics of Bioburden Testinghitham shehataNessuna valutazione finora

- Bioburden ControlDocumento48 pagineBioburden ControlSaint Tyagi100% (2)

- 18 3ppsandle 7 EJPPSDocumento7 pagine18 3ppsandle 7 EJPPSAthul KochakkanNessuna valutazione finora

- Whitepaper Benefits DNA Sequencing Microbial Identification Pharma Analytics June 2022Documento5 pagineWhitepaper Benefits DNA Sequencing Microbial Identification Pharma Analytics June 2022JohnNessuna valutazione finora

- Bioburden:The Burden On Our Biological OperationsDocumento48 pagineBioburden:The Burden On Our Biological OperationsSurendar Kesavan100% (1)

- CAP 1116 USP Control de AmbientesDocumento14 pagineCAP 1116 USP Control de AmbientesCamilo Florez100% (1)

- Usp 1035 - Biological Indicators For SterilizationDocumento4 pagineUsp 1035 - Biological Indicators For SterilizationoktaNessuna valutazione finora

- 61 Microbiological Examination of Nonsterile Products Microbial Enumeration TestsDocumento5 pagine61 Microbiological Examination of Nonsterile Products Microbial Enumeration TestsChrist FarandyNessuna valutazione finora

- Sterility Test Failure Investigations: Peer Review: MicrobiologyDocumento8 pagineSterility Test Failure Investigations: Peer Review: MicrobiologyAyman EshraNessuna valutazione finora

- 0056-0060 (61) Microbiological Examination of Nonsterile Products - Microbial Enumeration TestsDocumento5 pagine0056-0060 (61) Microbiological Examination of Nonsterile Products - Microbial Enumeration TestsMerrene Bright Divino JudanNessuna valutazione finora

- Investigating SterilityTest FailuresDocumento16 pagineInvestigating SterilityTest FailuresMahesh_ChokshiNessuna valutazione finora

- General Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseDocumento5 pagineGeneral Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseSuman Katteboina0% (1)

- 260 Ijar-8550 3Documento13 pagine260 Ijar-8550 3esraa asemNessuna valutazione finora

- Indicators, Disinfection and Sterilization SG 092019Documento11 pagineIndicators, Disinfection and Sterilization SG 092019Meena CtNessuna valutazione finora

- Usp 61 Microbiological Examination of Nonsterile Products Microbial Enumeration TestsDocumento5 pagineUsp 61 Microbiological Examination of Nonsterile Products Microbial Enumeration TestsyuniarwindiNessuna valutazione finora

- Introduction To Pharmaceutical MicrobiologyDocumento35 pagineIntroduction To Pharmaceutical MicrobiologylorrainebarandonNessuna valutazione finora

- Management Microbiological Control ProgramDocumento14 pagineManagement Microbiological Control ProgramNiken Diaz TantriNessuna valutazione finora

- Harmonized Microbial Limits Testing Val... Strategies - IVT - GMP - MicrobiologyDocumento9 pagineHarmonized Microbial Limits Testing Val... Strategies - IVT - GMP - MicrobiologyRouag AbdelkarimNessuna valutazione finora

- Remington Chapter 40 SterilizationDocumento26 pagineRemington Chapter 40 SterilizationAndhika Bintang Mahardhika50% (2)

- Usp42-Nf37 205Documento7 pagineUsp42-Nf37 205Mohamed HassanNessuna valutazione finora

- 4 Vol. 1 10 IJPSR2010 Review 4Documento11 pagine4 Vol. 1 10 IJPSR2010 Review 4amgranadosvNessuna valutazione finora

- General Chapters - 1035 - Biological Indicators For SterilizationDocumento6 pagineGeneral Chapters - 1035 - Biological Indicators For SterilizationKoeys KuswandaNessuna valutazione finora

- An Audit Approach To Address Microbial C PDFDocumento39 pagineAn Audit Approach To Address Microbial C PDFOmar Faruq100% (1)

- An Assignment On Methods of Sterilization: Submitted ToDocumento35 pagineAn Assignment On Methods of Sterilization: Submitted ToShahin Rahman 112700gmail.comNessuna valutazione finora

- Microbiological Examination of Nonsterile Products Microbial Enumeration Tests GoodDocumento6 pagineMicrobiological Examination of Nonsterile Products Microbial Enumeration Tests Goodmingsu1156Nessuna valutazione finora

- BBS3010 Molecular and Applied Microbiology Module: Industrial MicrobiologyDocumento24 pagineBBS3010 Molecular and Applied Microbiology Module: Industrial MicrobiologyJyothi MnNessuna valutazione finora

- 〈1229.3〉 MONITORING OF BIOBURDENDocumento3 pagine〈1229.3〉 MONITORING OF BIOBURDENWendy Joanna Zumba AlvaradoNessuna valutazione finora

- Bioburden Considerations in Equipment-Cleaning Validation: Did Not Include Swab Sampling of The Transfer LinesDocumento20 pagineBioburden Considerations in Equipment-Cleaning Validation: Did Not Include Swab Sampling of The Transfer LinesWa Ode FasridaNessuna valutazione finora

- Bioburden USP PDFDocumento4 pagineBioburden USP PDFKatyaSNNessuna valutazione finora

- USP 61 MLT of Non Sterile ProductsDocumento6 pagineUSP 61 MLT of Non Sterile ProductsMasood SabirNessuna valutazione finora

- 61 Microbiological Examination of Nonsterile Products Microbial Enumeration TestDocumento6 pagine61 Microbiological Examination of Nonsterile Products Microbial Enumeration TestVanNessuna valutazione finora

- 41 Sterilization Validation Key Steps To Dose Auditing 1Documento2 pagine41 Sterilization Validation Key Steps To Dose Auditing 1Vivian CerdasNessuna valutazione finora

- Establishment of Biocidal Activity Evaluation Study Protocol in Healthcare Facility For Routine Monitoring of Antibacterial Power of DisinfectantsDocumento9 pagineEstablishment of Biocidal Activity Evaluation Study Protocol in Healthcare Facility For Routine Monitoring of Antibacterial Power of DisinfectantsHammam HafidzurahmanNessuna valutazione finora

- 2 Basic Microbiological TestsDocumento6 pagine2 Basic Microbiological TestsMuhamadNabilFikriJamaluddinNessuna valutazione finora

- Bioprocess Technology IDocumento17 pagineBioprocess Technology IAnonymous S6jmQXHY100% (1)

- Cleaning Validation in Pharmaceutical IndustriesDocumento10 pagineCleaning Validation in Pharmaceutical Industriessamia khanNessuna valutazione finora

- Microbiological Enviromental MonitoringDocumento34 pagineMicrobiological Enviromental MonitoringAna Dulce100% (1)

- Bioburden Test, Microbiological Enumeration Test, Bacterial Endotoxins Test, Sterility Test and Microbial Testing of Water (Total Microbial Count Test and Test For Pathogen)Documento56 pagineBioburden Test, Microbiological Enumeration Test, Bacterial Endotoxins Test, Sterility Test and Microbial Testing of Water (Total Microbial Count Test and Test For Pathogen)Imraan KhanNessuna valutazione finora

- Pharmaceutical Microbiology: Types of TestsDocumento6 paginePharmaceutical Microbiology: Types of TestsKENGERALDNessuna valutazione finora

- Sterilization Indicators 1Documento11 pagineSterilization Indicators 1nusrath siddiquiNessuna valutazione finora

- Aptitud Capitulo 61Documento6 pagineAptitud Capitulo 61JuanNessuna valutazione finora

- Comparativa Terragene y 3MDocumento12 pagineComparativa Terragene y 3MBlackHorse13100% (2)

- Principal Investigator: Dr. Nutan Kaushik: Pharmaceutical & Biological AnalysisDocumento8 paginePrincipal Investigator: Dr. Nutan Kaushik: Pharmaceutical & Biological AnalysisRaviteja BNessuna valutazione finora

- 〈61〉 Microbiological Examination of Nonsterile Products Microbial Enumeration TestsDocumento6 pagine〈61〉 Microbiological Examination of Nonsterile Products Microbial Enumeration Testsahmed sonyNessuna valutazione finora

- 394 in Process Revision 1115 Bioburden Control of Nonsterile Drug Substances and ProductsDocumento9 pagine394 in Process Revision 1115 Bioburden Control of Nonsterile Drug Substances and Productsdeepanmb007Nessuna valutazione finora

- 61 Microbiological Examination of Nonsterile Products: Microbial Enumeration TestsDocumento5 pagine61 Microbiological Examination of Nonsterile Products: Microbial Enumeration TestsMarianita GonzalezNessuna valutazione finora

- 1.1.09 Tests For SterilityDocumento10 pagine1.1.09 Tests For SterilitySigrid MiNessuna valutazione finora

- Lab 1 Equipment and Biosafety-Dr - MazinDocumento32 pagineLab 1 Equipment and Biosafety-Dr - Mazinحسوني جيموز husuni jimuzNessuna valutazione finora

- Microbial Testing in Support of Aseptic ProcessingDocumento6 pagineMicrobial Testing in Support of Aseptic ProcessingmeghanalandeNessuna valutazione finora

- BioburdenGMPVol12No3 TimSandlepp10-12Documento4 pagineBioburdenGMPVol12No3 TimSandlepp10-12kim_jamjungNessuna valutazione finora

- OpthalmicDocumento6 pagineOpthalmicminhajuljim2000Nessuna valutazione finora

- HWM Rules 2016Documento68 pagineHWM Rules 2016Raja Rao KamarsuNessuna valutazione finora

- Ke Government Gazette Dated 2020 04 09 No 65 PDFDocumento12 pagineKe Government Gazette Dated 2020 04 09 No 65 PDFSidd SalviNessuna valutazione finora

- Annex 1HWMDocumento8 pagineAnnex 1HWMkrpnathNessuna valutazione finora

- Schedule I List of Processes Generating Hazardous Wastes S.No. Processes Hazardous WasteDocumento4 pagineSchedule I List of Processes Generating Hazardous Wastes S.No. Processes Hazardous WasteSidd SalviNessuna valutazione finora

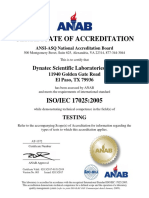

- 1512603584DynatecCertScope-ANAB-V003 Expires 01.31.19 PDFDocumento5 pagine1512603584DynatecCertScope-ANAB-V003 Expires 01.31.19 PDFSidd SalviNessuna valutazione finora

- Ke Government Gazette Dated 2020 04 09 No 65 PDFDocumento12 pagineKe Government Gazette Dated 2020 04 09 No 65 PDFSidd SalviNessuna valutazione finora

- 31 PDFDocumento310 pagine31 PDFSidd SalviNessuna valutazione finora

- Gazette Notification Functional Foods 06-01-2017Documento132 pagineGazette Notification Functional Foods 06-01-2017Dhananjay ThakurNessuna valutazione finora

- 1512603584DynatecCertScope-ANAB-V003 Expires 01.31.19 PDFDocumento5 pagine1512603584DynatecCertScope-ANAB-V003 Expires 01.31.19 PDFSidd SalviNessuna valutazione finora

- Food Analysis by HPLC PDFDocumento1.170 pagineFood Analysis by HPLC PDFrosamir875% (4)

- Quality of Probiotic UF Domiati Cheese Made by Lactobacillus RhamnosusDocumento10 pagineQuality of Probiotic UF Domiati Cheese Made by Lactobacillus RhamnosusSidd SalviNessuna valutazione finora

- ISO Air Quality IntroductionDocumento12 pagineISO Air Quality Introductionmiguem18xNessuna valutazione finora

- Seminar Eap 5Documento32 pagineSeminar Eap 5Hoàng Yến TháiNessuna valutazione finora

- Project Report On e BikesDocumento57 pagineProject Report On e Bikesrh21940% (5)

- Faunus Homebrew PDFDocumento3 pagineFaunus Homebrew PDFPaul FernandezNessuna valutazione finora

- Trinity The Father, The Son and The Holy SpiritDocumento3 pagineTrinity The Father, The Son and The Holy SpiritThomas Lorenz (Fit For Faith Ministries)100% (1)

- Public Procurement Rules 2004Documento35 paginePublic Procurement Rules 2004Mubashir SheheryarNessuna valutazione finora

- Java Programming - Module2021Documento10 pagineJava Programming - Module2021steven hernandezNessuna valutazione finora

- Chapter 18 Metric and Imperial Measures: Scheme of WorkDocumento2 pagineChapter 18 Metric and Imperial Measures: Scheme of WorkrightwayNessuna valutazione finora

- A Muslim Reformist in Communist Yugoslavia The Life and Thought of Husein Äx90 Ozo (Husein Mekic, Sejad) (Z-Library)Documento212 pagineA Muslim Reformist in Communist Yugoslavia The Life and Thought of Husein Äx90 Ozo (Husein Mekic, Sejad) (Z-Library)Raeed IslamNessuna valutazione finora

- ! Warning: Servomotor TestDocumento1 pagina! Warning: Servomotor Testjoku jokunenNessuna valutazione finora

- Safari - 15 Nov 2023 at 8:34 PMDocumento1 paginaSafari - 15 Nov 2023 at 8:34 PMrgk966c275Nessuna valutazione finora

- Education PhilosophyDocumento8 pagineEducation PhilosophyJustine Jerk BadanaNessuna valutazione finora

- People vs. Samson, September 2, 2015Documento5 paginePeople vs. Samson, September 2, 2015Alpha Grace JugalNessuna valutazione finora

- TPHSF Feb 2006Documento8 pagineTPHSF Feb 2006nsidneyNessuna valutazione finora

- Rebrand and Relaunch Hydrox CookiesDocumento9 pagineRebrand and Relaunch Hydrox CookiesAruba KhanNessuna valutazione finora

- Erinnerungsmotive in Wagner's Der Ring Des NibelungenDocumento14 pagineErinnerungsmotive in Wagner's Der Ring Des NibelungenLaur MatysNessuna valutazione finora

- Rudolf Steiner - The Gospel of ST MarkDocumento218 pagineRudolf Steiner - The Gospel of ST Markhumblejoe100% (9)

- Instant Download Developing Management Skills 10th Edition Whetten Test Bank PDF Full ChapterDocumento33 pagineInstant Download Developing Management Skills 10th Edition Whetten Test Bank PDF Full Chapterdonaldvioleti7o100% (9)

- Natelco Vs CADocumento10 pagineNatelco Vs CAcharmdelmoNessuna valutazione finora

- Take The MMPI Test Online For Free: Hypnosis Articles and InformationDocumento14 pagineTake The MMPI Test Online For Free: Hypnosis Articles and InformationUMINAH0% (1)

- Isomers: Constitutional Isomers Stereoisomers Conformational IsomersDocumento6 pagineIsomers: Constitutional Isomers Stereoisomers Conformational IsomersJules BrunoNessuna valutazione finora

- The Oxford Handbook of The Trinity (Introducción)Documento12 pagineThe Oxford Handbook of The Trinity (Introducción)casandraentroya100% (1)

- One Dollar and Eighty-Seven CentsDocumento3 pagineOne Dollar and Eighty-Seven CentsAmna RanaNessuna valutazione finora

- Biotransformation of DrugsDocumento36 pagineBiotransformation of DrugszeepharmacistNessuna valutazione finora

- Marathi Book ListDocumento4 pagineMarathi Book ListGajanan PatilNessuna valutazione finora

- Tesla Roadster (A) 2014Documento25 pagineTesla Roadster (A) 2014yamacNessuna valutazione finora

- Wheel Loader wl56Documento6 pagineWheel Loader wl56Shahzad AliNessuna valutazione finora

- Wed 0945-Avionics Modernization For LegacyDocumento38 pagineWed 0945-Avionics Modernization For LegacygasparferrerNessuna valutazione finora

- Let's DanceDocumento6 pagineLet's DancethierrysteNessuna valutazione finora

- Former UM Soccer Coach Sues University For DefamationDocumento12 pagineFormer UM Soccer Coach Sues University For DefamationNBC MontanaNessuna valutazione finora

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDa EverandSodium Bicarbonate: Nature's Unique First Aid RemedyValutazione: 5 su 5 stelle5/5 (21)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesDa EverandA New Approach to HAZOP of Complex Chemical ProcessesNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- A Chemical Engineer in the Palm Oil Milling IndustryDa EverandA Chemical Engineer in the Palm Oil Milling IndustryNessuna valutazione finora

- Physical and Chemical Equilibrium for Chemical EngineersDa EverandPhysical and Chemical Equilibrium for Chemical EngineersValutazione: 5 su 5 stelle5/5 (1)

- Phase Equilibria in Chemical EngineeringDa EverandPhase Equilibria in Chemical EngineeringValutazione: 4 su 5 stelle4/5 (11)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDa EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlValutazione: 4 su 5 stelle4/5 (4)

- Principles and Case Studies of Simultaneous DesignDa EverandPrinciples and Case Studies of Simultaneous DesignNessuna valutazione finora

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesDa EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNessuna valutazione finora

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Distillation Design and Control Using Aspen SimulationDa EverandDistillation Design and Control Using Aspen SimulationValutazione: 5 su 5 stelle5/5 (2)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Da EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Nessuna valutazione finora

- Fundamentals of Risk Management for Process Industry EngineersDa EverandFundamentals of Risk Management for Process Industry EngineersNessuna valutazione finora

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDa EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNessuna valutazione finora

- Biotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsDa EverandBiotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDa EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillValutazione: 3.5 su 5 stelle3.5/5 (3)

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesDa EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNessuna valutazione finora