Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

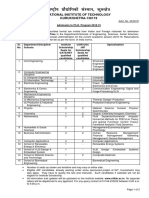

Material Testing Lab: Sr. No. Specifications Unit Price in Rs

Caricato da

rahul srivastavaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Material Testing Lab: Sr. No. Specifications Unit Price in Rs

Caricato da

rahul srivastavaCopyright:

Formati disponibili

Material Testing Lab

Sr. Specifications Unit price in

No. Rs

1 Brinell cum Rockwell Hardness Tester

Hardness is the property of a material that enables it to resist plastic deformation 120000

usually by penetration. However, the term hardness may also refer to resistance to

bending, scratching, abrasion or cutting.

There are various Hardness Testing Methods.

Hardness Testing Machine should be designed for conducting Brinell & Rockwell

Hardness Tests on metallic materials, alloys of all types, hard or soft & of all shapes.

Features:

Sturdy & Reliable Design. Easy to operate.

Accessories of Brinell & Rockwell Test are part of standard outfit.

There are 4 quick load change options 60,100,150 kgf for Rockwell Test

(HRA, HRB, HRC) and 187.5 kgf (BHN) for BrinelI Test in this machine.

Direct reading of RockwelI scales HR -A, B,C.

Samples upto 230mm high & 155mm Throat depth can be tested.

RockweII Scales – NABL Calibration can be provided on request.

Brinell Scales- NABL Calibration can be provided on request.

Technical Specification:

Rockwell Scales – A, B, C

Brinell Hardness

Hardness Resolution – 1.0 of a Rockwell unit

Test loads:

Rockwell – 10 kgf Pre Load/ 60, 100, 150 kgf Main load.

Brinell-10 kgf Pre Load/ 187.5 kgf Main load.

Display – Analogue.

Accuracy -Conforms to IS 1586 -2000 (2006)

Specimen accommodations:

Vertical space – 230mm

Horizontal space (from central line)-155mm

Machine Specifications:

Machine Dimensions –

655 mm(H) x 170 mm(W) x 475 mm(D)

Machine Weight- 85kg (Approximately)

Power Supply- 220V, 1ph, 50Hz (For Brinell Microscope only)

2 Fatigue Testing Machine

.Features:

Compact simple design, light weight.

Table top model.

Load changing simple – through lever arrangement.

Technical Specifications:

Maximum bending moment kg.cm 200

Bending moment adjustable kg.cm 25-200

kg.cm 5-125

Range

kg.cm 125-200

Gripping dia of specimen mm 12

Testing dia of Specimen mm 8

Rotating Speed rpm 4200 260000

Accuracy of applied bending moment ± 1%

Digital counter 8 digit

Power required HP 0.5

Main supply 3Ph, 415V, 50Hz, A.G.

Overall size (approx.} mm 1000 L x 500 W x 600 H

Weight (approx.} kg 120

3 Pendulum Impact Tester

Impact testers are designed to determine the strength of a sample under impact load.

This information is important as this strength determines the performance

characteristics of the material under impact loading conditions.

Interchangeable strikers, adjustable pendulum drop angle and easy to mount test

specimens in the specimen holders, Impact tester should be user friendly and measure

the impact resistance of a variety of materials in both lzod and Charpy methods. The

basic instrument for conducting both the test methods are same. However the

attachments and mounting arrangements for these tests are specific to the tests.

270000

Charpy Test lzod Test

Pendulum drop angle 140° 85°

Pendulum effective weight 20.59kgs. 21.79kgs.

Pendulum impact energy 30kg - m 16.52kg - m

Min. graduation 0.2kg - m 0.14kg - m

Least count 0.1 kg - m 0.1 kg - m

Distance of axis of hammer

825mm 825mm

rotation and centre

Striking Edge Angle 30° ± 1° 75° ± 1°

Radius of curvature 2.25mm 0.75mm

Horizontal:

10°

Width 18mm

Vertical

relief: 5°

Support Distance between arms 40 mm For gripping

Sloping angle 0° specimen

with

Relief angle 10° dimension

10mm X

Radius of curvature 1.25mm

10mm

4 Torsion Testing Machine

Torsion is the twisting of an object due to an applied torque & is hence expressed in

Nm or lbf ft.

Torsion Tests are done on materials to determine properties such as the modulus of

elasticity in shear, the torsion yield strength & the modulus of rupture.

Suitable for operation on 440V, 50Hz, Three Phase, AC supply.

Torsion testing equipment consists of:

• A twisting head with a chuck for gripping the specimen and for applying

the twisting movements to the specimen.

• A weight head, which grips the other end of the specimen & measures the

twisting movement or torque.

Features: 260000

• Sturdy & reliable design

• Easy to operate

• Measurement of Torque with electronic load cell.

• Accuracy of Torque measurements± 1% above 115th of the range.

• Can conduct torsion tests on both metallic & non-metallic materials.

Technical Specifications

Maximum capacity : 100Nm

Least Count : 0.01Nm

Maximum clearance between grips : 500mm

Grips for square specimens : 5-15mm

Grips for flat specimens : 5-12x40mm

Total 910000

Potrebbero piacerti anche

- What Child Is This: Cello SoloDocumento8 pagineWhat Child Is This: Cello SoloSylvia Abigail Vargas SánchezNessuna valutazione finora

- Subsea Xmas TreeDocumento8 pagineSubsea Xmas Treemadonnite3781100% (1)

- Hardness TestDocumento25 pagineHardness TestDeniThomasBoban100% (1)

- Audio SynthesisDocumento80 pagineAudio Synthesiscap2010Nessuna valutazione finora

- ACP Study Guide CurriculumDocumento198 pagineACP Study Guide CurriculumVivek Kumar Gupta100% (1)

- Pile Cap For 1 PilesDocumento5 paginePile Cap For 1 Pileshemantkle2u80% (5)

- Hh-411 Impact Type Hardness Testing Unit: Catalog No. E4299-810Documento6 pagineHh-411 Impact Type Hardness Testing Unit: Catalog No. E4299-810D.T.Nessuna valutazione finora

- Bearcat 101 (Manual)Documento32 pagineBearcat 101 (Manual)Koz Kosloff75% (4)

- Usage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SDocumento7 pagineUsage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SRavi TyagiNessuna valutazione finora

- LK Rockwell Machines Brochure PDFDocumento2 pagineLK Rockwell Machines Brochure PDFArun SasiNessuna valutazione finora

- Charpy Impact Test: Strength-Of-Materials Lab (../index - HTML)Documento5 pagineCharpy Impact Test: Strength-Of-Materials Lab (../index - HTML)Gond AbhishekNessuna valutazione finora

- MECH Lab RequirementDocumento4 pagineMECH Lab RequirementJaishree ChauhanNessuna valutazione finora

- Torsion Testing SystemDocumento3 pagineTorsion Testing Systemsrinath.gajapathy5478Nessuna valutazione finora

- Box Compression Tester SeriesDocumento3 pagineBox Compression Tester SeriesAkhmad ToipurNessuna valutazione finora

- Material Testing LabDocumento3 pagineMaterial Testing LabJaishree ChauhanNessuna valutazione finora

- ASTM D 785 - Rockwell Hardness TestingDocumento9 pagineASTM D 785 - Rockwell Hardness TestingkhuelvNessuna valutazione finora

- Manufacturers & Suppliers: Izod and Charpy Apparatus Make "Dinesh" Model DS 102Documento3 pagineManufacturers & Suppliers: Izod and Charpy Apparatus Make "Dinesh" Model DS 102Ashish VermaNessuna valutazione finora

- Brinell Hardness Tester Specifications & DetailsDocumento3 pagineBrinell Hardness Tester Specifications & Detailspatrick jeoNessuna valutazione finora

- Micro Hardness Testing Machines: IndexDocumento28 pagineMicro Hardness Testing Machines: IndexAlan GonzalezNessuna valutazione finora

- Micro Vickers Hardness Testing MachineDocumento2 pagineMicro Vickers Hardness Testing MachineJagdish RanaNessuna valutazione finora

- SM1001 Torsion Testing DatasheetDocumento3 pagineSM1001 Torsion Testing DatasheetChriv SokundavannNessuna valutazione finora

- Vibrophore 250Documento3 pagineVibrophore 250leonardorqNessuna valutazione finora

- Metrix Digital Metal Hardness Tester PDFDocumento18 pagineMetrix Digital Metal Hardness Tester PDFAJITHNessuna valutazione finora

- DS MCP50 enDocumento4 pagineDS MCP50 enthomi dhiaNessuna valutazione finora

- HTSS Product ProfileDocumento4 pagineHTSS Product ProfileGoutam Kumar DebNessuna valutazione finora

- Hardness Tester Machine Rockwell 600MRDDocumento2 pagineHardness Tester Machine Rockwell 600MRDĐào Trường AnNessuna valutazione finora

- MOS Assignment 4Documento12 pagineMOS Assignment 4L13 Krushna NemadeNessuna valutazione finora

- King Hardness Tester ManualDocumento26 pagineKing Hardness Tester ManualRAJIV GandhiNessuna valutazione finora

- HV 1000ZDocumento3 pagineHV 1000Zdinhhai1613Nessuna valutazione finora

- Browiner MX30 Mobile DR Service Manual 2016.11.10Documento91 pagineBrowiner MX30 Mobile DR Service Manual 2016.11.10Imecsa HondurasNessuna valutazione finora

- Componete ElectronicoDocumento5 pagineComponete ElectronicoStuxnetNessuna valutazione finora

- Creep Testing Kappa SSDocumento2 pagineCreep Testing Kappa SSGustavo LealNessuna valutazione finora

- NDW Series Computer Controlled Torsion Testing MachineDocumento5 pagineNDW Series Computer Controlled Torsion Testing Machinegosaye desalegnNessuna valutazione finora

- Jpi313003 PDFDocumento2 pagineJpi313003 PDFChi Yu WangNessuna valutazione finora

- Brinell Rockwell Vickers Hardness Tester (Electric)Documento8 pagineBrinell Rockwell Vickers Hardness Tester (Electric)abdul hameed khanNessuna valutazione finora

- Material Testing Laboratory List of Testing Equipments at BDL, Kachanbagh (Charges Are Indicative Only)Documento2 pagineMaterial Testing Laboratory List of Testing Equipments at BDL, Kachanbagh (Charges Are Indicative Only)akshay gargNessuna valutazione finora

- RASNE-3 Superficial Comments 01Documento2 pagineRASNE-3 Superficial Comments 01Prashant KumarNessuna valutazione finora

- 5990-7399EN - 200 Tablet HardnessDocumento3 pagine5990-7399EN - 200 Tablet HardnessElsayed ElazazyNessuna valutazione finora

- Rubber Hardness TesterDocumento2 pagineRubber Hardness Testerdaveva001Nessuna valutazione finora

- MOS Lab ReportDocumento25 pagineMOS Lab ReportTalha MustafaNessuna valutazione finora

- Product Information Zwickroell Vibrophore 100Documento3 pagineProduct Information Zwickroell Vibrophore 100csmanienNessuna valutazione finora

- Industrial Series HDX ModelsDocumento3 pagineIndustrial Series HDX Modelskuhn403825Nessuna valutazione finora

- Katalog Universal Testing MachineDocumento4 pagineKatalog Universal Testing MachineBayu Bayu AjyNessuna valutazione finora

- Welding Inspection: Mechanical Testing Course Reference WIS 5Documento47 pagineWelding Inspection: Mechanical Testing Course Reference WIS 5Joerge Ryan MaramotNessuna valutazione finora

- Universal Testing and Impact Machines SpecsDocumento1 paginaUniversal Testing and Impact Machines SpecsAshNessuna valutazione finora

- STIFFNESS TesterDocumento4 pagineSTIFFNESS TesterHafiani HichamNessuna valutazione finora

- Rockwell ZHRDocumento4 pagineRockwell ZHRstephane.benardNessuna valutazione finora

- Fig. 1: Lab Vane Shear ApparatusDocumento2 pagineFig. 1: Lab Vane Shear ApparatusKishanNessuna valutazione finora

- KYORITSU Earth Testers (4105A)Documento1 paginaKYORITSU Earth Testers (4105A)tivaro bakabtNessuna valutazione finora

- Model 7480 Series: 7/8" Diameter 5-Turn Wirewound Precision PotentiometerDocumento5 pagineModel 7480 Series: 7/8" Diameter 5-Turn Wirewound Precision PotentiometermAkavYNessuna valutazione finora

- Portable Hardness Tester: Designed To Test Large Hard PartsDocumento5 paginePortable Hardness Tester: Designed To Test Large Hard PartsElbolis_comNessuna valutazione finora

- Electric Dial Display Universal Hardness Testing Machine BRV-187.5EDocumento2 pagineElectric Dial Display Universal Hardness Testing Machine BRV-187.5E周记伟Nessuna valutazione finora

- Dynapocket mobileHardnessTesterDocumento2 pagineDynapocket mobileHardnessTesterengkassemNessuna valutazione finora

- RASNE-3 CommentsDocumento2 pagineRASNE-3 CommentsPrashant KumarNessuna valutazione finora

- Charpy Impact Testing MachineDocumento1 paginaCharpy Impact Testing Machineemperor_vamsiNessuna valutazione finora

- AD Series 740 - LowresDocumento2 pagineAD Series 740 - Lowressathish K KumarNessuna valutazione finora

- IT Solutions ConsultingDocumento4 pagineIT Solutions ConsultingShekharappa MallurNessuna valutazione finora

- Hioki 3454-11 BrochureDocumento2 pagineHioki 3454-11 BrochuresadvNessuna valutazione finora

- Strenx Tube 700QLH: General Product DescriptionDocumento2 pagineStrenx Tube 700QLH: General Product Descriptionflastrico832Nessuna valutazione finora

- GW CTPTAnalyserDocumento8 pagineGW CTPTAnalyserKunal SharmaNessuna valutazione finora

- Dumayao Experiment No. 6Documento5 pagineDumayao Experiment No. 6Angelito MacaraigNessuna valutazione finora

- Data Sheet For Precision Potentiometer: Singleturn Wirewound Potentiometer Series RPS50Documento5 pagineData Sheet For Precision Potentiometer: Singleturn Wirewound Potentiometer Series RPS50Vasile DumitruNessuna valutazione finora

- Why Check Hardness? Understanding Material Properties and Testing MethodsDocumento58 pagineWhy Check Hardness? Understanding Material Properties and Testing MethodsVishal MandlikNessuna valutazione finora

- Why Check Hardness? Key Factors of Hardness TestingDocumento58 pagineWhy Check Hardness? Key Factors of Hardness TestingTim NguyenNessuna valutazione finora

- (Indian Examination-201: PhysicsDocumento8 pagine(Indian Examination-201: Physicsrahul srivastavaNessuna valutazione finora

- Combinepdf NewDocumento30 pagineCombinepdf Newrahul srivastavaNessuna valutazione finora

- IFS Physics 2012 Part 2Documento5 pagineIFS Physics 2012 Part 2rahul srivastavaNessuna valutazione finora

- Kinematics of Mechanisms and Machines: Steering MechanismsDocumento29 pagineKinematics of Mechanisms and Machines: Steering Mechanismsrahul srivastavaNessuna valutazione finora

- Instructions For PHD Test Qualified CandidatesDocumento1 paginaInstructions For PHD Test Qualified Candidatesrahul srivastavaNessuna valutazione finora

- Govt. Engineering College Bharatpur TimetableDocumento7 pagineGovt. Engineering College Bharatpur Timetablerahul srivastavaNessuna valutazione finora

- Velocity Analysis: Method of IC - I: Anirvan DasguptaDocumento34 pagineVelocity Analysis: Method of IC - I: Anirvan Dasguptarahul srivastavaNessuna valutazione finora

- Velocity Analysis: Method of IC - I: Anirvan DasguptaDocumento34 pagineVelocity Analysis: Method of IC - I: Anirvan Dasguptarahul srivastavaNessuna valutazione finora

- Velocity Analysis: Method of IC - I: Anirvan DasguptaDocumento34 pagineVelocity Analysis: Method of IC - I: Anirvan Dasguptarahul srivastavaNessuna valutazione finora

- Govt. Engineering College Bharatpur TimetableDocumento7 pagineGovt. Engineering College Bharatpur Timetablerahul srivastavaNessuna valutazione finora

- Geometric Velocity Analysis - III: Anirvan DasguptaDocumento20 pagineGeometric Velocity Analysis - III: Anirvan Dasguptarahul srivastavaNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento3 pagineNew Microsoft Office Word Documentrahul srivastavaNessuna valutazione finora

- Govt. Engineering College Bharatpur TimetableDocumento7 pagineGovt. Engineering College Bharatpur Timetablerahul srivastavaNessuna valutazione finora

- Solar AC Using DessicantsDocumento12 pagineSolar AC Using Dessicantsrahul srivastavaNessuna valutazione finora

- Room Superintendent's Statement 02Documento1 paginaRoom Superintendent's Statement 02rahul srivastavaNessuna valutazione finora

- 14 Vapour Absorption Refrigeration SystemsDocumento20 pagine14 Vapour Absorption Refrigeration SystemsPRASAD326100% (8)

- Energy Storage Workshop Brochure - 31012020Documento17 pagineEnergy Storage Workshop Brochure - 31012020rahul srivastavaNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento3 pagineNew Microsoft Office Word Documentrahul srivastavaNessuna valutazione finora

- RajasthanDocumento5 pagineRajasthanrahul srivastavaNessuna valutazione finora

- Instructions For PHD Test Qualified CandidatesDocumento1 paginaInstructions For PHD Test Qualified Candidatesrahul srivastavaNessuna valutazione finora

- Room Superintendent's Statement 02Documento1 paginaRoom Superintendent's Statement 02rahul srivastavaNessuna valutazione finora

- 2019 - 2 - Advertisement No 3-2019 (Various Posts)Documento14 pagine2019 - 2 - Advertisement No 3-2019 (Various Posts)Sunny DuggalNessuna valutazione finora

- Final Year Students First Year To Final Year: in Mail An Has Been Asked To Send The FirmDocumento1 paginaFinal Year Students First Year To Final Year: in Mail An Has Been Asked To Send The Firmrahul srivastavaNessuna valutazione finora

- Supply Chain Management in Construction and Engineer-To-Order IndustriesDocumento9 pagineSupply Chain Management in Construction and Engineer-To-Order IndustriesMuhammad ShoaibNessuna valutazione finora

- SF DumpDocumento22 pagineSF Dumpjhastin alejosNessuna valutazione finora

- Product Guide: Accessories - Brass Trim - Sealants & Lubricants - Standpipe EquipmentDocumento60 pagineProduct Guide: Accessories - Brass Trim - Sealants & Lubricants - Standpipe EquipmentChristian DoriaNessuna valutazione finora

- Earthquake Prediction Technique: A Comparative StudyDocumento7 pagineEarthquake Prediction Technique: A Comparative StudyIAES IJAINessuna valutazione finora

- Hurst ViscosityDocumento64 pagineHurst ViscosityCarlos Hubert FarnsworthNessuna valutazione finora

- Supply ChainIPMDocumento7 pagineSupply ChainIPMMAHIN CHAWLANessuna valutazione finora

- 41a JAQWLM : Induction SoilDocumento3 pagine41a JAQWLM : Induction SoilTomislav JovanovicNessuna valutazione finora

- Fmea Presentation-How-To-Do-It-RightDocumento31 pagineFmea Presentation-How-To-Do-It-RightAmir Khakzad100% (1)

- Xcheng Poi SDK Specification v1.1Documento98 pagineXcheng Poi SDK Specification v1.1이동기Nessuna valutazione finora

- CSIR-Institute Junior Secretarial ApplicationDocumento2 pagineCSIR-Institute Junior Secretarial Applicationpratap tantyNessuna valutazione finora

- Rate Card Graphic DesignDocumento3 pagineRate Card Graphic Designashwin437100% (1)

- ICOTA Presentation 102010Documento11 pagineICOTA Presentation 102010gordonhighNessuna valutazione finora

- The Rate-Diversity Trade-Off For Linear Space-Time Codes: Badri Varadarajan and John R. BarryDocumento5 pagineThe Rate-Diversity Trade-Off For Linear Space-Time Codes: Badri Varadarajan and John R. BarryEMellaNessuna valutazione finora

- Assessment Task 1 knowledge questionsDocumento18 pagineAssessment Task 1 knowledge questionsjanukaNessuna valutazione finora

- Aiml Virtual InternshipDocumento21 pagineAiml Virtual InternshipPainampuram JuhithaNessuna valutazione finora

- 2.2.1.12 Lab - Windows Task ManagerDocumento11 pagine2.2.1.12 Lab - Windows Task ManagerKwimpal NychaNessuna valutazione finora

- Process Payments & ReceiptsDocumento12 pagineProcess Payments & ReceiptsAnne FrondaNessuna valutazione finora

- BMS-T017 Issue 2 - Orion IOM Manual PDFDocumento39 pagineBMS-T017 Issue 2 - Orion IOM Manual PDFnatNessuna valutazione finora

- International Cranes Below the Hook Ground PressureDocumento3 pagineInternational Cranes Below the Hook Ground PressurealbertoNessuna valutazione finora

- Design and Fabrication of Pedal Operated Washing MachineDocumento7 pagineDesign and Fabrication of Pedal Operated Washing MachineAayush KhandelwalNessuna valutazione finora

- Sapa 2022Documento8 pagineSapa 2022RL SanNessuna valutazione finora

- Automated Grading System For Teachers and StudentsDocumento2 pagineAutomated Grading System For Teachers and StudentsAnone Anone0% (1)

- Evidence-Based ManagementDocumento17 pagineEvidence-Based ManagementShruthiNessuna valutazione finora

- Understanding the Different Learning Delivery ModalitiesDocumento17 pagineUnderstanding the Different Learning Delivery ModalitiesMaryflor MoratoNessuna valutazione finora