Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CICO Plast Super P-190A

Caricato da

ASRAR AHMED KHANCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CICO Plast Super P-190A

Caricato da

ASRAR AHMED KHANCopyright:

Formati disponibili

Concrete Admixture (Plasticisers/WRA)

CICO PLAST SUPER P-190A

Concrete Superplasticiser / High Range Water Reducing Admixture

CICO PLAST SUPER-190A is new Water retaining structures.

generation concrete admixture based on

modified Sulphonated naphthalene Concrete tunnel lining.

formaldehyde and other organic polymers

ADVANTAGES

combining the properties of

superplasticiser with high degree of slump

Improves the workability of concrete

retention characteristics , high range

without increasing water.

water reducer and also acts as

Improves both early and ultimate

waterproofers for concrete, conforms to

strength without increasing cement

IS 9103, ASTM C-494, BS 5075

content and without reducing

USES workability.

Internal friction and thixotrophy of the

CICO PLAST SUPER-190A is used for mix is reduced to a minimum without

producing extremely flowing concrete, the risk of segregation, thus making

pumped concrete, pre-stressed, pre-cast concrete pumpable without formation

high strength and denser concrete as well of nesting.

as in industrial / commercial flooring and Significant water reduction minimizes

floor toppings. This product is most shrinkage crack thereby produces

suitable for Concrete Grade from M10 to close textured impervious high

M35. For higher grade of concrete consult strength concrete with improved

local CICO representative to select durability and surface finish.

suitable CICO product. Useful in most type of concrete above

and below ground subjected to water

pressure and aggressive environment.

APPLICATION Reduces concrete permeability value

At locations with congested and hence ingress of water is reduced

reinforcements, thin slender section

which protects embedded steel

or any other locations, where

improved workability and high against corrosion.

strength is required. Bond strengths of concrete to

reinforcement to steel is also

Pump concreting as it improves the increased considerably.

lubricating properties. Improves both early and ultimate

strength without increasing cement

Roof slabs for both residential as well

as industrial building. content and without reducing

workability. Saves cement (10 – 20%)

Medium to low grade concrete to keeping workability and strength

improve the cohesion. constant.

Concrete Admixture (Plasticisers/WRA)

PRECAUTIONS

COMPATIBILITY

Use CICO PLAST SUPER-190A with other

CICO PLAST SUPER-190A is compatible admixtures such as water reducing and air

with all types of Indian cement. But to entraining agents after testing slump,

get the maximum ultimate beneficial strength, etc.

properties it is advisable to conduct trial Should not be added directly to the dry

mixes before use. cement.

DOSAGE PACKAGING

The optimum does depends on type of Available in 20 Kg, 250 Kg barrel

mix, grade of concrete, cement content

and the desired workability. It is STORAGE

advisable to conduct laboratory or site

CICO PLAST SUPER P190A should be

trials with particular mix to achieve the

Stored in a cool dry place in the

optimum economical dose. As a guide the

temperature range from 5ᵒC to 40ᵒC in

does may vary from 0.4% to 2% by wt. of

sealed condition. Keep away from and

cement.

direct Sun Light

HEALTH & SAFETY

SHELF LIFE

Avoid contact with eyes. Prolonged contact

with bare skin may cause irritation. Wear 18 months

safety goggles and gloves during handling.

TECHNICAL DATA

Form Free flowing liquid

Colour Brown

Specific Gravity 1.15 ± 0.02

Effect on setting time Marginal retardation but well below its

acceptable limit.

Chloride content Nil as per BS 5075 Part 1

pH Value >6

Concrete Admixture (Plasticisers/WRA)

TABLE – I WORKABILITY Vs. DOSAGE (TYPICAL)

DOSE

W/C 3

TYPE OF MIX % CEMENT CONTENT Kg/M SLUMP

RATIO

(w/w)

Control Mix 0 0.55 350 50

CICO PLAST-SUPER P-190A 0.2 0.55 350 80

Do 0.4 0.55 350 150

Do 0.6 0.55 350 200

TABLE – II COMPRESSIVE STRENGTH Vs DOSAGE (TYPICAL)

DOSE

COMPRESSIVE STRENGTH

TYPE OF MIX % W/C RATIO CEMENT CONTENT Kg/M3

kg/cm2

(W/W)

7 days 28 days

Control Mix - 0.55 350 175 255

CICO PLAST-SUPER P-190A 0.2 0.53 350 210 305

Do 0.4 0.5 350 245 350

D0 0.6 0.47 350 300 410

Important Note:

All CICO products are sold in the market after strict Quality Control in line of ISO 9001 and guaranteed against any manufacturing defect. Although the

basic formulation of Company’s products generally remains unchanged, production refinements arising from continuing research and evaluation program

may occasionally result in marginal changes in properties. CICO aspires to ensure that any recommendation, advice, test data, specification, method

statement and other information given in this product datasheet is accurate and best of company’s knowledge. Since, the company (CICO TECHNOLOGIES

LTD) has no control over the selection of its product, applicators, application methodology, how and where it is applied, therefore, the company cannot

accept any liability directly or indirectly arising from the use of its product. It is important to any customer, user or specifier satisfies him / herself that the

product is suitable for the intended purpose including health, safety and environmental aspect. Unless or otherwise agreed in writing, all products of the

company are sold strictly pursuant to the terms of our standard conditions of sale which are available upon request. All information and technical

assistance is given without warranty or guarantee and is subject to change without notice. All customers, users, specifers should ensure that they

examine the suitability of the product with company’s latest product data sheet.

CICO TECHNOLOGIES LIMITED

st nd

CTL/07-14/01

Corp. Office: C-44/2, 1 & 2 Floor, Okhla Industrial Area,

Phase –II,New Delhi-110 020

Tel. No: 91-11-4050 9400, Fax: 91-11-4050 9413

E-Mail: cicotech@cicogroup.com

Web Site: www.cicogroup.com

Potrebbero piacerti anche

- Life Without A Centre by Jeff FosterDocumento160 pagineLife Without A Centre by Jeff Fosterdwhiteutopia100% (5)

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Correlation SecretDocumento23 pagineCorrelation SecretDavid100% (1)

- Jao Vs Court of Appeals G.R. No. 128314 May 29, 2002Documento3 pagineJao Vs Court of Appeals G.R. No. 128314 May 29, 2002Ma Gabriellen Quijada-TabuñagNessuna valutazione finora

- Agreement of PurchaseDocumento8 pagineAgreement of PurchaseAdv. Govind S. TehareNessuna valutazione finora

- THM07 Module 2 The Tourist Market and SegmentationDocumento14 pagineTHM07 Module 2 The Tourist Market and Segmentationjennifer mirandaNessuna valutazione finora

- Intro To LodgingDocumento63 pagineIntro To LodgingjaevendNessuna valutazione finora

- Fire Safety Management - Traditional Building Part#2Documento194 pagineFire Safety Management - Traditional Building Part#2Yoyon Haryono100% (1)

- Court Documents From Toronto Police Project Brazen - Investigation of Alexander "Sandro" Lisi and Toronto Mayor Rob FordDocumento474 pagineCourt Documents From Toronto Police Project Brazen - Investigation of Alexander "Sandro" Lisi and Toronto Mayor Rob Fordanna_mehler_papernyNessuna valutazione finora

- ERP ConceptsDocumento27 pagineERP ConceptsPranav JainNessuna valutazione finora

- Cico Plast Super C804Documento2 pagineCico Plast Super C804ASRAR AHMED KHANNessuna valutazione finora

- CICO Plast Super K-353Documento2 pagineCICO Plast Super K-353Bharat Pest Control ServicesNessuna valutazione finora

- Cico Plast-N: Normal Water Reducing Admixture / Plasticiser For ConcreteDocumento2 pagineCico Plast-N: Normal Water Reducing Admixture / Plasticiser For ConcreteASRAR AHMED KHANNessuna valutazione finora

- CICO Plast N PDFDocumento2 pagineCICO Plast N PDFASRAR AHMED KHANNessuna valutazione finora

- Pages From LBS - RCF4 - DFAC Cabling - Additional Submittals - 03JAN23 - Red SizeDocumento7 paginePages From LBS - RCF4 - DFAC Cabling - Additional Submittals - 03JAN23 - Red Sizemohammed mustafaNessuna valutazione finora

- Fairflo - Data SheetDocumento2 pagineFairflo - Data Sheetyuvraj783Nessuna valutazione finora

- Super Plasticizer For High Strength ConcreteDocumento2 pagineSuper Plasticizer For High Strength Concretedachepalli963Nessuna valutazione finora

- Water ProofDocumento3 pagineWater ProofMohamed KhanNessuna valutazione finora

- MasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGDocumento3 pagineMasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGvahab_shaikNessuna valutazione finora

- TDS - Conplast SP430 - IndiaDocumento2 pagineTDS - Conplast SP430 - IndiaKarthik TumuluriNessuna valutazione finora

- Sika Air Mix - PDSDocumento4 pagineSika Air Mix - PDSRonnie NdozirehoNessuna valutazione finora

- Rheobuild 1000Documento2 pagineRheobuild 1000Mcr KumaraNessuna valutazione finora

- Construction Chemicals: Total Solution ofDocumento4 pagineConstruction Chemicals: Total Solution ofdwijNessuna valutazione finora

- 6.6 Bondit SBRDocumento4 pagine6.6 Bondit SBRCristal Haze VictoriaNessuna valutazione finora

- Standard Product Proposal For High Rise Building 07-07-2017Documento18 pagineStandard Product Proposal For High Rise Building 07-07-2017eufrosina hernandezNessuna valutazione finora

- Sika WT 110 P Pds enDocumento3 pagineSika WT 110 P Pds enReno MaulanaNessuna valutazione finora

- SikaTop Seal 200Documento5 pagineSikaTop Seal 200Levi Leonardo Abayon JuniorNessuna valutazione finora

- TDS - Rheomac 707Documento3 pagineTDS - Rheomac 707Alexi ALfred H. Tago100% (1)

- Sikatop 109 SealingDocumento4 pagineSikatop 109 SealingRajdeep ShitNessuna valutazione finora

- Rheomac 707 PDFDocumento3 pagineRheomac 707 PDFMohamed KhanNessuna valutazione finora

- Master Life WP-707Documento3 pagineMaster Life WP-707sufian100% (1)

- Rheomac® 707Documento4 pagineRheomac® 707M HAFEEZ RAJANessuna valutazione finora

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Documento4 pagineBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNessuna valutazione finora

- SikaTop® Armatec®-110 EpoCem® - PDS - GCC - (10-2016) - 2 - 1Documento3 pagineSikaTop® Armatec®-110 EpoCem® - PDS - GCC - (10-2016) - 2 - 1kamran abbasiNessuna valutazione finora

- CIKO FloGroutDocumento3 pagineCIKO FloGroutAbdul YaskarNessuna valutazione finora

- TDS Conplast SP430 G8 IndiaDocumento2 pagineTDS Conplast SP430 G8 IndiaZeeshaan BhattNessuna valutazione finora

- Sikagrout 215 M: Non-Shrink Cementitious Grout For Marine Structure and Concrete RepairDocumento2 pagineSikagrout 215 M: Non-Shrink Cementitious Grout For Marine Structure and Concrete RepairDani LerviNessuna valutazione finora

- Conplast SP430 G8: High Performance Superplasticising MixtureDocumento2 pagineConplast SP430 G8: High Performance Superplasticising MixtureBUNU SAHOONessuna valutazione finora

- Masteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerDocumento2 pagineMasteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerMuhammad Fadhil ImansyahNessuna valutazione finora

- Developments in Epoxy Modified CementsDocumento12 pagineDevelopments in Epoxy Modified Cementsb4rfNessuna valutazione finora

- TDS SikaCem 135intraplastDocumento3 pagineTDS SikaCem 135intraplastDipNessuna valutazione finora

- MasterEase 3501 v3Documento2 pagineMasterEase 3501 v3dachepalli963Nessuna valutazione finora

- Sika Viscocrete - 3005-Copy - Pt.enDocumento2 pagineSika Viscocrete - 3005-Copy - Pt.enallanNessuna valutazione finora

- Costamix-200m 20201Documento2 pagineCostamix-200m 20201Moyinoluwa Bukola EbitighaNessuna valutazione finora

- Sika Viscocrete - 3005.pt - enDocumento3 pagineSika Viscocrete - 3005.pt - enallanNessuna valutazione finora

- Ituplus Ituplus: B B G 4200 G 4200Documento4 pagineItuplus Ituplus: B B G 4200 G 4200Engr KamalNessuna valutazione finora

- Eucon HC 250Documento2 pagineEucon HC 250Updates for upcoming KingNessuna valutazione finora

- Epoject 304I: General DescriptionDocumento2 pagineEpoject 304I: General Descriptionnoblas melNessuna valutazione finora

- Material Safety Data Sheet SikabondingDocumento3 pagineMaterial Safety Data Sheet SikabondingHarieNessuna valutazione finora

- Masterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteDocumento2 pagineMasterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteweamNessuna valutazione finora

- Naphthaplast G 808Documento2 pagineNaphthaplast G 808imran jamalNessuna valutazione finora

- Estop Admix PC90 PDFDocumento2 pagineEstop Admix PC90 PDFOkie RezkianNessuna valutazione finora

- Isobond: SBR Bonding AdmixtureDocumento3 pagineIsobond: SBR Bonding AdmixtureHussain MarzooqNessuna valutazione finora

- MasterEase 3503 v1Documento2 pagineMasterEase 3503 v1dachepalli963Nessuna valutazione finora

- Sika MonoTop 615 PDS (CE)Documento6 pagineSika MonoTop 615 PDS (CE)Mihai CîrsteaNessuna valutazione finora

- Alccofine 1108SRDocumento2 pagineAlccofine 1108SRLaxmana PrasadNessuna valutazione finora

- Mea Polybit Tds Polybit Polythane PR en MeaDocumento2 pagineMea Polybit Tds Polybit Polythane PR en MeaShahsoor Shah MajeedNessuna valutazione finora

- Cemtec 190 SPDocumento2 pagineCemtec 190 SPpravi3434Nessuna valutazione finora

- BASF Products Guide PDFDocumento22 pagineBASF Products Guide PDFAtiq uRehman100% (1)

- Bitugum: SmoothDocumento2 pagineBitugum: Smoothsr2011glassNessuna valutazione finora

- Brochure Product Summary Guide BFL PDFDocumento33 pagineBrochure Product Summary Guide BFL PDFTanvir Ahmed KhanNessuna valutazione finora

- SikaWT 200P en GBDocumento3 pagineSikaWT 200P en GBSmári ValgarðssonNessuna valutazione finora

- Sikagrout® - 200 PDFDocumento2 pagineSikagrout® - 200 PDFMohamed SalahNessuna valutazione finora

- Brochure Masterlife - SraDocumento6 pagineBrochure Masterlife - SraДанило ГадайчукNessuna valutazione finora

- Masterseal M 811 TdsDocumento4 pagineMasterseal M 811 TdsAdityaVikramVermaNessuna valutazione finora

- Auracast 200 Dec20Documento3 pagineAuracast 200 Dec20binausahagadaNessuna valutazione finora

- Sikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingDocumento5 pagineSikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingHaradhon DattaNessuna valutazione finora

- Plastiretard: Set-Retarding Admixture For ConcreteDocumento3 paginePlastiretard: Set-Retarding Admixture For ConcreteacarisimovicNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Preamble To Price ScheduleDocumento3 paginePreamble To Price ScheduleASRAR AHMED KHANNessuna valutazione finora

- Percentage Boq: Validate Print HelpDocumento18 paginePercentage Boq: Validate Print HelpASRAR AHMED KHANNessuna valutazione finora

- Vol II PDFDocumento138 pagineVol II PDFASRAR AHMED KHANNessuna valutazione finora

- Tech 87 SPPPDocumento114 pagineTech 87 SPPPASRAR AHMED KHANNessuna valutazione finora

- Vol IDocumento136 pagineVol IASRAR AHMED KHANNessuna valutazione finora

- DRDOTendernotice 2 PDFDocumento220 pagineDRDOTendernotice 2 PDFASRAR AHMED KHANNessuna valutazione finora

- TD Palanatanki PDFDocumento214 pagineTD Palanatanki PDFASRAR AHMED KHANNessuna valutazione finora

- CICO Plast Super P-190ADocumento3 pagineCICO Plast Super P-190AASRAR AHMED KHANNessuna valutazione finora

- Government of Rajasthan Public Health Engineering DepartmentDocumento3 pagineGovernment of Rajasthan Public Health Engineering DepartmentASRAR AHMED KHANNessuna valutazione finora

- LR XRF 129 s2 Puma Iron Ore As Fused Beads Doc-l80-Exs129 HighDocumento4 pagineLR XRF 129 s2 Puma Iron Ore As Fused Beads Doc-l80-Exs129 HighASRAR AHMED KHANNessuna valutazione finora

- Appc Soil Properties 718Documento5 pagineAppc Soil Properties 718pinkuru100% (1)

- Indian Standard: Methods of Test For Determination of Strength Properties of Natural Building StonesDocumento8 pagineIndian Standard: Methods of Test For Determination of Strength Properties of Natural Building StonesASRAR AHMED KHANNessuna valutazione finora

- TD Palanatanki PDFDocumento214 pagineTD Palanatanki PDFASRAR AHMED KHANNessuna valutazione finora

- Comparison of Core and Cube Compressive Strength of Hardened ConcreteDocumento5 pagineComparison of Core and Cube Compressive Strength of Hardened ConcreteRajmonda RamaNessuna valutazione finora

- Is 10500 SpecificationDocumento10 pagineIs 10500 SpecificationbrahmishtanNessuna valutazione finora

- ELCODocumento4 pagineELCOASRAR AHMED KHANNessuna valutazione finora

- Ce742lec 25&26Documento83 pagineCe742lec 25&26Anshul SoniNessuna valutazione finora

- S2R XRF 82 Main Limestone ComponentsDocumento4 pagineS2R XRF 82 Main Limestone ComponentsASRAR AHMED KHANNessuna valutazione finora

- DBM Report PDFDocumento4 pagineDBM Report PDFASRAR AHMED KHANNessuna valutazione finora

- 1121 1Documento8 pagine1121 1Bhaskar Jyoti DasNessuna valutazione finora

- Hussain ProjectDocumento1 paginaHussain ProjectASRAR AHMED KHANNessuna valutazione finora

- SpecDocumento1 paginaSpecASRAR AHMED KHANNessuna valutazione finora

- BTech Civil Scheme and Syllabi Subject To Approval of AcademDocumento47 pagineBTech Civil Scheme and Syllabi Subject To Approval of Academdinesh_nitu2007Nessuna valutazione finora

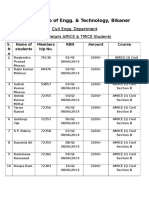

- Govt. College of Engg. & Technology, Bikaner: Civil Engg. Department Fees Details AMICE & TMICE StudentsDocumento4 pagineGovt. College of Engg. & Technology, Bikaner: Civil Engg. Department Fees Details AMICE & TMICE StudentsASRAR AHMED KHANNessuna valutazione finora

- Panchat FormDocumento3 paginePanchat FormASRAR AHMED KHANNessuna valutazione finora

- Klarna: Klarna A Company Valued To Be 5.5 Billion and 8 Most Valued Fintech Company in The WorldDocumento1 paginaKlarna: Klarna A Company Valued To Be 5.5 Billion and 8 Most Valued Fintech Company in The WorldChetan NarasannavarNessuna valutazione finora

- 008 Supply and Delivery of Grocery ItemsDocumento6 pagine008 Supply and Delivery of Grocery Itemsaldrin pabilonaNessuna valutazione finora

- Pentagram Business PlanDocumento13 paginePentagram Business PlantroubledsoulNessuna valutazione finora

- Wa0009.Documento14 pagineWa0009.Pradeep SinghNessuna valutazione finora

- Profix SS: Product InformationDocumento4 pagineProfix SS: Product InformationRiyanNessuna valutazione finora

- CBDCs For Dummies Everything You Need ToDocumento18 pagineCBDCs For Dummies Everything You Need Tolati.training7Nessuna valutazione finora

- COSMO NEWS September 1, 2019 EditionDocumento4 pagineCOSMO NEWS September 1, 2019 EditionUnited Church of Christ in the PhilippinesNessuna valutazione finora

- Schopenhauer and KantDocumento8 pagineSchopenhauer and KantshawnNessuna valutazione finora

- 1219201571137027Documento5 pagine1219201571137027Nishant SinghNessuna valutazione finora

- Social Studies 5th Grade Georgia StandardsDocumento6 pagineSocial Studies 5th Grade Georgia Standardsapi-366462849Nessuna valutazione finora

- Post Employee Benefit Psak 24 (Guide)Documento21 paginePost Employee Benefit Psak 24 (Guide)AlvianNessuna valutazione finora

- Strength Exp 2 Brinell Hardness TestDocumento13 pagineStrength Exp 2 Brinell Hardness Testhayder alaliNessuna valutazione finora

- Section 9 - Brickwork and BlockworkDocumento6 pagineSection 9 - Brickwork and BlockworkShing Faat WongNessuna valutazione finora

- Diffusion Osmosis Enzymes Maths and Write Up Exam QuestionsDocumento9 pagineDiffusion Osmosis Enzymes Maths and Write Up Exam QuestionsArooj AbidNessuna valutazione finora

- English Solution2 - Class 10 EnglishDocumento34 pagineEnglish Solution2 - Class 10 EnglishTaqi ShahNessuna valutazione finora

- Anthem Harrison Bargeron EssayDocumento3 pagineAnthem Harrison Bargeron Essayapi-242741408Nessuna valutazione finora

- Sokkia GRX3Documento4 pagineSokkia GRX3Muhammad Afran TitoNessuna valutazione finora

- Kami Export - Tools in Studying Environmental ScienceDocumento63 pagineKami Export - Tools in Studying Environmental ScienceBenBhadzAidaniOmboyNessuna valutazione finora

- Geotagging ManualDocumento93 pagineGeotagging ManualAlthea AcasNessuna valutazione finora

- All-India rWnMYexDocumento89 pagineAll-India rWnMYexketan kanameNessuna valutazione finora

- MF 2 Capital Budgeting DecisionsDocumento71 pagineMF 2 Capital Budgeting Decisionsarun yadavNessuna valutazione finora