Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HP75 Series: Hy-Pro G6 Dualglass

Caricato da

Oscar NavarroTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HP75 Series: Hy-Pro G6 Dualglass

Caricato da

Oscar NavarroCopyright:

Formati disponibili

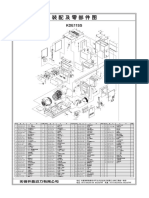

HP75 Element

HP75 Series

Interchanges for spin-on filter

HC7500, 50-AT series

Hy-Pro G6 Dualglass

High Performance Filter Elements

Performance

Temperature: -45f to 225f, -43c to 107c (buna)

-20f to 250f, -29c to 120c (viton)

Element collapse 100 psid (7 bar)

Media

G6 media pleat pack features our latest

generation of graded density glass media that Interchange by series: (For complete part

delivers required cleanliness while optimizing numbers check the interchange guide)

dirt capacity.

Dynamic Filter Efficiency Pall Hy-Pro

DFE rated elements perform true to rating even

under demanding variable flow and vibration HC7500S##4H HP75L4-#MB

conditions. Today’s industrial and mobile HC7500S##4Z HP75L4-#MV

hydraulic circuits require elements that deliver HC7500S##8H HP75L8-#MB

HC7500S##8Z HP75L8-#MV

specified cleanliness under all circumstances.

Wire mesh supports the media to ensure against

cyclical flow fatigue, temperature, and chemical Parker Hy-Pro

resistance failures possible in filters with 50AT HP75L4-##B

synthetic support mesh. 50AT-2 HP75L8-##B

*For Fluorocarbon seals where Pall number ends

Tested to ISO quality standards with “Z” change “B” in Hy-Pro number to “V”.

ISO 2941 Collapse and burst resistance

ISO 2942 Fabrication and Integrity test Media types available include Dualglass, Wire mesh,

ISO 2943 Material compatibility with fluids Water removal and Dynafuzz media types are

ISO 3724 Flow fatigue characteristics available. Call or consult the Hy-Pro on line

ISO 3968 Pressure drop vs. flow rate interchange guide at www.filterelement.com

ISO 16889 Multi-pass performance testing

Fluid Compatibility

Petroleum based fluids, water glycols, polyol

esters, phosphate esters, HWBF

For technical service call 317.849.3535 or fax 317.849.9201 www.filterelement.com

L4 Dualglass Dp vs flow rate L8 Dualglass Dp vs flow rate

flow rate lpm flow rate lpm

0 23 45 68 91 114 136 159 182

0 47 93 140 186 233 279 326 372

12 0.8 12 0.8

1 3

9 1 3 0.6 9 0.6

Dp bar

Dp psi

Dp bar

Dp psi

6 6

6 0.4 6 0.4

12 12

3 25 0.2 3 25 0.2

0 0.0 0 0

0 6 12 18 24 30 36 42 48 0 12 24 36 48 60 72 84 96

flow rate gpm flow rate gpm

Pressure Drop Calculation

Pressure drop curves based on oil viscosity of 150 SUS, and specific gravity = 0.9. Dp across element

is proportionally related to viscosity and specific gravity. For new DP use the following conversion formula:

DP element = DP curve x Actual Viscosity/150 x Actual SG/0.86

table 1 table 2 table 3 table 4 table 5

HP75L __ - __ __ __ __

table 1 table 2 table 3 table 4

code length code filtration rating code media type code seal

4 single 1 B2.5[c] = 1000 (B1 = 200) C Cellulose B Nitrile (buna)

8 double 3 B5[c] = 1000 (B3 = 200) M G6 Dualglass V Fluorocarbon

or 3u nominal cellulose* E EPR

6 B7[c] = 1000 (B6 = 200) table 5

12 B12[c] = 1000 (B12 = 200) code special option

10 10u nominal cellulose* PLP water removal

25 B22[c] = 1000 (B25 = 200) capabilities

or 25u nominal cellulose*

Hy-Pro filters are tested to the latest industry New (ISO16889) vs Old (ISO4572) size comparison

standard ISO16889 (replacing ISO4572) resulting in

A new scale for defining particle sizes and determining Bx(c)=1000 (ISO16889) 2.5 5 7 12 22

a beta ratio. Bx=200 (ISO4572) <1 3 6 12 25

TB75-0402

Potrebbero piacerti anche

- HP74/76/76V Series: Hy-Pro G6 DualglassDocumento2 pagineHP74/76/76V Series: Hy-Pro G6 DualglassOscar NavarroNessuna valutazione finora

- Element06DNEMNov 19 01Documento2 pagineElement06DNEMNov 19 01Danilo AugustoNessuna valutazione finora

- 150-151 E, M Feb-14-02 Mahle Duke EnergyDocumento2 pagine150-151 E, M Feb-14-02 Mahle Duke EnergyOscar NavarroNessuna valutazione finora

- TESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveDocumento32 pagineTESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveAnonymous v7XdaQuNessuna valutazione finora

- JCB HP HYDRAULIC FLUID 46 - enDocumento2 pagineJCB HP HYDRAULIC FLUID 46 - enMiguel MacedoNessuna valutazione finora

- Schlumberger: PIPESIM Open Link - Single Branch Demo (Artificial Lift Performance)Documento7 pagineSchlumberger: PIPESIM Open Link - Single Branch Demo (Artificial Lift Performance)Julie SaavedraNessuna valutazione finora

- BrochureDocumento10 pagineBrochureMohamed ImranNessuna valutazione finora

- Performance Data: Section: Date: December 2008Documento26 paginePerformance Data: Section: Date: December 2008cesar moraNessuna valutazione finora

- H83 100-250 Element R8Documento4 pagineH83 100-250 Element R8Pat YNessuna valutazione finora

- SPD210GBDocumento2 pagineSPD210GBVenustiano MirandaNessuna valutazione finora

- Sp20 DescripcionDocumento2 pagineSp20 DescripcionJuan Pablo Moreno Téllez Moreno TéllezNessuna valutazione finora

- Dat004 Eng PDFDocumento68 pagineDat004 Eng PDFAslam ShaikhNessuna valutazione finora

- Gulf Oil Marine - Product Data SheetDocumento10 pagineGulf Oil Marine - Product Data SheetObydur RahmanNessuna valutazione finora

- Norgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Documento4 pagineNorgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Iswar Rauf Aboo 'AqilahNessuna valutazione finora

- Low Pressure Filter: Spin-On CartridgesDocumento10 pagineLow Pressure Filter: Spin-On CartridgesIgorNessuna valutazione finora

- Gear Pumps and Motors "B" Series Group 3: Technical CatalogueDocumento32 pagineGear Pumps and Motors "B" Series Group 3: Technical CatalogueИгорь ТерещенкоNessuna valutazione finora

- US Echo II HE00172EN0517Documento2 pagineUS Echo II HE00172EN0517Mohamed amine BenfarhatNessuna valutazione finora

- HP5H/5N Series Hy-Pro G8 Dualglass: High Performance Filter ElementsDocumento3 pagineHP5H/5N Series Hy-Pro G8 Dualglass: High Performance Filter ElementsRizkyNessuna valutazione finora

- HP2727 Filter Element Data SheetDocumento3 pagineHP2727 Filter Element Data Sheetjose manuelNessuna valutazione finora

- CENT Pump - 7Documento2 pagineCENT Pump - 7diepriyeNessuna valutazione finora

- Spray Ball Terkait CIPDocumento6 pagineSpray Ball Terkait CIPTuti SusilawatiNessuna valutazione finora

- 01.fire Pump Performance CurveDocumento1 pagina01.fire Pump Performance CurveHossein ForouzanNessuna valutazione finora

- GALAPESCA Firepump Performance CurveDocumento1 paginaGALAPESCA Firepump Performance CurveFrancisco AlarconNessuna valutazione finora

- Schott Brochure Schott Vials English Us 20092017Documento28 pagineSchott Brochure Schott Vials English Us 20092017Tomena ÁkosNessuna valutazione finora

- 150FV054-IFT-Data SheetDocumento1 pagina150FV054-IFT-Data SheetgerardoNessuna valutazione finora

- VT IPH 21 BDI 90115 enDocumento16 pagineVT IPH 21 BDI 90115 enwag008Nessuna valutazione finora

- Gear Pumps and Mo T ORS "B" Series Group 2Documento35 pagineGear Pumps and Mo T ORS "B" Series Group 2Daniel Zambra ZambraNessuna valutazione finora

- Coolant Pump PDFDocumento32 pagineCoolant Pump PDFPravin SatheNessuna valutazione finora

- X PumpsDocumento4 pagineX Pumpspankaj chacholiyaNessuna valutazione finora

- PDS - GulfSea Synth Compressor Oil 46 68Documento2 paginePDS - GulfSea Synth Compressor Oil 46 68Md.Obydur RahmanNessuna valutazione finora

- X35P1 GBDocumento8 pagineX35P1 GBScarduelliNessuna valutazione finora

- 05 Radial Piston Pumps - 1RP2Documento3 pagine05 Radial Piston Pumps - 1RP2kamalNessuna valutazione finora

- Q12 057 Riello BX Low Nox Manual AddendumDocumento22 pagineQ12 057 Riello BX Low Nox Manual AddendumKrystian RosiakNessuna valutazione finora

- PDS - GulfSea Hydraulic AW Series-1Documento2 paginePDS - GulfSea Hydraulic AW Series-1Zaini YaakubNessuna valutazione finora

- PDS - GulfSea Hydraulic HVI Plus 68Documento2 paginePDS - GulfSea Hydraulic HVI Plus 68Obydur Rahman100% (1)

- Zjys 4Documento5 pagineZjys 4Eduardo Del BenNessuna valutazione finora

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDocumento6 pagineCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingNessuna valutazione finora

- CP 4600 100Documento2 pagineCP 4600 100kuanyiNessuna valutazione finora

- Boss CatalogDocumento44 pagineBoss CatalogSATENDER KUMARNessuna valutazione finora

- 11-5k Annular BOP Operation Manual-Shaffer TypeDocumento19 pagine11-5k Annular BOP Operation Manual-Shaffer TypeDaniel RinconNessuna valutazione finora

- Air-To-Water Heat Pump: Shanghai Hezhong Carrier Air-Conditioning Equipment Co., LTDDocumento7 pagineAir-To-Water Heat Pump: Shanghai Hezhong Carrier Air-Conditioning Equipment Co., LTDguy namNessuna valutazione finora

- Hallstar Novel Plasticizers For Low Fusion Temperature Plastisols 2Documento23 pagineHallstar Novel Plasticizers For Low Fusion Temperature Plastisols 2Ljupco AleksovNessuna valutazione finora

- VT IPV 21 BDI 90116 enDocumento20 pagineVT IPV 21 BDI 90116 enEraldo MendesNessuna valutazione finora

- Catalogo Bombas Salami Tipo PBDocumento235 pagineCatalogo Bombas Salami Tipo PBTomas GilbertoNessuna valutazione finora

- 175 Resina Cationica - (Resintech) Modelo CG8Documento2 pagine175 Resina Cationica - (Resintech) Modelo CG8Lore PretoNessuna valutazione finora

- Mangueras IndustrialesDocumento14 pagineMangueras Industrialesroberto carlos ortizNessuna valutazione finora

- 150HV051-IFT-Data SheetDocumento1 pagina150HV051-IFT-Data SheetgerardoNessuna valutazione finora

- Design D and DA Control ValvesDocumento12 pagineDesign D and DA Control Valvesluis rodriguezNessuna valutazione finora

- s-5610q1 5620 5620d1Documento4 pagines-5610q1 5620 5620d1Ujwal KhandokarNessuna valutazione finora

- Acondicionador de Flujo Alta PerformanceDocumento4 pagineAcondicionador de Flujo Alta PerformanceFederico Javier GarciaNessuna valutazione finora

- Pulsa 340 Brochure EnglishDocumento2 paginePulsa 340 Brochure Englishratatrampa25Nessuna valutazione finora

- Denison-Parker Premier SeriesDocumento40 pagineDenison-Parker Premier SeriesDamNessuna valutazione finora

- 4754 4751 Series Duplex Filters FLTR Purple EngineeringDocumento3 pagine4754 4751 Series Duplex Filters FLTR Purple EngineeringFLTR PURPLE E.Nessuna valutazione finora

- Rotrex Technical Datasheet C30 Range V4.0Documento7 pagineRotrex Technical Datasheet C30 Range V4.0Vivien ErussardNessuna valutazione finora

- No P&ID No Drawing Line NumberDocumento8 pagineNo P&ID No Drawing Line NumberAhmed SemarangNessuna valutazione finora

- Sensata-5100 Series-Hermetically Sealed Thermostat Probe-DatasheetDocumento5 pagineSensata-5100 Series-Hermetically Sealed Thermostat Probe-DatasheetVictor RamirezNessuna valutazione finora

- PD Meter BiRotor Plus Datasheet Low TempDocumento6 paginePD Meter BiRotor Plus Datasheet Low Tempeka pramudia santosoNessuna valutazione finora

- EHYD6 Hydraulic Valves HY14-2502k001Documento9 pagineEHYD6 Hydraulic Valves HY14-2502k001Ahmet SaygılıNessuna valutazione finora

- High Pressure Full Flow Bi-Directional FilterDocumento7 pagineHigh Pressure Full Flow Bi-Directional FilterOscar NavarroNessuna valutazione finora

- Oil Analysis Patch Test KitDocumento1 paginaOil Analysis Patch Test KitOscar Navarro100% (1)

- PF2 High Pressure In-Line Filter: Featuring Hy-Pro G6 Dualglass Filter Element TechnologyDocumento4 paginePF2 High Pressure In-Line Filter: Featuring Hy-Pro G6 Dualglass Filter Element TechnologyOscar NavarroNessuna valutazione finora

- PFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateDocumento8 paginePFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateOscar NavarroNessuna valutazione finora

- HP140 Series: Hy-Pro G5 DualglassDocumento2 pagineHP140 Series: Hy-Pro G5 DualglassOscar NavarroNessuna valutazione finora

- HP140 Series: Hy-Pro G5 DualglassDocumento2 pagineHP140 Series: Hy-Pro G5 DualglassOscar NavarroNessuna valutazione finora

- Breathers Mar-20-06 PDFDocumento8 pagineBreathers Mar-20-06 PDFOscar NavarroNessuna valutazione finora

- Bomba Serie 42 SauerDocumento190 pagineBomba Serie 42 SauerOscar Navarro100% (2)

- Spin-On Breathers: Adaptors and Disposable BreathersDocumento4 pagineSpin-On Breathers: Adaptors and Disposable BreathersOscar NavarroNessuna valutazione finora

- 2 Design of DOSAGE DESIGNDocumento16 pagine2 Design of DOSAGE DESIGNMarjo100% (1)

- Volvo BL 71 ManualDocumento280 pagineVolvo BL 71 ManualAlberto G.D.100% (2)

- Breastfeeding W Success ManualDocumento40 pagineBreastfeeding W Success ManualNova GaveNessuna valutazione finora

- Niveshdaily: From Research DeskDocumento53 pagineNiveshdaily: From Research DeskADNessuna valutazione finora

- Safety Bulletin 09 - Emergency Escape Breathing Device - Product RecallDocumento2 pagineSafety Bulletin 09 - Emergency Escape Breathing Device - Product RecallMuhammadNessuna valutazione finora

- Caring For Women Experiencing Breast Engorgement A Case ReportDocumento6 pagineCaring For Women Experiencing Breast Engorgement A Case ReportHENINessuna valutazione finora

- Literature Review Template DownloadDocumento4 pagineLiterature Review Template Downloadaflsigfek100% (1)

- Alaba Adeyemi AdediwuraDocumento12 pagineAlaba Adeyemi AdediwuraSchahyda ArleyNessuna valutazione finora

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDocumento18 pagineIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamNessuna valutazione finora

- Fuzzy Gain Scheduled Pi Controller For ADocumento5 pagineFuzzy Gain Scheduled Pi Controller For AOumayNessuna valutazione finora

- Computer System Validation - Definition and Requirements - MustRead PDFDocumento3 pagineComputer System Validation - Definition and Requirements - MustRead PDFtraining validNessuna valutazione finora

- Quality Control of Rigid Pavements 1Documento58 pagineQuality Control of Rigid Pavements 1pranjpatil100% (1)

- A Literature Review of Retailing Sector and BusineDocumento21 pagineA Literature Review of Retailing Sector and BusineSid MichaelNessuna valutazione finora

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionDocumento17 pagineApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamNessuna valutazione finora

- Pathophysiology of Myocardial Infarction and Acute Management StrategiesDocumento11 paginePathophysiology of Myocardial Infarction and Acute Management StrategiesnwabukingzNessuna valutazione finora

- Studies On Drying Kinetics of Solids in A Rotary DryerDocumento6 pagineStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNessuna valutazione finora

- Conducting Focus GroupsDocumento4 pagineConducting Focus GroupsOxfam100% (1)

- Mueller Hinton Agar (M-H Agar) : CompositionDocumento2 pagineMueller Hinton Agar (M-H Agar) : CompositionRizkaaulyaaNessuna valutazione finora

- Maths Formulas For IGCSEDocumento2 pagineMaths Formulas For IGCSEHikma100% (1)

- Python in Hidrology BookDocumento153 paginePython in Hidrology BookJuan david Gonzalez vasquez100% (1)

- Trina 440W Vertex-S+ DatasheetDocumento2 pagineTrina 440W Vertex-S+ DatasheetBrad MannNessuna valutazione finora

- SPC FD 00 G00 Part 03 of 12 Division 06 07Documento236 pagineSPC FD 00 G00 Part 03 of 12 Division 06 07marco.w.orascomNessuna valutazione finora

- PDFDocumento3 paginePDFAhmedraza123 NagdaNessuna valutazione finora

- CH-5 Further Percentages AnswersDocumento5 pagineCH-5 Further Percentages AnswersMaram MohanNessuna valutazione finora

- Sample Learning Module As PatternDocumento23 pagineSample Learning Module As PatternWilliam BulliganNessuna valutazione finora

- Li JinglinDocumento3 pagineLi JinglincorneliuskooNessuna valutazione finora

- PD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsDocumento20 paginePD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsHazel Jael HernandezNessuna valutazione finora

- Chapter 1 - Main Hydrological ConceptsDocumento16 pagineChapter 1 - Main Hydrological ConceptsWhy Merah0% (1)

- KDE11SSDocumento2 pagineKDE11SSluisgomezpasion1Nessuna valutazione finora

- SafetyRelay CR30Documento3 pagineSafetyRelay CR30Luis GuardiaNessuna valutazione finora